Flushability & Septic Safety standards determine the maintenance overhead of high-traffic institutional plumbing. Procuring materials that fail rapid disintegration benchmarks leads to chronic blockages and significant emergency plumbing labor costs that erode facility budgets.

This evaluation benchmarks paper performance using the 100% Virgin Wood Pulp standard. We analyze how a precise 13–22g/m² ply density ensures the rapid fiber fragmentation required to meet North American and European septic safety protocols.

What Makes Toilet Paper “Septic-Safe”?

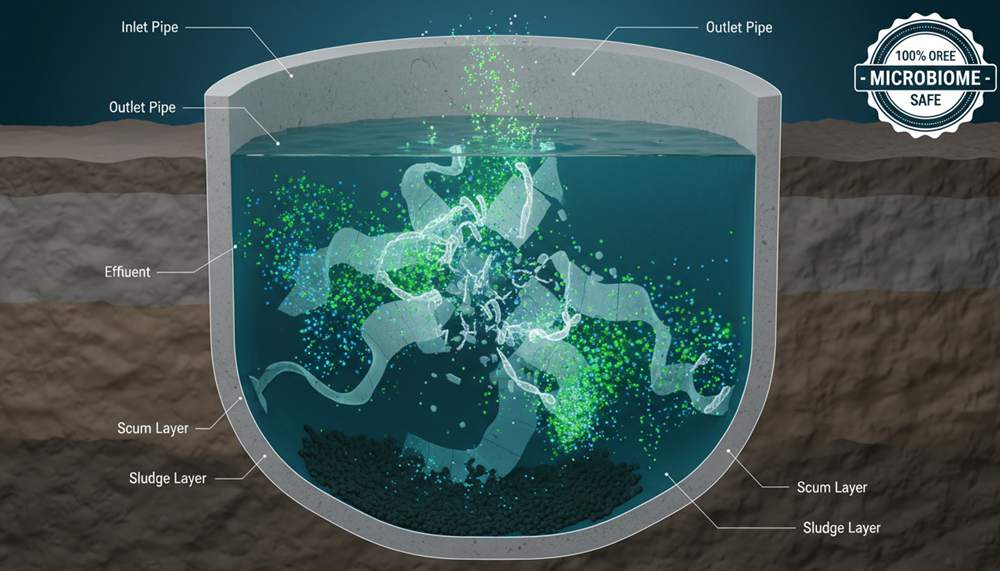

Septic-safe paper dissolves quickly using short-fiber structures and OBA-free materials. This protects plumbing and maintains the bacterial balance required for effective waste decomposition in septic tanks.

Dissolution Speed and Fiber Fragmentation

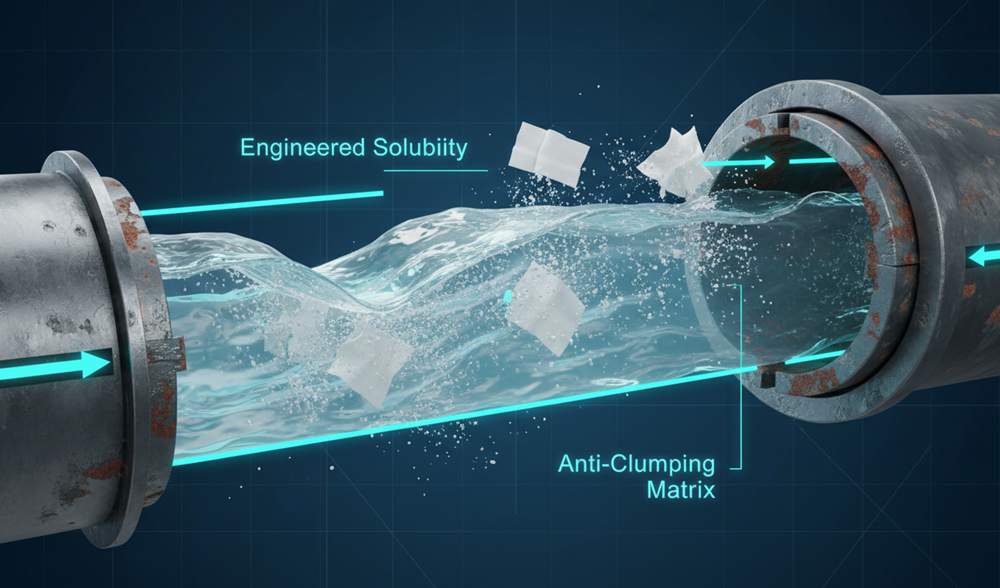

Plumbing health depends on how paper fragments once it hits the waste stream. If the material stays intact too long, it catches on pipe joints or settles as a solid mass in the tank, leading to drainage field failure. Effective septic-safe paper balances usability with immediate structural failure upon saturation.

- Disintegration Rate: Rapid breakdown turns the paper into fine particles, preventing clogs in aging or low-flow systems.

- Fiber Composition: Short-fiber materials break apart more efficiently than the heavy, long-fiber bonds used in premium non-septic towels.

- Wet-Strength Balance: Engineering ensures the paper remains durable during use but loses all integrity shortly after flushing.

- Solids Reduction: Highly biodegradable fibers reduce the total volume of solids, which extends the intervals between professional tank pump-outs.

100% OBA-Free Virgin Wood Pulp Specifications

As a dedicated B2B source factory in Hebei, Top Source Hygiene manufactures toilet paper that prioritizes the septic tank’s biological health. We eliminate specific chemicals that typically kill the anaerobic bacteria needed to process human waste. This technical approach moves beyond marketing labels to actual material science.

- OBA-Free Guarantee: We exclude Optical Brightening Agents to protect the sensitive bacterial ecosystem essential for waste decomposition.

- Ply Density: We maintain a strict 13–22g/m² per ply to ensure the paper is thin enough for fragmentation while providing the softness wholesalers expect.

- Material Purity: Using 100% Virgin Wood Pulp ensures a lint-free experience without the heavy binders or resins often found in recycled alternatives.

- PH Neutrality: Chlorine-free processing helps maintain the chemical balance within specialized or older plumbing networks.

Distributors targeting the North American or European markets need these specific parameters to meet local compliance. Our engineering for 2026 focuses on ensuring that even high-ply luxury rolls maintain these rapid-dissolving characteristics for professional-grade reliability.

The Jar Test: A DIY Method to Verify Rapid Disintegration

The jar test simulates flush turbulence to confirm that toilet paper fragments quickly, ensuring it won’t clog septic tanks or aging drainage systems.

| Test Observation | Septic Risk Level | Technical Implication |

|---|---|---|

| Immediate Clouding/Fragmenting | Low | High-purity fibers; low binder use. |

| Large Intact Sheets | High | Excessive ply-bonding or high GSM. |

| Slow Clumping | Moderate | Poor fiber orientation for dispersion. |

Simulating Plumbing Turbulence in a Standard Container

Visualizing how paper behaves inside a pipe or tank doesn’t require a lab. You can replicate the mechanical forces of a standard toilet flush using a simple container. This test separates marketing claims from actual performance, showing how quickly the fibers lose their structural bond once saturated.

- Fill: Pour water into a clear jar until it is halfway full.

- Submerge: Place a single sheet of toilet paper inside the water.

- Agitate: Shake the jar vigorously for exactly 30 seconds to mimic pipe turbulence.

- Inspect: Look for large clumps or intact pieces that signal a high risk for blockages.

Rapidly dissolving fibers create a cloudy suspension. If the water remains clear with a solid piece of paper floating in it, the product relies too heavily on chemical binders or dense fiber weaving, which often leads to buildup in drainage tanks.

Engineering Fibers for Septic Compatibility and Rapid Breakdown

Manufacturing a roll that is both strong during use and weak in the drain requires precise material selection. We focus on fiber length and ply density to ensure the paper meets international safety standards without sacrificing the tactile quality buyers expect.

- 100% Virgin Wood Pulp: We use long-fiber pulp that provides high tensile strength when dry but loses integrity immediately upon total submersion.

- Ply Density (13–22g/m²): We strictly control the weight per ply to balance softness with fast disintegration.

- 100% OBA-Free: By avoiding optical brightening agents and heavy chemical binders, the paper breaks down naturally without disrupting septic bacterial ecosystems.

- Standard Compliance: Engineering processes align with North American and European septic safety protocols to prevent plumbing emergencies.

Managing the ratio of fiber to air in the embossing process also plays a role. Using point-to-point embossing increases absorbency while creating “entry points” for water to penetrate the paper layers, accelerating the breakdown process during the flush.

Premium Custom Toilet Paper At Wholesale Prices

Why Schools and Hospitals Need Fast-Dissolving Paper

Fast-dissolving paper pulps in six seconds, preventing blockages in high-traffic plumbing systems. This cuts maintenance costs, allowing institutions to reallocate budgets from emergency repairs to essential supplies.

Reducing Infrastructure Strain and Maintenance Costs

High-traffic facilities cannot afford out-of-service washrooms during peak hours. In schools and clinics, conventional toilet paper often fails to break down fast enough, catching on the rough interior surfaces of aging pipes. This accumulation creates massive blockages that require expensive, labor-intensive emergency servicing.

- Reliability: Keeps washrooms operational during heavy usage cycles in schools and outpatient clinics.

- Asset Protection: Lowers the physical strain on wastewater systems in older institutional buildings.

- Fiscal Efficiency: Optimizes facility budgets by focusing on high-volume consumables instead of recurring plumbing labor costs.

Top Source Hygiene provides high-capacity models like the TSH-JRT08 (Jumbo Roll) and TSH-1071 specifically for these environments. These models ensure that even with high footfall, the plumbing remains clear and the facility stays compliant with sanitation standards.

Engineering Rapid Disintegration for Institutional Hygiene

We manufacture our institutional paper using 100% Virgin Wood Pulp to achieve a specific balance. The sheets remain strong and absorbent during use but lose structural integrity the moment they hit the water. This rapid fiber breakdown is a technical requirement for hospitals where sanitation systems must be 100% reliable.

- Material Purity: 100% OBA-Free (No Optical Brightening Agents) ensures safety for patients with sensitive skin.

- Plumbing Standards: Engineered to meet North American and European septic-safe and flushability requirements.

- Lamination Quality: High-pressure ply-bonding prevents layers from separating before disposal.

- Compliance: Materials align with ISO 9001, FDA, and EU hygiene directives.

Using shorter fibers in our 100% Virgin Wood Pulp allows the paper to pulp in under six seconds. This is critical for large-scale operations where a single clog can shut down an entire wing of a medical facility. By prioritizing rapid disintegration, we protect the microbiome of local septic systems while maintaining the “Pure Quality” our B2B partners expect.

Septic-Safe vs. Biodegradable: Understanding the Nuances

Biodegradability describes eventual decay, but septic-safe paper must disintegrate in seconds and maintain a neutral pH to protect the tank’s bacterial ecosystem and prevent plumbing obstructions.

The Functional Gap Between Biodegradability and Septic Compatibility

Biodegradability refers to the eventual decomposition of materials in a natural environment. In the context of plumbing, this timeline is often too slow. A product can be biodegradable but still cause massive blockages in a confined septic tank because it doesn’t break apart fast enough to move through the system.

Septic systems rely on a delicate balance of anaerobic bacteria to digest waste. Products that are truly safe for these systems must meet specific chemical and physical criteria:

- Neutral pH Balance: Extreme acidity or alkalinity destroys beneficial waste-digesting bacteria, leading to sludge buildup.

- Chemical Restrictions: Low phosphorus content and the total absence of harsh synthetic chemicals like bleach are critical for ecosystem health.

- Disintegration Speed: Paper must dissolve into tiny particles upon immersion to avoid catching on pipe joints or rough interior surfaces.

- Misleading Labels: Many “flushable” or “biodegradable” wipes fail to break down quickly, posing a severe risk to older drainage systems.

Engineering Rapid Disintegration with OBA-Free Virgin Wood Pulp

At Top Source Hygiene, we manufacture toilet paper specifically for high-sensitivity plumbing. Our engineering process focuses on material integrity and rapid dissolution to ensure compatibility with North American and European 2026 standards.

We use 100% virgin wood pulp combined with long-fiber technology. This provides the tensile strength required for professional use while ensuring the paper dissolves almost immediately when submerged. For B2B clients and hospitality groups, this reduces maintenance overhead and prevents facility downtime.

- Model TSH-2559: Our global retail favorite, specifically engineered for rapid disintegration in residential and commercial septic tanks.

- OBA-Free Manufacturing: We guarantee no Optical Brightening Agents are used. This ensures no fluorescent whiteners disrupt the bacterial balance.

- Ply-Density Control: We maintain a strict 13–22g/m² density to balance user comfort with high-wet-strength durability.

- Fiber Performance: Short-fiber recycled options are available, but our virgin long-fiber tech offers superior dissolution without leaving residue.

Professional buyers should prioritize products labeled for rapid dissolution over generic eco-claims. Choosing the right material density prevents the “clumping” effect common in thick, multi-ply luxury rolls that often plague older plumbing infrastructure.

Are Multi-Ply Luxury Rolls Risky for Old Plumbing Systems?

Thick multi-ply paper risks clogging aging pipes by dissolving slowly. Top Source Hygiene uses engineered virgin pulp to ensure rapid disintegration without sacrificing luxury softness.

Older plumbing systems face structural limitations that clash with dense, luxury paper. Unlike thin alternatives, thick multi-ply rolls often clump when exposed to water agitation. This accumulation creates physical blockages before the fibers can fully disperse through the sewer line.

The Mechanics of Paper Accumulation in Aging Pipes

Aging infrastructure requires paper that reacts immediately to water contact. In vintage buildings, the combination of narrow diameters and restricted flow creates a high-risk environment for standard retail brands.

- Fiber Clumping: High-density layers resist instant disintegration, forming clusters that move slowly through the line.

- Internal Friction: Aging cast iron or clay pipes feature jagged interior surfaces that catch slow-dissolving fibers.

- Hydraulic Force: Low water pressure in many older residential buildings lacks the power required to push dense paper clusters through the main sewer line.

Engineered Rapid Disintegration for Safe Multi-Ply Use

We manufacture luxury rolls that balance high-end softness with infrastructure safety. By controlling fiber length and bonding techniques at our Hebei facility, we ensure the paper breaks down quickly once it clears the toilet trap.

- Material Specification: We use 100% Virgin Wood Pulp with a strictly controlled ply density of 13–22g/m² to balance tensile strength with solubility.

- Regulatory Compliance: Precision perforation and fiber selection ensure our products meet North American and European standards for rapid disintegration.

- Bonding Technology: Advanced ply-bonding maintains layer integrity during use but allows for a quick breakdown once the paper enters the septic system.

- Product Focus: Models like the TSH-2559 are engineered specifically for retail markets where septic safety and plumbing compatibility are primary concerns.

Frequently Asked Questions

1. Is 3-ply septic safe?

Yes, provided it is engineered for rapid disintegration.

While 3-ply is thicker than standard commercial rolls, septic safety depends on fiber length and ply-bonding technology. High-quality 3-ply rolls (like our $13-22g/m^2$ virgin pulp series) are designed to lose structural integrity immediately upon saturation. However, low-grade 3-ply with excessive chemical binders or heavy embossing can clump, posing a risk to older septic systems.

2. How to test flushability?

Professional labs use the “Slosh Box” or “Basket Immersion” tests.

In a B2B context, we evaluate flushability by measuring the time it takes for fibers to fragment under standardized water turbulence. For institutional buyers, the goal is a product that achieves full disintegration in under 10–15 seconds to ensure it clears the “S-trap” and moves through low-flow plumbing without snagging on pipe joints.

3. Does bamboo paper dissolve?

Yes, but often slower than wood pulp.

Bamboo fibers are naturally longer and stronger than hardwood pulp.1 While bamboo is biodegradable, its high tensile strength means it can take longer to fragment in water. For septic-heavy markets, we recommend bamboo-wood blends or specific short-fiber bamboo processing to ensure the paper meets the same rapid-dissolve standards as 100% virgin wood pulp.

4. Why did my toilet clog?

Clogs are usually caused by “wet-strength” imbalance or infrastructure friction.

In high-traffic facilities, clogs occur when paper stays intact too long. This is often due to:

-

Non-flushable additives: Using “wet-strength” resins that prevent paper from breaking down.2

-

Infrastructure issues: Aging cast-iron pipes with internal corrosion that “catch” slow-dissolving fibers.

-

Low-flow toilets: Insufficient hydraulic force to push high-GSM (heavy) paper through the system.

5. What is the jar test?

The “Jar Test” is the industry-standard DIY verification for fiber fragmentation.

To perform it:

-

Place two sheets of paper in a jar half-filled with water.

-

Shake vigorously for 30 seconds.

-

The Verdict: If the paper has turned into a cloudy suspension of fine particles, it is Septic Safe. If large, intact clumps remain, it poses a High Clog Risk for institutional plumbing.

6. Is recycled paper safer for pipes?

Generally yes, but at the cost of user comfort.

Recycled paper contains shorter, “tired” fibers that have been processed multiple times.3 These shorter fibers break apart very easily in water, making them excellent for septic systems.4 However, recycled paper is often scratchier and less absorbent.5 At Top Source Hygiene, we use engineered 100% Virgin Wood Pulp to provide the best of both worlds: the premium softness of long fibers with the rapid-dissolve safety of short-fiber fragmentation.

Final Thoughts

Saving a few cents on inferior paper creates a liability for your clients and a risk to your long-term dealer reputation. Our 100% Virgin Wood Pulp rolls, maintained at a precise 13–22g/m² density, offer the only reliable way to balance luxury softness with rapid disintegration. This technical standard prevents the catastrophic blockages often caused by slow-dissolving retail brands.

Verify our fiber integrity yourself by requesting a sample kit or scheduling a consultation for a trial 40HQ order. We provide full OEM support and private label customization from our Hebei facility to meet specific regional compliance standards. Contact our team to secure your 2026 inventory and protect your wholesale margins with professional-grade hygiene solutions.