Procuring premium tissue products requires balancing a mandatory 85% to 88% ISO brightness target against the regulatory reality that chlorinated bleaching byproducts are classified as acute hazardous wastes under RCRA and CERCLA. While the EPA established Elemental Chlorine Free (ECF) as the industry’s Best Available Technology (BAT) as early as 1998 to minimize dioxin risk, B2B buyers must now navigate a market where Totally Chlorine Free (TCF) alternatives offer zero-chlorine compliance at the cost of significantly higher raw wood fiber consumption and increased energy demand.

This technical evaluation breaks down the operational performance of ECF versus TCF standards, detailing how manufacturers like Top Source Hygiene align production with Green Seal GS-18 and EU Ecolabel requirements. We analyze the toxicological safety of optical brighteners such as FB-220 and FB-71, while auditing the high-resolution testing protocols of EPA Method 1668 to provide a data-driven framework for chemical safety and environmental compliance.

Why is Toilet Paper White? The Role of Bleaching

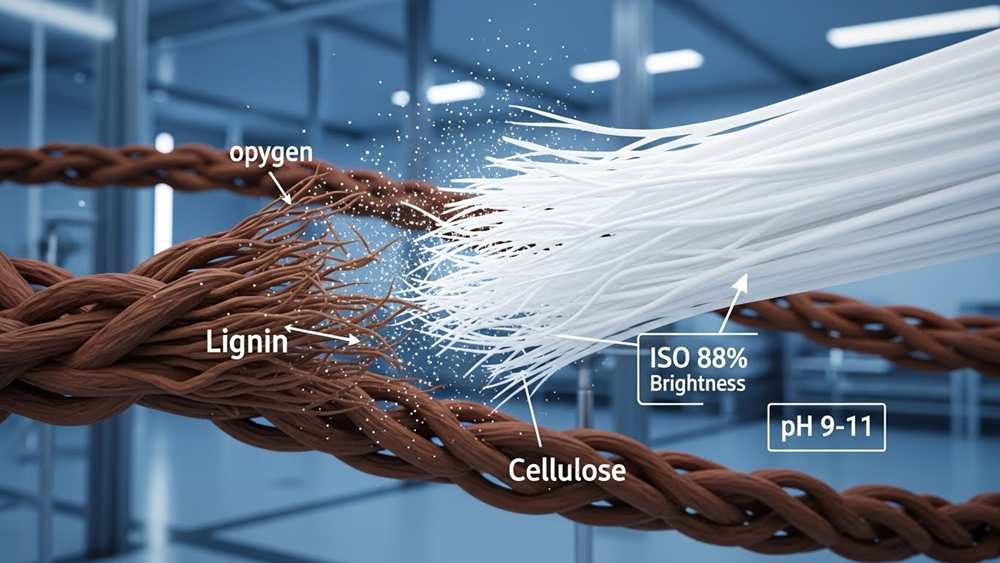

Bleaching removes lignin to turn brown wood pulp white, creating the soft, absorbent, and hygienic texture consumers expect from high-quality tissue products.

The Science of Whiteness: Lignin Removal and Fiber Softening

Raw wood fibers contain lignin, a natural binder that makes wood brown and rigid. Removing this organic polymer is necessary to create the soft, flexible texture required for high-end tissue products. Without its removal, the paper remains stiff and abrasive.

Bleaching breaks the chromophore bonds in the pulp. This process prevents the paper from yellowing over time and ensures visual consistency across high-volume production batches. Also, 100% virgin wood pulp responds more efficiently to bleaching than recycled fibers, leading to better fiber strength and higher absorbency rates.

Technical Benchmarks: Brightness Targets and Chemical Stages

- Brightness Targets: Premium toilet paper typically aims for 85% to 88% on the ISO brightness scale.

- Oxidative Bleaching: Processes use hydrogen peroxide (H2O2) at 30-90°C and a pH of 8-12 to achieve 10-20 points of brightness gain.

- Reductive Stage: Sodium dithionite or sodium hydrosulfite (0.1-0.6% dosage) is often applied for an additional 4-14 points of brightness.

- Bleaching Methods: ECF (Elemental Chlorine Free) uses chlorine dioxide to minimize dioxins; TCF (Totally Chlorine Free) uses peroxide or ozone for chlorine-free compliance.

- Pulp Consistency: Modern OEM facilities maintain 20-35% consistency post-thickening to maximize chemical efficiency.

ECF (Elemental Chlorine Free) vs. TCF (Totally Chlorine Free)

ECF uses chlorine dioxide for efficient 88% brightness, while TCF eliminates chlorine via oxygen agents but consumes significantly more energy and raw wood fiber.

| Feature | ECF (Elemental Chlorine Free) | TCF (Totally Chlorine Free) |

|---|---|---|

| Primary Chemical | Chlorine Dioxide (ClO2) | Hydrogen Peroxide (H2O2) / Ozone |

| Dioxin Risk | Negligible / Undetectable | Zero |

| Fiber Efficiency | High (Standard Yield) | Lower (Requires more wood per ton) |

| Industry Status | Global Standard / EPA BAT | Niche / Eco-premium |

Bleaching Chemistry and Dioxin Reduction Profiles

Modern tissue production relies on ECF to hit whiteness targets between 85% and 88%. This process replaces elemental chlorine gas with chlorine dioxide. This chemical shift targets lignin and inks without creating the high levels of toxic byproducts found in legacy 1970s-era mills. Most Chinese manufacturing bases, including Mancheng, adopt ECF to balance cost with strict environmental discharge limits.

TCF eliminates chlorine compounds entirely. It utilizes an oxidative process, often followed by a reductive stage, to break chromophore bonds in the pulp. While this guarantees zero chlorine-based dioxins, the process is chemically aggressive and can degrade fiber strength if not managed precisely.

- Oxidative Temperature: 30-90°C (typically 60°C for 3-5 hours).

- H2O2 Dosage: 0.2% to 2% by weight.

- pH Environment: 8-12 (Optimal range 9-11).

- Reductive Agents: Sodium dithionite or sodium hydrosulfite.

Operational Performance and Regulatory Standards

The US EPA identified ECF as the “Best Available Technology” (BAT) in 1998. Their research showed that transitioning the entire industry to TCF would cost billions while only reducing total dioxin exposure by roughly one gram. European BAT/BREF documentation supports this, stating there is no appreciable real-world difference in the environmental impact of effluent between modern ECF and TCF plants.

TCF requires more energy and more raw wood fiber per ton of pulp to meet the same brightness and strength specifications as ECF. This makes TCF products more expensive and harder to source under tight lead times. ECF remains the pragmatic choice for B2B buyers who need to satisfy both ISO brightness standards and environmental compliance without paying a “green-wash” premium.

- Brightness Gains: Hydrogen peroxide adds 10-20 points; sodium hydrosulfite adds 4-14 points.

- Lead-Time Compatibility: ECF supports standard 15-25 day OEM cycles.

- Process Consistency: Medium/high consistency levels (20-35%) post-thickening.

Dioxins and Furans: The Chemical Safety Audit

TEQ methodology normalizes 210 congeners to the 2,3,7,8-TCDD benchmark. This allows auditors to assess cumulative toxicity against federal drinking water limits and FDA safety advisories to prevent bioaccumulation.

| Parameter | Regulatory Limit / Standard | Governing Authority |

|---|---|---|

| Drinking Water (2,3,7,8-TCDD) | 30 pg/L (0.00000003 mg/L) | EPA (SDWA) |

| Fish & Shellfish Consumption | 50 ppt (parts per trillion) | FDA |

| Analysis Methodology | Method 1668 (HRGC/HRMS) | EPA |

| Waste Classification | Acute Hazardous Waste | RCRA / CERCLA |

TEQ Methodology and Toxicity Equivalency Factors (TEF)

Auditors utilize the Toxicity Equivalency Quotient (TEQ) to quantify the cumulative risk of complex chemical mixtures. This methodology is necessary because analyzing 210 individual congeners of dioxins (PCDD) and furans (PCDF) in isolation fails to capture their combined biological impact. By normalizing every compound to a single standard, manufacturers can prove compliance with site-wide cleanup levels.

- Benchmark Standard: 2,3,7,8-TCDD serves as the reference point with a Toxicity Equivalency Factor (TEF) of 1.

- Ecological Screening: WAC 173-340-900 (Tables 749-2 and 749-3) requires dioxins and furans to be treated as separate mixtures for simplified terrestrial evaluations.

- Aggregation Rules: Compounds are aggregated into a single TEQ value for site-wide cleanup levels outside specific screening tables.

- Non-Detect Protocols: Zero-substitution for non-detect congeners is strictly forbidden unless laboratory Practical Quantitation Limits (PQL) meet Ecology Memorandum #11 thresholds.

Regulatory Limits and High-Resolution Analysis Standards

To mitigate the risks of bioaccumulation, the industry has shifted toward Elemental Chlorine Free (ECF) and Totally Chlorine Free (TCF) bleaching. ECF processes use chlorine dioxide to target whiteness levels of 85-88%, while TCF utilizes hydrogen peroxide or ozone at temperatures between 30-90°C. These transitions are verified through high-resolution testing that detects trace pollutants standard methods miss.

- Testing Gold Standard: EPA Method 1668 uses High-Resolution Gas Chromatography/High-Resolution Mass Spectrometry (HRGC/HRMS) to identify chlorinated dioxins, furans, and PCBs.

- Food Chain Safety: The FDA issues consumption advisories for any fish or shellfish exceeding 50 ppt of 2,3,7,8-TCDD to prevent chronic human exposure.

- Legal Classification: RCRA and CERCLA (Superfund) frameworks classify chlorinated dioxins as acute hazardous wastes, triggering the highest level of handling and reporting requirements.

- Industrial Reporting: TSCA 40 CFR Part 766 mandates that manufacturers test and report on specific chemical substances to ensure bleaching byproducts remain below toxic thresholds.

Safety audits focus on these specific benchmarks because dioxins are highly persistent. Whether you are managing industrial effluent or sourcing paper pulp, the presence of these compounds indicates a failure in the bleaching or waste treatment cycle. High-resolution data is the only defense against the legal and environmental liabilities associated with these chlorinated compounds.

Scale Your Brand with Global OEM/ODM Toilet Paper Experts

The Rise of Unbleached (Natural) Tissue: B2B Market Trends

Unbleached tissue adoption is surging, driven by GS-18 compliance and superior mechanical strength including a tear index exceeding 6 mN.m²/g and high opacity.

B2B buyers are pivoting to unbleached products to hit aggressive ESG targets. This shift isn’t just about the “natural” look; it’s a strategic move to eliminate chemical effluents and meet strict procurement policies in North America and Europe.

Market Drivers and Sustainability Compliance (GS-18 & EU Ecolabel)

Regulatory frameworks now penalize traditional chemical whitening. Major hospitality and retail players use unbleached fibers to signal environmental responsibility while ensuring compliance with international green standards.

- Green Seal GS-18: This standard strictly prohibits chemical whitening or bleaching for certified sanitary paper products.

- EU Ecolabel: Requires a minimum pulp fiber content of 90% and demands rigorous emissions tracking across pulping and converting.

- FWA Removal: Eliminating fluorescent whitening agents (FWA) reduces chemical discharge and appeals to health-conscious commercial end-users.

- OEM Strategy: Manufacturers like Top Source Hygiene now prioritize 100% virgin wood pulp options to navigate Western “green” procurement mandates.

Technical Specifications and Material Performance (ISO & TAPPI Standards)

Unbleached sulfate pulp, such as eucalyptus globulus UBP, retains natural lignin. This retention results in higher fiber viscosity and superior mechanical durability compared to heavily processed bleached alternatives.

- Tear Index: Targets 6–10 mN.m²/g per ISO 5269-1:2005, providing high durability for commercial hand towels.

- Burst Index: Exceeds 1 kPa.m²/g, ensuring the tissue maintains integrity when wet.

- Opacity & Capillarity: Features opacity ratings >70% and capillarity ≥60 mm/10 min for high-speed moisture absorption.

- Thermal Processing: Pulp is processed at 145-155°C using 2300-2500 kg Na₂O active alkali to preserve fiber width and coarseness.

- Validation Metrics: Labs utilize TAPPI T 569 for internal strength and Emtec TSA testing to verify that softness matches bleached standards.

By skipping the chlorine, oxygen, or peroxide bleaching stages, manufacturers significantly reduce water consumption. The resulting product offers a high-performance, high-opacity solution for jumbo rolls and commercial hygiene systems.

Fluorescent Whitening Agents (FWA): Safety and Compliance

FWAs like FB-220 are non-toxic and skin-safe. They meet EC 1935/2004 standards, show minimal bioaccumulation, and pose no acute health risks in industrial paper production.

Toxicological Profile and Human Health Assessment

Toxicological data confirms that modern optical brighteners do not pose the risks often associated with industrial dyes. Clinical studies show these agents are not absorbed by the skin. Even during direct, prolonged contact or on open wounds, the chemicals show no adverse effects on healing or pathology. Most core agents used in the industry are categorized as Not Bioaccumulative (Not B) and Not Toxic (Not T).

- FB-220 (CAS RN 16470-24-9): Carries no GHS classification under Regulation (EC) No 1272/2008 for acute toxicity, skin corrosion, or irritation.

- Core Agents: FB-71 (CAS RN 16090-02-1) and FB-28 (CAS RN 4193-55-9) meet strict safety criteria and do not bioaccumulate in human tissue.

- Environmental Metrics: Australian assessments record Bioconcentration Factors (BCF) between 1.4–4.7 L/kg at standard dosages, well below the thresholds for environmental concern.

Global Regulatory Standards and Migration Testing

Safety in B2B sourcing relies on strict adherence to migration limits. While FWAs are prohibited in cosmetics, they are heavily regulated in paper and textile manufacturing to ensure consumer safety. Compliance officers prioritize testing protocols that measure how these molecules behave under heat or varying pH levels, particularly in food-contact scenarios.

- EC 1935/2004: The mandatory EU standard for food-contact paper, ensuring no harmful migration occurs from brighteners into food products.

- Oeko-Tex Standard 100: Verifies that FWAs in hygiene and textile products meet rigorous safety and environmental thresholds for human use.

- Testing Protocols: Standards like HG/T 4433-2012 and FZ/T 01137-2016 provide the industrial framework for measuring brightener intensity and presence.

- Sustainability Labels: Blue Angel and FSC certifications require manufacturers to minimize FWA usage to lower the chemical load in industrial wastewater effluent.

Current REACH regulations impose no specific restrictions on these substances, highlighting their established safety profile when managed under professional industrial controls. Sourcing teams should focus on entity-specific CAS assessments to ensure regional compliance.

Environmental Impact of Bleaching Effluent on Waterways

Legacy bleaching effluents introduce 250+ organochlorine compounds and high COD, causing fish lethality at 3.2% concentration. Modern ECF/TCF shifts neutralize these risks and meet strict BAT standards.

Chemical Oxygen Demand and Organochlorine Persistence

Bleachery discharge contains approximately 250 identified organochlorine compounds. Environmental monitors use Adsorbable Organic Halides (AOX) as the standard surrogate measure to track these persistent pollutants across river systems.

- Chemical Oxygen Demand (COD): Levels reach 996 mg/L in specific stages, depleting dissolved oxygen and blocking light for benthic growth.

- Environmental Persistence: Chlorinated organics remain detectable in sediment and biota up to 1,400 km downstream from the discharge point.

- KOH-Based Mitigation: Potassium hydroxide bleaching reduces COD loads to 312 mg/L after three hours of treatment, outperforming calcium hypochlorite methods.

Ecotoxicity and Best Available Technology (BAT) Standards

Legacy effluent from chlorine-based mills is toxic to aquatic life even at high dilution rates. Canadian mill studies prove that 75% of untreated legacy effluent kills fish at concentrations of just 3.2%.

- Elemental Chlorine Free (ECF): Substitutes 100% of molecular chlorine with chlorine dioxide to meet EPA Best Available Technology guidelines.

- Totally Chlorine Free (TCF): Eliminates all chlorine compounds using hydrogen peroxide or ozone to remove dioxin risks entirely.

- Solids Management: Integrating extended delignification with biological treatment stages reduces Total Suspended Solids (TSS) by 90% before water release.

- Biological Stress: Plankton populations show chronic reproductive anomalies and biochemical stress when exposed to legacy diluted effluents.

Final Thoughts

ECF is the pragmatic standard for balancing cost and brightness. TCF offers a green label but forces you to pay a premium for negligible environmental gains and higher fiber waste.

Use ECF for high-volume retail to protect margins. If targeting eco-conscious B2B contracts, pivot to unbleached products to meet GS-18 compliance and eliminate bleaching costs entirely.

Frequently Asked Questions

Is bleached toilet paper safe for sensitive skin?

Bleached toilet paper is generally not recommended for sensitive skin. Elemental chlorine processes leave residual irritants like dioxins in the fibers. To minimize irritation risks, sourcing managers should specify Elemental Chlorine Free (ECF), Process Chlorine Free (PCF), or Totally Chlorine Free (TCF) options, though unbleached paper remains the safest technical choice.

What is the difference between ECF and TCF bleaching?

ECF (Elemental Chlorine Free) uses chlorine dioxide (ClO2) and handles pulps with higher kappa numbers (>20), maintaining high yields. TCF (Totally Chlorine Free) relies on oxygen, peroxide, or ozone. While TCF eliminates all chlorine derivatives, it requires cleaner incoming pulp (kappa <15) and typically results in lower bleached pulp yields and higher wood consumption.

Why do some brands choose unbleached (brown) toilet paper?

Manufacturers opt for unbleached paper to bypass chemical processes that create dioxins and other persistent pollutants. This decision reduces environmental impact, eliminates consumer exposure to residual bleaching chemicals, and mitigates risks related to skin irritation or endocrine disruption.

Are there “forever chemicals” (PFAS) in the bleaching process?

PFAS are not an inherent part of the ECF or TCF pulp bleaching cycle. However, some industrial applications use PFAS-based surfactants as processing aids—at concentrations between 0.025-0.05% by weight—to improve bleach penetration in leather and textiles. They are rarely used in standard tissue production unless specific grease-resistant properties are required.

How to audit a supplier’s chemical safety lab reports?

Audits should evaluate Chemical Hygiene (GHS-compliant SDS), documented SOPs, personnel training records, and hazardous waste disposal. Categorize findings into Immediate, Serious, or Low Risk. A valid audit report must contain individual safety scores for each facility area and photographic evidence of current safety practices and storage conditions.

Does the bleaching process affect the softness of the fibers?

Bleaching increases fiber flexibility, which directly improves perceived softness. While it reduces tensile strength (from approximately 431N to 414N in tested samples), it significantly boosts elongation at break from 12.67% to 22.57%. This makes the final product less rigid and more comfortable for the end user.