Sourcing toilet tissue with optimized Embossing & Micro-structure is the primary defense against rising pulp costs and uncompetitive roll diameters. Relying on flat, non-engineered fiber mats forces distributors to pay for excess pulp mass, which erodes profit margins on every 40HQ container shipment.

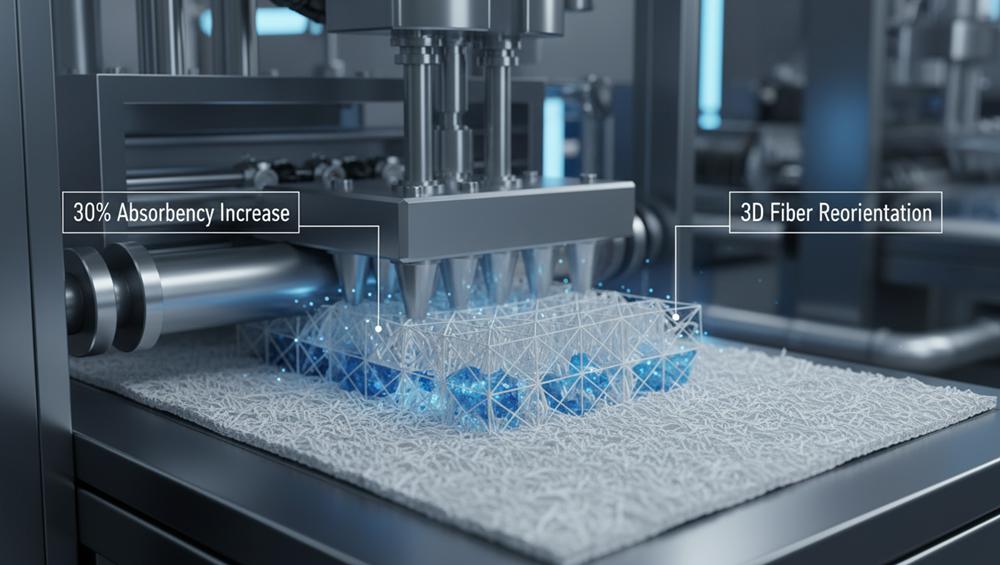

We apply CNC-precision point-to-point technology to increase liquid absorbency by 30% while maintaining a strict 13–22g/m² density per ply. This engineering creates the mechanical bulk required for luxury brands without exceeding the fiber weight limits of 100% virgin wood pulp standards.

How Does Advanced Embossing Change the Physical Geometry of Tissue?

Advanced embossing converts 2D fiber mats into 3D structures, increasing bulk and absorbency while reducing raw material costs through engineered air pockets and precision ply-bonding.

Three-Dimensional Fiber Reorientation and Surface Architecture

The embossing process fundamentally reshapes the tissue sheet by shifting it from a flat fiber mat into a three-dimensional architecture. Mechanical rollers create raised and depressed designs that modify the physical structure of the paper. While the pressure densifies the base fibers, the resulting pattern creates significant net thickness and volume. This geometric shift allows manufacturers to produce high-bulk rolls that require less raw fiber without sacrificing the premium hand-feel distributors expect.

Top Source Hygiene utilizes 100% Virgin Wood Pulp for these applications because the long-fiber structure maintains integrity even under high-pressure geometric transformation. This ensures the tissue remains soft to the touch while the peaks and valleys of the pattern function as structural supports that prevent the sheet from collapsing.

- Fiber Shift: Rollers move fibers from a 2D plane into a 3D structure.

- Thickness Gain: Net sheet thickness increases despite localized fiber densification.

- Air Pockets: Geometric valleys trap moisture, significantly improving liquid capacity.

- Texture Balance: Patterns provide a softer surface without breaking the tensile strength of the pulp.

CNC-Precision Point-to-Point Embossing and Ply Integrity

CNC-precision is the technical standard for high-volume B2B manufacturing. This accuracy ensures that the protrusions from one roller align exactly with those on the second roller, a method known as point-to-point embossing. This alignment is critical for maintaining ply integrity in 3-ply to 5-ply luxury products. By bonding the layers at specific geometric points using high-pressure lamination, we ensure the tissue does not separate during use.

This precision directly impacts the bottom line for wholesalers. By optimizing the physical volume of the roll through geometric modifications rather than just adding more fiber, we achieve consistent roll diameters and weights that maximize 40HQ container payloads. This process allows us to maintain a strict density of 13–22g/m² while providing the “quilted” feel associated with premium brands.

- Absorbency Increase: CNC patterns improve liquid uptake by 30% over standard pressing.

- Ply Bonding: High-pressure lamination prevents layer separation in multi-ply rolls.

- Density Range: Maintained at 13–22g/m² per ply to balance strength and softness.

- Clean Tearing: Precision perforation lines work with the embossed pattern to prevent shredded edges.

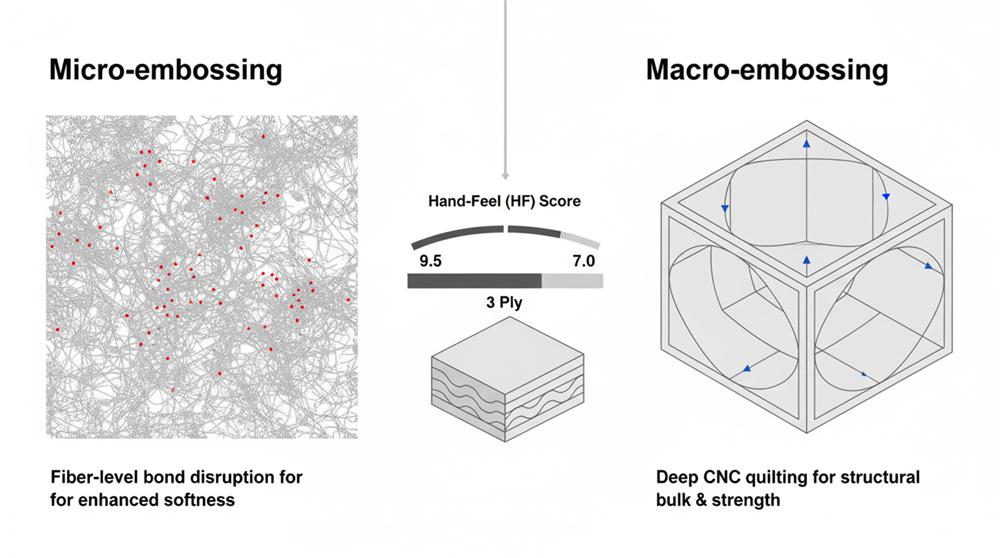

What Are the Functional Differences Between Micro and Macro Embossing?

Micro-embossing breaks fiber stiffness for surface softness, while macro-embossing uses deep CNC patterns to lock multiple plies and increase absorbency by 30% without adding fiber cost.

Tactile Softness Through Fiber-Level Micro-Embossing

We apply micro-embossing as an initial stage in the manufacturing process to address the natural rigidity of 100% virgin wood pulp. This technique uses light, shallow patterns to disrupt the paper structure at the fiber level. By breaking down these bonds, we transform a stiff base sheet into a more pliable, skin-friendly material.

This fiber-level transformation increases the surface area of individual plies. The result is a consistent, lint-free texture that feels significantly softer to the touch. For premium products like our TSH-4010 luxury rolls, this stage is critical to ensure the 5-ply structure remains flexible rather than dense and abrasive.

CNC Point-to-Point Embossing for Structural Bulk and Absorbency

Macro-embossing serves a mechanical role by modifying the three-dimensional geometry of the entire multi-ply stack. We use CNC-precision rollers to create deep indentations that provide the “quilted” look and feel associated with high-end tissue. Unlike micro-embossing, this process works across all layers simultaneously to ensure structural integrity.

- Absorbency Optimization: These deep patterns create pockets that increase total liquid absorption capacity by 30%.

- Ply-Bonding Integrity: Our point-to-point (PTP) technology uses high-pressure lamination to lock up to 5 plies together, preventing layer separation during use.

- Frictionless Bulk: The process traps air between the layers, increasing roll diameter and hand-feel without requiring additional pulp fiber.

This mechanical bulk is essential for high-yield models like the TSH-3396. It allows us to maintain a thick, premium profile while optimizing the weight-to-volume ratio in a 40HQ container. By combining micro-softness with macro-strength, we deliver a roll that remains durable in high-traffic commercial environments and gentle enough for residential retail.

Premium OEM Customization For Global Brands

Why Are Nested Lamination Techniques Superior for Multi-Ply Integrity?

Nested lamination interlocks embossed patterns to stabilize multi-ply structures. This mechanical bond ensures 3-ply and 5-ply tissues remain intact without using heavy chemical adhesives.

Structural Benefits of Interlocking Ply Geometry

Standard tissue production often struggles with ply separation, especially in high-density 4-ply or 5-ply rolls. Nested lamination addresses this by using a point-to-valley alignment. Instead of layers sitting loosely on top of each other, the embossed peaks of one ply fit precisely into the recesses of the adjacent layer. This creates a physical lock that prevents the “sliding” effect common in low-quality multi-ply products.

- Mechanical Locking: Aligns embossed peaks into valleys to secure the structure without stiffening the paper.

- Edge Precision: Reduces “shredded edges” by optimizing the ply-stacking sequence during the high-speed rewinding phase.

- Bulk Retention: Creates internal air pockets between layers, maintaining a cloud-like softness while increasing total roll diameter.

- Layer Stability: Prevents ply separation in premium models like the TSH-4010 luxury hospitality rolls.

High-Pressure Lamination for Adhesive-Free Bonding

We use CNC-precision high-pressure lamination to bond layers together. This technology focuses on mechanical fiber entanglement rather than chemical glues. By applying targeted pressure at the embossing points, the 100% virgin wood pulp fibers interweave, creating a durable bond that holds up even when wet. This is particularly vital for maintaining the 13–22g/m² density standards required for international markets.

- Chemical-Free Safety: Eliminates the need for 100% glue reliance, ensuring the final product remains OBA-Free and safe for sensitive skin.

- Wet-Strength Durability: Maintains structural integrity when exposed to moisture, preventing the tissue from pilling or falling apart during use.

- Enhanced Absorbency: Integrates point-to-point embossing logic within the nested structure to increase liquid capacity by 30%.

- Precision Specs: Calibrated for 100% virgin wood pulp to ensure the long fibers provide maximum tensile strength under pressure.

Can We Increase Paper Bulk (The ROI of Air) Without Adding Fiber Cost?

Manufacturers increase paper thickness by trapping air within the fiber matrix using high-lignin pulp and precision embossing, reducing raw material costs while maintaining high-end product volume.

| Pulp Type | Bulk Efficiency | Structural Behavior |

|---|---|---|

| High-Yield Pulp | Highest | Retains lignin; fibers remain stiff and resist collapse. |

| Kraft Pulp | Moderate | Standard fibers with moderate densification. |

| Recycled Pulp | Lowest | Short, broken fibers that pack tightly and lose volume. |

The Physics of Bulk and Fiber Porosity

Paper bulk measures the ratio of sheet thickness to basis weight. In B2B manufacturing, high bulk is “the ROI of air” because it allows a roll to look and feel substantial without consuming extra wood pulp. We achieve this by manipulating the internal pore structure of the paper web during the wet-end and pressing stages.

- Fiber Resilience: Moderate beating operations preserve the natural curl and “spring” of the fibers, preventing the sheet from densifying into a thin, hard layer.

- High-Yield Selection: Using high-yield pulp keeps lignin and hemicellulose intact. These components act as structural reinforcements that keep fibers from collapsing.

- Chemical Debonders: We apply quaternary ammonium salts as surfactants. These agents reduce internal bonding to increase the microscopic air space between fibers.

Leveraging Point-to-Point Embossing and GSM Calibration

Mechanical modification is the final step in bulk optimization. By using specific pattern geometries, we change the three-dimensional architecture of the tissue. This process ensures a 3-ply roll has the physical presence of a 4-ply product while maintaining the light weight necessary for cost-effective logistics.

- Point-to-Point (PTP) Patterns: This CNC-precision technique aligns protrusions to trap air between plies, increasing physical volume and absorbency by 30%.

- GSM Calibration: We maintain a strict ply density of 13–22g/m². This range provides the ideal structural integrity to hold embossed peaks without crushing under the weight of the roll.

- High-Pressure Lamination: Multi-ply sheets are secured using ply-bonding technology. This keeps the quilted texture locked in place without adding fiber mass or heavy adhesives.

- Material Strength: We exclusively use 100% Virgin Wood Pulp. Long-fiber pulp provides the high tensile strength needed to maintain a high-porosity, low-density structure without tearing on high-speed lines.

How Does Custom Logo Embossing Serve as a Brand Security Feature?

Custom embossing creates a 3D tactile barrier. Using CNC patterns prevents counterfeiting and ensures end-users receive authentic, high-purity virgin wood pulp products from Top Source Hygiene.

Tactile Authentication and the Physics of Anti-Counterfeiting

Industrial tissue production involves complex mechanical transformations. When we emboss a logo, we are not simply adding a visual mark; we are fundamentally changing the physical architecture of the paper fibers. This structural change acts as a first line of defense for distributors.

- Industrial Replication Barrier: Raised three-dimensional impressions require specialized industrial embossing machinery, making it impossible for small-scale counterfeiters to duplicate.

- Overt Verification: Hospitality guests and retail customers can verify product authenticity instantly through touch, even in low-light environments.

- Non-Ink Security: The non-color nature of the imprint ensures the logo cannot be reproduced via standard commercial ink printers.

- Structural Signature: Physical depth in the virgin wood pulp fibers makes it easy for quality control teams to identify if a product was substituted with a generic alternative.

Utilizing CNC-Precision Point-to-Point Technology for Brand Integrity

Top Source Hygiene utilizes CNC-precision tooling to ensure brand marks remain consistent across massive production runs. This technology maintains the visual integrity of the logo while reinforcing the mechanical bond between the paper plies.

- CNC-Engraved Precision: We create high-definition patterns tailored to specific private label requirements, ensuring sharp edges and clear branding.

- Point-to-Point Lamination: This technology bonds multi-ply sheets by embedding the security logo deep into the 100% virgin wood pulp structure.

- Profit Protection: Exclusive custom designs prevent market competitors from selling identical-looking generic stock, strictly protecting dealer margins.

- Logistics Durability: High-pressure lamination ensures the security mark remains visible even after high-density mechanical compression for 40HQ container logistics.

To What Extent Does Embossing Depth Affect Roll Tightness and Logistics?

Embossing creates bulk by trapping air, increasing roll diameter without adding weight. We use mechanical compression during bagging to maintain high-payload shipping volumes in 40HQ containers.

The Trade-off Between Structural Bulk and Winding Density

Deep embossing patterns modify tissue geometry by creating raised and depressed designs. This physical engraving increases sheet thickness through air pocket creation in the nip region, which often increases paper bulk by 30% compared to non-embossed material. While this improves the hand-feel, it significantly alters how the paper behaves on the rewinding line.

- Dimensional Footprint: Increased bulk leads to larger roll diameters. If winding tension is not perfectly calibrated, this reduces the number of rolls that fit into a standard retail pack.

- Pattern Preservation: Precise tension control is required to ensure deep-embossed 100% virgin wood pulp sheets do not lose their texture under high winding pressure.

- Vibration Control: Matching material thickness to pattern depth prevents log vibration, allowing our production lines to maintain speeds up to 600 m/min without sacrificing roll tightness.

Optimizing 40HQ Container Payloads via Mechanical Compression

Managing logistics for high-bulk products requires specific factory technology to avoid “shipping air.” For our wholesale partners, landed cost depends entirely on maximizing the 40HQ container payload. We solve the bulk-vs-density conflict through two primary manufacturing stages.

- Point-to-Point Technology: Our CNC-precision rollers bond plies securely. This high-pressure lamination ensures layers do not separate when the rolls are subjected to heavy stacking pressure.

- Bagging Compression: Mechanical systems compress the rolls during the bagging phase. This reduces total volume for transport while allowing the long-fiber virgin pulp to recover its fluffiness after the end-user opens the pack.

- Payload Efficiency: Our Hebei loading teams maximize container space to reach payloads of 7,000kg to 9,000kg, even with premium, high-bulk 5-ply models like the TSH-4010.

- Secondary Packaging: We utilize reinforced 5-ply export cartons to protect the structural integrity of deep-embossed rolls during high-density stacking.

Frequently Asked Questions

How does deeper embossing affect toilet paper strength and softness?

Deep embossing patterns increase surface area to boost absorbency and improve tactile softness, but they often reduce mechanical tensile strength. We solve this by using 100% virgin wood pulp, which provides the long-fiber integrity required to withstand high-pressure patterns. By 2026, professional manufacturers will rely on precise pressure settings to ensure sheets remain durable while feeling significantly thicker than flat alternatives.

What is the difference between Point-to-Point (PTP) and nested embossing?

Point-to-Point (PTP) embossing aligns protrusions directly against each other, which maximizes ply-bonding and can increase liquid absorption by 30%. Nested embossing fits protrusions into the valleys of the opposing ply to create a softer, cushioned feel. High-volume factories typically prefer nested embossing because it handles high-speed production with fewer mechanical failures while maintaining a professional interlocked pattern.

How can manufacturers prevent custom embossing patterns from shredding the fiber?

Preventing fiber damage requires 100% virgin wood pulp and CNC-engraved brass dies that maintain precise, clean edges. Shredding usually happens when machines exceed the material’s elastic limit, causing micro-fractures. We implement a strict reconditioning schedule for rollers every six to twelve months and use infrared sensors to ensure pressure and temperature remain consistent across the web.

Does high-precision embossing reduce the total amount of pulp required?

Precision embossing does not change the fiber mass per roll, but it drastically improves production efficiency. Advanced systems reduce material waste during product changeovers from 100 meters to less than 5 meters. This ensures that more of the raw material reaches the final 40HQ container as a sellable product instead of ending up in the scrap bin.

How do embossing patterns influence performance in high-speed dispensing systems?

Embossed textures improve surface grip and structural handling of the paper. This allows for controlled, single-sheet dispensing in commercial environments like malls and offices. The added texture helps the paper unroll smoothly at high speeds without slipping or jamming, which is essential for high-capacity Jumbo Roll Tissue (JRT) systems.

Final Thoughts

Relying on low-density recycled fibers leads to ply separation and flattened rolls that damage your brand’s credibility. Our CNC point-to-point embossing and 100% Virgin Wood Pulp ensure a 30% increase in absorbency while maintaining the structural bulk premium markets demand. Investing in engineered performance like the TSH-4010 series protects your margins by delivering consistent, high-wet-strength quality across every 40HQ container.

Stop guessing about roll diameter and verify our 13–22g/m² density standards firsthand. We recommend requesting a physical sample kit to test our mechanical ply-bonding and tactile softness against your current supplier. Contact our Hebei-based production team today to discuss your private label requirements or to lock in your next shipment schedule.

SEO

Title: Surface Engineering: How Embossing Redefines Fiber Performance and Bulk

Description: Toilet paper embossing for 100% virgin wood pulp. Hebei factory direct source. 13-22g/m² density. B2B wholesale and OEM supply only.

URL: toilet-paper-embossing

Keywords: Toilet Paper Embossing