Implementing precision tension control science eliminates the mechanical instability that causes high-speed web breaks and costly machine downtime. Fluctuating torque during the rewinding process creates micro-tears and inconsistent roll density, which directly impacts dealer margins and increases customer complaints regarding shredded edges.

Our manufacturing process protects 100% Virgin Wood Pulp fibers by integrating digital servo-driven feedback loops. We synchronize 13–22g/m² ply density with CNC-precision embossing to maintain structural integrity, ensuring that every 40HQ container batch meets the durability standards required by institutional buyers.

The Fragility of Tissue: Why is Tension Management Your Secret Weapon?

Precise tension control prevents micro-tears in wood pulp, ensuring structural integrity during high-speed production without sacrificing softness or final product strength.

High-speed manufacturing turns tissue fragility into a liability if not managed with precision. We use load cell sensors to create real-time feedback loops that measure force changes and adjust motor torque every millisecond. This stability is what keeps a 40HQ container order consistent from the first roll to the last.

Dynamics of Web Stability in Paper Manufacturing

Web stability is the primary defense against machine downtime. When tension fluctuates during rewinding, the paper web experiences mechanical stress that creates invisible weak points. These points eventually fail during consumer use or cause the machine to “snap” the paper mid-run.

Improper tension management leads to three specific production failures:

- Inconsistent Perforation: Tension spikes change the depth of the perforation blade, causing “shredded edges” where the paper refuses to tear cleanly.

- Variable Roll Density: Uneven pull creates rolls that are either too soft to survive shipping or so tight they crush the bulkiness of the fibers.

- Micro-Tear Initiation: High-speed finishing often induces tiny structural breaks that compromise the 13–22g/m² ply strength before the product even leaves the factory.

Maintaining Fiber Integrity with Ply Bonding Technology

Top Source Hygiene utilizes 100% virgin wood pulp because its long-fiber structure provides the tensile strength needed to survive high manufacturing tension. Unlike recycled blends that become brittle, these virgin fibers remain flexible under the pull of servo-driven unwinders.

We protect the material’s premium characteristics through integrated technology:

- High-Pressure Ply Bonding: We fuse layers of 13–22g/m² tissue using mechanical pressure. Precise tension ensures these layers stay bonded without using adhesives that stiffen the paper.

- Brightness Protection: Maintaining a stable web prevents excessive friction. This preserves the 85-92% natural brightness of our wood pulp without needing chemical bleaching agents.

- Embossing Precision: Our point-to-point CNC embossing requires exact web tension to increase absorbency by 30% while keeping the quilted texture intact.

By controlling the “stretch” and “pull” at every stage, we ensure that bulk wholesalers receive a product that feels soft but performs with industrial-grade durability. This technical balance is why our rolls maintain high-wet-strength standards across global markets.

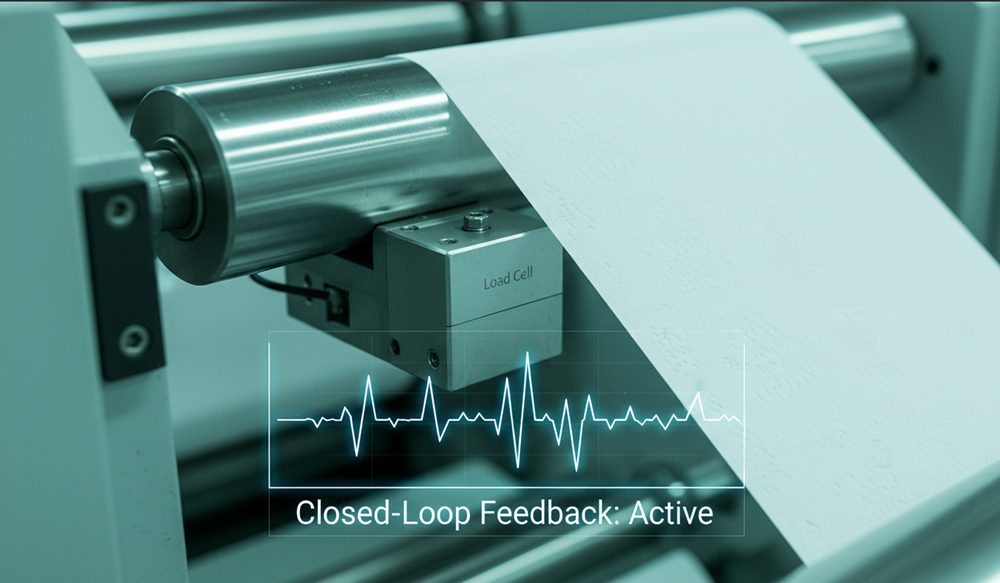

How Load Cell Sensors Create Real-Time Feedback Loops in Rewinding?

Load cells use strain gauges to monitor tension, automatically adjusting motors to prevent paper breaks and preserve the fiber integrity of 100% virgin wood pulp.

| Tension Phase | Sensor Action | Manufacturing Result |

|---|---|---|

| Detection | Strain gauge resistance shift | Precise voltage data generation |

| Adjustment | Torque/Speed setpoint correction | Counteraction of high-speed inertia |

| Optimization | Continuous closed-loop feedback | 40% reduction in material breakage |

Closed-Loop Monitoring and Signal Conversion Mechanics

Load cells function as the nervous system of the rewinding line. They convert physical force into electrical signals through a repeatable three-step cycle that maintains equilibrium during high-speed production. This precision is what separates industrial-grade output from inconsistent retail batches.

- Signal Generation: Internal strain gauges deform under the weight of the paper web, shifting electrical resistance to create millisecond-accurate voltage data.

- Dynamic Correction: The control system uses torque or speed setpoint adjustments to counteract friction and jumbo roll inertia as the diameter changes.

- Breakage Prevention: These micro-adjustments reduce industrial material breakage rates by up to 40%, ensuring the line stays active during high-volume runs.

Maintaining Tensile Integrity in High-Ply Virgin Wood Pulp

Premium tissue manufacturing requires a delicate balance. High-ply products made from 100% virgin wood pulp offer superior softness but remain vulnerable to over-stretching if tension fluctuates. Top Source Hygiene utilizes sensor feedback to protect the structural integrity of these long-fiber materials.

- Ply Protection: Sensors regulate tension for delicate 13–22g/m² plys, ensuring TSH-2559 and TSH-4010 models maintain softness without tearing.

- Lamination Stability: Stable web tension protects high-pressure lamination during ply-bonding, keeping multi-layer sheets securely attached.

- Processing Accuracy: Feedback loops facilitate uniform point-to-point embossing and clean perforation lines across 40HQ container batches for the 2026 supply cycle.

We use this technology to stabilize the web as it moves through the rewinder. By eliminating slack and preventing excessive pull, the machine produces rolls with consistent density and diameter, meeting the strict procurement standards of global wholesalers.

Premium Custom Toilet Paper for Global Brands

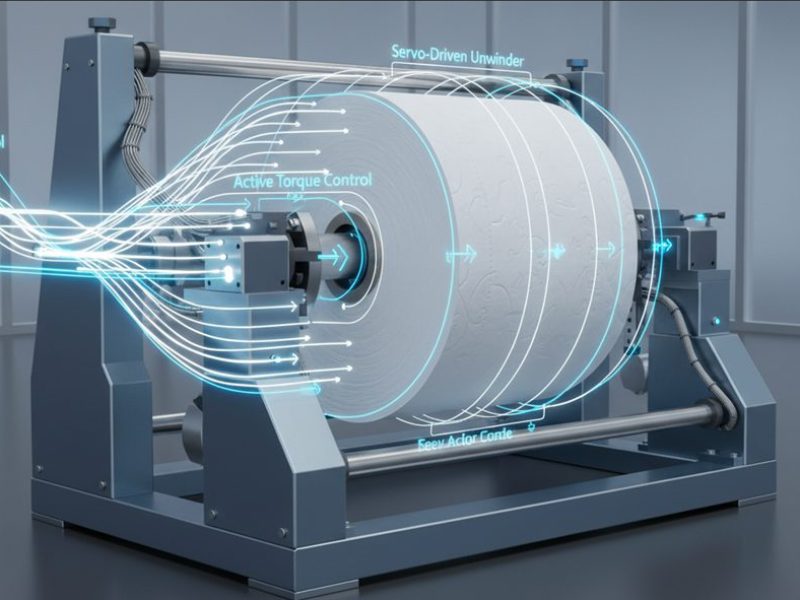

Servo-Driven Unwinders: Compensating for Jumbo Roll Inertia

Servo systems use active torque control and real-time algorithms to manage jumbo roll mass, preventing tension spikes as diameters shrink to ensure stable feeding for high-density paper.

Managing the physical weight of a massive paper roll requires more than simple friction braking. As a roll unwinds, its mass and inertia change every second. Digital servo-driven technology addresses this by using nested control loops that adjust motor torque every millisecond based on direct load cell feedback.

Active Torque Control for Dynamic Mass Management

Passive systems struggle with the heavy mass of industrial rolls, often leading to overruns or web breaks during speed changes. Active servo control prevents these issues by constantly recalculating the required force to keep the web stable.

- Gearbox Optimization: Integrating high-precision gear reduction ratios lowers the reflected load inertia, allowing the servo motor to maintain high responsiveness without mechanical instability.

- Feedforward Logic: The control system uses feedforward commands to anticipate the torque needed during high-speed line starts, eliminating the “jerk” that causes paper snapping.

- Fiber Protection: Our 100% virgin wood pulp features long-fiber structures that handle high tensile stress, but the servo drive ensures rapid stops do not exceed these physical limits.

- Real-Time Adjustments: Current and torque loops operate faster than the eye can see, rejecting external disturbances like splice variations or downstream speed shifts instantly.

Radius Compensation for TSH-JRT08 High-Density Rolls

High-capacity models like the TSH-JRT08 and our 5000g industrial bundles carry immense weight. As the roll diameter decreases, the angular velocity must increase to maintain a constant linear feed speed. Manual adjustments cannot keep up with this non-linear change.

- Continuous Radius Monitoring: Sensors or load-based calculations track the shrinking roll diameter to automatically adjust the motor’s angular velocity.

- Current Scaling: The drive scales electrical current in direct relation to roll weight, which prevents common defects like telescoping or roll wander at low diameters.

- Density Preservation: We calibrate the tension profiles for 13–22g/m² ply density, ensuring the precision embossing on our commercial jumbo tissues remains crisp and uncrushed.

- Torque Curves: Specialized software curves manage the specific inertia profile of 5000g heavy-duty rolls, maintaining constant tension from the first meter to the core.

These digital controls ensure that high-volume distributors receive consistent roll density and diameter across every 40HQ container. By removing the guesswork from inertia management, the production line stays at peak speed without compromising the integrity of the 100% wood pulp fibers.

Does Web Tension Directly Impact Your Perforation and Embossing Depth?

Web tension stabilizes the substrate to ensure consistent embossing depth and clean perforation, preventing fiber elongation that compromises roll bulk and ply bonding.

The Role of Tension in Regulating Bulk and Surface Consistency

Web tension functions as a primary thickness-control factor by stabilizing the paper from the initial unwind stand to the final rewinder. High tension leads to material thinning, which partially offsets the bulk gains achieved through the embossing process. We manage these dynamics to ensure the finished product retains its specified density and hand-feel.

- Structural Uniformity: Consistent tension prevents wrinkles and “baggy edges” that cause uneven depth across the width of the roll.

- Repeatable Results: Stable web dynamics allow our micrometric screws to maintain precise nip pressure for predictable texture results.

- Fiber Stability: Proper management ensures the 100% virgin wood pulp maintains its fiber integrity throughout the converting line.

Optimizing Tension for CNC-Precision Point-to-Point Embossing

Top Source Hygiene utilizes CNC-precision embossing patterns to increase absorbency by 30% without tearing the delicate 13–22g/m² plies. Maintaining tension within strict parameters ensures the long-fiber wood pulp does not stretch, which preserves the cloud-like softness of the quilted texture and prevents GSM weight loss during production.

- Clean Perforation: Precise tension prevents shredded edges, ensuring a smooth tear for the final 2026 retail product standards.

- Ply-Bonding Integrity: High-pressure lamination requires synchronized web speeds to keep layers together during the embossing strike.

- Technical Specifications: We calibrate tension to match the high-wet-strength durability of our 100% OBA-free materials.

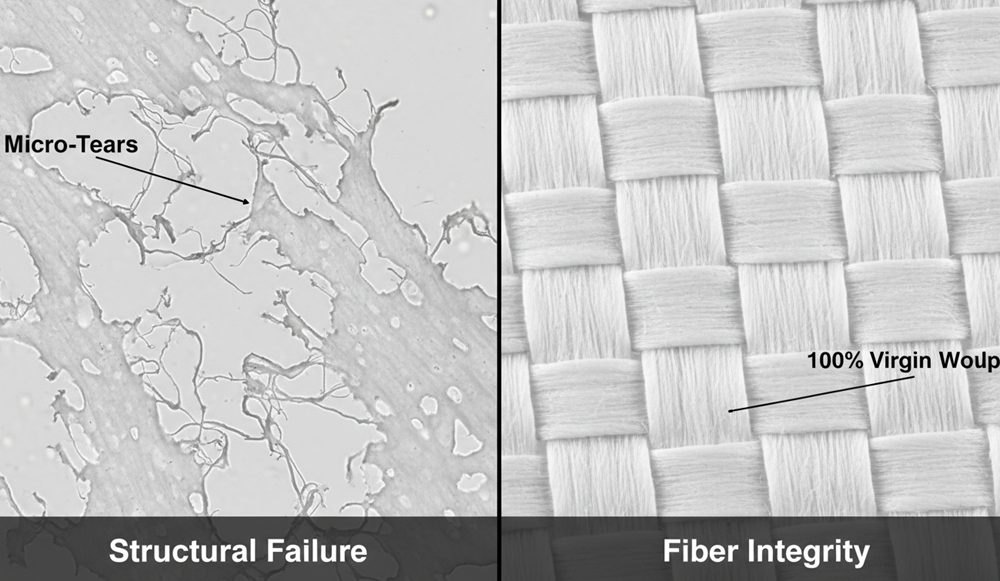

Can We Reduce “Micro-Tears” That Lead to High Customer Complaints?

We eliminate micro-tears by using 100% Virgin Wood Pulp for superior tensile strength and CNC-precision perforation blades that ensure a clean, consistent break every time.

Root Causes of Structural Snapping and Sheet Fraying

Most customer complaints regarding “shredding” or messy tears stem from fundamental flaws in the fiber matrix or the winding process. When the paper lacks structural integrity, it snaps unevenly under the slightest tension.

- Fiber Integrity: Short-fiber recycled materials lack the interlocking strength required to withstand high-speed rewinding tension, leading to fraying.

- Moisture Imbalance: Inconsistent control during the drying phase creates brittle zones in the sheet that fracture before they even reach the perforation line.

- Web Tension Errors: Imbalances during the winding process pull the paper past its elastic limit, causing microscopic structural failures that manifest as tears during end-use.

Precision Perforation and Long-Fiber Tensile Strength

Top Source Hygiene solves these durability issues by focusing on material purity and mechanical precision at our Hebei production hub. We move beyond generic paper standards to provide a predictable, high-strength product.

- 100% Virgin Wood Pulp: We utilize long-fiber integrity to increase natural resistance to shredding, providing a significantly stronger base than recycled alternatives.

- CNC-Precision Perforation: Our lines create exact break points that prevent the “shredded edge” effect common in lower-grade rolls.

- High-Pressure Ply-Bonding: Lamination ensures multi-ply layers remain unified, preventing air pockets that lead to mid-roll splitting.

- Strict GSM Control: Maintaining 13–22g/m² per ply provides the necessary density to support clean tearing without sacrificing the softness customers expect.

- Standard Compliance: All processes meet ISO 9001 and FDA standards, ensuring batch-to-batch consistency for B2B distributors.

How to Scale Production Speed Without Sacrificing Final Tensile Strength?

Scale production by synchronizing extrusion temperatures with 100% virgin wood pulp density and high-pressure ply-bonding to maintain structural integrity at high velocities.

Synchronizing Web Velocity with Multi-Variable Optimization

Simply maximizing machine velocity often degrades tensile strength. Data suggests a performance sweet spot—typically between 50 and 150 units of measure—depending on the specific material density. We reach these speeds by coordinating web velocity with precise mechanical adjustments rather than just pushing the motor limits.

- Thermal Management: Adjusting extrusion temperatures and controlling cooling phases improves material flow and inter-layer consolidation.

- Fiber Orientation: Strategic fiber alignment provides the mechanical reinforcement needed to prevent micro-tears during high-velocity rewinding.

- Dimensional Control: Coordinating layer height with production speed prevents the thinning of the web, ensuring the final product meets 2026 durability standards.

The Impact of 100% Virgin Wood Pulp and High-Pressure Lamination

Top Source Hygiene utilizes 100% virgin wood pulp with long-fiber characteristics. This material foundation allows the paper to withstand intense tension during the rewinding process without snapping, a common issue with low-grade or recycled pulps.

- Ply-Bonding Technology: High-pressure lamination bonds 2-ply to 5-ply layers, ensuring they do not separate during rapid perforation or consumer use.

- GSM Discipline: We maintain a strict density range of 13–22g/m² per ply to balance cloud-like softness with high-wet-strength durability.

- Structural Embossing: Point-to-point CNC embossing increases absorbency by 30% while serving as a physical anchor for the multi-ply sheets.

- Safety Standards: All high-speed production lines maintain 100% OBA-Free (No Optical Brightening Agents) protocols to ensure the final product is safe for sensitive skin.

Training Protocols: Empowering Operators in High-Tension Environments

We train operators to manage 100% virgin wood pulp tensile limits through PLC interfaces, ensuring perforation precision and ply-bonding integrity for high-volume B2B distribution.

Standardizing Competency in High-Speed Web Tension Management

High-speed rewinding at our Hebei industrial hub requires operators who understand the physical limits of long-fiber wood pulp. We move beyond basic machine operation into deep mechanical coursework to prevent micro-tears and material waste.

- Fiber Physics: Theoretical coursework covering 100% virgin wood pulp tensile strength and fiber performance limits.

- Emergency Response: Scenario-based drills for web breaks to minimize downtime during high-speed 40HQ production runs.

- Mechanical Safety: Strict lockout/tagout (LOTO) procedures and hazard recognition for high-torque rewinding systems.

- Regulatory Compliance: Annual competency assessments to verify compliance with ISO 9001 and EU hygiene production standards.

PLC-Guided Calibration for Batch Consistency and Precision Perforation

Batch consistency across large-scale B2B orders relies on exact PLC calibration. Our operators use real-time feedback loops to adjust lamination and embossing parameters, protecting the profit margins of our global distributors.

- Embossing Precision: Training on CNC settings for point-to-point embossing to maintain a 30% absorbency increase across the “Big 10” inventory models.

- Lamination Control: Fine-tuning ply-bonding pressure to prevent layer separation in 3-ply and 4-ply ultra-soft rolls.

- Density Management: Monitoring ply density variables between 13–22g/m² to ensure natural brightness without chemical whitening.

- Visual Verification: Mandatory pre-shipment protocols to guarantee batch color consistency and 100% OBA-free safety for international markets.

FAQ

1. What are the most common causes of paper breaks during the high-speed manufacturing process?

Paper breaks are primarily caused by “Tension Spikes” and “Inertia Mismatch.” When the machine accelerates or a jumbo roll has a slight eccentricity, traditional drives cannot react fast enough. This creates a sudden “snap” force that exceeds the tensile limit of the wood pulp. Additionally, inconsistent moisture levels in the paper can create brittle zones that fail under standard operating tension.

2. How do load cell sensors maintain perfectly consistent tension?

They act as the “Nervous System” of the line. Load cells utilize strain gauges to detect physical force (measured in Newtons or PLI—Pounds per Linear Inch). This data is fed into a PID controller that makes micro-adjustments to the motor speed every few milliseconds. By maintaining a constant “closed-loop” feedback, the system compensates for the shrinking diameter of the unwinding jumbo roll, ensuring the pull-force never fluctuates.

3. Does web tension accuracy affect the final diameter and density?

Absolutely. Tension is the primary lever for “Bulk Management.”

-

Too much tension: Stretches the fibers, resulting in a tight, thin roll that feels hard and “non-premium.”

-

Too little tension: Causes “telescoping” (layers sliding) and loose edges, making the roll unstable for automated packaging and reducing the total paper volume in a 40HQ container.

4. Why is digital servo-driven technology superior to traditional mechanical drives?

Precision and “Radius Compensation.” Mechanical drives rely on belts and gears that have “backlash” and wear over time. Digital servos use Absolute Encoders to track position and torque with 0.01% accuracy. Servos can execute complex “Torque Curves,” meaning they can automatically increase the motor’s angular velocity as the jumbo roll empties, keeping the linear feed speed perfectly stable without human intervention.

5. How can a manufacturer prevent “over-stretching” that thins the GSM?

By maintaining tension within the “Elastic Zone” of the fiber. If the tension exceeds the yield point, the paper undergoes plastic deformation, permanently thinning the GSM (Basis Weight). We prevent this by calibrating our PLC to the specific tensile profile of 100% Virgin Wood Pulp. We use “Soft Starts” and regulated nip pressures to ensure the paper “relaxes” into the rewinder, preserving the original 13–22g/m² density.

6. What happens to the embossing pattern if tension is too high?

You lose 30% of your absorbency and visual “Pop.” If the web is under excessive tension, the paper is pulled flat against the embossing rollers. This prevents the fibers from fully seating into the CNC-precision Point-to-Point cavities. The result is a shallow, faint pattern that lacks air pockets. For the end-user, this means the tissue feels rougher and fails to trap moisture effectively.