TEA & Energy Absorption metrics determine if your paper inventory survives high-speed commercial dispensers or snaps under sudden tension. For maintenance managers, low-TEA paper leads to frequent roll snap-offs, increasing labor costs and tenant dissatisfaction in high-traffic environments. Ignoring these mechanical properties risks high replacement rates and inventory waste across jumbo roll distribution chains.

Our Hebei facility engineers 100% Virgin Wood Pulp rolls with 13–22g/m² ply density to maximize work-to-break capacity. By auditing ply-bonding and creping ratios, we ensure models like the TSH-JRT08 handle the kinetic stress of automated motors, providing a resilient solution for 40HQ bulk wholesale orders.

Why Is Tensile Energy Absorption (TEA) More Critical Than Tensile Strength?

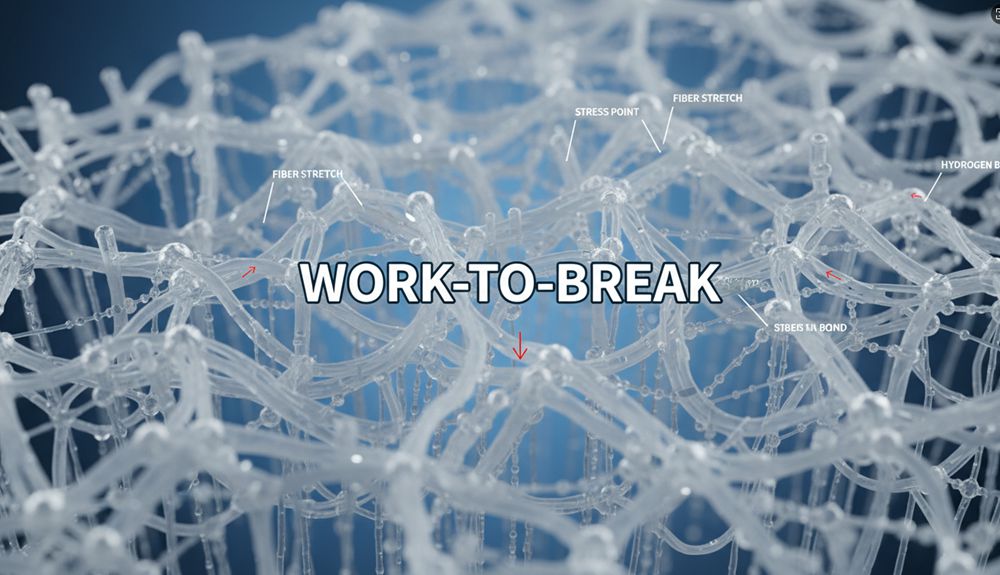

TEA measures the total energy a sheet absorbs before breaking. While tensile strength marks the peak limit, TEA determines if the paper survives sudden tugs without snapping.

Distinguishing Peak Load Capacity from Work-to-Break Energy

Tensile strength is a static measurement that identifies the maximum force a material handles at the exact moment of failure. While useful for slow-pull scenarios, it fails to account for the dynamic stress common in professional environments. TEA provides a more realistic performance metric by calculating the cumulative work performed on the paper throughout its entire elongation phase.

- Energy Dissipation: High TEA prevents brittle failure by allowing fibers to deform and absorb energy rather than snapping immediately when they hit peak force.

- Dynamic Loading: Industrial dispensers in 2026 subject paper to repetitive stress cycles and sudden impact forces that static strength tests cannot predict.

- Toughness vs. Strength: A sheet with moderate strength but high TEA is often more durable than a high-strength, brittle sheet that lacks flexibility.

Long-Fiber Virgin Wood Pulp and Multi-Ply Bonding Resilience

We engineer Top Source Hygiene products to maximize energy absorption through specific material selection and fiber architecture. By focusing on the structural integrity of the fiber network, we ensure our toilet rolls maintain their shape and function under the high-tension requirements of high-capacity commercial dispensers.

- 100% Virgin Wood Pulp: Our Hebei facility utilizes long-fiber wood pulp to maximize the network’s ability to stretch, which directly increases the TEA score compared to short-fiber recycled alternatives.

- Ply-Bonding Technology: High-pressure lamination ensures that multi-ply layers move in unison, allowing the total energy absorption to distribute across all layers.

- 3D Fiber Movement: Precision embossing at 13–22g/m² density creates micro-textures that allow for three-dimensional fiber movement, providing a mechanical “cushion” during consumer handling.

How Does Fiber Physics Dictate the Energy Absorption Capacity of Paper?

Fiber physics dictates resilience through the interaction of fiber stiffness and bonding. High TEA results from long cellulose fibers distributing stress, enabling elongation instead of sudden fracture.

Mechanisms of Fiber Network Deformation and Stress Distribution

The total energy absorption capacity of a paper sheet correlates to the area under the stress-strain curve until the point of fracture. In a paper matrix, the network architecture and specific fiber orientation dictate how the material manages interlaminar shear during loading. If the fibers are poorly aligned or too short, the material snaps because it cannot redistribute the force.

Hydrogen bonding between cellulose fibers enables collective deformation. This allows the paper to dissipate energy throughout the entire network instead of experiencing a localized failure. Fiber length and aspect ratios are the primary drivers here, as they determine the number of bonding sites available for efficient stress transfer across the sheet.

Leveraging Long-Fiber Virgin Pulp and Ply-Bonding for Resilience

Top Source Hygiene applies these physical principles by selecting specific raw materials and manufacturing standards that favor energy dissipation. We focus on maintaining fiber integrity to prevent roll snap-offs in high-speed commercial environments.

- Fiber Selection: We utilize 100% virgin wood pulp with a high long-fiber content to maximize the strain-to-failure ratio.

- Ply-Bonding Technology: High-pressure lamination ensures multi-ply sheets act as a single energy-absorbing unit rather than sliding layers.

- GSM Precision: We strictly control weight between 13–22g/m² per ply to ensure fiber density is sufficient for high wet-strength durability.

- Embossing Patterns: Point-to-point embossing increases the surface area and bulk, which improves the paper’s ability to stretch and absorb mechanical energy during dispensing.

By controlling the density and the bonding process, we produce a sheet that stretches under tension. This mechanical stretch is vital for B2B wholesalers serving high-traffic hospitality or industrial clients where dispenser reliability is a non-negotiable requirement.

Build Your Brand With Premium Custom Tissue

Can High TEA Scores Effectively Prevent Roll Snap-offs in High-Speed Dispensers?

High TEA scores prevent snap-offs by absorbing sudden kinetic energy through combined tensile strength and fiber elongation, ensuring reliability in high-speed commercial automated dispensers.

| Metric | Measurement Focus | Dispenser Performance Impact |

|---|---|---|

| Tensile Strength | Peak load capacity | Resists breaking under a slow, steady pull. |

| TEA Score | Total work absorbed (J/m²) | Absorbs the kinetic “jerk” of automated motors. |

| Elongation | Stretch percentage | Provides the buffer to prevent fiber fracture. |

Mechanics of Kinetic Energy and Paper Web Resilience

High-speed dispensers do not apply force gently. They create instantaneous tension spikes that frequently exceed the static load thresholds of standard toilet paper. While tensile strength measures the peak load at failure, Tensile Energy Absorption (TEA) calculates the “work-to-break.” This represents the total energy the paper manages before the fiber matrix fractures.

Paper elongation acts as the primary defense against these mechanical shocks. When an automated system yanks the sheet, the paper must stretch to dissipate energy. Brittle paper with high strength but low TEA snaps immediately because it cannot deform. In high-capacity jumbo roll dispensers like the TSH-JRT08, inertial resistance from the heavy roll creates massive back-tension. Only a high TEA web survives these high-velocity pulls without a catastrophic snap-off.

Optimizing TEA Through Long-Fiber Pulp and Ply-Bonding

Manufacturing rolls for industrial environments requires specific fiber physics. We utilize 100% Virgin Wood Pulp from our Hebei facility because its high-purity long fibers provide the interlocking matrix necessary for elasticity. Short fibers found in recycled alternatives often lack the bond strength to handle rapid acceleration without shredding.

- Fiber Integrity: Long-fiber pulp increases fiber slippage capacity, allowing the sheet to absorb energy rather than resisting it until failure.

- Ply-Bonding: We implement high-pressure lamination to ensure multi-ply sheets stay together during rapid unwinding, preventing layer separation.

- Ply Density: Maintaining a density of 13–22g/m² per ply balances material thickness with the flexibility required for high TEA scores.

- Precision Perforation: CNC-calibrated perforation ensures sheets separate cleanly at the intended point, preventing a full web snap-off during the tear cycle.

By 2026, industry standards for high-traffic environments will focus almost exclusively on TEA metrics. Our production process prioritizes this energy absorption to ensure that high-density models, such as the TSH-3082, perform reliably in the most demanding commercial automated systems.

To What Extent Do Creping and Lamination Processes Impact Your TEA Scores?

Creping generates internal stretch through fiber de-densification, while precision lamination secures ply integrity, allowing industrial paper to absorb kinetic energy without snapping under high-speed tension.

Fiber Bond Disruption and Internal Stretch Generation

Creping fundamentally dictates how a tissue sheet handles stress. At our Hebei production facility, we treat creping as a mechanical “explosion” of the fiber matrix. This process breaks the rigid hydrogen bonds in the 100% Virgin Wood Pulp, transforming a flat sheet into a three-dimensional structure capable of significant elongation.

- De-densification: High-energy creping expands tightly packed fiber layers, creating the void spaces necessary for elastic deformation.

- Fiber Slippage: Controlled mechanical disruption allows individual fibers to slide rather than snap, preventing catastrophic failure during rapid unwinding.

- Internal Stretch: This metric serves as the most accurate predictor of bulk-to-basis weight efficiency, ensuring the paper remains resilient without unnecessary fiber density.

- Moisture Control: We maintain strict moisture levels at the creping blade to optimize adhesive tack, ensuring the energy distribution remains uniform across the entire roll.

Ply-Bonding Technology and Structural Energy Dissipation

While creping handles the internal mechanics, lamination provides the structural integrity required for multi-ply products. For distributors sourcing 3-ply or 5-ply rolls, the quality of the ply-bond directly affects the total energy absorption (TEA) score and prevents the roll from delaminating in automatic dispensers.

- High-Pressure Lamination: This technique secures multiple sheets into a single unit, ensuring they act as a composite material that dissipates energy collectively.

- CNC Point-to-Point Embossing: Our precision patterns increase surface area and create air pockets, which historically improves total absorbency and energy capacity by 30%.

- GSM Precision: We maintain a strict range of 13–22g/m² per ply to strike the balance between a soft “hand-feel” and the high-wet-strength durability required for commercial environments.

- Uniform Adhesion: Precision adhesive application eliminates localized weak spots, which are the primary cause of “roll snap-offs” in high-speed industrial dispensers.

By mastering both the micro-folds of the crepe and the structural bond of the laminate, Top Source Hygiene produces tissue that exceeds standard TEA requirements. This dual-layered mechanical approach ensures that even our highest-ply products remain flexible enough to withstand the dynamic forces of modern dispensing systems.

How Do We Precisely Measure TEA Under ISO 1924-3 Laboratory Standards?

ISO 1924-3 measures energy absorption by integrating the force-elongation curve at 100 mm/min. This ensures our 100% virgin pulp products meet global durability standards for B2B distribution.

ISO 1924-3 Methodology and Force-Elongation Integration

ISO 1924-3 dictates a specific protocol to simulate real-world stress on paper products. Unlike older methods, this standard uses an accelerated elongation rate to capture how the fiber network reacts to sudden tension, providing a more accurate durability profile for high-speed dispensing.

- Elongation Rate: 100 mm/min ± 10 mm/min to mimic dynamic stress scenarios.

- Test Span: A precise 100 mm distance between clamping lines ensures uniform tension.

- Calculation: Mean area under the force-elongation curve (millijoules) divided by the initial width and length.

- Directional Data: Laboratories report Machine Direction (MD) and Cross Direction (CD) separately to calculate the geometric mean.

We use the geometric mean of MD and CD to ensure the finished roll performs consistently. This mathematical integration tells us the total work the paper performs before failure, which is a far more reliable indicator of quality than peak tensile strength alone.

Quality Control for 100% Virgin Wood Pulp Fiber Integrity

At Top Source Hygiene, our Hebei manufacturing hub links these laboratory metrics directly to material selection. High TEA scores are not accidental; they result from using long-fiber virgin pulp that allows the paper to stretch and absorb energy rather than snapping under pressure.

- Material: 100% long-fiber virgin wood pulp to maximize the stress-strain curve area.

- Ply Density: Strictly maintained between 13–22g/m² to balance softness with high-wet-strength durability.

- Verification: In-house testing verifies batch tensile consistency before 40HQ container loading.

- Compliance: Production protocols meet ISO 9001 and EU hygiene standards through rigorous TEA validation.

By choosing virgin pulp over recycled waste, we ensure a higher energy absorption capacity. This material integrity prevents the “shredding” issues common in lower-grade bulk tissue. Our pre-shipment visual verification process confirms that every batch loaded at Tianjin port meets these specific technical requirements.

Does TEA Optimization Allow for Thinner Yet More Resilient Tissue?

TEA optimization allows for thinner paper by increasing the energy a sheet absorbs before failure. By focusing on 13–22g/m² ply density, we create resilient tissue that stretches instead of snapping.

The Relationship Between Energy Absorption and Material Efficiency

TEA measures the total work required to break a paper strip. It effectively accounts for both the maximum load a sheet can carry and its ability to stretch before it fails. Unlike simple tensile strength, TEA shows how the material behaves under the sudden stress of a dispenser pull.

Optimization focuses on the energy-to-weight ratio. This allows manufacturers to reduce the Grams per Square Meter (GSM) while maintaining structural integrity. By engineering the fiber network to dissipate energy, we produce a thinner product that performs like a much heavier sheet.

- Dynamic Impact: High TEA values ensure thin sheets absorb energy during rapid unwinding rather than snapping under tension.

- Micro-fold Structure: Precision creping techniques enhance the folds within the paper, providing the “give” necessary for resilience in lightweight tissue.

- Structural Integrity: Strategic fiber alignment prevents the “shredding” often associated with low-GSM recycled papers.

Leveraging 100% Virgin Wood Pulp for High-Performance Low-GSM Sheets

Top Source Hygiene utilizes 100% Virgin Wood Pulp. Long fibers create a more interconnected network than recycled alternatives. This long-fiber structure naturally supports higher TEA, which is the foundation for producing ultra-thin 13–22g/m² plies that do not shred during use.

We use high-pressure lamination and ply-bonding technology to combine these thin, high-TEA layers. This creates a resilient 3-ply or 4-ply finished product that feels soft but resists breaking. Using premium fibers eliminates the need for chemical fillers or artificial thickness.

- Material: 100% Virgin Wood Pulp (OBA-Free).

- Ply Density: 13–22g/m² strictly controlled for efficiency.

- Brightness: 85-92% natural brightness achieved without heavy bleaching.

- Performance: High-pressure ply-bonding ensures layers stay together under dynamic load.

This engineering approach allows high-speed dispensers to function without roll snap-offs. By maximizing the energy absorption of each individual fiber bond, we deliver a product that uses less material while providing superior durability for high-traffic environments.

Frequently Asked Questions

What is the core difference between tensile strength and Tensile Energy Absorption (TEA)?

Tensile strength identifies the peak stress a sheet handles at the exact moment of fracture. TEA measures the total energy the paper absorbs during the entire stretching process until it breaks. For high-speed dispensing, TEA is a more accurate predictor of performance because it accounts for the paper’s toughness and ability to dissipate energy under sudden tension.

Why does high-ply toilet paper often snap prematurely in automatic dispensers?

Snapping usually occurs because the dispenser is calibrated for a specific paper tension. Multi-ply rolls often have high thickness but may lack the inter-ply bonding strength to withstand mechanical pulling forces. If the layers separate or the paper lacks sufficient internal stretch, it will fail at the dispenser rollers rather than tearing at the perforation.

How do manufacturers increase TEA without adding extra fiber or weight?

Factories use topology optimization and process parameter tuning during production. By adjusting temperature differentials on the Yankee dryer and optimizing the solution allocation ratios, manufacturers can improve energy absorption by over 25%. This allows the tissue to remain resilient and thin without increasing raw material costs.

Does the creping ratio affect the absorbency and durability of the tissue?

Yes. The creping ratio creates micro-folds that increase the sheet’s bulk by 200% to 350%. This structural transformation disrupts hydrogen bonds, allowing the fibers to expand. This expansion provides the ‘internal stretch’ necessary for the paper to deform and absorb energy without snapping, while simultaneously improving liquid absorbency.

How does moisture content impact the final energy absorption of a paper roll?

Moisture weakens the fiber-to-fiber bonds within the 100% virgin wood pulp. If the paper absorbs environmental humidity, the structural integrity of the lattice decreases, leading to a significant drop in TEA. This makes the paper more prone to ‘shredded edges’ and mechanical failure during use in high-traffic commercial environments.

Final Thoughts

Relying on static tensile strength alone exposes your distribution chain to frequent roll snap-offs and customer complaints. Our 100% virgin wood pulp products prioritize high Tensile Energy Absorption to withstand the sudden kinetic “jerk” of modern automated dispensers. This engineering choice secures your reputation for reliability and prevents the costly waste associated with brittle, low-grade alternatives.

Verify our fiber resilience firsthand by requesting a technical sample kit or a trial 40HQ container of our high-density TSH-3082 industrial rolls. We offer full private label customization and provide pre-shipment visual verification to ensure every batch meets your specific TEA requirements. Contact our Hebei manufacturing team today to optimize your next shipment for maximum payload and performance.