Relying on a subjective “hand-feel” puts your retail contracts and supply chain reliability at risk. B2B buyers now demand quantifiable data that proves a product meets rigorous industrial benchmarks. Shifting to standardized mechanical testing ensures your shipments maintain consistent quality across global borders while satisfying the demands of high-capacity retail environments.

We explore the technical protocols for validating tissue performance, including ISO 12625-4 tensile strength measurements and Tissue Softness Analyzer (TSA) metrics. This guide looks at how engineers maintain thickness tolerances within 12.5% and use the Slosh Box method to meet IWSFG flushability standards. The following sections explain how to use these lab results to satisfy FTC and FDA marketing compliance requirements.

The Science of Tissue Testing: Beyond the “Touch Test”

Modern tissue testing replaces the subjective ‘touch test’ with quantifiable ASTM and ISO protocols. By 2026, professional manufacturing relies on mechanical characterization, ensuring that products meet specific tensile energy absorption and thickness tolerance benchmarks (within 12.5%) for global retail compliance.

Transitioning from Subjective Feel to Objective Metrics

Traditional sensory evaluation lacks the reproducibility needed for global OEM and ODM supply chains. Relying on human touch introduces variables that modern industrial standards cannot accommodate. Professional manufacturing now uses ISO 12625-4:2022 to establish a framework for measuring tensile strength, stretch at maximum force, and tensile energy absorption across tissue products. This shift ensures that softness and durability are measured through repeatable mechanical actions rather than variable human perception.

ASTM F2150 protocols enable the characterization of physical and mechanical properties that define the structural integrity of tissue-engineered scaffolds. These standards provide specific methods for identifying impurities and verifying compressive properties. Quantitative benchmarks allow manufacturers to maintain consistent quality for high-capacity products, such as 5-ply toilet paper and industrial jumbo rolls, ensuring every batch meets the same mechanical profile for retail readiness.

Mechanical Protocols and Precision Tolerances

Precise lab-based validation requires strict adherence to specimen uniformity. ASTM standards require thickness variations to remain at or below 12.5% within a single specimen. Engineers achieve these tolerances using high-precision slicing methods that result in variation as low as 4.3% to 6.6%, which significantly outperforms the 16.1% variation typically seen with standard vibratomes. Maintaining this level of precision ensures that tensile data reflects the true fiber characteristics of the tissue matrix.

Testing facilities utilize specific coupon geometries to reduce data errors. Scaled-down dumbbell shapes, based on ASTM D638 and D412, reduce midsubstance failures to 20% during tensile testing by optimizing how the material interacts with the grips. For advanced validation, labs compare non-destructive bulge tests with biaxial tensile tests to evaluate the anisotropy and durability of fiber-reinforced matrices. These scientific protocols provide the engineering rigor necessary to support premium product claims in a competitive global market.

ISO 12625: The Global Standard for Tissue Products

ISO 12625 provides a unified testing methodology for tissue paper and finished products, ensuring consistency across global supply chains. By 2026, it remains the benchmark for measuring thickness, grammage, and tensile strength, allowing manufacturers to validate quality claims with repeatable laboratory data rather than subjective tactile assessments.

| ISO Standard Part | Primary Metric | Key Technical Parameters |

|---|---|---|

| ISO 12625-3 | Thickness & Bulk | 2.0 kPa static load; 35.7 mm pressure-foot |

| ISO 12625-4 | Tensile Strength | 50 %/min elongation rate; 50 mm wide strips |

| ISO 12625-6 | Grammage | Conditioned mass per unit area (g/m²) |

Standardized Framework for Quality Definitions and Grammage

ISO 12625-1 establishes the harmonized vocabulary and general guidance for all tissue product testing. This foundation ensures that manufacturers and laboratories use identical terminology, which eliminates confusion when comparing product specifications across different regions.

ISO 12625-6 defines the specific procedure for measuring grammage in g/m², providing weight accuracy for both retail and commercial tiers. Lab technicians must condition specimens in controlled environments because humidity can significantly skew weight and thickness results. The standard requires testing on single-ply or multi-ply samples without separating bonded layers to maintain the integrity of the finished product during the evaluation process.

Technical Metrics for Bulk and Tensile Performance

Precision in thickness measurement determines the perceived quality of creped and uncreped tissues. ISO 12625-3 specifies the use of a 35.7 mm diameter pressure-foot that applies a static load of 2.0 kPa. Measurement resolution must reach 0.001 mm to calculate bulking thickness and apparent bulk density accurately. These values help R&D teams validate premium claims regarding softness and absorbency.

Mechanical durability depends on the mandates found in ISO 12625-4. This part of the standard requires a constant elongation rate of 50 %/min on 50 mm wide strips to determine tensile energy absorption and stretch at break. For high-durability items like kitchen towels or facial tissues, ISO 12625-5 validates wet tensile strength. These controlled tests prevent failure modes such as slippage or jaw breakage, ensuring that the paper performs reliably under both dry and saturated conditions.

Testing for Absorbency: Rate vs. Capacity

Absorbency testing separates rate, which is the speed of liquid uptake (g/min), from capacity, the total weight of fluid retained (g). While rate determines how quickly a spill disappears, capacity defines the product’s limit before failure. Engineers use standardized tests like ISO 535 and ASTM D4772 to validate these metrics.

Distinguishing Liquid Uptake Rate from Total Storage Capacity

Absorbency rate (Q) measures the initial speed of fluid uptake in g/min. This metric determines how quickly a material pulls moisture away from a surface, which proves vital for preventing skin irritation and surface wetness. While the rate focuses on the speed of the wicking process, absorbent capacity (C) measures the total volume a material can hold. Engineers calculate this capacity using the gravimetric formula C = (Ww – Wd), which finds the difference between the wet weight and the dry weight of a sample at full saturation.

High-performance tissues and hygiene products balance these two physical properties to ensure reliability. Capillary action within the fiber structure drives a fast absorption rate, but fiber density and material composition provide the necessary capacity to prevent leaking. If a material has a high rate but low capacity, it will saturate too quickly and fail during use. Conversely, a high capacity with a slow rate often leads to surface pooling and discomfort.

Standardized Testing Protocols and Metric Validation

Laboratory teams use specific international standards to verify material performance and support product claims. The ISO 535 Cobb test quantifies surface absorbency by measuring the weight of water absorbed in g/m² over 60 or 180 seconds. This test specifically evaluates sized paper and paperboard to determine liquid resistance. For nonwovens and medical dressings, drop tests and gravimetric methods assess wettability and the initial speed of liquid uptake, providing data on how the material reacts upon the first contact with moisture.

Engineers also perform centrifuge retention tests to simulate real-world conditions. This method measures the fluid retained after the material undergoes mechanical pressure, ensuring that products like diapers or incontinence pads maintain their capacity even when compressed. Compliance with standards such as ASTM D4772 for terry fabrics and NWSP 10.2 for wiping materials provides a technical benchmark. These metrics allow manufacturers to validate performance claims for high-absorbency products while maintaining consistency across global supply chains.

Build Your Premium Toilet Paper Brand with Global OEM Experts

Measuring “Hand-Feel” with Tissue Softness Analyzers (TSA)

A Tissue Softness Analyzer (TSA) provides an objective measurement of haptic quality by analyzing acoustic vibrations and mechanical stiffness. By isolating specific parameters like TS7 for softness and TS750 for roughness, the system generates a Hand Feel (HF) score that correlates with human perception, replacing subjective manual testing with stable, reproducible laboratory data.

Tactile Sensors and Acoustic Mimicry

The emtec TSA device replicates the function of human skin sensors, specifically lamellar corpuscles, to detect micro-surface variations via vibrations near 300 Hz. Acoustic analysis isolates physical properties by measuring sound frequency peaks during contact between a rotor and the tissue sample. These objective HF scores eliminate the inconsistency of human hand panels, which often fluctuate due to cultural preferences, tester mood, or specific testing methods like z-folding.

Core Parameters for Softness and Stiffness

The TS7 parameter measures softness at a 6.5 kHz frequency peak, where lower values signify higher softness influenced by fiber furnish and chemical additives. Surface roughness and creping effects appear in the TS750 parameter at 200–1,000 Hz, identifying how embossing patterns impact the final texture. Operators also measure in-plane stiffness through mechanical deformation force to complete the haptic evaluation. Final HF scores incorporate physical factors like thickness, grammage, and plies to achieve high correlation with human tactile perception.

Chemical Safety: Testing for Formaldehyde and Brighteners

Testing for formaldehyde and brighteners ensures tissue products meet safety standards for skin contact. Manufacturers use water extraction (ISO 14184-1) and air sampling (ASTM D5197) to detect trace chemicals. Leading suppliers in 2026 prioritize 100% virgin pulp to eliminate these additives entirely, ensuring compliance with FDA and EU hygiene regulations.

Detection Methods for Formaldehyde and Brighteners

ISO 14184-1 water extraction identifies free and partially hydrolyzed formaldehyde in finished paper goods. This colorimetric analysis captures fixed formaldehyde, providing a streamlined approach for routine quality control in tissue manufacturing. For deeper analysis, manufacturers use ISO 14184-2 to simulate consumer exposure by measuring gaseous releases under accelerated heating. This process involves suspending the material over water in a sealed environment to track volatile emissions that might occur during actual use.

The shift toward 100% virgin wood pulp eliminates the need for fluorescent whitening agents (FWAs) that frequently cause skin irritation. By removing these additives entirely, suppliers ensure the end product remains hypoallergenic and safe for sensitive skin. Factory-level quality audits in 2026 rely on rapid colorimetric screening as a primary tool to verify the absence of these chemicals throughout the production cycle.

Analytical Standards and Safety Thresholds

ASTM D5197-21 utilizes HPLC/UHPLC analysis to detect formaldehyde across a range of 10 ppb to 1 ppm. The method employs silica gel cartridges coated with 2,4-dinitrophenylhydrazine (DNPH) to derivatize the sample, ensuring high sensitivity for material off-gassing. In industrial settings, OSHA Method 52 establishes a reliable quantitation limit of 16 ppb. This gas chromatography technique monitors occupational safety during the manufacturing process with a precision of ±25% at a 95% confidence level.

Top hygiene brands maintain a 100% fluorescent-free standard to meet North American FDA and European FSC requirements. When testing products with complex pigments or dyes, ISO 14184-3 liquid chromatography provides high-precision measurement. This chromatographic separation prevents color interference, allowing for accurate quantification of free and hydrolyzed formaldehyde in specialized tissue products that use organic or synthetic colorants.

Flushability and Disintegration Speed Validation

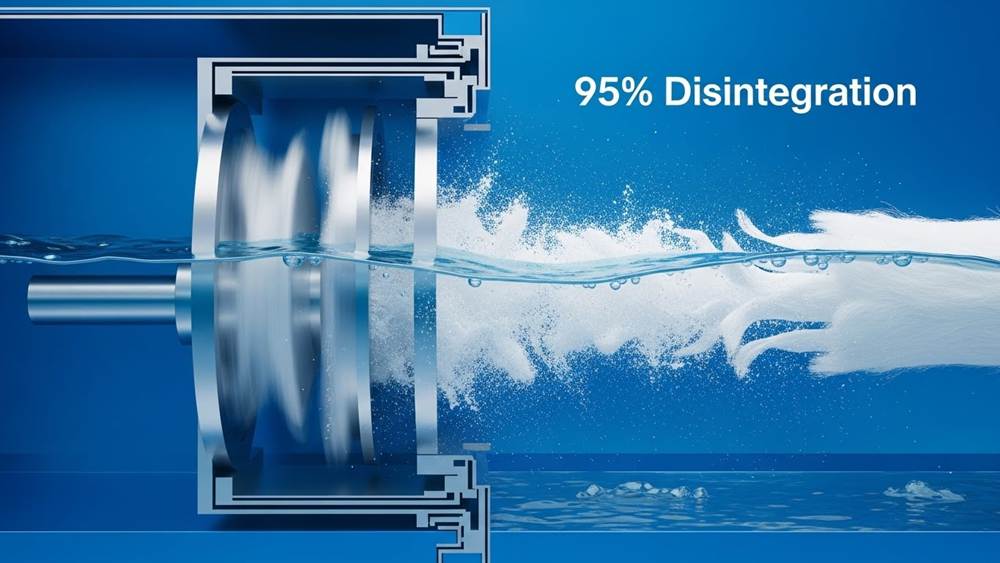

Flushability validation measures how quickly fibers break apart under hydraulic stress to prevent sewer blockages. Testing centers on the Slosh Box method, where products must meet specific mass-throughput thresholds—such as 60% to 95% disintegration—within set timeframes. Standards like GD4 and IWSFG PAS 3 define these benchmarks to ensure compatibility with municipal wastewater infrastructure.

Slosh Box Testing: Simulating Wastewater Agitation

Mechanical agitation via the FG502 Slosh Box simulates the hydraulic forces and turbulence encountered in municipal sewer pipes. Test protocols involve rotating chambers at precise speeds, typically 16 to 26 rpm, to observe how fiber structures decouple over time. Physicists measure settling velocity to confirm particles are not buoyant, with an average target of >0.1 cm/sec to prevent surface accumulation in tanks. Validation requires multiple replicates, such as the 5-replicate IWSFG PAS 3 method, to ensure consistency across product batches.

Technical Benchmarks: GD4 and IWSFG Performance Thresholds

The GD4 Edition 4 standard requires at least 60% of product dry mass to pass through a 12.5 mm sieve after 60 minutes of agitation. IWSFG PAS 3 maintains stricter 2026 requirements, demanding >95% mass throughput through a 25 mm sieve within only 30 minutes at 16-18 rpm. Biodisintegration criteria (IWSFG Part A) mandate that >95% of initial dry mass must pass through a 1 mm sieve after 14 days in a wastewater environment. Long-term environmental safety is validated via OECD 311 biodegradation tests, requiring >70% theoretical gas production over 56 days.

Using Lab Reports for Marketing and Retail Compliance

By 2026, manufacturers must use scientific evidence of ‘sufficient quality and quantity’ to validate marketing assertions. Lab reports serve as the primary defense against deceptive practice allegations, providing independent verification of product performance and safety standards required by agencies like the FTC and FDA.

| Regulatory Framework | Core Requirement | Retail Application |

|---|---|---|

| FTC Substantiation | Sufficient quality and quantity evidence | Validating performance and health claims |

| FDA SSA Standard | Significant Scientific Agreement | Presumptive truth for health-related assertions |

| GLP Standards | Data integrity and quality assurance | Supporting regulatory filings (FDA/EPA) |

| OIG Seven Elements | Operational compliance programs | Ensuring auditability and fraud prevention |

Validating Performance Assertions with Scientific Evidence

The FTC mandates that manufacturers provide evidence of “sufficient quality and quantity” for all health and performance assertions. To meet this standard, clinical studies must utilize defined treatment and control groups to ensure objective data comparison. Independent experts should validate these findings to provide transparency for premium claims, such as softness or skin safety in tissue products. Providing raw data and detailed protocols during audits remains more effective than submitting simplified abstracts, as regulators require proof of methodology.

Frameworks for Global Retail and Regulatory Auditability

The OIG Seven Elements framework establishes a structured compliance program for laboratory operations and data integrity. This system includes written policies, internal monitoring, and corrective action plans to mitigate risks of fraud or data manipulation. Good Laboratory Practice (GLP) standards ensure high data quality for submissions to the FDA and EPA. For the 2026 retail market, Significant Scientific Agreement (SSA) standards govern health-related claims. Integrating ISO 9001 and FSC certification reports further assists manufacturers in securing placement within European and North American retail sectors by demonstrating environmental and quality management adherence.

Final Thoughts

Transitioning from subjective touch tests to quantitative data protects brands and ensures product consistency across global supply chains. Manufacturers who prioritize ASTM and ISO protocols replace guesswork with repeatable mechanical benchmarks. This data-driven approach builds trust with retail partners and proves that a product delivers on its physical promises, from specific tensile energy absorption to precise thickness tolerances.

Strict adherence to chemical safety and disintegration standards prevents legal risks and costly recalls in an increasingly regulated market. Since global retail chains demand third-party validation, these lab reports serve as essential documentation for market entry and consumer safety. By 2026, scientific evidence acts as the foundation for any tissue brand aiming to secure a competitive position in North American and European sectors.

Frequently Asked Questions

What are the most critical lab tests for toilet paper quality validation?

Primary testing focuses on structural integrity and performance. Essential tests include tensile strength to measure tear resistance, bursting strength for durability, and wet strength for functional use. Additionally, absorbency and ply bond tests ensure the layers adhere properly and function as intended under 2026 industry standards.

How is tissue softness measured without relying on subjective human touch?

Laboratories use a Tissue Softness Analyzer (TSA) to generate an objective Hand Feel (HF) value. This device uses acoustic sensors to measure fiber stiffness (TS7) and surface roughness (TS750). These factors are combined with stiffness and elasticity data to create a scientific softness rating that correlates closely with human perception.

Which international standards govern tissue paper manufacturing and testing?

The ISO 12625 series is the primary global standard. It dictates specific protocols for thickness and bulking (ISO 12625-3), tensile strength (ISO 12625-4), and wet tensile strength (ISO 12625-5). Compliance with these standards ensures products meet the technical requirements for North American and European retail markets.

Can retail brands use factory in-house lab reports for regulatory compliance?

In-house reports are generally insufficient for US or EU market entry. Regulatory bodies like the CPSC and EU authorities require validation from third-party labs accredited to ISO 17025 or CNAS standards. Importers must typically provide these accredited results within five days if a shipment is detained for inspection.

How do labs determine if a product is truly septic-safe?

Safety validation relies on a disintegration speed test. The industry standard requires toilet paper to break down within a maximum of 3 minutes. High-quality septic-safe products are engineered to dissolve into small particles within 1 to 2 minutes under standardized agitation to prevent plumbing and municipal sewer blockages.