ISTA-6 Testing for ODM defines the survival rate of high-volume hygiene products in the modern parcel network. Traditional packaging engineered for retail shelves frequently collapses during the twenty shipping touchpoints, leading to a 15.2% return rate that destroys B2B profit margins.

Our manufacturing process utilizes reinforced 5-ply export cartons and mechanical compression to stabilize 100% Virgin Wood Pulp bundles. We optimize 40HQ container density up to 9,000kg, eliminating the need for expensive secondary fillers and protecting your brand from logistics-related financial loss.

Why Does Traditional Retail Packaging Constantly Fail in E-commerce Supply Chains?

Retail packaging prioritizes shelf aesthetics, failing under e-commerce pressure. Transitioning to 5-ply export cartons and compression-optimized bundles eliminates secondary fillers and slashes damage rates during the 20+ handling touchpoints.

The Operational Conflict Between Visual Design and Parcel Handling

Most consumer-facing packaging is engineered for a quiet life on a retail shelf. It emphasizes vibrant graphics and theft-prevention elements that offer zero structural value in a modern logistics hub. When these designs enter the e-commerce stream, they often collapse because they weren’t built for the “last mile” reality.

Retail logistics rely on centralized warehouse-to-store pallet movements where items remain relatively static. In contrast, parcel shipping involves up to 20 different touchpoints and high-speed conveyor systems. Traditional boxes usually contain excess headspace and air, creating a structural weakness that leads to crushed edges and deformed products during impact.

We see wholesalers lose significant margin by overcompensating for these weak designs. They often resort to secondary fillers like bubble wrap and shrink bands, which increases the total cost of goods sold (COGS) and complicates the unboxing experience. Shifting the focus from shelf stability to transit protection is the only way to stabilize these costs.

- Handling Points: DHL estimates packages are handled 20 times more in e-commerce than in traditional retail.

- Air Gaps: Excess headspace in retail boxes increases the risk of shock-related deformations.

- Financial Impact: Non-compliant packaging triggers retailer chargebacks and high return rates.

Mitigating Transit Damage with 5-Ply Export Cartons and Compression

Industrial-grade specifications solve durability issues at the source. At Top Source Hygiene, we eliminate the need for secondary plastics by using transit-ready packaging formats designed specifically for bulk B2B distribution and 40HQ container density.

Using 100% Virgin Wood Pulp provides the base tensile strength needed to survive pressure changes. We complement this material quality with specific mechanical enhancements that reinforce the entire bundle against vertical and horizontal stress during shipping.

- 5-Ply Export Cartons: Reinforced corrugated layers provide the vertical strength required for high-stacking in overseas containers.

- Mechanical Compression: This technology stabilizes paper rolls to maintain fluffiness while preventing shifting inside the bag.

- Format B Bundle Packs: High-density unit consolidation resists impact better than individual retail wraps.

- Material Integrity: High-purity wood pulp ensures individual sheets resist tearing even when subjected to exterior pressure.

Passively accepting damage as a cost of doing business is a mistake. By switching to compression-optimized bundles and reinforced outer cartons, distributors reduce product loss and ensure the lowest landed cost per roll without wasting money on air and extra plastic.

Are You Familiar with the ISTA-6 Standards for Drop, Vibration, and Compression?

ISTA-6 standards use drop and vibration tests to verify package durability. We utilize 5-ply cartons and mechanical compression to ensure bulk hygiene products survive global container logistics.

Understanding Drop and Vibration Testing Protocols for Global Transit

Standard retail packaging often fails in e-commerce and bulk export because it prioritizes shelf appearance over physical survival. ISTA-6 protocols shift the focus to mechanical resilience, simulating the 20-plus touchpoints a package encounters during transit. These tests identify structural vulnerabilities before the product leaves our Hebei facility.

- ISTA 6-FEDEX-A Procedures: These require a single sample to undergo ten drops across every corner and edge to pinpoint exactly where the packaging might fail under stress.

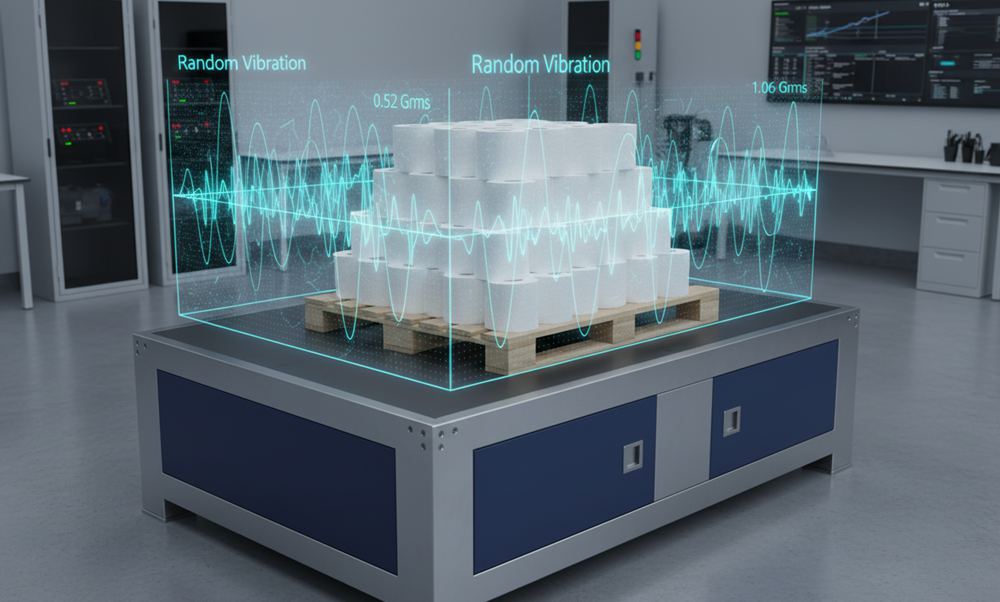

- Random Vibration Testing: Our protocols reproduce real-world shipping conditions using three 15-minute sequences that simulate truck (0.52 Grms) and air (1.06 Grms) movements.

- Concentrated Impact: For flat or elongated paper bundles, we drop a 21 lb. wooden box on the midpoint to check for puncture resistance and seal integrity.

Dynamic Compression and 5-Ply Export Carton Integrity

Static stacking tests don’t reflect the reality of a swaying 40HQ container on the open sea. We use dynamic compression testing to evaluate how our bundles handle shifting weights and environmental pressures. This data helps us optimize the stacking patterns for our high-capacity 5-ply cartons.

- Reinforced 5-Ply Cartons: Top Source Hygiene uses these heavy-duty containers to ensure that toilet paper bundles withstand the extreme pressures of bottom-row stacking in a fully loaded 40HQ.

- Mechanical Compression: We utilize specialized technology during the bagging process to minimize roll bulk. This maximizes container space while maintaining the 13–22g/m² ply density and natural fluffiness.

- Sidewall Detection: Computerized controls during compression testing detect minor sidewall damage that traditional manual checks often miss, ensuring the box maintains its shape throughout the journey.

By adhering to these ISTA-6 benchmarks, we eliminate the need for excessive secondary packaging like bubble wrap. This reduces your landed costs and ensures that our 100% Virgin Wood Pulp products arrive in retail-ready condition.

Scale Your Brand With Premium Custom Toilet Paper

How to Design “Ship-in-Own-Container” (SIOC) Units That Reduce Shipping Costs?

SIOC units eliminate secondary boxing by engineering primary packaging for ISTA-6 durability. Success relies on right-sizing and high-density materials to slash dimensional weight and material expenses.

Optimizing Dimensional Weight Through Right-Sized Geometry

Standard e-commerce shipping often fails because retail boxes contain excessive air and unnecessary display cardboard. By designing SIOC-compliant units, we remove the need for secondary boxing and void-fill materials like air pillows, which immediately reduces the total package volume by approximately 50%.

- Girth Calculation: Keep package girth—length plus twice the width and height—under 165 inches to stay below LTL routing thresholds for items under 100 lbs.

- Conveyor Compatibility: Align package footprints with automated fulfillment center systems to prevent manual handling surcharges and “oversized” penalties.

- Dimensional Weight: Shrink the gap between actual weight and dimensional weight by tightening primary packaging, a critical move for 2026 carrier pricing models.

- Material Removal: Eliminating secondary layers directly cuts total cost of goods sold (COGS) by removing the expense of outer brown boxes and tape.

Utilizing Mechanical Compression and 5-Ply Bundle Reinforcement

Factory-level engineering determines if a package survives the final mile delivery. We use specific manufacturing techniques that prioritize density and structural strength over retail aesthetics that offer no protection in transit.

- Mechanical Compression: We apply Top Source Hygiene’s mechanical compression technology during the bagging process to increase paper density and maximize 40HQ container payloads.

- TSH-3396 Solid-Core: This coreless design eliminates empty space inside the roll, creating a solid internal support that resists crushing during ISTA-6 vertical compression tests.

- 5-Ply Export Bundles: We replace standard retail wraps with high-density poly bundles or reinforced 5-ply export-grade materials to provide the structural integrity needed for high-stacking.

- 100% OBA-Free Virgin Pulp: Using genuine wood pulp maintains the fiber strength and tensile durability required to withstand the vibration stresses of last-mile delivery.

Can Impact-Resistant Packaging Drastically Reduce Your Customer Return Rates?

Impact-resistant packaging slashes e-commerce return rates by preventing transit crushing in 40HQ containers, ensuring high-density rolls arrive in retail-ready condition to protect distributor margins and supply chain efficiency.

The Correlation Between Transit Integrity and Retail Returns

Online shopping return rates currently sit at 15.2%, nearly triple the 5% rate seen in physical retail. For B2B distributors, a damaged outer bundle often leads to bulk rejections at regional distribution centers. When secondary packaging arrives deformed or torn, customers assume internal contamination or defects, especially with hygiene products where OBA-free purity is a primary selling point.

- E-commerce Return Benchmark: 15.2% average return rate vs. 5% for brick-and-mortar retail.

- Handling Intensity: DHL reports e-commerce packages undergo up to 20 touch points before reaching the final user.

- Material Selection: High-density polyethylene (HDPE) maintains structural integrity through multiple vibration and drop cycles.

- Hygiene Perception: Maintaining the aesthetic state of toilet paper rolls prevents rejections based on perceived contamination.

Reinforced 5-Ply Export Cartons for High-Stacking Stability

International logistics creates massive static and dynamic loads during the shipping cycle. We design our packaging to survive the extreme pressures of a 40HQ container, where bottom-layer bundles must support up to 9 tons of vertical weight. This specialized construction prevents the “accordion” effect that often destroys lower-tier cargo during long-haul sea transit from our Hebei facility.

- Carton Material: Reinforced 5-ply export-grade corrugated fiberboard designed for 9,000kg payloads.

- Mechanical Compression: We stabilize high-density models like TSH-3396 within the bundle to eliminate internal shifting.

- Secondary Protection: Multi-layer PE bags protect 100% OBA-free hygiene standards and prevent paper perforation.

- Loading Optimization: Dedicated Hebei teams maximize every inch of the 40HQ container to ensure the lowest landed cost per roll.

By focusing on transit integrity, we help wholesalers avoid the compounding financial losses of product damage, retailer chargebacks, and reverse logistics. Our engineering process aligns with ISTA-6 standards to ensure that even high-capacity items like the 5000g TSH-3082 bundles survive rigorous handling without losing their retail-ready shape.

What Is the Long-Term Financial ROI of Passing E-commerce Certifications?

ISTA-6 certification generates a 200% ROI by 2026, securing a 2:1 revenue-to-investment ratio through drastic reduction in damage-related returns and maximized 40HQ container density.

| Performance Metric | Standard Packaging | Certified (ISTA-6) Packaging |

|---|---|---|

| Projected ROI (2026) | Negative/Flat | 200% |

| Revenue-to-Investment Ratio | 1:1 | 2:1 |

| Operational Efficiency | Baseline | +45% Improvement |

| Typical Container Payload | Sub-optimal | 7,000kg – 9,000kg (40HQ) |

Measurable Savings from Lower Damage and Return Rates

Standardized e-commerce packaging acts as a direct margin protector rather than just a compliance cost. Companies investing in these protocols expect a 2:1 baseline ROI by 2026. This return stems from the elimination of retailer chargebacks and the hidden costs associated with processing damaged goods.

- ROI Performance Floor: A 10% or higher ROI is the standard industry benchmark for performance, though early adopters frequently exceed this.

- Operational Efficiency: Validated packaging designs combined with automated compliance tracking increase long-term operational efficiency by up to 45%.

- Profit Protection: Standardized testing ensures B2B profit margins remain intact by lowering return rates that typically plague online retail supply chains.

Maximizing ROI via 40HQ Loading Optimization and 5-Ply Export Packaging

Financial returns in the paper industry depend heavily on logistics density. Top Source Hygiene utilizes specific manufacturing standards to ensure international buyers minimize the landed cost per roll. High-density loading directly correlates to higher revenue per shipment.

- Container Payload: We optimize 40HQ containers to carry between 7,000kg and 9,000kg, ensuring maximum weight utilization and lower freight costs.

- Reinforced Protection: 5-ply reinforced export cartons prevent crushing during high-stacking, eliminating financial loss from unsellable, deformed inventory.

- Compression Technology: Mechanical compression allows more product per cubic meter while maintaining the 100% wood pulp fiber integrity required for premium household rolls like the TSH-2559.

- Space-Saving Design: High-density solid rolls, such as the TSH-3396 (5000g), are engineered specifically to maximize transport efficiency and wholesale value.

Why Is Independent Lab Validation Essential for Your B2B Retail Partnership?

Third-party validation confirms OBA-free status and ply density, protecting B2B partners from regulatory fines and ensuring product performance in high-volume e-commerce and retail supply chains.

Objective Verification of Material Integrity and Safety

Independent labs provide the only objective proof that a manufacturer adheres to stated specifications. While many suppliers claim high quality, third-party testing verifies the actual fiber length and tensile strength of our 100% Virgin Wood Pulp. This verification ensures the paper maintains integrity under the stresses of high-volume retail handling and household use.

- Material Purity: Labs confirm the use of high-purity, long-fiber wood pulp without recycled waste to ensure a lint-free experience.

- OBA-Free Status: Certified testing guarantees the absence of Optical Brightening Agents and fluorescent whiteners, ensuring safety for sensitive skin.

- Compliance Standards: Testing aligns product safety with ISO 9001, FDA, and EU hygiene requirements, facilitating smooth customs clearance via HS Code 4818.1000.

Validating Rapid Disintegration and Septic Safe Performance

Technical performance dictates whether a product remains on retail shelves or faces costly returns. In North American and European markets, septic-safe engineering is a non-negotiable requirement. Labs simulate standard plumbing environments to confirm rapid disintegration rates, which prevents residential blockages and protects the distributor from liability.

- Ply Density Control: Verification confirms a strict density range of 13–22g/m² per ply, balancing cloud-like softness with high-wet-strength durability.

- Natural Brightness: Labs measure brightness levels between 85-92%, confirming the aesthetic is achieved through fiber selection rather than aggressive chemical bleaching.

- Layer Integrity: Testing validates our high-pressure lamination and ply-bonding technology, ensuring layers do not separate during transit or use.

By utilizing these independent reports, B2B buyers mitigate the risks associated with manufacturer bias. These documents serve as the technical foundation for private label brands and hospitality groups that require consistent, high-purity hygiene solutions across multiple global regions.

Frequently Asked Questions

What is ISTA-6 testing and why is it necessary for e-commerce tissue brands?

ISTA-6 is a rigorous performance certification that simulates real-world shipping hazards like drops, shocks, and vibrations. For brands selling through Amazon FBA or major global retailers in 2026, passing these tests ensures that tissue products—especially bulky bundles—survive the distribution network without damage, protecting profit margins from high return rates.

Can custom ODM packaging for toilet rolls pass SIOC certification?

Yes. Custom-designed packaging qualifies for Ships-In-Own-Container (SIOC) certification when engineered with rigid materials and precise dimensions. We develop prototypes using production-grade 100% Virgin Wood Pulp products to ensure the packaging meets Amazon’s specific durability requirements for Type A through Type H classifications.

What are the primary failure points in bulk tissue packaging during transit?

The most common failures involve seal integrity compromise, physical punctures, and flex cracking in thin films. To prevent these issues, we utilize high-density solid rolls like the TSH-3396 and reinforced 5-ply export cartons that maintain structural integrity even under the extreme compression of a 9-ton 40HQ container load.

How much does professional packaging testing typically cost?

Professional ISTA-6 testing generally ranges from $800 to $2,000 per sequence. The final cost depends on the product weight category and the complexity of the protocol, such as Type A testing for parcels under 50 lbs versus specialized incline and compression tests for heavy 5,000g industrial bundles.

Does ISTA-compliant packaging come as a standard ODM service?

ISTA compliance is not a default service but a certification earned through accredited labs. As an OEM/ODM specialist based in the Hebei Paper Industrial Hub, we facilitate this process by providing production-equivalent samples and ensuring materials meet international ISO 9001 and FDA hygiene standards before laboratory validation.

How do you reduce shipping damage for international 40HQ container orders?

We use mechanical compression technology to minimize roll bulk and maximize payload efficiency up to 9,000kg. Our Hebei loading teams use 5-ply reinforced cartons and provide pre-shipment visual verification through photos and videos to ensure all bundles are secured against the vibrations and shocks of long-haul maritime transit.

Final Thoughts

Cheap packaging creates an expensive supply chain. While flimsy bundles lower your initial production costs, they trigger high return rates and retail chargebacks that our 5-ply export cartons and mechanical compression prevent. Shifting to ISTA-6 compliant materials ensures your margin stays in your pocket rather than being lost to transit damage or bulk rejections.

Verify these durability standards by requesting a set of production samples or our latest third-party lab reports. We recommend starting with a 40HQ trial order to evaluate our loading density and 100% Virgin Wood Pulp performance under real-world logistics stress. Contact our Hebei team to align your private label specifications with global transit-ready standards.

SEO

Title: Transit-Ready Branding: The ROI of ISTA-6 and Drop-Test Compliance

Description: ISTA-6 Testing Standards for 100% wood pulp rolls. 5-ply export cartons secure 9,000kg 40HQ bulk wholesale orders from Hebei.

URL: ista-6-testing-standards

Keywords: ISTA-6 Testing Standards