Scent & Fragrance ODM has become the essential differentiator for luxury hygiene brands aiming to capture the 40% mood boost triggered by olfactory cues. Failing to move beyond generic paper creates a missed opportunity in brand loyalty, as facilities using signature scents report a 15% increase in repeat guest visits.

We analyze how core-scenting technology on 100% OBA-Free Virgin Wood Pulp ensures 30% longer aroma retention compared to surface treatments. By examining high-density specs like the TSH-4010 luxury roll, this guide provides the technical roadmap for secure, hypoallergenic scent integration in high-traffic hospitality sectors.

Why Is Scent Becoming the Most Powerful Branding Tool in Modern Restrooms?

Scent triggers emotional memory. Facilities use fragrance to boost guest mood by 40%, signaling high hygiene and transforming restrooms into touchpoints that drive trust and repeat visits.

Psychological Impact of Olfactory Branding on Brand Trust

Scent hits the brain faster than any other sense. It bypasses logical processing and goes straight to the emotional core. When a guest walks into a facility, the smell dictates their perception of the brand before they see the counters. Research shows pleasant ambient scents lift guest mood by 40% and improve luxury service evaluations.

Consistency works as a silent signal for high housekeeping standards. For facility managers, this means more than just masking odors; it creates a specific brand identity. These subconscious cues reduce guest anxiety and build professional trust by proving attention to detail in the most intimate spaces.

- Mood Improvement: 40% increase in guest sentiment following exposure to pleasant scents.

- Customer Loyalty: 10-15% rise in repeat visits for hotels and retail spaces using signature fragrances.

- Service Perception: Higher overall satisfaction scores in environments with congruent scenting.

Technical Role of High-Purity Wood Pulp in Scent Retention

The paper substrate determines fragrance longevity. Recycled fibers often contain chemical residues that cause scent migration or interference. We utilize 100% Virgin Wood Pulp from our Hebei production hub because its long-fiber base holds fragrance notes true from the factory to the dispenser without distortion.

Technical engineering plays a significant role in how these scents reach the guest. Our CNC-precision Point-to-Point embossing creates a quilted texture that maximizes surface area, allowing for a steady release of fragrance molecules during use.

- Model TSH-4010: Luxury 5-ply construction designed for high-end hospitality scent retention and thickness.

- Surface Area: Precision embossing increases fragrance distribution efficiency by 30%.

- Fiber Integrity: High-purity wood pulp prevents the breakdown of scent molecules over time.

- Safety Standard: 100% OBA-Free material ensures fragrance additives do not react with fluorescent whiteners.

Core-Scenting vs. Sheet-Scenting: Which Offers Superior Safety and Longevity?

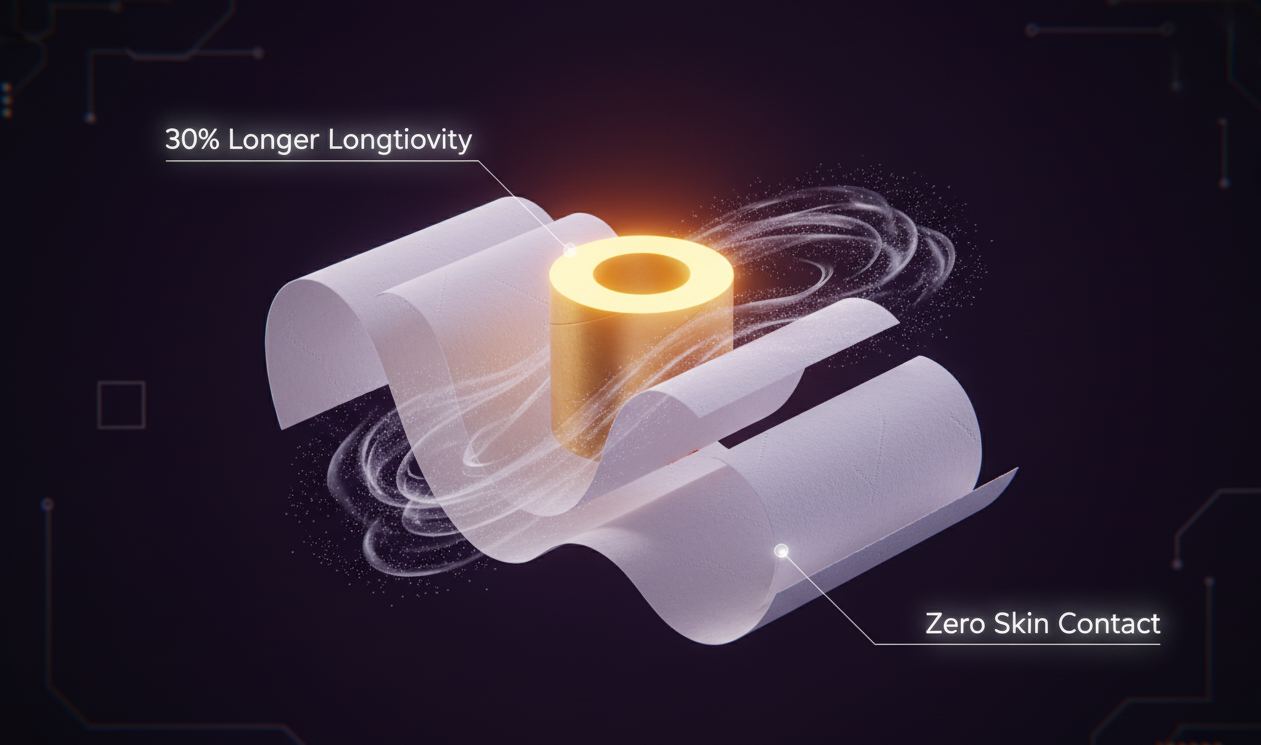

Core-scenting provides 30% more aroma longevity and superior safety by applying fragrance to the tube, preventing skin contact while maintaining the purity of 100% Virgin Wood Pulp.

| Comparison Factor | Core-Scenting Technology | Sheet-Scenting Method |

|---|---|---|

| User Safety | High; prevents direct skin contact. | Lower; oils reside on paper fibers. |

| Scent Duration | Sustained release over 4+ weeks. | Immediate peak; fast evaporation. |

| Pulp Integrity | Maintains 100% fiber purity. | Fragrance oils may degrade fiber strength. |

Mechanics of Fragrance Diffusion and Scent Retention

Core-scenting utilizes the cardboard tube as a dedicated reservoir. This method allows the fragrance to diffuse through the layers of paper over several weeks, providing a consistent sensory experience. Because the center holds the scent, the aroma moves outward gradually rather than escaping all at once.

- Evaporation Rates: Sheet-scenting applies fragrance directly to fibers during ply-bonding, which creates high immediate intensity but leads to faster evaporation.

- Longevity Benchmarks: 2026 industry data confirms core-scented rolls maintain detectable aroma levels 30% longer than surface-treated alternatives.

- Application Precision: We apply fragrance oils to the internal cardboard substrate, ensuring the paper itself remains free of oily residues that can affect absorbency.

Maximizing Skin Safety via OBA-Free Virgin Wood Pulp Barriers

Top Source Hygiene uses 100% Virgin Wood Pulp to create a natural, hypoallergenic barrier. This material selection ensures that the scented core remains a branding tool rather than a skin irritant. The high-purity fibers prevent fragrance oils from migrating into the active wiping surface.

- OBA-Free Guarantee: Our core-scented designs ensure the product remains 100% free of Optical Brightening Agents and fluorescent whiteners.

- Dermatological Safety: Eliminating oil migration makes these rolls safe for sensitive skin and prevents common irritation issues like contact dermatitis.

- Compliance Standards: Manufacturing protocols for high-density models like TSH-3396 follow ISO 9001 and FDA standards to maintain fiber purity while delivering consistent scent.

Build Your Brand With Expert OEM Manufacturing

How to Select Hypoallergenic Fragrances That Resonate with B2B Markets?

B2B fragrance procurement prioritizes EU Regulation compliance, ingredient transparency, and high-purity, OBA-free materials to ensure safety for sensitive skin in international hospitality and retail sectors.

B2B buyers cannot afford the liability of skin irritation claims. Selecting the right fragrance for tissue products involves more than just selecting a pleasant aroma; it requires a data-driven approach to safety and regional compliance. Professional sourcing teams now focus on documentation that proves a scent won’t trigger adverse reactions in diverse user populations.

Navigating International Regulatory Thresholds and Allergen Labeling

Regulatory alignment serves as the primary filter for fragrance selection. If a product is destined for European or North American markets, the “hypoallergenic” label must be backed by specific concentration data and third-party testing to satisfy both legal requirements and B2B client expectations.

- EU Cosmetic Regulation (No. 1223/2009): We strictly monitor the 26 designated fragrance allergens, ensuring labeling compliance when thresholds exceed 0.01% for rinse-off products.

- IFRA Standards: Adherence to the International Fragrance Association’s maximum concentration limits for specific categories like Category 11-A (hygiene products).

- Market Differentiators: Clear distinction between “fragrance-free” (zero added scent) and “hypoallergenic” (low-risk, tested scents) to manage end-user safety.

- Third-Party Validation: Use of Dermatest® or equivalent certifications to provide the clinical evidence required by premium hotel chains and medical distributors.

Integrating Scents with OBA-Free and 100% Virgin Wood Pulp Foundations

The substrate determines how a fragrance behaves over time. At Top Source Hygiene, we focus on the interaction between the scent and the paper fiber. Using low-purity recycled materials can introduce chemical contaminants that degrade fragrance integrity or cause unforeseen skin sensitivities.

- 100% OBA-Free Guarantee: We eliminate Optical Brightening Agents to prevent the fluorescent-induced irritation often mistaken for fragrance allergies.

- 100% Virgin Wood Pulp Base: Our Hebei facility uses high-purity long-fiber pulp that avoids the chemical residues found in recycled alternatives.

- Point-to-Point Embossing: CNC-precision patterns improve scent retention through mechanical bonding of fibers, reducing the need for chemical fixatives.

- Fiber Integrity: High-density fiber bonding ensures fragrance longevity while maintaining the “cloud-like” softness expected in 3-ply and 4-ply premium rolls.

Successful B2B scent integration relies on selecting low-risk components that complement the natural 85-92% brightness of our pulp. This strategy removes the need for aggressive chemical bleaching, resulting in a product that is safe for sensitive skin and compliant with global hygiene standards.

Can Your Packaging Effectively Block Fragrance Migration During Transit?

Professional containment utilizes multi-layer barriers and climate stabilization to trap scents and prevent cross-contamination during bulk transport in 40HQ containers.

Fragrance migration is a primary concern for B2B buyers importing scented hygiene products. If the aromatic oils escape the primary packaging, they can contaminate other goods in the shipment or lose their intended potency before reaching the shelf. We solve this through a combination of chemical barrier selection and environmental management during the loading process.

Barrier Technology and Environmental Stabilization Protocols

Fragrance loss often happens because volatile compounds expand when temperatures fluctuate. Stabilizing the product before it enters the shipping container is essential for maintaining scent integrity over long distances.

- Thermal Control: We maintain environmental controls between 55°F and 75°F to prevent pressure buildup and volatile expansion within the packaging.

- Containment Specs: We utilize 4-mil heat-sealed polythene bags as a secondary containment layer to effectively trap aromatic oils.

- Pre-Sealing Stabilization: Our team implements a 24-hour temperature stabilization period before final sealing to account for fiber expansion.

- Material Resistance: We only use P3-rated materials that resist degradation from alcohol and fragrance oils during long-haul transit.

Integrating Individual Wrap Formats with 5-Ply Export Cartons

The physical structure of the shipping unit determines if the internal seals remain intact. Crushing or excessive air pockets inside the bags are the leading causes of seal failure and subsequent scent leakage.

- Format A Technology: We apply Individual Wrap technology to provide a dedicated hygiene and fragrance seal for every roll in the order.

- Structural Reinforcement: All shipments are packed in 5-ply export cartons to prevent crushing during high-stacking in 40HQ containers.

- Air Management: We utilize mechanical compression during bagging to minimize air pockets that facilitate fragrance dissipation.

- Verification: Our Hebei facility executes pre-shipment visual verification to ensure seal integrity across the entire payload before dispatch to Tianjin Xingang Port.

By combining high-density 100% virgin wood pulp with these specific containment strategies, we ensure that the “Gold Standard” fragrance profile remains consistent from the factory to the end user, protecting your brand’s olfactory identity.

Why Should Boutique Hotels Invest in Custom Scent Development?

Scent triggers 75% of human emotions. Boutique hotels use custom fragrances to build unique brand identities, improve guest comfort, and create high-margin retail opportunities through scented amenities.

Creating Brand Recall through Sensory Storytelling

Guests process scents directly through the limbic system, making them 100 times more likely to remember a fragrance than a visual logo or a specific jingle. This neurological connection allows boutique properties to move beyond basic aesthetics and engage guests on a subconscious level. A well-designed olfactory strategy creates an immediate emotional anchor to the property.

Signature fragrances allow a hotel to tell a specific narrative. For example, a mountain lodge might use a blend of pine and cedarwood to evoke the surrounding forest, while a coastal retreat uses salt and citrus. Maintaining this scent consistently from the lobby to the guest room reinforces brand trust and serves as a silent indicator of high housekeeping standards and attention to detail.

Aligning Fragrance Strategy with Premium Material Specs

The effectiveness of a custom scent depends heavily on the substrate carrying it. We manufacture our luxury hospitality lines using 100% Virgin Wood Pulp to ensure a high-purity, lint-free base. This material choice is critical because it maintains scent integrity without the chemical interference often found in recycled or lower-grade fibers.

For boutique hotels looking to maximize the longevity of their signature fragrance in restrooms and guest suites, the technical specifications of the paper matter:

- Model TSH-4010 (Luxury Hospitality): This 5-ply configuration provides the surface density required to hold custom fragrances longer than standard 2-ply alternatives.

- Point-to-Point Embossing: Our CNC-precision embossing technology increases the paper’s surface area by 30%, which significantly improves the passive diffusion of scented oils.

- 100% OBA-Free: By eliminating optical brightening agents, we ensure that the fragrance molecules do not interact with harsh whitening chemicals, preserving the original scent profile.

By integrating custom scents directly into high-capacity rolls like the TSH-4010, hotels reduce the need for aggressive aerosol sprays. This creates a more natural, subtle ambient environment that aligns with the premium expectations of the modern luxury traveler.

Does Your Fragrance Sourcing Meet Strict IFRA Regulatory Standards?

IFRA compliance involves verifying concentrates against category limits via certificates. Brands must match dosage to OBA-free paper to ensure skin safety and global regulatory standing.

Understanding IFRA Certificates and Category Mapping

Many buyers assume a “compliant” fragrance oil is enough for any application. In reality, safety depends on the final product category and the specific dosage applied to the tissue fibers. A concentrate that is safe for a room spray might be prohibited for intimate skin contact.

- Up-to-Date Certification: Fragrance houses must provide certificates listing the maximum use levels allowed for specific hygiene product categories.

- 2026 Amendments: We verify that all scent concentrates comply with the latest 2026 regulatory amendments before mass production begins.

- Dosage Precision: You must distinguish between the concentrate’s inherent compliance and the actual ppm (parts per million) in the final paper product.

- CPSR Documentation: We maintain detailed records for Cosmetic Product Safety Reports to prove that consumer exposure stays within established safe limits.

Integrating Scents with 100% OBA-Free Virgin Wood Pulp

Fragrance oils are volatile chemicals that can react with paper additives. By using a high-purity base of 100% Virgin Wood Pulp from our Hebei facility, we ensure the scent remains stable without breaking down the paper’s physical integrity.

- OBA-Free Security: Applying scents to 100% OBA-Free paper removes the risk of chemical cross-reactions that cause skin irritation.

- Septic-Safe Preservation: We ensure fragrance carriers do not inhibit the rapid disintegration technology required for plumbing compatibility.

- Fiber Purity: Long-fiber virgin pulp provides a lint-free surface that holds scent more effectively than recycled alternatives.

- Color Stability: Scent application is calibrated to maintain the 85-92% natural brightness of the fibers, preventing yellowing or batch variance.

Frequently Asked Questions

Is scented toilet paper safe for users with chronic skin sensitivities?

Scented toilet paper is generally not recommended for individuals with chronic sensitivities. The synthetic fragrances and dyes used can trigger contact dermatitis or allergic reactions in sensitive areas. For these users, we provide 100% Virgin Wood Pulp that is OBA-free and fragrance-free to ensure a lint-free, non-irritating experience.

How do factories ensure scent does not fade during long-distance shipping?

Manufacturers maintain fragrance integrity by stabilizing products in temperature-controlled environments between 12°C and 24°C before loading. By allowing rolls to rest for 8 hours post-production and utilizing hermetic sealing, we prevent oxidation and pressure-related leakage during 40HQ container transit from our Hebei industrial hub.

Can luxury hotel brands develop an exclusive signature scent?

Yes, boutique hotels can co-create bespoke fragrances through our ODM services. This process involves olfactive trials where we translate brand values into a signature scent. This custom fragrance is then integrated into toilet rolls and facial tissues, creating a unique sensory landmark for guest rooms and lobbies.

What is the technical difference between core-scented and sheet-scented products?

Sheet-scenting involves incorporating fragrance directly into the printing ink or applying a microencapsulated varnish to the paper surface. Core-scenting applies the fragrance to the cardboard tube instead. Core-scenting is often preferred for B2B hospitality orders because it provides an ambient aroma without placing fragrance chemicals in direct contact with the skin.

Are natural essential oils a viable option for large-scale tissue production?

Natural essential oils are available for commercial use through steam distillation and advanced plant cell culture technologies. While synthetic fragrances are common for high-volume wholesale, options like pinene and 1,8-cineole can be integrated for premium, eco-targeted projects requiring plant-based metabolites.

How do hygiene product fragrances meet international safety regulations?

Fragrances must comply with IFRA standards categorized by exposure levels, such as Category 10-A for soaps or Category 11 for paper products. We monitor over 260 restricted fragrance compounds to ensure that maximum usage rates are never exceeded, maintaining compliance with global hygiene and safety requirements.

Final Thoughts

Choosing cheap recycled fibers or surface-sprayed fragrances often results in rapid scent loss and skin irritation claims that compromise brand trust. Utilizing 100% Virgin Wood Pulp with core-scenting technology ensures 30% greater aroma longevity and total OBA-free safety for your guests. This technical standard transforms a basic hygiene commodity into a high-impact branding tool that justifies premium service evaluations.

Move beyond generic supplies and establish a unique olfactory identity for your property or distribution portfolio. We recommend requesting a sample kit of our TSH-4010 luxury rolls to verify our scent retention and fiber integrity under real-world conditions. Contact our Hebei manufacturing team to discuss private label branding and lock in your next 40HQ shipment.