Moisture content math determines whether a 40HQ shipment arrives as premium inventory or a mold-prone liability. Inaccurate water weight calculations during maritime transit from Hebei lead to container rain, causing structural collapse and direct financial loss for logistics directors.

This analysis examines how 100% Virgin Wood Pulp and 13–22 GSM density standards stabilize bulk quality. We evaluate how mechanical compression and reinforced 5-ply export cartons maintain fiber integrity, helping you secure a predictable 7,000kg to 9,000kg payload every time.

How Does Paper Hygroscopy Affect Bulk Sourcing?

Paper fibers absorb moisture, causing weight shifts and structural degradation. We mitigate this using 100% virgin pulp and mechanical compression to stabilize bulk quality and shipping costs.

Moisture Equilibrium and Its Impact on Bulk Paper Weight

Paper is a living material in a logistics sense. Wood pulp fibers naturally seek equilibrium with the surrounding air. When shipping from our Hebei manufacturing hub through humid maritime routes, rolls can absorb water vapor, leading to “container rain” or condensation inside 40HQ containers. This physical shift changes the weight of the shipment before it reaches its destination.

Weight fluctuations directly influence the landed cost per roll. Since we maximize 40HQ payloads between 7,000kg and 9,000kg, even a small percentage increase in moisture content can alter the total tonnage. Beyond weight, hygroscopic swelling affects the physical dimensions of the product.

- Fiber Swelling: Absorbed moisture expands individual fibers, which can increase roll diameter and cause tight-packed bundles to warp.

- Perforation Alignment: Moisture-induced expansion can shift precision perforation lines, leading to “shredded edges” when the end-user tries to tear a sheet.

- Weight Variations: Moving goods from high-humidity coastal ports to dry inland warehouses in 2026 climate zones causes the paper to release moisture, potentially making rolls feel “lighter” than the factory manifest.

Fiber Integrity and 13–22 GSM Density Standards

We manage hygroscopic risks by controlling the material density and the fiber source. 100% Virgin Wood Pulp uses long fibers that provide higher tensile strength compared to recycled alternatives. Long fibers create a more stable matrix that resists the softening effect of water molecules, ensuring the paper doesn’t become brittle or lose its “cloud-like” softness during transit.

Density control is the primary technical defense against atmospheric changes. By strictly adhering to a 13–22g/m² GSM standard per ply, we ensure the paper has enough structural mass to maintain its quilted texture even when relative humidity fluctuates. This prevents the “pilling” or linting that often occurs in lower-grade bulk paper exposed to moisture.

- Material Selection: We exclusively use 100% Virgin Wood Pulp to maintain long-fiber strength and OBA-free safety.

- GSM Stability: Maintaining 13–22g/m² prevents the paper from losing its structural “snap” in humid environments.

- Mechanical Compression: Our bagging process uses high-pressure technology to eliminate air pockets. Reducing the air volume inside the packaging limits the surface area of the paper exposed to ambient humidity.

- Secondary Protection: We use reinforced 5-ply export cartons or heavy-duty poly bundles to act as a secondary vapor barrier for 40HQ shipments.

Why is 5%-8% the Optimal Moisture Range for Storage?

A 5%-8% moisture range stops microbial growth while preventing fiber brittleness. This ensures organic materials remain flexible and structurally sound for long-term bulk storage and transport.

The Balance Between Microbial Stability and Structural Integrity

Bulk inventory requires precise environmental control to survive global supply chains. Deviation from this narrow window triggers immediate physical or biological degradation. High moisture levels act as a catalyst for mold, while excessive dryness ruins the fiber’s natural flexibility.

- Microbial Risk: Moisture levels exceeding 10% accelerate the growth of mold and fungal colonies, leading to permanent fiber damage.

- Desiccation Injury: Materials become brittle and prone to cracking when moisture drops below 5%.

- EMC Factors: Equilibrium Moisture Content (EMC) dictates how materials naturally absorb or release water based on ambient storage temperature.

- Chemical Stability: Maintaining this range minimizes chemical breakdown and insect activity in organic-based bulk goods.

Preserving Tensile Strength in 100% Virgin Wood Pulp

For Top Source Hygiene products, moisture control directly impacts performance. We use premium long-fiber wood pulp that depends on specific hydration levels to maintain its “cloud-like” softness and high-wet-strength durability. Incorrect moisture levels during 40HQ container transport can compromise an entire shipment’s quality.

- Fiber Retention: Optimal moisture ensures 100% Virgin Wood Pulp fibers retain their long-fiber tensile strength for a lint-free experience.

- Ply-Bonding Integrity: Excess moisture compromises ply-bonding technology, causing layers to separate in high-density 3-ply and 5-ply rolls.

- Embossing Protection: The 5%-8% window protects point-to-point embossing patterns from flattening during long-term high-stacking in 40HQ containers.

- Density Performance: Proper moisture levels ensure the 13–22g/m² ply density maintains durability without premature disintegration.

Leading OEM/ODM Toilet Paper Customization Partner

How Does High Moisture Degrade Tensile Strength?

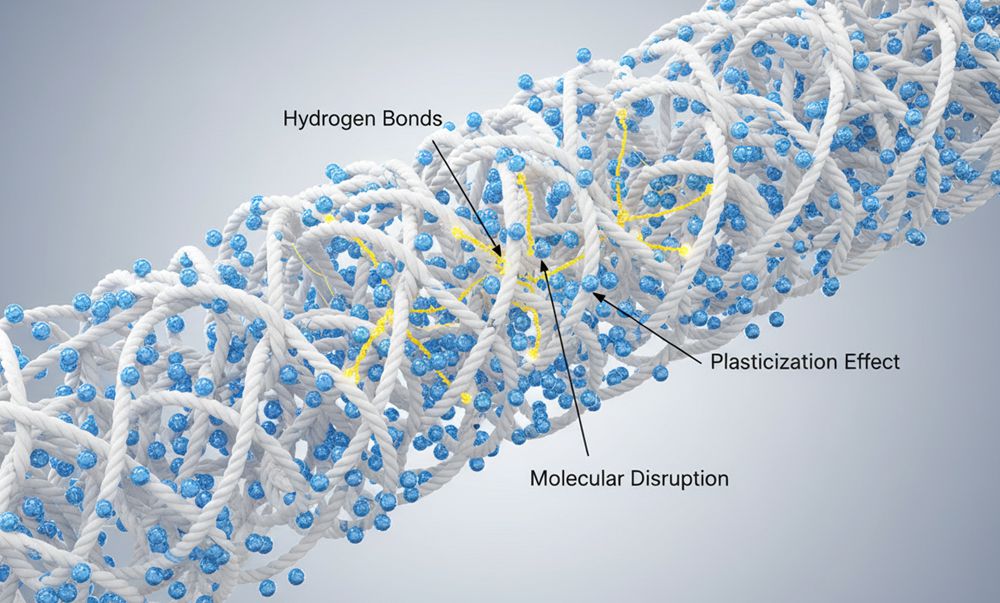

Water displaces hydrogen bonds between fibers, causing swelling and debonding. This plasticization effect reduces paper stiffness and can slash overall tensile strength by up to 15%.

Molecular Disruption of Hydrogen Bonding

The structural integrity of paper depends on the microscopic network of hydrogen bonds connecting cellulose fibers. When humidity rises, water molecules penetrate this fiber matrix and physically push these connections apart to form new, weaker bonds with the cellulose itself.

- Fiber Displacement: Absorbed water molecules displace original inter-fiber links, effectively lubricating the matrix and allowing fibers to slide.

- Plasticization: This effect makes the paper more ductile and stretchy, but it destroys the material’s stiffness and load-bearing capacity.

- Humidity Thresholds: Tensile strength typically remains stable until relative humidity exceeds 65%, at which point the structural drop-off becomes sharp and non-linear.

Strength Retention via 100% Virgin Wood Pulp

Top Source Hygiene manages these moisture risks by using specific material grades and manufacturing pressures. We focus on fiber density and mechanical bonding to ensure rolls maintain their shape and strength during long-distance sea freight and warehouse storage.

- Material Selection: We exclusively use long-fiber 100% Virgin Wood Pulp to create a dense, resilient network that naturally resists fiber debonding.

- High-Pressure Ply-Bonding: Our multi-ply sheets undergo high-pressure lamination, which secures the layers against separation even in fluctuating ambient humidity.

- Density Standards: We strictly control ply density between 13–22g/m² to provide a structural buffer that keeps the paper stiff during transit through humid climate zones.

How to Manage Moisture Risks During Sea Freight?

Sea transit creates “container rain” that destroys bulk paper. We mitigate this using calcium chloride desiccants to keep humidity below 40% and reinforced 5-ply export cartons for protection.

| Moisture Risk Factor | Impact on Paper Integrity | TSH Protection Standard |

|---|---|---|

| Relative Humidity >60% | Accelerates mold growth and fiber softening. | Calcium Chloride desiccants (300% absorption). |

| Container Rain | Liquid droplets cause spotting and core collapse. | Secondary poly-bundle moisture barriers. |

| High-Stack Pressure | Damp cartons lose 30% of tensile strength. | Reinforced 5-ply export-grade cartons. |

Mechanisms of Container Rain and Humidity Fluctuations

Container breathing occurs as ships move between varying climate zones. During daily temperature cycles, the air pressure inside the 40HQ container shifts, pulling moisture-laden air into the cargo space. When the temperature drops at night, this moisture condenses on the cold steel ceiling and “rains” down on the cargo.

Paper is highly hygroscopic. It acts like a sponge, pulling water from the air until it reaches equilibrium. If relative humidity exceeds 60%, mold growth becomes a certainty. Even before mold appears, moisture acts as a plasticizer, weakening the hydrogen bonds between fibers. This leads to reduced tensile strength and rolls that feel “mushy” or lose their embossing definition.

- Humidity Threshold: We target levels below 40% to prevent surface degradation.

- Absorption Power: Our calcium chloride desiccants absorb over 300% of their weight, far exceeding standard silica gel.

- Dew-point Control: These agents continuously adjust absorption to keep internal air below the dew-point throughout the voyage.

Secondary Protection and 5-Ply Export Carton Strategies

Primary product packaging alone cannot withstand a 30-day sea voyage. We implement a multi-layered defense strategy at our Hebei manufacturing hub to ensure rolls arrive in showroom condition. This starts with the physical structure of the shipping unit.

Standard cartons fail in high-humidity sea environments. We use reinforced 5-ply export cartons that maintain structural integrity even when atmospheric moisture levels fluctuate. These cartons provide the necessary compression strength to support high-stacking in 40HQ containers without crushing the bottom layers.

- Moisture-Resistant Wrapping: Secondary poly bundle wrapping acts as a “second skin” if condensation breaches the outer carton.

- Mechanical Compression: We use high-pressure bagging to minimize air pockets where moisture could accumulate inside the packaging.

- Loading Precision: Our Hebei teams maximize 40HQ payloads (7-9 tons) to reduce dead air space, further limiting the volume of air that can carry moisture.

By controlling the micro-environment inside the container and utilizing high-barrier secondary materials, we eliminate the risk of mold and structural degradation. This ensures that the 100% virgin wood pulp maintains its premium softness and tensile strength from our factory to your warehouse.

Why Should Factories Use Real-Time Online Moisture Sensors?

Online sensors provide instant data to automate dryer settings, slashing energy costs while preserving fiber strength and batch consistency in 100% virgin pulp production.

Instant Feedback and Continuous Process Monitoring

Manual testing creates massive blind spots in high-speed converting lines. A ten-minute delay for lab results often leads to entire batches of non-conforming product. Real-time sensors provide instant feedback, allowing operators to catch moisture spikes before they ruin the run.

- PLC Automation: Sensors integrate with programmable logic controllers to adjust dryer temperatures in real time without human intervention.

- Energy Efficiency: Precise monitoring reduces fuel consumption by ensuring ovens only run at the exact temperature required for each specific batch.

- Waste Reduction: Plug-and-play systems identify irregularities instantly, reducing product loss and minimizing downtime during grade changes.

- Data Density: These systems perform thousands of measurements per second, replacing slow organoleptic testing with hard technical data.

Maintaining Fiber Performance for 100% Virgin Wood Pulp

Top Source Hygiene relies on long-fiber virgin wood pulp to maintain the tensile strength required for premium 2-ply and 3-ply rolls. Moisture control is the primary factor in ensuring these fibers do not become brittle or lose their bonding capacity during the high-heat drying phase.

- Tensile Strength: Proper moisture levels protect the long-fiber structure, ensuring our paper meets the durability standards required by global wholesalers.

- Density Control: We stabilize ply density between 13–22g/m², preventing excess water weight from skewing shipping costs or causing structural weakness.

- Natural Aesthetics: Maintaining specific moisture levels preserves the 85-92% natural brightness of the wood pulp without needing OBA whiteners.

- Septic Safety: Correct water content during the point-to-point embossing process ensures rapid disintegration while maintaining the crisp definition of the quilted pattern.

By stabilizing these parameters, the factory ensures that every 40HQ container sent from our Hebei hub meets the exact specifications promised to B2B distributors. Real-time sensors take the guesswork out of consistency, protecting both the product integrity and the importer’s profit margins.

How to Prevent Financial Loss from Mold Damage?

Stop mold losses by combining real-time humidity sensors with 5-ply reinforced cartons. Proactive monitoring avoids $6,000 remediation fees and preserves stock integrity during global shipping.

Implementing Real-Time Humidity Monitoring and Inspection Protocols

Moisture control determines the shelf life of paper products. Relying on manual checks is a risk we don’t take. By 2026, standardizing digital oversight will be the only way to safeguard large-scale inventory from invisible dampness.

- Leak Detection: Use infrared cameras and leak detection systems to find hidden moisture in warehouse attics and crawl spaces before it spreads.

- Environment Control: Maintain humidity between 35% and 55% using industrial dehumidifiers to keep 100% virgin wood pulp fibers from absorbing ambient water.

- Compliance Logs: Document all inspection records and repair logs to support insurance claims and verify property value during audits.

- Immediate Remediation: Fix plumbing and roof leaks the moment they appear to avoid structural damage and the high cost of material replacement.

Utilizing 5-Ply Reinforced Export Cartons and Moisture-Resistant Packaging

Packaging acts as your final defense during the rigorous 40HQ container transit process. We focus on high-density materials that shield the product from the “container rain” effect common in global shipping routes.

- Reinforced Cartons: Use 5-ply reinforced export cartons to prevent crushing and moisture ingress when stacking heavy bundles in shipping containers.

- Vapor Barriers: Apply secondary poly bundle protection for individual rolls to maintain the integrity of premium wood pulp fibers against high-humidity sea air.

- Mechanical Compression: Use factory-grade compression technology during bagging to eliminate air pockets that harbor dampness and encourage mold growth.

- Quality Assurance: Verify batch color consistency and fiber performance before every shipment to ensure the stock meets 100% OBA-free purity standards.

Frequently Asked Questions

What is the ideal moisture content for bulk toilet paper during storage?

Maintain moisture levels between 2% and 7%. For our 100% Virgin Wood Pulp rolls, the optimal range is 4% to 7%. Keep your storage environment’s relative humidity between 35% and 55% to stop fiber degradation and mold growth before the product reaches the distributor.

How does high humidity impact the tensile strength of paper rolls?

Humidity levels above 70% weaken the fiber-to-fiber bonding essential for tissue integrity. If the moisture content in the paper hits 14%, tensile strength typically drops by 50%. This causes the paper to lose its load-bearing capacity, leading to easy tearing and “shredded edges” during use.

Why do some rolls feel heavier even with a lower sheet count?

Weight depends on basis weight (GSM) and paper density, not just sheet count. Premium models like the TSH-4010 use higher-caliper 100% Virgin Wood Pulp, which feels sturdier and heavier in the hand. Retailers often find that these denser 5-ply rolls outperform lightweight rolls with high sheet counts in luxury hospitality settings.

What logistics strategies prevent mold growth during 2026 sea freight shipments?

We use moisture-resistant container liners, silica gel desiccants, and plastic slip sheets instead of wooden pallets. This eliminates organic moisture sources and blocks vapor transfer. Our Hebei loading teams focus on 40HQ payload optimization to ensure products stay dry and stable throughout long-distance transit from Tianjin port.

How do factories monitor moisture levels on the production line?

Our facility uses real-time microwave sensors directly on the converting lines. These sensors penetrate multiple plies with an accuracy of ±0.05%. This allows our operators to adjust dryer settings instantly if moisture exceeds the 8% threshold, ensuring consistent batch quality for B2B orders.

Does excess moisture affect the quality of embossed patterns?

Yes. Moisture softens the paper structure and triggers fiber recovery from mechanical deformation. This causes the pattern definition to fade and reduces roll volume. Maintaining dry conditions is vital to preserving our 30% absorbency-boosting point-to-point embossing, which otherwise appears flat and less premium.

SEO

Title: The Equilibrium of Moisture: Managing Water Content for Shelf Life

Description: Toilet Paper Moisture Content standards. 100% Virgin Wood Pulp specs for bulk buyers. Hebei factory wholesale. 40HQ container loads.

URL: toilet-paper-moisture-content

Keywords: Toilet Paper Moisture Content