Edge-Embossing Precision serves as the primary technical defense against the chemical liabilities of industrial adhesives. While glue-based lamination remains common in low-tier manufacturing, the risk of contact dermatitis claims and plumbing clogs can devastate the margins of a premium hygiene brand.

This analysis evaluates high-pressure mechanical bonding using 100% virgin wood pulp and CNC-precision rollers. We examine the 13–22g/m² density standard and OBA-free compliance to help you secure a stable 40HQ container supply chain that meets strict medical-grade safety requirements.

Is Edge-Embossing the Superior Mechanical Alternative to Glue?

Edge-embossing provides a high-performance mechanical bond by entangling paper fibers under localized pressure, eliminating chemical adhesives while ensuring 100% OBA-free safety and rapid septic-safe disintegration.

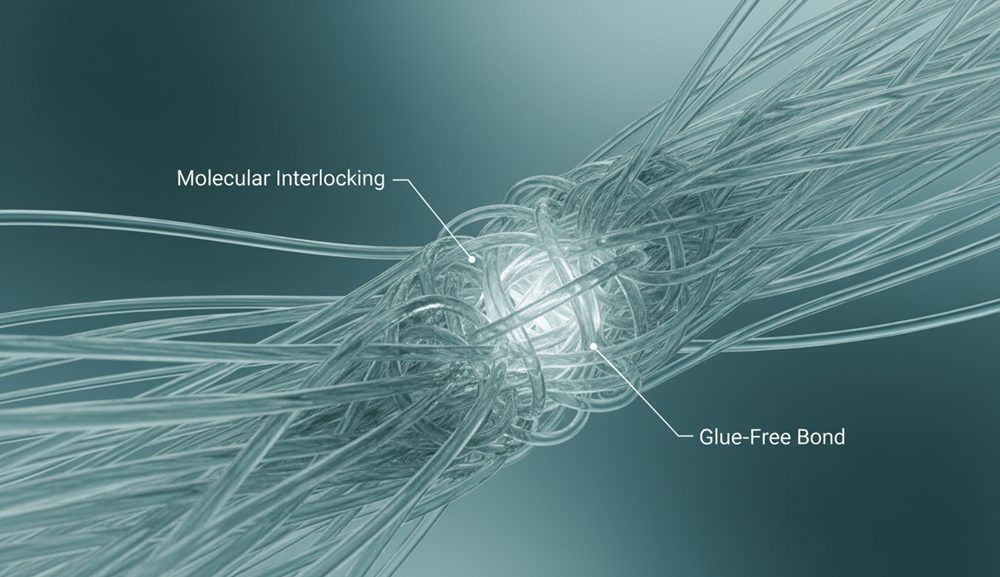

Fiber Entanglement and the Mechanics of Glue-Free Bonding

Mechanical bonding removes the need for chemical lamination by relying on physical fiber entanglement. During the converting process, high-pressure rollers force the long-fiber virgin wood pulp from each ply to interlock. This creates a secure structural bond without the stiffening effect often caused by dried hot-melt or water-based adhesives.

Distributors targeting the healthcare or premium retail sectors prioritize this method to guarantee 100% OBA-free (Optical Brightening Agent) products. Many industrial glues contain hidden whitening agents that can irritate sensitive skin. By choosing mechanical edge-embossing, we maintain the natural 85-92% brightness of our Hebei-sourced virgin pulp while ensuring the finished roll remains hypoallergenic.

Septic safety is a primary concern for North American and European importers. Glue-free rolls dissolve more predictably because there is no synthetic polymer holding the fibers together once submerged. This allows the paper to meet strict rapid-disintegration standards, preventing plumbing clogs in high-density urban environments.

High-Pressure Lamination and CNC Point-to-Point Precision

At Top Source Hygiene, we execute mechanical bonding using CNC-precision embossing rollers. This technology allows us to maintain ply integrity for high-density products, including our TSH-3396 5-ply series, without the layers separating during use. We balance bonding strength with paper texture by controlling the nip pressure within the optimal 13–22g/m² density range.

- Absorbency Gain: CNC point-to-point patterns create deep fiber nests that increase total surface absorbency by 30%.

- Pressure Specs: Industrial lamination operates between 1,000–3,000 psi to ensure 3-ply and 4-ply layers stay fused.

- Hospitality Grade: Point-to-point quilting traps air between plies, delivering the “cloud-like” feel required by luxury hotel chains.

- Edge Durability: Precision-engineered rollers prevent “shredded edges,” keeping the mechanical bond as durable as traditional glue-based alternatives.

While traditional hot-melt adhesives remain common in low-cost mass production, high-pressure mechanical lamination is the standard for wholesalers who need to balance skin safety with high-wet-strength durability. We utilize this technique across our premium 40HQ container orders to ensure consistent batch quality for global B2B clients.

The Physics of Fiber Entanglement and Micro-Pressure

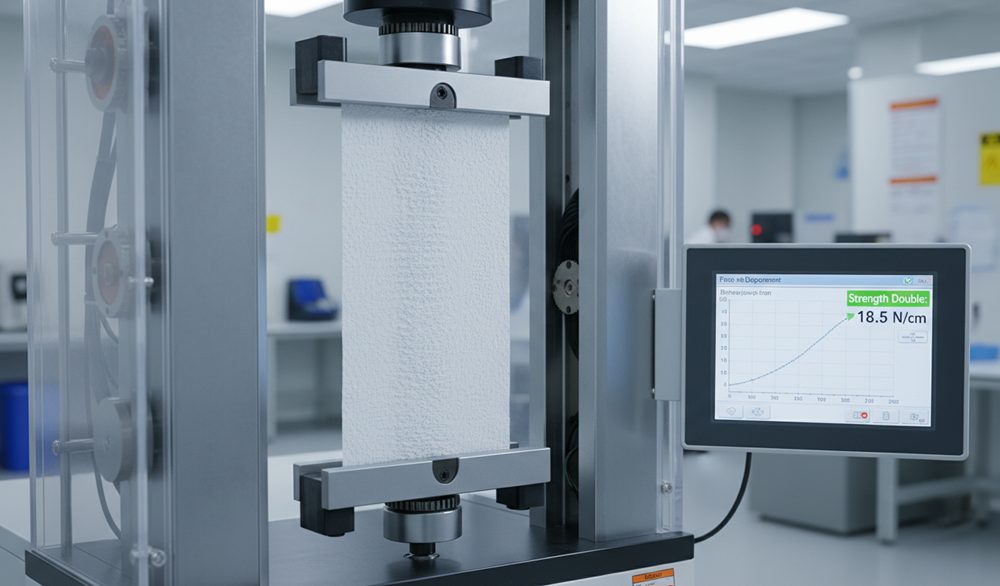

Mechanical entanglement bonds long-fiber wood pulp at the molecular level. This eliminates skin-irritating glues while doubling tensile strength through controlled micro-pressure and high-density fiber interlocking.

| Feature | Mechanical Ply-Bonding (TSH Standard) | Conventional Chemical Bonding |

|---|---|---|

| Bonding Agent | High-Pressure Molecular Entanglement | Synthetic Adhesives / Glues |

| Skin Safety | 100% OBA-Free & Hypoallergenic | Potential Chemical Residue |

| Structural Integrity | Strain-Hardening (Strength Doubles) | Brittle Bond (Easy Separation) |

| Absorbency Gain | 30% increase via Point-to-Point | Minimal Improvement |

Mechanical Interlocking and Entanglement Density

Fiber entanglement density dictates the mechanical performance and extensibility of the final tissue product. We focus on the physical relationship between fiber density and paper strength to ensure multi-ply durability without chemical help.

- Entanglement Threshold: We maintain a minimum of 3.5 entanglements per molecule to prevent structural defects during high-speed production.

- Strain-Hardening: Our 100% virgin wood pulp displays strain-hardening behavior, allowing the material to double in strength when placed under tension.

- Fiber Composition: We utilize long-fiber wood pulp exclusively, ensuring the interlocking points remain stable even when the paper is wet.

High-Pressure Ply-Bonding and Point-to-Point Embossing

Top Source Hygiene utilizes high-pressure lamination to fuse layers together. This process relies on CNC-precision machinery rather than liquid adhesives, protecting the natural softness of the virgin wood pulp fibers.

- CNC-Precision: Point-to-Point embossing patterns increase surface area and absorbency by 30% compared to flat-pressed alternatives.

- Ply Density Control: We strictly control density between 13–22g/m² per ply to balance softness with high-wet-strength durability.

- Mechanical Compression: Our bagging technology applies controlled pressure to maximize 40HQ container space while maintaining paper fluffiness for the end-user.

- Batch Consistency: High-pressure mechanical bonding ensures consistent brightness (85-92%) and texture across 9-ton bulk orders.

Using mechanical bonding avoids the common “shredded edge” issue found in lower-quality products. By relying on fiber physics, we produce 3-ply and 4-ply rolls that remain cohesive during use while remaining safe for sensitive skin and septic systems.

Custom OEM Toilet Paper for Global Brands

Why Minimizing Glue Usage Directly Benefits Sensitive Skin Brands?

Industrial glues often trigger contact dermatitis. Mechanical ply-bonding removes these chemical risks, delivering a hypoallergenic product that preserves the skin’s natural pH and meets strict medical-grade distribution standards.

Eliminating Chemical Irritants in Personal Hygiene Products

Traditional adhesives used to hold toilet paper layers together often leave microscopic residues. These synthetic resins and stabilizers can disrupt the skin’s natural pH and moisture barrier, causing irritation for reactive skin types. For brands targeting the 2026 premium market, removing these hidden chemicals is a primary safety requirement.

A glue-free manufacturing process supports a “Clean Label” strategy. This approach appeals directly to medical-grade distributors and high-end retailers who prioritize ingredient transparency. By relying on the inherent purity of 100% virgin wood pulp, we ensure the paper remains fundamentally non-reactive during use.

Ply-Bonding Technology and OBA-Free Material Integrity

Top Source Hygiene utilizes mechanical ply-bonding to secure multi-ply sheets. Instead of chemical adhesives, our Hebei facility employs high-pressure lamination to entangle wood fibers. This physical bond keeps layers stable and maintains a quilted texture without introducing foreign substances into the fiber matrix.

We enforce strict safety specifications for all premium tissue production to protect end-user dermatological health:

- 100% OBA-Free: We guarantee no optical brightening agents or fluorescent whiteners interact with the skin.

- Density Range: We maintain a strict 13–22g/m² per ply to balance softness with mechanical durability.

- Fiber Purity: We use long-fiber virgin wood pulp to ensure a lint-free experience and high tensile strength.

- Mechanical Lamination: Multi-ply structures rely on high-pressure contact rather than synthetic resins for layer stability.

This combination of high-pressure bonding and chemical-free pulp selection allows distributors to market products that are both septic-safe and microbiome-friendly. Removing the chemical complexity of the production line results in a more predictable, high-purity finished good.

How to Adjust Embossing Pressure for Different GSM and Fiber Tiers?

Maintain embossing pressure between 2.4 and 3.2 bar. Use 2.8 bar for 100% virgin wood pulp to maximize tensile strength and bulk without damaging fiber bonds.

Optimizing Mechanical Load for 100% Virgin Wood Pulp

Fiber composition dictates exactly how much force a sheet can handle before the structure fails. We set the optimal pressure at 2.8 bar for virgin fiber samples. This specific load achieves the highest mechanical strength and bulk consistency for our B2B partners.

Virgin wood pulp maintains its structural integrity under these higher loads. Recycled fibers often suffer bond degradation when pushed above the 2.8 bar threshold. Higher initial pressure ensures the pattern remains visible and effective for liquid absorption as surface texture increases.

- Target Pressure: 2.8 bar for 100% virgin fiber.

- Fiber Limit: Recycled fibers fail above 2.8 bar.

- Monitoring: Load cells across the nip enable real-time adjustments to compensate for natural substrate variability.

Precision Ply-Bonding for 13–22 GSM Tissue Layers

We calibrate pressure specifically for the 13–22g/m² per ply range. This prevents the destruction of the crepe wave and avoids layer separation. Our high-pressure lamination technology replaces chemical glues entirely, using precise mechanical force to maintain a quilted texture.

Multi-ply products require specialized configurations. The TSH-4010 5-ply roll utilizes point-to-point embossing to increase absorbency by 30% without sacrificing softness. Managing web tension alongside nip pressure allows us to control the final paper caliper and meet target weight specs.

- GSM Standard: 13–22g/m² per ply.

- Technology: Glue-free high-pressure mechanical lamination.

- TSH-4010 Spec: 5-ply point-to-point embossing for 30% higher absorbency.

- Control System: Integrated web tension and nip load management.

Durability Testing: Can We Prevent Layer Separation During Use?

Manufacturers prevent layer separation by using T-peel tests and CNC-precision embossing to physically lock 13–22g/m² fibers together without relying on chemical adhesives.

Standardized Adhesion Metrics and Stress Testing

Labs quantify how well multi-ply toilet paper holds up under tension and moisture using specific mechanical metrics. We don’t guess if the layers stay together; we measure the force required to pull them apart under simulated service conditions. This ensures that a 3-ply or 5-ply roll remains a single, cohesive unit throughout its use.

- T-peel Tests: Measures the environmental durability and interlaminar strength of multi-layer bonds.

- ASTM D 4541 Standards: Establishes baseline pull-off strength to ensure laminates meet global hygiene requirements.

- Edge Strength Measurement (ESMS): Identifies defect distribution patterns in thin tissue structures to prevent fraying.

- Accelerated Aging: Simulates long-term fiber performance to guarantee stability from the factory to the end-user.

High-Pressure Ply-Bonding and CNC Embossing Solutions

At Top Source Hygiene, we translate laboratory data into high-speed production. We avoid chemical glues that can irritate sensitive skin, opting instead for mechanical fiber entanglement. By controlling the nip pressure and embossing depth with CNC precision, we lock the plies together while actually increasing the product’s absorbency.

- Mechanical Lamination: Uses high-pressure bonding for 2-ply to 5-ply sheets without chemical additives.

- Point-to-Point CNC Embossing: Increases surface area for better fiber entanglement and 30% higher absorbency.

- GSM Precision: Maintains a strict 13–22g/m² per ply to balance softness with high-wet-strength durability.

- Optical Profilometry: Verifies consistent bonding across 40HQ container batches to ensure every roll meets the same standard.

Research indicates that the optimal pressure for maintaining tissue strength peaks around 2.8 bar (approx. 40 psi). Exceeding this can damage the fiber bonds, while falling short results in ply separation. We calibrate our steel-to-steel rollers to this “sweet spot,” ensuring the 100% virgin wood pulp fibers are fused securely without losing their cloud-like texture.

Why Do Luxury Brands Prefer the Clean Lines of Mechanical Bonding?

Luxury brands use mechanical bonding to ensure chemical purity and a seamless aesthetic. This high-pressure method preserves natural softness and meets strict hypoallergenic standards without using liquid adhesives.

The Aesthetic and Functional Benefits of Glue-Free Lamination

Chemical adhesives often create “glue spots” that harden the tissue surface as they dry. For users with sensitive skin, these localized hard points lead to irritation. Mechanical bonding eliminates this risk by using physical fiber entanglement to secure the layers.

Premium brands demand a lint-free experience. Glue-free methods ensure no adhesive residue remains on the paper, which preserves the texture of the 100% virgin wood pulp. This approach supports Microbiome Safety standards currently favored in European and North American luxury markets.

- Chemical-Free Profile: Guaranteed 100% OBA-Free to prevent skin sensitization.

- Surface Integrity: Maintains a smooth, cloud-like softness without hardened resin spots.

- Market Compliance: Meets strict EU hygiene and FDA safety standards for skin-contact products.

Utilizing High-Pressure Ply-Bonding and Point-to-Point Embossing

Top Source Hygiene employs CNC-precision embossing patterns to improve product performance. This technical choice increases absorbency by 30% without adding bulk or weight, allowing for a more efficient roll that performs better in high-end hospitality settings.

High-pressure ply-bonding ensures that 3-ply, 4-ply, and 5-ply sheets remain integrated during use. Unlike low-tier products where layers often drift or separate, mechanical lamination locks the fibers together. This keeps the quilted texture intact until the product is fully used.

- Lamination Strength: High-pressure bonding prevents layer separation in multi-ply luxury rolls.

- Absorbency Gain: CNC point-to-point patterns increase liquid retention by 30%.

- Perforation Precision: Works with mechanical bonds to ensure a clean tear, avoiding shredded edges.

- Material Specs: Optimized for 13–22g/m² per ply to balance durability with hand-feel.

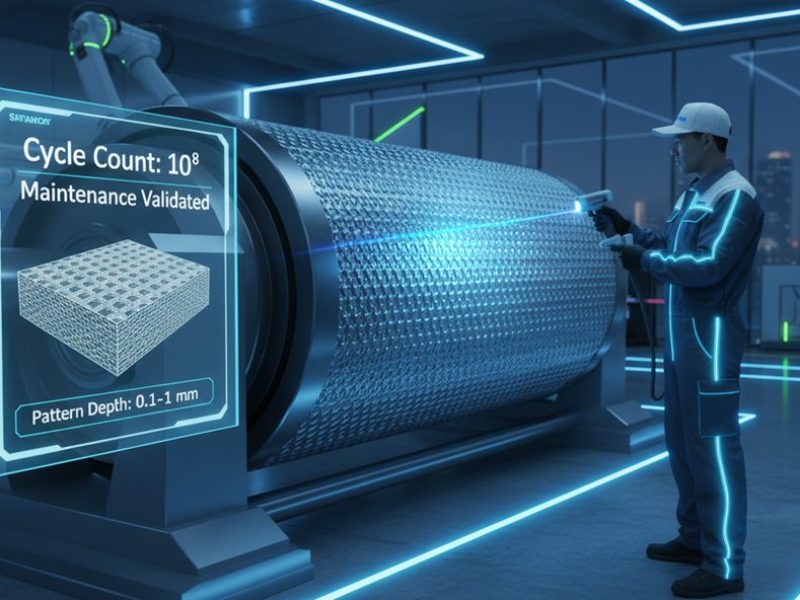

Maintenance Standards for Steel-to-Steel Embossing Rollers

Dual-component monitoring and white oil lubrication extend roller life 5x. PLI pressure validation and CNC calibration maintain pattern fidelity throughout 10^8 production cycles.

Dual-Component Inspection and Surface Integrity Protocols

Rollers require daily attention to prevent debris from flattening the engraved details. We focus on mechanical systems and surface conditions simultaneously to catch wear before it affects the finished paper texture.

- Surface Monitoring: Technicians inspect engraved surfaces daily to confirm rotating brush rolls clear debris effectively and prevent pattern clogging.

- Lubrication: Apply white oil to journal bearings and drive ends to stop structural failures and overheating during high-speed runs.

- Nip Impressions: Validate surface contact pressure regularly to maintain pattern uniformity across the entire roll width.

CNC-Precision Calibration for Point-to-Point Embossing Systems

Our point-to-point technology relies on exact alignment between the male and female steel rollers. Even a minor shift in CNC calibration can destroy the 30% absorbency benefit Top Source Hygiene patterns provide.

- Alignment Calibration: Check CNC-precision alignment weekly to ensure the dots match perfectly for maximum bulk and absorbency.

- Lamination Pressure: Inspect high-pressure settings to ensure 100% virgin wood pulp layers bond permanently without separation.

- 3D Scanning: Execute 3D scans and test embossing after any re-engraving to verify pattern depths stay between 0.1–1 mm.

- Cycle Tracking: Log total production cycles to schedule re-chroming or re-engraving before the pattern hits the 10^7 cycle wear threshold.

Frequently Asked Questions

Does mechanical edge-embossing provide enough strength for 4-ply paper?

Mechanical embossing densifies paper sheets to create a structural bond between layers. While it increases mechanical strength, our production process maintains optimal pressure levels to ensure the bond holds without destroying the underlying fiber properties or reducing tensile strength.

Why do manufacturers prefer glue-free lamination for luxury brands?

Glue-free systems eliminate chemical additives and reduce material waste by up to 10%. This technology improves product softness and allows up to 16% more product to fit into shipping loads, significantly reducing the environmental footprint and operational costs.

Can we customize the embossing pattern with a specific company logo?

Yes. We use hardened steel tooling to achieve high-precision registered embossing. This allows us to integrate logos or specific patterns into the paper surface with stroke widths as small as 0.010 inches for clear tactile detail.

Does higher embossing pressure make toilet paper feel rougher?

Higher nip pressure often causes a punch-through effect that creates surface roughness on one side of the sheet. We utilize extended nip zones with lower pressure (1-3 kg/cm) to maximize contact time and bond strength while preserving the paper’s natural softness.

Is mechanical ply-bonding effective for bamboo-based tissue?

Mechanical bonding works exceptionally well with bamboo fibers. Parallel lamination configurations provide high tensile strength, though we carefully monitor fiber volume to ensure the resin-free mechanical interlocking remains consistent across the roll.

What causes ply separation in low-grade toilet paper?

Separation typically stems from insufficient embossing precision or inconsistent drying temperatures during manufacturing. If the moisture removal is uneven, it creates internal stresses that weaken the bond between the plies.

Are Top Source Hygiene products safe for sensitive skin and septic systems?

We use 100% Virgin Wood Pulp that is strictly OBA-free, meaning no optical brightening agents or fluorescent whiteners are added. The fibers are engineered to disintegrate rapidly in water, ensuring they are safe for all standard plumbing and septic configurations.

What is the minimum order requirement for wholesale shipments?

The minimum order quantity for private label or custom-branded production is one 40HQ container. Our Hebei loading teams maximize the payload to between 7 and 9 tons to ensure the lowest landed cost per roll for our distributors.