Standard retail packaging often inflates e-commerce budgets by 20% because it lacks the structural strength to survive modern parcel networks. Since the last-mile phase alone represents 53% of total shipping costs, using unoptimized boxes leads to expensive damage and causes 23% of consumers to abandon a brand entirely. Companies must shift from shelf-ready designs to transit-optimized packaging to protect their margins and customer retention.

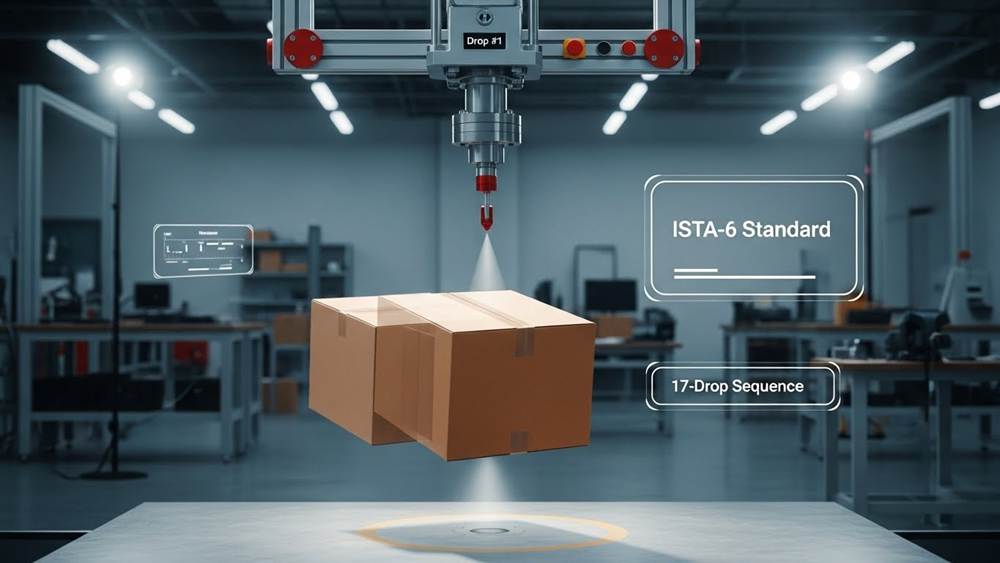

We outline the engineering standards required to pass ISTA-6 testing and achieve Amazon FBA compliance. This analysis covers mandatory 17-drop sequences, dimensional weight (DIM) optimization, and the certification steps needed to prevent the $1.99 per-unit chargebacks applied to uncertified bulky items. By following these protocols, logistics teams ensure their products survive high-speed automated sorting while minimizing environmental waste and shipping fees.

Why Standard Retail Packaging Fails in E-commerce

Retail packaging focuses on in-store aesthetics and theft prevention rather than the physical demands of parcel shipping. This design gap leads to higher damage rates, increased shipping costs, and significant environmental waste, often adding 20% or more to the total packaging budget compared to transit-optimized alternatives.

Structural Vulnerabilities in Multi-Touch Parcel Networks

Retail designs prioritize air pillows and excess headspace to maintain shelf presence and visual appeal. These features create internal voids that increase the risk of package collapse during high-speed automated sorting. While traditional retail stock moves in organized pallets, e-commerce items pass through multiple individual handling points at distribution centers and LTL carrier facilities. This increased contact raises the probability of structural failure.

Standard blister packs and thin printed cardboard lack the puncture resistance required for the last-mile phase of delivery. This specific stage represents 53% of total shipping costs. When packaging fails to protect the product during these transitions, retailers face immediate losses. Using materials designed for the retail shelf rather than the conveyor belt results in higher damage rates across the entire parcel network.

Financial Impact of Delivery Failures and Returns

Failed first-time deliveries cost retailers an average of $17.20 per order. This figure does not include the $12 to $25 cost for each customer support ticket generated by the delivery issue. Inadequate protection also contributes to 9.5 billion pounds of return waste sent to landfills every year. This volume strains corporate sustainability targets and increases disposal fees for businesses across all sectors.

Poor delivery experiences drive 23% of consumers to abandon brands entirely. This creates a direct link between packaging integrity and long-term customer retention. During peak season logistics, failure rates reach 20% for packages not specifically designed to withstand the increased velocity of parcel sorting systems. Retailers using unoptimized packaging see higher costs from reships and lost loyalty as their parcels struggle with mechanical stress.

Understanding ISTA-6 Testing: Drops, Vibrations, and Amazon Project 6.

ISTA-6 protocols simulate the harsh environments of Amazon’s fulfillment network through rigorous physical stress tests. By 2026, these standards continue to utilize specific drop sequences, random vibration profiles, and integrity checks for liquids to ensure packaging survives small-parcel and LTL distribution without damage or leakage.

| Package Weight | Small Parcel Drop Height | Heavy/LTL Drop Height |

|---|---|---|

| 0–21 lb (0–9 kg) | 30 inches (762 mm) | 18 inches (457 mm) |

| 21–70 lb (9–32 kg) | 18–24 inches | 18 inches (457 mm) |

| 70–150 lb (32–68 kg) | N/A (LTL focus) | 12 inches (305 mm) |

Fundamentals of Amazon Project 6 Certification

Amazon differentiates packaging requirements through two primary protocols: Over-Boxing (OB) and Ships In Own Container (SIOC). The ISTA 6-Amazon.com-OB standard evaluates individual products intended for placement in larger Amazon shipping containers. In contrast, Project 6-Amazon.com-SIOC protocols test items that ship to the end consumer without an additional outer box. These standards ensure that products arrive intact regardless of whether they are packed in a secondary carton or handled as a standalone unit.

Testing labs categorize shipments by weight and dimensions to apply appropriate stress levels. Type A covers items under 50 lb, while Type C handles large LTL shipments exceeding 100 lb. These categories ensure the testing intensity matches the actual physical demands of the distribution environment. Using general simulation models, these tests replicate the acceleration levels and impact energies found in high-volume fulfillment centers. Accredited labs use these results to determine if a design qualifies for Frustration-Free Packaging status.

Mandatory Sequences for Drops, Vibration, and Integrity

The core testing regime for small parcels involves a shock sequence of 17 free-fall drops. Equipment used for these tests must comply with ISO 2248 or ASTM D5276 standards to ensure repeatable impact accuracy. Drop heights correlate directly to package weight, reaching up to 30 inches for the lightest parcels and decreasing to 12 inches for heavy items up to 150 lb. This scaling accounts for the different ways humans and machines handle packages of varying mass during sorting and delivery.

Vibration testing simulates the mechanical stress of trailer transport and delivery routes. Labs run random vibration profiles for 2.5 hours at a 0.53 Grms level. Hardware must meet ISO 13355 or ASTM D4728 specifications to replicate truck and air transport spectra accurately. This phase often includes top-load weights to simulate stacking and compression experienced in a fully loaded trailer or distribution center floor.

Specific product categories require additional integrity checks. Liquid products undergo an 8-hour leak test to prevent transit damage and cross-contamination. Fragile items face hazard block tests using hardwood or metal blocks to simulate concentrated impacts from other parcels. Throughout these sequences, atmospheric conditioning per ASTM D4332 manages how materials like corrugated board react to temperature and humidity fluctuations, ensuring the packaging maintains its structural integrity under environmental stress.

Reducing “Dimensional Weight” (DIM) Shipping Fees

DIM weight billing charges for the space a package occupies rather than its actual mass. For 2026 shipping standards, companies minimize these fees by reducing external cubic inches and shortening dimensions to stay under the 165-inch girth limit while maintaining ISTA-6 structural compliance.

Volumetric Formulas and Carrier Thresholds

Carriers calculate billed weight by dividing the cubic volume of a package by a specific divisor, such as 139, 166, or 194. A lower divisor increases the billable weight, making it essential for shippers to minimize external dimensions to control costs. Small parcel networks generally cap shipments at 150 lbs and a maximum combined length and girth of 165 inches. Shippers use the formula L + 2W + 2H to find the girth; exceeding this limit usually forces the shipment into the more expensive LTL freight category. Amazon SIOC Types A, B, and C specifically apply to these parcel shipments that stay within the 165-inch girth boundary.

Engineering Density and Stability for ISTA-6 Compliance

Reducing package size requires precision engineering to maintain structural integrity during transit. Designers often replace generic containers with product-specific die-cut cartons to eliminate excess void space and lower the total cubic volume. Any package standing 48 inches or taller must pass a 22-degree tip-over test to ensure it remains stable within 2026 logistics chains. Shippers also perform vertical compression tests (Test Block 9) where the carton must hold a calculated force for one hour to validate that thinner corrugated walls will not collapse. Horizontal clamp tests further dictate how much material a designer can remove, ensuring the box survives the mechanical pressure of automated sorting systems.

Build Your Global Hygiene Brand with Our OEM Expertise

Frustration-Free Packaging (FFP) vs. SIOC Standards

Amazon categorizes packaging into three tiers based on durability and ease of unboxing. Frustration-Free Packaging (FFP) requires 100% recyclable materials and tool-free opening, while Ships in Own Container (SIOC) eliminates the need for an Amazon overbox. Meeting these standards by 2026 prevents per-unit chargebacks and reduces dimensional weight costs.

| Packaging Tier | Standard Name | Key Technical Requirements |

|---|---|---|

| Tier 1 | FFP | Unboxing ≤ 120s; 100% curbside recyclable; tool-free opening; no overbox. |

| Tier 2 | SIOC | No Amazon overbox required; must pass ISTA-6 transit cycle testing. |

| Tier 3 | PFP | Zero additional prep needed at FC; requires Amazon overbox for transit. |

Tiered Hierarchy and Sustainability Requirements

FFP represents the highest level of Amazon’s packaging evolution, combining transit durability with consumer-facing ergonomics. This tier mandates that customers can open the package in 120 seconds or less without using scissors or box cutters. Designers must eliminate plastic inserts, filler chips, or shredded paper to meet sustainability goals. All materials must be 100% curbside recyclable, with plastic use restricted to SPI resins 1 (PET), 2 (HDPE), and 5 (PP). Tier 2 (SIOC) focuses on the physical integrity of the vendor’s box, ensuring it survives the ISTA-6 transit cycle independently. This reduces waste and shipping volume by removing the need for an external Amazon shipping container. Tier 3 (PFP) ensures products are ready for fulfillment center handling without extra prep, though they still require an Amazon overbox for final delivery.

Mandatory Certification Thresholds and Financial Penalties

Amazon enforces strict certification for items exceeding 18″ x 14″ x 8″ or weighing 20 lbs and above. Sortable products that fall within these dimensions but lack valid certification trigger a $1.99 chargeback per unit sold. Logistics compatibility begins at minimum dimensions of 6″ x 4″ x 0.375″. Packaging efficiency is measured through box utilization scores, which track the ratio of the product volume to the total package volume. Fragile items, such as glass, ceramics, or electronics sensitive to an 18-inch drop, must achieve at least a 30% utilization score. Non-fragile items must exceed 50%. These requirements aim to minimize void space and reduce the environmental footprint of the shipping process.

Case Pack Labeling and FNSKU Requirements at Source

Every unit within a case pack must carry a unique FNSKU label while the outer case remains free of competing barcodes. Labels require a minimum 300 DPI resolution on non-reflective stock, measuring at least 1 by 2.625 inches, with specific clearance from edges and seams to ensure reliable scanning by January 1, 2026.

Mandatory FNSKU Standards for Case-Packed Units

Logistics teams must affix a unique FNSKU barcode to every individual unit inside the case pack to meet 2026 tracking mandates. This process ensures that fulfillment systems track each item accurately as it moves through the network. We cover all existing manufacturer barcodes, such as UPC or EAN, completely with opaque labeling material to prevent automated scanners from registering the wrong data.

The exterior of the shipping case must remain clear of all barcodes to avoid confusion during the automated receiving process. For inventory using multi-layer packaging, we label every exposed layer of inner boxes. This redundancy guarantees scannability across various stages of handling without requiring staff to open secondary containers to identify products.

Precision Printing and Placement Specifications

Technical standards require printing labels with thermal or laser printers at a minimum resolution of 300 DPI for black ink clarity. We utilize label sizes between 1×2 inches and 2×3 inches on white, non-reflective adhesive paper to maintain high-speed scanning compatibility. Using non-reflective materials prevents glare from interfering with laser-based fulfillment equipment.

Correct label placement protects barcode integrity during transit. We observe mandatory white space margins of 0.25 inches on the sides and 0.125 inches on the top and bottom of each FNSKU. Staff must place labels on flat exterior surfaces only, maintaining a 0.25-inch clearance from any container edges or seams. This positioning prevents the barcode from wrapping around corners or peeling when the box brushes against conveyor rails.

Poly-bag Safety Specs: Warning Text and Thickness

E-commerce standards in 2026 require poly-bags to maintain a minimum thickness of 1.5 mil and include visible suffocation warnings on any opening 5 inches or wider. Specific regional laws in Massachusetts and New York further dictate font sizes and text placement based on the total dimensions of the bag.

Film Thickness and Material Requirements

Warehouse safety and product durability depend on specific material standards. We use poly-bags with a minimum thickness of 1.5 mil (0.0015 inches) to prevent puncturing and protect units during the fulfillment process. Selecting transparent materials allows automated scanners to read barcodes through the film without manual intervention, which speeds up receiving and sorting tasks.

Efficient packaging design limits shipping volume and material waste. We restrict excess bag material to a maximum of 3 inches beyond the product dimensions. Fully seal all bags to protect hygiene products and sensitive items from environmental contaminants during long-term storage in the warehouse.

Suffocation Warning Triggers and Text Standards

Legal compliance requires clear typography and strategic warning placement. Apply a printed suffocation warning to every bag featuring a flat opening of 5 inches or larger. While some local laws only target thinner films, marketplace standards require these warnings regardless of thickness to ensure maximum consumer safety. Adopt the standard industry warning text: “WARNING: To avoid danger of suffocation, keep this plastic bag away from babies and children. This bag is not a toy.”

Regional regulations dictate specific font sizes based on the bag’s total surface area. Following Massachusetts type-size rules, we use 14-point font for bags with a combined length and width between 25 and 40 inches. For oversized bags exceeding a combined 60 inches, we increase the font size to 24-point. Large-format packaging requires warnings on both sides of the bag at 20-inch intervals to meet strict multi-state compliance and ensure visibility from any angle.

Palletization for Amazon: Chep vs. Standard Pallets

Amazon requires a standard 40 x 48 inch footprint for all inbound pallets in 2026. While CHEP pooling offers durability, ISTA-6 Type F certification focuses on the load’s stability during LTL handling. The choice between CHEP and white-wood remains a logistics decision, as long as the pallet matches the configuration used in testing.

Amazon Pallet Standards and Footprint Requirements

All U.S. inbound shipments must use 40 in × 48 in four-way access wood pallets. Maximum pallet height limits range from 72 to 98 inches based on the freight class and destination facility. These dimensions ensure compatibility with Amazon’s automated sorting systems and standard rack configurations. Suppliers must verify the specific height requirements for their destination fulfillment center to avoid refused shipments.

CHEP pooled pallets provide a durable, reusable option with rental fees, while standard white-wood pallets serve as cost-effective, one-way alternatives. Both pallet types are acceptable as long as they maintain structural integrity. Pallets must remain in good condition without broken boards or protruding nails to pass safety inspections at the loading dock. Amazon rejects damaged pallets to prevent equipment malfunction and workplace injuries.

ISTA-6 Type F Testing for Pallet-Handled Freight

ISTA-6 Project 6A Type F protocols simulate LTL delivery specifically for individually palletized products. This test differentiates palletized freight from smaller parcel-handled items. Testing requires a vertical compression load, calculated by a specific formula, held for one hour to simulate stack pressure. A pallet sits on top of the test item during this phase to represent the weight of a stacked unit load in a trailer.

Laboratories use support blocks measuring 90–100 mm in height to perform tip and edge tests for material handling simulation. These tests replicate the impact and tilt experienced during forklift transport. Labs must test items on the same pallet type—CHEP or standard—that the manufacturer intends to use for actual 2026 distribution. Using a different pallet in the field than the one used during lab certification may invalidate the ISTA-6 results.

Final Thoughts

Success in the Amazon marketplace depends on packaging that survives the physical stress of automated sorting and last-mile delivery. Shifting from retail-focused designs to transit-optimized containers prevents structural failure and lowers the risk of package collapse. These changes reduce the financial burden of returns and help brands reach their sustainability targets.

Implementing these technical standards by 2026 helps businesses avoid per-unit chargebacks and manage high shipping fees. Precise labeling and durable materials ensure packages move through fulfillment centers without manual delays. Brands that integrate these logistics requirements into their supply chain build better customer loyalty through reliable, damage-free deliveries.

Frequently Asked Questions

How do factories ensure Amazon FBA labeling compliance?

Factories apply FNSKU labels using thermal or laser printers at a resolution of at least 300 DPI. They print on non-reflective white material sized between 1×2 and 2×3 inches and cover all previous barcodes to ensure scannability.

Why is ISTA-6 testing critical for shipping tissue products?

ISTA-6 protocols simulate distribution hazards such as drops and vibrations to confirm that shipping containers maintain physical integrity. This testing remains vital for products under 50 lbs to ensure they withstand the rigors of parcel delivery.

Can custom packaging help avoid Amazon oversized fees?

SIPP-certified custom packaging avoids the $2.07 per unit uncertified fee and earns a $2.06 reduction. By 2026, this creates a total savings of $4.13 per unit compared to uncertified bulky items.

What is the recommended number of rolls for an Amazon-friendly bundle?

ISTA 6-Amazon and APASS protocols do not specify a numeric roll count. Packaging certification focuses on weight-based categories and durability during transit simulations rather than the quantity of items inside the bundle.

Are poly-bags or corrugated boxes better for parcel shipping?

Corrugated boxes provide the necessary compression and impact resistance for parcel shipping. While poly-bags offer moisture protection, they typically fail the 18 to 24-inch drop tests required for ISTA 6-Amazon SIOC compliance.

How do manufacturers prevent crushed cores in the supply chain?

Manufacturers use ISTA 6 compression testing to simulate the weight of stacked packages in warehouses. This process verifies that the packaging protects the product from deformation or crushing during storage.