Micro-Perforation Engineering is the technical difference between a luxury guest experience and the operational drain of paper waste. Poor sheet separation leads to unravelling rolls and increased facility maintenance, directly impacting hospitality satisfaction scores and procurement margins.

This analysis benchmarks CNC-precision blades and 100% Virgin Wood Pulp against the 13-22 GSM performance standard. We evaluate how specialized lamination and tear-force calibration secure your 40HQ payload, ensuring every roll maintains structural integrity from the factory to the dispenser.

Why Should Perforation Quality Be Your Top Guest Satisfaction Metric?

Guest satisfaction depends on tactile details. Clean perforation prevents paper shredding and waste, signaling professional care and high-end standards in hospitality environments.

Correlation Between Tear Consistency and Guest Experience

The physical interaction a guest has with a paper roll often dictates their perception of facility maintenance. When a sheet fails to separate cleanly, it leads to unravelling rolls or paper clumping in dispensers. This creates a messy environment and forces guests to use more effort for basic hygiene tasks.

- Dispenser Integrity: Consistent sheet separation prevents the roll from unravelling onto bathroom floors or clumping in recessed dispensers.

- Effortless Separation: Precision lines reduce the physical force required, eliminating the frustration of mid-sheet tearing or “tailing.”

- Visual Maintenance: Neat, clean edges keep bathrooms looking professionally maintained, which contributes to a 20% increase in satisfaction scores for hotel facility managers.

Precision Perforation and Tensile Performance

Manufacturing high-quality paper requires a balance between fiber strength and tear-line precision. At Top Source Hygiene, we use clean-cut perforation lines designed to work with the specific properties of our 13-22 GSM paper. This engineering ensures the roll stays intact during transport but releases the moment a guest pulls a sheet.

- Material Strength: Our use of 100% Virgin Wood Pulp provides the long-fiber integrity necessary to hold perforation patterns during high-speed production.

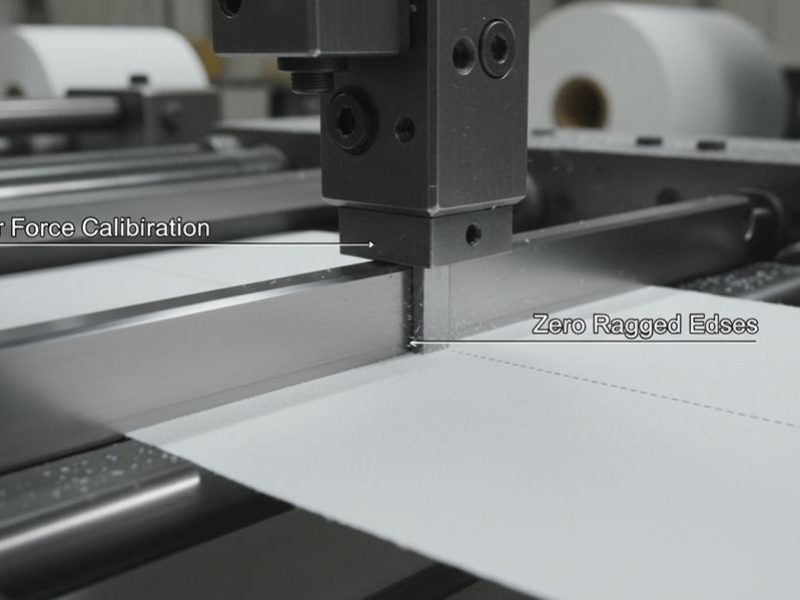

- Manufacturing Calibration: We use CNC-precision tools to create clean-cut lines, preventing the shredded, ragged edges common in recycled or low-grade rolls.

- Tear Force Balance: The ratio of “ties” to “cuts” is engineered to ensure sheets remain connected on the roll but release instantly with minimal pull force.

- Ply-Bonding Synergy: Multi-ply sheets are laminated under high pressure so that layers don’t separate when a guest initiates a tear.

Straight vs. Spiral Perforation: Is There a Scientific Winner for the Perfect Tear?

Straight perforation paired with high-tensile 100% virgin wood pulp ensures the most predictable linear tear and eliminates the shredded edges common in lower-grade tissue products.

| Performance Metric | Straight Perforation | Spiral/Wavy Perforation |

|---|---|---|

| Tear Direction | Predictable horizontal snap. | Multi-angle initiation. |

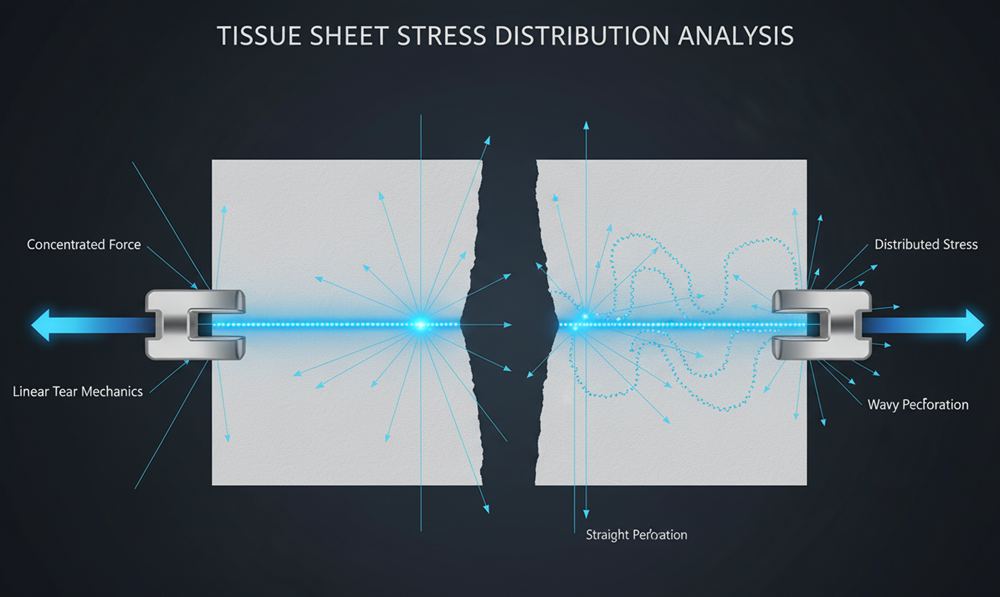

| Stress Point | Concentrated along a single axis. | Distributed across wider surface. |

| Shred Risk | Low (with long-fiber pulp). | Higher risk of diagonal fraying. |

| Standard Use | Global B2B and retail standard. | Specialized consumer branding. |

Stress Distribution and Linear Tear Mechanics

Straight perforation lines concentrate the pulling force along a single horizontal axis. This setup allows for an intuitive and rapid break that follows the intended path. While some manufacturers experiment with wavy geometries to account for varied pulling angles, these patterns often distribute stress across too wide an area. This can reduce the crispness of the “snap” and lead to diagonal tearing into the next sheet.

Effective paper engineering in 2026 relies on the alignment of fibers. Our production process ensures that straight cuts work with the natural grain of the pulp rather than against it. We optimize the tear by focusing force on the perforation line, which prevents the paper from yielding in unintended directions.

- Fiber Path: Alignment favors straight cuts to ensure the break follows the perforation.

- Force Profile: Straight lines provide a clear, singular separation point.

- Consistency: Linear mechanics perform reliably regardless of the roll’s remaining diameter.

Clean-Cut Precision and Long-Fiber Integrity for Shred-Free Tearing

We use CNC-precision perforation technology to create clean-cut lines. This removes the “shredded edges” that buyers often see in non-factory-direct products. The quality of the tear depends largely on the material strength. We use 100% virgin wood pulp to provide the long-fiber integrity required to resist premature tearing while maintaining a crisp separation point.

Ply stability also plays a role in how a sheet separates. We apply point-to-point embossing patterns to stabilize the layers. This ensures the perforation blades cut through every ply simultaneously, which prevents sheet delamination or “ghosting” where one layer tears before the other.

- Technology: CNC-precision perforation eliminates ragged fiber edges.

- Material: 100% Virgin Wood Pulp offers high tensile strength for a clean break.

- Layer Bonding: Point-to-point embossing increases absorbency by 30% and locks plies together.

- Safety Standards: All perforated products are 100% OBA-Free and septic-safe.

Premium Custom Toilet Paper at Wholesale Prices

How to Adjust Tear Force for Residential vs. High-Traffic Industrial Use?

Adjusting tear force balances perforation-to-bond ratios and 100% Virgin Wood Pulp density to ensure easy residential tearing while preventing industrial dispenser shredding.

Calibrating Perforation Ratios for Variable Pull-Force Environments

Residential users expect a low-resistance, clean break that prioritizes hand comfort. In contrast, industrial environments use high-speed dispensers that exert massive torque on the paper. To manage these different demands, we calculate the “Percent of Hold” by multiplying the Teeth-Per-Inch (TPI) by the tie width (the uncut area). This formula allows us to engineer rolls that withstand the aggressive mechanical pulling found in commercial stalls without pre-maturely shredding inside the housing.

- Elmendorf Testing: We use the Elmendorf method to simulate the real-world pull-force exerted by users in high-frequency commercial environments.

- CNC-Precision Calibration: Our machines adjust perforation lines to increase bond strength for jumbo rolls, preventing mid-sheet failure during high-speed extraction.

- Hygiene Alignment: We fine-tune perforation depth to ensure a lint-free tear that meets 2026 hospitality standards for premium guest experiences.

Utilizing 100% Virgin Wood Pulp for Industrial Tensile Control

The base material determines the limits of tear force adjustment. As a Hebei-based factory, we prioritize long-fiber 100% Virgin Wood Pulp because it provides the natural tensile strength required for heavy-duty applications. While recycled fibers often snap under the torque of a commercial dispenser, our long-fiber sheets maintain structural integrity, allowing for higher ply density without becoming brittle.

- Industrial Integrity: We utilize specific long-fiber blends in models like TSH-3082 to handle the rapid mechanical dispensing common in airports and malls.

- Density Management: We maintain a strict ply density between 13-22g/m² to provide necessary wet strength for industrial use.

- High-Pressure Ply-Bonding: We use lamination technology to ensure multi-ply sheets stay intact during the high-torque pulling typical of high-traffic environments.

Does Your Ply-bonding Strength Directly Interfere with Perforation Quality?

Weak bonding allows layers to shift, causing jagged, uneven tears. Solid ply cohesion ensures the blade cuts all plies simultaneously for a clean, professional break.

The Impact of Ply Slippage on Tear Precision

Ply-slippage happens when friction between layers is too low. This instability causes the top and bottom plies to hit the perforation blade at slightly different angles, ruining the synchronization of the tear line.

- Multi-Ply Tension: Uneven tension across 2-ply to 5-ply products often results in “shredded edges,” where one layer tears while the other remains partially attached.

- Fiber Distortion: Robust ply-bonding provides the structural stability needed to prevent fiber distortion during the rapid impact of the perforation knife.

- Mechanical Accuracy: Without a unified bond, layers slide during high-speed converting, creating a mismatch between the blade and the material.

High-Pressure Lamination for Clean-Cut Perforation Lines

Top Source Hygiene utilizes high-pressure lamination technology to bond multi-ply sheets. This process eliminates the need for excessive adhesives that can dull perforation blades and lead to inconsistent quality over long production runs.

- Density Performance: Our bonding techniques maintain precision even on high-density materials ranging from 13g/m² to 22g/m² per ply.

- Fiber Locking: We use CNC-precision embossing patterns to lock fibers in place. This ensures perforation integrity remains consistent across roll widths from 102mm to 132mm.

- Blade Longevity: Avoiding glue-heavy bonding prevents residue buildup on knives, ensuring the thousandth roll is as clean as the first.

For wholesalers, this means fewer customer complaints about stringy or “un-tearable” rolls. When we lock the plies together through lamination and point-to-point embossing, we guarantee that the perforation serves as the single point of failure, allowing for a smooth separation every time.

How to Achieve Zero “Missed” Perforations in High-Speed Manufacturing?

Eliminate missed perforations using M2 tool steel and engineered punch clearances. We combine CNC-precision blades with high-pressure ply-bonding to ensure clean-cut lines in 100% virgin wood pulp production.

Optimizing Punch Clearance and Thermal Resistance in High-Speed Tooling

High-speed production generates intense heat that compromises standard tool steels. Small punches lack the mass to dissipate thermal energy, leading to hardness loss and dimensional instability. To maintain consistency, we utilize specific material and mechanical standards:

- High-Speed Tool Steel: We select M2 or CPM-10V steels that maintain hardness above 1000°F. These outperform conventional A2 or D2 steels in high-friction environments.

- Engineered Clearance: Precise punch-to-matrix clearance reduces stripping friction. This keeps the relationship between hole size and punch point predictable as tools wear.

- Orientation Control: Implementing 0-180 degree phasing with weight bar positioning eliminates variability caused by hoop stresses and near-wellbore tortuosity.

- Predictive Modeling: Advanced software identifies ideal phasing designs to minimize inconsistent perforation geometry across high-speed stages.

Maintaining Precision Perforation Lines for 100% Virgin Wood Pulp

Perforation quality depends heavily on how the raw material reacts to the blade. 100% virgin wood pulp features long fibers that require sharp, stable contact to avoid shredding. Top Source Hygiene ensures clean-cut lines by integrating material integrity with mechanical precision:

- CNC-Precision Blades: Our factory uses CNC-ground perforation blades to create crisp separation points, preventing “shredded edges” during the user tear.

- Ply-Bonding Technology: We use high-pressure lamination to keep multi-ply sheets aligned. This prevents layers from drifting away from the perforation line during high-speed winding.

- GSM Density Control: We maintain a strict 13–22g/m² density per ply. This provides the tensile strength necessary for the long-fiber pulp to resist premature tearing.

- Quality Verification: Every batch undergoes visual inspection and pre-shipment verification to confirm perforation depth meets international hygiene standards.

By focusing on these technical tolerances, manufacturers can maintain a zero-defect rate even at the 300,000 punch-per-minute threshold required for modern global distribution.

Can Customizing Sheet Length Improve Your Total Consumption ROI?

Customizing sheet length and density boosts ROI by cutting waste and maximizing container payloads. High-density coreless models like TSH-3396 lower landed costs per meter in high-traffic zones.

Controlling Consumption Rates Through Strategic Sheet Sizing

Standardized sizing often ignores the specific demands of commercial restroom hardware. When sheet length fails to match dispenser pull-mechanisms, users typically over-pull, leading to massive material discharge and unnecessary cost. Calibrating the dimensions ensures each pull delivers the required amount without excess.

- Precision Widths: Customizing roll widths to 102mm or 105mm maintains user comfort while lowering the total fiber weight per order, stretching your procurement budget further.

- Dispenser Calibration: Matching sheet length to mechanical rotation limits prevents “runaway” rolls and floor litter in high-traffic environments.

- Fiber Density: Utilizing 13–22g/m² per ply provides the necessary tensile strength to ensure the sheet separates at the perforation instead of shredding mid-pull.

Maximizing 40HQ Payload with TSH-3396 High-Density Configurations

Logistics costs dictate the final margin for international distributors. By focusing on roll density and core design, we maximize the physical paper volume inside every 40HQ container to drive down the landed cost per roll.

- TSH-3396 Configuration: This 5000g coreless model provides 100% paper utilization, removing the dead space and weight associated with traditional cardboard tubes.

- Mechanical Compression: Our bagging process employs industrial compression technology to pack more volume into each cubic meter without compromising the fluffiness of the 100% virgin wood pulp.

- Payload Efficiency: We aim for a 7,000kg to 9,000kg payload per 40HQ, ensuring buyers move the maximum amount of product for every dollar spent on ocean freight.

- Storage Optimization: High-density rolls like the TSH-3396 or TSH-3082 reduce the warehouse footprint required for the same meterage of paper compared to low-density residential alternatives.

Frequently Asked Questions

Why does toilet paper often tear unevenly or shred at the edges?

Uneven tears happen when straight perforations fail to align with the different angles at which users pull the paper. Stress concentrates at a single point rather than distributing across the line. We use wavy or CNC-precision perforation patterns to create multiple initiation points, ensuring a clean break regardless of the pulling direction or how the roll is hung.

Can I request a specific tear force for a private label brand?

Yes. We engineer tear strength by adjusting the Teeth Per Inch (TPI) and the tie width—the uncut space between sheets. Using the formula TPI × Tie Width = Percent of Hold, we calibrate the exact resistance you need. Most premium retail brands currently target the 28 to 45 TPI range for smooth separation without accidental breaking during dispensing.

How do you maintain perforation consistency across a 40HQ container order?

We use PLC systems and servo-motor-driven cylinders to maintain identical tension and spacing during high-speed production. Real-time camera monitoring and software-controlled parameters prevent tool wear issues. This ensures the first roll and the 40,000th roll in your shipment share the same structural integrity and tear resistance.

Does the perforation pattern affect how quickly paper dissolves in septic systems?

Material is the primary factor, but precision micro-perforation helps by increasing the surface area exposed to water. Since we use 100% Virgin Wood Pulp, our 3-ply and 4-ply rolls dissolve rapidly. This combination makes the paper safe for high-traffic commercial plumbing and residential septic systems without risking clogs.

What is the difference between straight and spiral perforation in production?

Spiral designs generally handle high-speed converting better than straight designs by reducing mechanical vibration and improving waste evacuation. For the distributor, this means receiving rolls with fewer structural defects and cleaner edges. The spiral arrangement dissipates stress more effectively, preventing the “ragged edge” look common in low-end manufacturing.