Technical precision in tissue manufacturing hinges on the r=0.927 correlation between fiber length and tear strength, a metric that dictates the boundaries of high-speed production runnability. For industrial operations managing high-volume outputs like Top Source Hygiene’s 2,860-ton monthly capacity, 100% virgin wood pulp is a mechanical requirement to maintain an ash content precision target of 0.01% at 900 °C, eliminating the structural inconsistencies and chemical contaminants inherent in recycled alternatives.

This analysis deconstructs the anatomy of primary fiber, benchmarking the chemical performance of 16-18% hemicellulose against the rigid protocols of ISO 29681. We evaluate the structural synergy between NBSK and BEK pulp types while outlining the technical and ESG implications of FSC 100% versus FSC Mix labeling standards in the global supply chain.

What Exactly is “Virgin” Wood Pulp?

Virgin wood pulp is primary fiber harvested from timber, not recycled waste. It provides maximum tensile strength and purity for high-end tissue production without chemical contaminants.

The Anatomy of Primary Fiber: Extraction and Composition

The industry tracks primary timber consumption using Roundwood Equivalent (RWE) volumes measured in cubic meters. Unlike recycled alternatives, virgin pulp skips the waste stream entirely, sourcing fibers directly from forest roundwood to ensure structural integrity.

- Kraft Process: Chemical delignification involves wood reception, debarking, and chipping to isolate pure cellulose.

- Contaminant Profile: Total absence of secondary residues like residual inks or fluorescent whiteners found in recycled paper.

- Fiber Selection: Species origin and fiber length dictate the mechanical performance and final product grade.

Technical Benchmarks: ISO Standards and Chemical Purity

Precision manufacturing relies on specific ISO benchmarks to verify pulp quality. These standards ensure the material can withstand the mechanical stresses of high-speed tissue converting lines while maintaining softness.

- ISO 29681: Establishes pH measurement protocols for bleached virgin pulps with low ionic strength.

- Ash Content: Testing occurs at 900 °C with a precision target of 0.01% or better to confirm material purity.

- Optical Specs: Light-absorption coefficients measured at 457 nm verify brightness values without excessive chemical loading.

- Morphology: Analysis of species-specific fiber length and structure predicts performance in 2-ply to 5-ply configurations.

Long Fiber vs. Short Fiber: Why Can’t You Have One Without the Other?

Paper engineering balances long fibers for structural strength with short fibers for smoothness and opacity. Omitting either results in structural failure or poor surface quality.

| Pulp Type | Avg. Length (mm) | Coarseness (mg/100m) | Primary Function |

|---|---|---|---|

| Scand. Softwood Kraft | 3.0 – 3.7 | 160 – 200 | Tensile & Tear Strength |

| Aspen Hardwood Kraft | 1.0 – 1.3 | 86 | Opacity & Smoothness |

| Birch Hardwood Kraft | 1.1 – 1.5 | 114 | Surface Formation |

| Radiata Pine | 2.5 | 250 | Bulk & Absorbency |

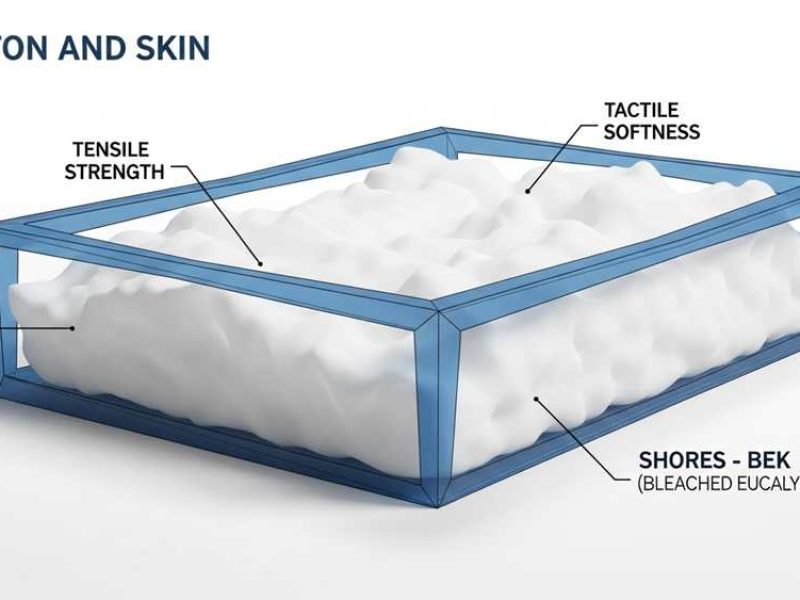

The Structural Synergy: Strength vs. Formation Roles

Paper engineering requires a mechanical skeleton. Long fibers, typically sourced from Scandinavian Softwood Kraft, provide the necessary tensile and tear strength to ensure a sheet does not disintegrate during use. However, using these fibers exclusively creates a coarse, uneven surface. Short fibers from hardwoods like Aspen or Birch act as the filler, increasing the fiber population density to improve opacity and smoothness.

- Long Fiber Role: Distributed mechanical stress resistance and durability.

- Short Fiber Role: High population density for “cloud-like” hand-feel and coating holdout.

- Formation Risk: 100% long fiber blends lead to “picking” or surface linting due to high coarseness.

- Structural Failure: 100% short fiber blends lack the bonding length required to survive high-speed production tension.

The Science of the Blend: Fiber Dimensions and Flexibility Ratios

The physical dimensions of the fiber dictate the paper’s performance. Softwood fibers are over three times the length of hardwood fibers, allowing them to bridge larger gaps in the paper web. The Fiber Flexibility Index, or L/T ratio (length to wall thickness), explains 88% of the tensile strength variation in unbeaten pulp.

Engineers use Bleached Softwood Kraft (BSKP) to maintain “wet web strength.” This prevents the sheet from breaking on the paper machine during drainage. Hardwood pulps, such as Aspen Kraft, provide a much lower coarseness (86 mg/100m), which is essential for premium tissue and print grades where surface integrity and softness are non-negotiable.

- Softwood Width: 27–38 µm with wall thickness up to 3.5 µm.

- Hardwood Width: 15–25 µm, providing a denser, smoother matrix.

- Tensile Correlation: L/T ratio accounts for 80% of strength in beaten pulp.

- Production Efficiency: BSKP reinforcement allows for higher machine speeds without downtime.

The Tensile vs. Softness Paradox: How Fiber Length Dictates Performance

Long softwood fibers drive tensile strength via a high L/T ratio, but manufacturers must blend them with shorter fibers to prevent stiffness and maintain premium tactile softness.

| Fiber Metric | Correlation (r) | Performance Impact |

|---|---|---|

| Fiber Length (Tear Index) | 0.927 | Explains 92% of variation in tearing strength. |

| L/T Ratio (Tensile Index) | 0.798 | Determines hydrogen bonding surface area. |

| L/T Ratio (Burst Strength) | 0.709 | Influences fiber conformability and web integrity. |

The Mechanics of Bonding: Why Fiber Length Determines Structural Integrity

Fiber length serves as the primary engine for tensile strength. Longer fibers provide the necessary surface area for hydrogen bonding and better conformability as the paper web dries. When fibers are long and flexible, they intertwine more effectively, creating a network that resists breaking under tension.

The industry uses specific technical markers to predict how wood pulp will perform in high-speed manufacturing environments:

- L/T Ratio: The Length-to-Thickness ratio is the strongest predictor for durability in unbeaten pulps (r=0.798).

- Fiber Morphology: Thicker cell walls relative to length reduce flexibility, which actually limits the bond area and lowers tensile performance.

- Softwood Kraft Pulp (SUKP): This material excels because its long fibers create a dense network that manages stretch-at-break better than short-fiber alternatives.

Solving the Softness Paradox: Technical Ratios and Refining Strategies

The “Paradox” exists because the same hydrogen bonds that give a paper towel its strength also make the sheet stiff. High-performance manufacturing avoids this by using 100% virgin pulp. Recycled fibers often show increased contact angles (up to 52°), which reduces wettability and creates a harsh, “bony” texture.

Engineers resolve the tension between durability and hand-feel through precise fiber management and chemical processing:

- Strategic Blending: Adding 1-5% long, low-bonding fibers to a refined softwood base shifts the tensile-tear curve, increasing strength without increasing sheet density.

- Lignin Management: Using Chemi-thermomechanical pulp (CTMP) can reduce the fiber contact angle from 48° to 38°, enhancing flexibility and softness.

- Purity Standards: ISO 29681 and ash content measurements at 900 °C ensure the pulp remains free of the ionic contaminants that interfere with fiber bonding.

By focusing on the r=0.927 correlation between fiber length and tear strength, manufacturers produce paper that remains strong enough for commercial use while maintaining a cloud-like tactile profile. Softwood provides the skeleton, while hardwood and specific refining techniques provide the skin.

Scale Your Global Brand with Expert OEM Toilet Paper Manufacturing

Beyond Cellulose: Do You Know How Hemicellulose Affects Sheet Integrity?

Hemicellulose (16-18%) acts as a chemical bridge, doubling tensile strength to 260 MPa and protecting fiber integrity during high-speed manufacturing.

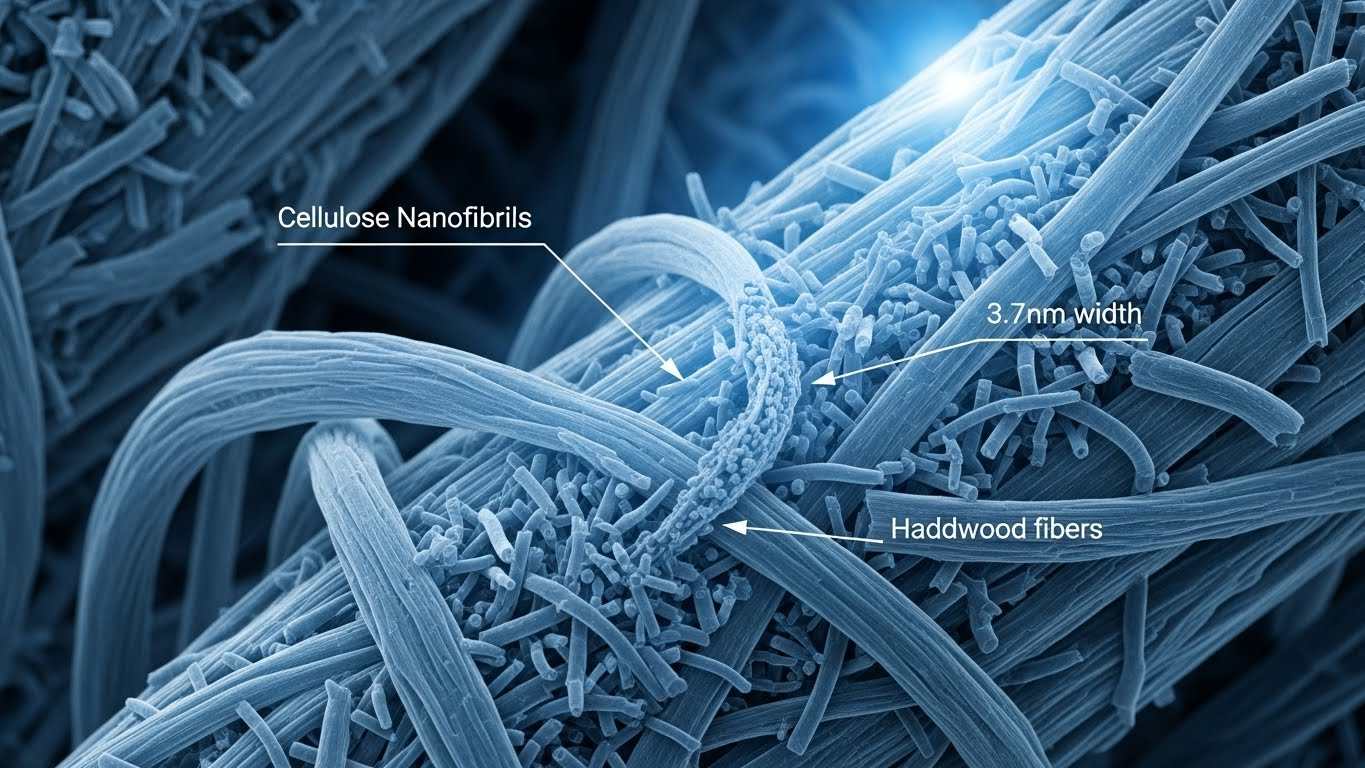

The Bonding Bridge: How Hemicellulose Enhances Fiber Fibrillation

Hemicellulose acts as a lubricant and facilitator for enzymes like LPMO. This access to wood cell walls allows for far more efficient nanofibrillation than what you find in low-hemicellulose pulps. It essentially prepares the fiber to bond before the mechanical work even begins.

The chemical makeup determines the final fiber width. Kraft pulp with 16-18.5% hemicellulose yields Cellulose Nanofibrils (CNFs) with a width of just 3.7 nm. In contrast, dissolving pulps with only 4% hemicellulose produce much thicker 50-100 nm aggregates, which reduces the surface area available for bonding.

Beyond size, hemicellulose provides a protective shield. It prevents cellulose chains from breaking down during manufacturing processes like irradiation. This minimizes molecular weight loss and maintains the fiber length necessary for a durable sheet.

Quantifying Performance: Tensile Strength and Manufacturing Runnability

Hemicellulose levels dictate the mechanical limits of the paper sheet. The data shows that stripping away too much hemicellulose compromises the structural integrity of the final product:

- Tensile Strength: 16% hemicellulose achieves 260 MPa vs. 138 MPa for 4% variants.

- Young’s Modulus: High-hemicellulose pulp reaches 16.9 GPa, providing superior stiffness.

- Optical Transmittance: Efficient fibrillation enables up to 86% transmittance in specialized nanopapers.

- Toughness: Low-hemicellulose dissolving pulps drop to a mere 5.1 MJ m⁻³ in toughness.

For industrial scale, runnability is the priority. Retained hemicellulose boosts water retention and wet web strength. These metrics are critical for maintaining the speed of paper machines, particularly for operations like Top Source Hygiene’s 2,860-ton monthly production. Higher content also increases the volume of “fines” and bonding sites, which directly improves tear strength and dimensional stability under stress.

Is Your “Premium” Sourcing Genuinely Sustainable? The Role of FSC-Certified Forests

FSC certification guarantees ethical sourcing through rigid audits. Buyers must distinguish between 100% virgin fiber and Mix labels containing risk-assessed “controlled wood” to ensure true ESG compliance.

FSC Labeling Decoded: Distinguishing Between 100%, Mix, and Recycled Standards

Vague “green” claims often collapse under scrutiny. FSC labels provide the technical evidence required to verify material composition and forest management practices. Each label dictates a specific ratio of certified fiber to other inputs.

- FSC 100%: This material comes exclusively from FSC-certified forests. It prohibits any blending with uncertified virgin fiber.

- FSC Mix: Manufacturers blend FSC-certified material with recycled content or “Controlled Wood” (CW). The CW component must pass audits to ensure it avoids high-risk or illegal sources.

- FSC Recycled: Requires 100% reclaimed fiber. Documentation must specify the balance between pre-consumer and post-consumer waste.

- Management Standards: Certification mandates biodiversity protection, water conservation, and the preservation of indigenous rights.

Traceability and Verification: The Role of Chain of Custody (CoC) and ISO Standards

Chain of Custody (CoC) protocols track wood pulp from the forest floor to the final paper product. This verification loop ensures that premium pulp isn’t mixed with “controversial” wood—such as timber from Genetically Modified (GM) trees—during global transit.

- Risk Mitigation: Controlled Wood (CW) protocols specifically filter out timber from Intact Forest Lands (IFLs) to prevent habitat destruction.

- Industrial Benchmarks: Companies like P&G target 100% FSC-certified fiber by 2030, currently sourcing 95% of their pulp from caribou-protected regions in Quebec and Ontario.

- Standard Integration: Suppliers often combine FSC audits with ISO 9001 (Quality), 14001 (Environment), and 45001 (Safety) to streamline ESG compliance.

- LEED Contribution: Verifiable FSC CoC documentation directly supports LEED certification points for green building projects.

For B2B buyers, these certifications move sustainability from a marketing talking point to a legal and technical safeguard. Audited supply chains reduce the risk of sourcing from high-risk plantations, ensuring that “premium” products meet global environmental benchmarks.

Final Thoughts

Premium tissue requires a precise mechanical skeleton of long softwood fibers and a smooth hardwood skin. Sacrificing virgin pulp purity for recycled fillers results in linting, stiffness, and costly production downtime.

Audit your supply chain for FSC 100% certification and ISO 29681 compliance immediately. Demand a technical breakdown of the fiber blend to ensure high L/T ratios that maximize both tensile strength and tactile softness.

Frequently Asked Questions

What is the difference between hardwood and softwood pulp?

Hardwood pulp uses shorter, thicker fibers from deciduous trees like eucalyptus to provide smoothness and opacity. Softwood pulp relies on longer, thinner fibers from coniferous trees like pine for high tensile and tear strength. Softwood contains approximately 55% cellulose and 26% lignin, while hardwoods maintain lower lignin levels.

Why is 100% virgin pulp considered the gold standard for premium paper?

Virgin pulp uses long, unbroken fibers that deliver superior stiffness, smoothness, and print quality, often hitting 91±1.5% whiteness. It meets strict food-grade safety standards and maintains the high-bulk properties required for premium tissue and packaging that recycled fibers cannot match.

Does fiber length affect the flushability of toilet paper?

Yes. Longer fibers increase sheet strength but resist disintegration. Technical guidelines for flushable products require fiber lengths under 10 mm. This ensures the paper breaks down rapidly enough to pass through wastewater systems without causing blockages.

How can you tell if a paper product is mixed with straw pulp?

Technicians use a Fiber Quality Analyzer (FQA) to spot straw pulp. It typically shows a fiber aspect ratio of 30–50 and a high fine fiber content of 40–45%. Straw-mixed paper also exhibits a lower number average length (Ln) of 0.5–0.7 mm compared to pure wood pulp.

What are NBSK and BEK in paper manufacturing?

NBSK (Northern Bleached Softwood Kraft) provides mechanical strength and tear resistance using long-fiber spruce or pine. BEK (Bleached Eucalyptus Kraft) is a hardwood pulp prized for high brightness, opacity, and smoothness. BEK is the primary choice for soft, high-quality tissue applications.

Why do some ‘premium’ rolls still feel scratchy?

Scratchiness occurs when manufacturing processes like creping—which scrunches the paper to create softness—are insufficient. High-brightness standards (ISO 2470: 92%+) can also lead to stiffer fibers if chemical bleaching is not balanced with mechanical surface treatments.