Sourcing sustainable tissue requires more than just accepting a certificate PDF. As the recent permanent blocking of Shandong Join Bums (FSC-C159817) demonstrates, relying on surface-level documentation can expose your supply chain to verifiable fraud and immediate trademark revocations. A “blocked” status differs significantly from a temporary suspension, effectively stripping a supplier of export rights and leaving shipments stranded.

This guide details the necessary Quality Control & FSC verification protocols to protect your brand, moving beyond basic registry checks to deep-dive audits of product codes like W11.7. We examine the mathematical realities of mass-balance sheets—where missing the 70% certified input threshold triggers fraud alerts—and explain how to use Scanning Electron Microscopy to validate fiber composition when DNA testing falls short.

The Rise of “Fake” FSC Claims in the China Tissue Market

Fake FSC claims in China often involve using valid certificate numbers for non-registered product groups or failing fiber composition thresholds. FSC recently blocked Shandong Join Bums (FSC-C159817) for such violations, setting a precedent that strips the violator of all trademark rights.

Case Study: The “Shandong Join Bums” Certificate Block (FSC-C159817)

FSC formally blocked Shandong Join Bums Eco Tissues Co. Ltd. (Certificate FSC-C159817 / SCS-COC-007503) after investigators confirmed the company made verifiable false claims. A “blocked” status differs significantly from a temporary suspension; it effectively permanently revokes the entity’s right to use FSC trademarks or sell certified goods under that license. This enforcement action serves as a concrete precedent, confirming that integrity failures in the tissue sector trigger severe sanctions that immediately invalidate the legal right to export certified products.

Technical Non-Compliance: Mismatched Product Codes (W11.7) and Fiber Thresholds

Fraudulent claims frequently manifest when manufacturers fail to register specific output under the explicit category “W11.7 – Household and sanitary tissue” within the FSC Product Classification system. Without this registration, any FSC claim on tissue products is invalid by default. Violations also commonly involve missing the “FSC Mix” requirement of 70% certified input or the “FSC Recycled” mandate, which demands 100% reclaimed content with at least 85% post-consumer fiber.

Auditors identify these discrepancies by reconciling mass-balance sheets against production volumes. They verify that the input volumes of certified or reclaimed pulp match the strict percentage thresholds required for the final label. If a mill claims FSC Mix credits but lacks the corresponding 70% certified input data, or sells tissue not listed under W11.7, the claim is flagged as fraudulent.

How to Verify an FSC Certificate Number (FSC Public Search)

Verification begins at fsc.org by searching the license code to confirm ‘Active’ status and the 5-year validity window. A complete audit takes 30-45 minutes and must verify that the legal entity name on the invoice matches the certificate holder exactly. Crucially, buyers must validate that the certificate’s scope explicitly covers the product’s technical specs, such as specific GSM ranges or TAPPI test standards.

| Verification Checkpoint | Validation Logic | Technical Standard / Metric |

|---|---|---|

| Registry Status Check | Certificate must be “Active” within 5-year window | FSC Public Search Database |

| Legal Entity Match | Invoice name must match Certificate Holder exactly | Corporate Identity / CoC Line Item |

| Technical Scope | Scope includes specific grade (e.g., 110 GSM Kraft) | TAPPI T 441 / ISO 2758 |

| Multi-Site Compliance | Valid sub-code and Central Office audit status | FSC-STD-40-004 / FSC-STD-20-011 |

Performing the Registry Status Check

To initiate verification, access the FSC Public Search registry at fsc.org. Enter the specific certificate code (e.g., “FSC-C123456”) or the license number directly into the search field. The system returns the current status, which must read “Active” to validate any commercial claim. Buyers should verify the issue and expiry dates fall within the standard 5-year validity period, ensuring the certificate has not expired or been suspended pending an audit.

A critical failure point in supply chain verification involves the Legal Entity Name. The company name listed on the commercial invoice must match the “Licensee Name” in the registry exactly. If a supplier invoices under a different subsidiary name—for example, “ABC Trading International” instead of the certified “ABC Paper Mills Ltd”—the Chain of Custody (CoC) is technically broken unless the trading arm holds its own valid certificate. We recommend allocating approximately 10 minutes for this initial registry check, or up to 45 minutes if you require a full evidence pack download for compliance logs.

Auditing Product Scope and Technical Specifications

Merely holding a valid certificate does not guarantee that a specific product is certified. You must analyze the “Product Scope” section of the registry entry to confirm it covers the specific technical grades being purchased. Generic categories like “Paper” are insufficient for high-compliance procurement; look for precise descriptors such as “bleached kraft liner” or “uncoated paperboard.”

Cross-reference the certificate’s scope against the technical metrics on your purchase order. For instance, if you purchase 110 GSM kraft liner requiring a Cobb value <25 g/m² (per TAPPI T 441 or ISO 2758), the certificate scope must align with these material definitions. For suppliers operating under a Central Office Audit Program (multi-site certificates), ensure compliance with FSC-STD-40-004 by verifying the specific site sub-code. Finally, check that the commercial invoice lists the unique CoC number line-by-line for every certified item, as this creates the auditable link between the physical goods and the digital registry.

Understanding FSC 100% vs. FSC Mix vs. FSC Recycled

FSC 100% contains only fiber from certified forests, while FSC Recycled uses exclusively verified reclaimed material. FSC Mix, the most common industrial label, combines certified or recycled fiber with ‘Controlled Wood’ (risk-assessed non-certified inputs) and typically requires at least 70% certified/recycled content or equivalent credits.

Defining the Hierarchy: FSC 100%, Recycled, and Mix

The FSC labeling system functions as a strict material classification framework governed by the FSC Chain of Custody (CoC) standard FSC-STD-40-004. At the top of this hierarchy, the FSC 100% label acts as the highest level of assurance. Products carrying this claim contain inputs originating exclusively from FSC-certified forest units. Manufacturers must maintain full traceability back to the source, ensuring no uncontrolled material or non-certified wood enters the production line for these specific items.

FSC Recycled distinguishes itself by focusing entirely on circularity rather than forest management. This label applies solely to products composed of verified recovered materials, validated under standard FSC-STD-40-007. It strictly excludes virgin certified fiber to highlight waste reduction, making it a distinct category for companies prioritizing post-consumer or pre-consumer reclaimed inputs over fresh timber sourcing.

FSC Mix operates as a hybrid classification designed to support large-scale industrial manufacturing. Unlike the pure input streams of the 100% or Recycled labels, FSC Mix permits a combination of FSC-certified fiber, verified recycled material, and Controlled Wood. This flexibility allows manufacturers to scale production while maintaining baseline ethical sourcing standards, provided strict segregation and volume control measures remain in place.

The Technical Mechanics of FSC Mix and Controlled Wood

Calculating eligibility for the FSC Mix label involves specific Chain of Custody methodologies, typically the percentage system or the credit system defined in FSC-STD-40-004. To apply the label, manufacturers generally must demonstrate that at least 70% of the product’s fiber comes from FSC-certified or recycled sources, or possess sufficient “credits” accumulated from certified inputs to cover the output volume.

The non-certified portion of an FSC Mix product cannot simply be arbitrary wood; it must qualify as “Controlled Wood.” This material must meet the due diligence requirements of FSC-STD-40-005, which mandates rigorous risk assessments to exclude five categories of unacceptable sources, such as illegally harvested timber or wood harvested in violation of traditional rights. This ensures that even the non-certified portion of the product does not contribute to deforestation or human rights abuses.

Multi-component products follow the “lowest claim” rule during assembly. If a manufacturer joins a component with an FSC 100% claim (e.g., a table top) to a component with an FSC Mix claim (e.g., table legs), the final product claim defaults to FSC Mix. This protocol prevents the dilution of the higher standard and ensures that the final consumer label accurately reflects the minimum assurance level present in the finished good.

Build Your Unique Toilet Paper Brand with Expert OEM Manufacturing

Chain of Custody (CoC): Tracking Fiber from Forest to Roll

Chain of Custody (CoC) is the unbroken path that products take from the forest to the consumer, encompassing all stages of processing, manufacturing, and distribution. Under standards like FSC-STD-40-004 V3-0, manufacturers must track all forest-based components with a functional purpose. This ensures that the fiber in the final tissue roll matches the certified input claims via specific accounting methods like physical segregation or mass-balance calculations.

| Control System | Accounting Mechanism | Typical Application |

|---|---|---|

| Transfer System | Maintains a strict 1:1 link between specific certified inputs and outputs. | Operations where certified batches remain physically segregated. |

| Percentage System | Uses mass-balance formulas (e.g., FSC% = QC/QT × 100) to determine claim eligibility. | Continuous processing lines where mixing raw materials is unavoidable. |

| Credit System | Banks certified input volume as credits to allocate against future outputs. | Fluctuating supply chains; claim periods are often capped (e.g., 3 months). |

Defining the Scope: From Raw Pulp to Finished Product

CoC certification operates under strict boundaries defined by global standards such as FSC-STD-40-004 V3-0. These standards mandate that the chain of custody encompasses every change of legal ownership and physical processing stage, from the forest management unit to the final sale to the consumer. For tissue manufacturers, this traceability requirement applies to all forest-based components that serve a functional purpose. If a component’s removal would compromise the product’s function (such as the tissue paper itself), it must be tracked.

While the primary fiber content is the main focus, standards provide limited exemptions for minor components. Materials that comprise less than 5% of the total weight or volume of the product may technically be exempt from strict CoC control, provided they do not constitute the primary wood constituent. However, manufacturers must still verify that these exempt components do not violate controlled wood requirements regarding legality and origin.

Control Systems: Transfer, Percentage, and Credit Methods

To bridge the gap between incoming raw materials and outgoing finished rolls, manufacturers employ one of three authorized control systems. The Transfer System is the most direct method, preserving the identity of the input material through to the final product. This method suits operations that can physically separate certified material from non-certified material throughout the production run.

In high-volume mills where physical separation is impractical, the Percentage System (Mass Balance) allows for the mixing of inputs. Manufacturers calculate the certified content using the formula FSC% = (QC / QT) × 100, where QC represents the quantity of claim-contributing inputs and QT represents the total forest-based inputs. This mathematical approach ensures that the volume of certified product sold does not exceed the volume of certified material purchased, adjusted for conversion factors.

Alternatively, the Credit System permits manufacturers to accumulate “credits” from certified inputs. These credits are banked and then allocated to a portion of the output, allowing specific batches to be sold with a “100%” or “Mix” claim up to the limit of the credit balance. SFI standards typically cap this claim period, requiring that credits be used within a specific window, such as three months, to prevent the indefinite rolling of claims. Regardless of the system used, valid documentation—including the supplier’s unique CoC certificate code and specific claim type—must accompany every sales invoice to maintain the chain.

The Consequences of Selling Non-Certified Goods as FSC

Selling non-certified goods as FSC triggers immediate certificate suspension (often within 3 business days) and substantial financial penalties governed by FSC-PRO-10-003 V1-0. Penalties are calculated based on claim severity, duration, and company size, potentially reaching hundreds of thousands of dollars, alongside ‘blocked status’ bans preventing re-entry for up to 60 months.

Immediate Certification Suspension and Withdrawal Protocols

Certification Bodies (CBs) enforce strict administrative actions immediately upon detecting deliberate misrepresentation or ineligible product use. Under FSC protocols, if an organization is flagged for “specified risk” in FSC Risk Assessments or extraordinary events, the CB must suspend or withdraw the certificate within 3 business days of notification. This rapid enforcement mechanism halts the trade of all certified material to preserve the integrity of the supply chain.

These measures apply broadly to Chain of Custody (CoC) and Controlled Wood (CW/CoC) certificates. While some Forest Management (FM) certificates might face different protocols depending on trade-only contexts, the primary impact falls on organizations making false claims about product origins. Suspension effectively freezes an organization’s ability to sell goods with FSC claims until compliance is restored or the withdrawal is finalized.

Calculating Financial Penalties and Blocked Status Durations

Financial repercussions for false claims follow a specific mathematical formula outlined in FSC-PRO-10-003 V1-0. The penalty calculation is defined as: (Flat Rate 60 × Claim Severity × Claim Duration) × Company Size Factor. This structure ensures that fines scale with the magnitude of the violation. For example, a medium severity claim persisting for 12 months by a large company could result in penalties as high as 278,640 USD, while smaller infractions might incur fines around 11,700 USD.

Beyond monetary fines, the FSC imposes a “blocked status” on the responsible organization and individuals. This exclusion period typically mirrors the severity of the financial penalty, lasting between 30 and 60 months. During this time, legal successors remain liable for penalties, and responsible individuals are prohibited from establishing new organizations to re-enter the FSC system. This prevents evasion tactics and ensures long-term accountability for supply chain violations.

Lab Testing: DNA Fiber Analysis for Bamboo Content

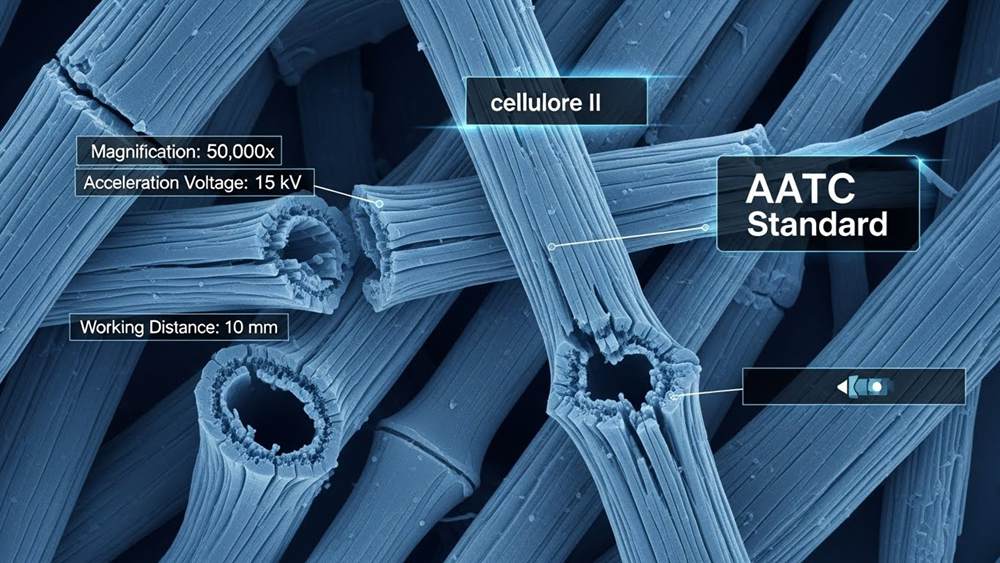

While brands often request DNA verification, the established AATCC technical standard relies on Scanning Electron Microscopy (SEM) and X-ray diffraction (XRD) to distinguish native bamboo from regenerated rayon (cellulose II). DNA analysis is scientifically valid for raw pulp inputs if purity ratios meet specific thresholds (OD260/OD280 > 2.0), but no codified ISO or ASTM standard currently exists for DNA testing in finished regenerated fabrics.

Microscopy vs. DNA: The Current Verification Standard

Most commercial “bamboo” tissue functions as regenerated cellulose, commonly known as rayon or viscose. The harsh chemical processing involved in manufacturing typically degrades the original cellular structure, making the extraction of intact DNA chains difficult. As a result, the industry relies on physical structural analysis rather than molecular biology for finished goods verification.

The AATCC “Assessment of the Validity of Claims” (2009) established Scanning Electron Microscopy (SEM) and Wide-Angle X-ray Diffraction (WAXR) as the definitive methods for validating fiber origin. Laboratory tests specifically search for a “cellulose II” diffraction pattern. This signature identifies rayon, contrasting sharply with the irregular, thick-walled morphology found in native bamboo bast fibers. Current molecular DNA techniques detect single-molecule gaps but lack the codified ISO standards necessary to reliably type finished textile fibers.

DNA Purity Metrics and Extraction Protocols

DNA barcoding remains an effective tool for verifying raw materials, such as bamboo pulp or paper, before they enter the regeneration bath. For these inputs, valid DNA extraction depends on strict purity protocols. Laboratories measure the OD260/OD280 ratio via UV spectrophotometry; a ratio exceeding 2.0 generally indicates the sample is free from significant RNA contamination.

Recent methodological advances using bamboo paper adsorbents have achieved up to 4.2 times higher DNA extraction efficiency compared to conventional techniques. To ensure accuracy, technicians must also monitor the OD260/OD230 ratio. Keeping this metric under 2.0 helps detect residual polysaccharides or salts, which frequently skew results in plant-based fiber analysis.

Third-Party QC: When to Hire an Independent Inspector

Hiring an independent inspector is necessary when regulatory schemes, such as ICC-ES AC10, or legal standards require impartial evidence of conformity. Unlike internal QC, third-party bodies accredited under ISO/IEC 17020 operate as ‘Category A’ entities, ensuring the inspection results are legally defensible and free from organizational conflicts of interest.

The Standard of Independence: ISO/IEC 17020 and Category A Criteria

Independent inspection bodies must be accredited under ISO/IEC 17020:2012, specifically as “Category A” organizations. This technical classification mandates total independence from the parties involved in the design, manufacture, or sale of the inspected items. Unlike internal quality control teams, these entities specialize solely in inspection and testing to ensure maximum impartiality.

U.S. federal quality standards and model codes, such as ICC Chapter 4, explicitly bar inspectors from performing management functions or inspecting their own work. This separation prevents organizational impairments that could compromise data integrity. Consequently, third-party conformity assessment provides objective evidence distinct from supplier self-declarations, which is necessary for legal defense and formal certification.

Operational Triggers: From ICC-ES AC10 Mandates to ESG Verification

Product certifications often mandate ongoing surveillance to maintain valid listings. For example, manufacturers holding an ICC-ES evaluation report must undergo periodic Quality Assurance Inspections (QAI) in accordance with AC10. These audits verify that production quality matches the originally tested samples over time, ensuring continued code compliance.

Brands claiming specific eco-credentials, such as FSC 100% or recycled content, utilize third-party audits to validate Chain of Custody (CoC) when switching suppliers. This process minimizes greenwashing risks by tracing materials back to the source through independent verification. External inspection is also critical during pre-shipment for high-stakes orders, where regulatory compliance regarding safety codes or chemical limits must be verified by a licensed agency before goods leave the factory.

Final Thoughts

Protecting a supply chain requires more than a casual glance at a certificate PDF. Procurement teams must actively reconcile invoice details against the FSC public registry and validate that technical specifications align exactly with the declared scope. The recent enforcement actions against non-compliant entities demonstrate that regulatory bodies are tightening their grip, creating immediate legal and commercial risks for buyers who overlook these critical administrative details.

Sustainable procurement functions as a strict exercise in risk management rather than simple compliance. Relying on unverified claims leaves brands vulnerable to financial penalties and sudden supply disruptions if a partner loses their license. Integrating independent laboratory analysis and third-party inspections into the quality control process transforms sustainability from a marketing slogan into a verifiable asset that withstands external scrutiny.

Frequently Asked Questions

How can I verify if my supplier’s FSC certificate is real?

You can verify a certificate by entering the unique License Code (FSC-C######) or Certificate Code (XXX-COC-######) into the FSC Global Certificate Database at info.fsc.org. A valid certificate must show an “Active” status, match the legal entity name, and list the specific product scope (e.g., bleached kraft liner) you are purchasing.

What is an FSC Chain of Custody (CoC) audit?

An FSC CoC audit is a systematic evaluation by an accredited certification body to confirm an organization tracks certified materials correctly from the forest to the final product. Auditors review documentation, control systems, and conduct on-site interviews to ensure compliance with FSC standards.

Why do some “bamboo” papers contain wood pulp?

Manufacturers often blend bamboo pulp with wood or grass pulp to optimize paper strength, whiteness, and cost. Pure bamboo paper is naturally yellowish, so commercial blends may contain varying percentages of wood pulp to achieve specific bulk or color properties.

How can I spot false sustainability claims on Alibaba?

Avoid suppliers relying solely on generic terms like “eco-friendly” without proof. Demand a valid Chain of Custody (CoC) certificate number and verify it in the public database. Prioritize suppliers with third-party verified badges or those who provide QR codes linking to digital traceability logs.

What are the penalties for using the FSC logo without a license?

Unlicensed use constitutes trademark infringement and can lead to financial penalties calculated under FSC-PRO-10-003, suspension or termination of certification, and civil legal action. FSC treats this as a high-risk compliance event that can permanently block a company from the certification system.

Does the factory provide individual FSC invoices per batch?

FSC standards do not require a separate physical invoice for every single batch, but the sales document must reference the product’s batch or shipping documentation. This link ensures traceability between the specific goods received and the supplier’s Chain of Custody code.