Bridging the softness gap is the primary technical challenge for hospitality buyers protecting luxury brand equity. Failing to distinguish between high-purity virgin fibers and recycled blends often leads to contract cancellations and negative consumer feedback regarding skin irritation.

We solve this by benchmarking production against the 100% OBA-free virgin wood pulp standard and 13–22g/m² ply density calibration. Our findings focus on optimizing TSA scores to ensure consistent hand-feel across 40HQ bulk orders for professional wholesalers.

The Role of Eucalyptus Fiber in Achieving Premium Softness

Eucalyptus fiber uses a rounded cellulose structure to reduce skin friction. Top Source Hygiene blends these high-purity fibers with 100% virgin wood pulp for a naturally silky, lint-free finish.

Natural Cellulose Smoothness and Surface Friction Reduction

Eucalyptus fiber stands out because of its molecular geometry. These fibers possess a naturally smooth, rounded surface that allows the tissue to glide over skin. Unlike the more textured profiles found in bamboo or the variable quality of cotton, eucalyptus minimizes mechanical friction. This structural advantage makes it the preferred choice for premium tissue products designed for sensitive skin.

- Glide Performance: Rounded fiber surfaces reduce abrasion on the skin’s surface compared to jagged or textured fibers.

- Material Comparison: Provides a silkier hand-feel than bamboo, which often retains a more fibrous or “toothy” texture.

- Pilling Resistance: High fiber integrity ensures the softness lasts during use without the material breaking down into lint or pills.

- Closed-Loop Processing: Manufacturing methods preserve the natural smoothness of the fiber, eliminating the need for temporary chemical softening agents.

Integrating Long-Fiber Virgin Wood Pulp for Texture Consistency

At Top Source Hygiene, we combine eucalyptus properties with strict 100% virgin wood pulp standards. We source high-purity long fibers from the Hebei industrial hub to ensure every roll meets B2B quality benchmarks. By avoiding recycled content, we maintain the tensile strength needed for multi-ply products without sacrificing the “cloud-like” feel buyers expect.

- Irritation Prevention: We use 100% OBA-free pulp, ensuring no fluorescent whiteners or chemical residues contact the skin.

- Tensile Strength: Long fibers from our North China sourcing hub provide a durable structure that resists tearing when wet.

- Lint-Free Experience: The absence of recycled waste prevents “dusting,” a common complaint in lower-grade commercial tissues.

- Natural Brightness: We achieve an 85-92% brightness level through careful fiber selection rather than harsh chemical bleaching.

Why Does Bamboo Tissue Often Feel “Scratchy” to Consumers?

Roughness in bamboo tissue is typically caused by low-quality manufacturing or chemical residues, not the fibers. High-grade bamboo uses smooth, long-fiber structures and advanced embossing for premium softness.

The Misconception of Plant Rigidity and Fiber Processing

Consumers often associate bamboo with the rigid material used in scaffolding, furniture, and flooring. This creates a psychological bias where users expect the tissue to be stiff or abrasive. In reality, the “scratchiness” people report rarely comes from the plant itself. It is almost always the result of cost-cutting measures during production or poor material selection.

While bamboo fibers are naturally longer and stronger than wood pulp—which provides excellent durability—they require specific softening techniques to achieve a luxury hand-feel. When manufacturers skip these steps or use low-ply counts, the paper feels thin and rough. Unlike low-quality recycled wood pulp, which contains short, jagged fibers that break easily and irritate the skin, high-purity bamboo remains lint-free and smooth when processed correctly.

Friction and irritation are frequently caused by these three factors:

- Chemical Additives: Harsh bleaching agents or artificial fragrances can cause micro-inflammation on sensitive skin, which users perceive as a “scratchy” texture.

- Fiber Blending: Mixing high-quality bamboo with short-fiber recycled waste creates a surface with uneven friction points.

- Low GSM (Grammage): If the ply density is too low, the paper lacks the “cushion” needed to protect the skin during use.

Improving Texture Through Point-to-Point Embossing and OBA-Free Standards

We solve texture issues at the engineering level. For 2026, premium bamboo tissue standards rely on CNC-precision Point-to-Point embossing. This technique creates micro-pockets of air between the layers, which increases the “loft” or thickness of the tissue. This added bulk acts as a shock absorber for the skin, significantly reducing surface friction compared to flat or poorly embossed sheets.

To ensure a skin-friendly experience, we adhere to these technical specifications:

- 100% OBA-Free Material: We guarantee zero Optical Brightening Agents, preventing the chemical-induced sensitivity that leads to a “harsh” feel.

- Ply Density (13–22g/m²): We strictly control the weight per ply to balance structural strength with tactile softness.

- High-Pressure Ply-Bonding: We use mechanical lamination to fuse layers without adding stiff adhesives, keeping the final product flexible.

- Precision Perforation: Clean-cut lines prevent the “shredded edge” effect that can feel abrasive during use.

By focusing on these mechanical standards, bamboo tissue matches the cloud-like feel of virgin wood pulp while retaining its superior tensile strength. For distributors, this means fewer complaints about “scratchiness” and higher customer retention in the premium and eco-friendly segments.

Leading OEM Toilet Paper Manufacturing Solutions

Measuring Hand-Feel: Wood Pulp’s TSA Score Advantage

TSA technology provides an objective Hand-Feel (HF) score by analyzing fiber stiffness and surface micro-vibrations. Virgin wood pulp consistently outscores alternatives due to its superior long-fiber structure.

| TSA Metric | Focus Area | Virgin Wood Pulp Performance |

|---|---|---|

| TS7 Softness | Micro-surface vibrations | High (Smooth fiber structure) |

| TS750 Roughness | Macro-surface friction | Low (Uniform creping profile) |

| D (Stiffness) | Material rigidity | Optimized (High flexibility) |

| HF Value | Total Hand-Feel score | Superior (Premium market standard) |

Key Haptic Parameters in TSA Measurement

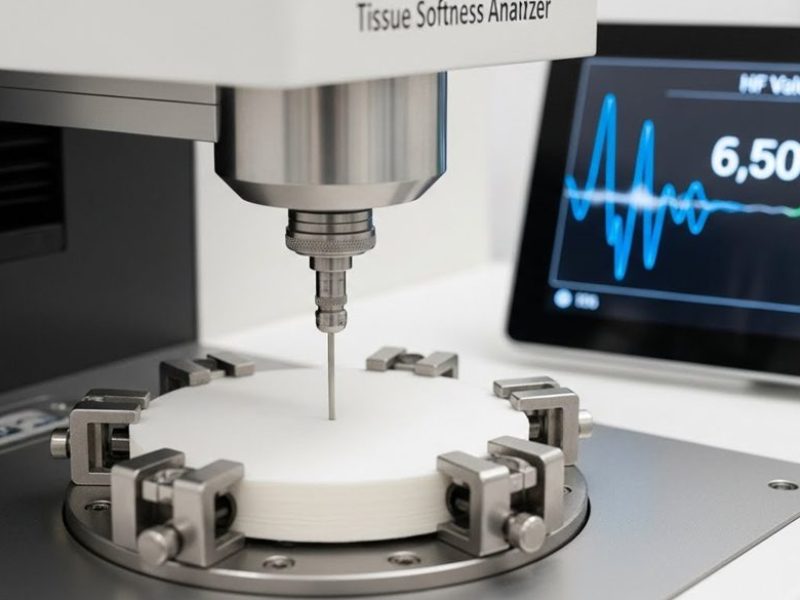

The Tissue Softness Analyzer (TSA) removes human bias from quality control. It uses high-frequency sound analysis and deformation testing to generate data that mirrors human sensory perception.

- TS7 Softness: This parameter detects micro-surface vibrations. It determines fiber stiffness and the smoothness of the surface structure at a microscopic level.

- TS750 Roughness: This analyzes macro-surface variations. It captures the physical peaks and valleys created during the creping and embossing stages of manufacturing.

- D (Stiffness): This measures the in-plane material rigidity. It ensures the tissue remains flexible enough for consumer use while maintaining structural integrity.

- HF (Hand-Feel) Value: The TSA combines all individual parameters into a single mathematical score. This value correlates with human panel assessments with nearly 100% accuracy.

How Long-Fiber Selection Improves Hand-Feel Scores

Material selection directly dictates the final HF value. Top Source Hygiene focuses on specific fiber characteristics in the Hebei industrial hub to ensure consistent TSA performance across all wholesale batches.

- 100% Virgin Wood Pulp: This high-purity base eliminates the scratchy texture common in recycled materials. It provides a naturally smooth foundation for premium tissue.

- Strategic Long-Fiber Selection: Long-fiber wood pulp enhances tensile strength. We use it to maintain a cloud-like softness profile without the paper becoming brittle.

- Ply Density Control (13–22g/m²): Strictly controlling the GSM per ply optimizes the balance between durability and tactile comfort. Too much density ruins the soft feel; too little ruins the strength.

- 100% OBA-Free Manufacturing: We guarantee no optical brightening agents. This ensures that chemical additives do not interfere with the natural smoothness of the wood fibers.

![]()

How Creping Technology Enhances Wood Pulp’s Cushion Effect

Creping uses mechanical force to break fiber bonds and create micro-folds. This expands paper thickness and lowers density, turning flat wood pulp into a soft, springy cushion.

Converting Flat Sheets into Elastic Micro-Fold Networks

The mechanical interaction between the Yankee cylinder and the crepe blade defines the final texture of the tissue. As the wet web adheres to the rotating heated cylinder, it strikes a stationary steel or ceramic blade at high speed. This impact forces the fibers to buckle rather than stay flat.

This process fundamentally changes the sheet structure through three specific actions:

- Energy Transfer: The blade transfers kinetic energy directly into the sheet, disrupting the hydrogen bonds that hold fibers together in a stiff, flat plane.

- Z-Direction Expansion: The impact generates thousands of microscopic folds. These increase the thickness perpendicular to the surface, creating a “bulky” feel.

- Internal Separation: Partial separation of fiber layers reduces overall density, allowing the material to compress and spring back like a cushion.

The resulting network of micro-folds transforms the paper from a rigid surface into an elastic, textured material. This texture is what end-users perceive as “cushiony” softness during use.

Ply-Bonding and GSM Calibration for Sustained Bulk

At Top Source Hygiene, we calibrate the creping process to match specific manufacturing standards. We use 100% Virgin Wood Pulp because its long fibers maintain structural integrity during the creping impact. This prevents the micro-folds from collapsing during the secondary lamination stages.

We manage the cushioning effect through these technical specifications:

- GSM Range (13–22g/m²): We strictly control the weight per ply to ensure the paper remains thick enough to hold a crepe while staying light enough to feel fluffy.

- High-Pressure Lamination: Multi-ply layers are bonded using mechanical pressure. This secures the sheets together without flattening the delicate creped structures created on the Yankee cylinder.

- Fiber Selection: Premium long-fiber pulp supports higher crepe frequency, meaning more micro-folds per inch for a more luxurious hand-feel.

By coordinating pulp quality with mechanical geometry, we produce rolls that meet 2026 hygiene standards for high-bulk performance. This ensures the tissue provides a consistent, high-wet-strength experience without sacrificing the springy texture wholesalers expect.

Can Bamboo Ever Match the Softness of 100% Virgin Wood Pulp?

Modern processing allows bamboo to rival virgin pulp in silkiness, yet 100% long-fiber wood pulp remains the benchmark for consistent, cloud-like plushness in the B2B luxury sector.

By 2026, the gap between bamboo and wood pulp has narrowed significantly. Bamboo is no longer the “eco-alternative” that feels like cardboard. Advanced manufacturing now yields a fiber structure that mimics the smoothness of premium virgin pulp, though the tactile profile remains distinct.

Fiber Smoothness and Density Comparison

Bamboo fibers are naturally long and round. When processed correctly, they create a surface that glides against the skin rather than abrading it. This creates a “silky” feel rather than the “plush” feel associated with wood. The structural integrity of these fibers provides several technical advantages:

- Fiber Structure: Bamboo fibers are naturally longer and smoother than recycled options, providing a texture that rivals premium virgin pulp.

- High Density: The dense nature of bamboo fibers allows for a stronger sheet that resists tearing while maintaining soft surface contact.

- Breathability: Bamboo offers air permeability 3.5 times higher than cotton, improving moisture management and overall skin comfort.

The Role of Ply Density and Long-Fiber Selection

While bamboo has improved, 100% virgin wood pulp maintains its dominance in the luxury hospitality and premium retail sectors. This advantage comes down to how we manipulate long-fiber density to create “loft” or bulk in the tissue. Top Source Hygiene focuses on specific technical metrics to ensure this softness isn’t just a surface treatment but a structural property.

- Controlled GSM: We maintain a strictly controlled density of 13–22g/m² per ply to ensure maximum plushness without sacrificing strength.

- Lamination Tech: Point-to-point embossing and high-pressure lamination bond multi-ply sheets together, eliminating the stiffness found in lower-grade alternatives.

- Purity Standards: Keeping all products 100% OBA-free ensures that the softness comes from fiber purity and mechanical creping, not chemical softening agents.

Wholesalers choose between the two based on the target market’s tactile preference. Bamboo appeals to users seeking a silky, hypoallergenic, and durable feel. Virgin wood pulp, however, remains the primary choice for clients requiring that specific “cloud-like” cushion that high-end consumers expect from luxury brands.

Frequently Asked Questions

1. Why is wood pulp toilet paper softer than bamboo?

It comes down to “Fiber Morphology.” Wood pulp (especially hardwood like Eucalyptus) has shorter, more rounded fibers that create a “plush” or “cushioned” feel. Bamboo fibers are naturally longer and more rigid. While this makes bamboo exceptionally strong, it requires significantly more mechanical processing (like intensive creping) to mimic the natural loft and cloud-like texture of 100% Virgin Wood Pulp.

2. What is the softest type of toilet paper?

A 4-ply or 5-ply roll made from 100% OBA-Free Virgin Wood Pulp with high Eucalyptus content. The softest rolls utilize a combination of:

-

Short-fiber hardwood: For surface smoothness.

-

High-frequency creping: To create micro-folds for elasticity.

-

Point-to-Point embossing: To trap air between layers, creating a “pillowy” effect that reduces skin friction.

3. Is bamboo toilet paper good for sensitive skin?

Yes, due to its natural hypoallergenic properties. High-quality bamboo is naturally anti-bacterial and lint-free. However, for it to be truly safe for sensitive skin, it must be 100% OBA-Free (no optical brightening agents). At Top Source Hygiene, we ensure our bamboo series avoids harsh chemical whiteners, making it an excellent choice for users prone to irritation who still want sustainable material.

4. How can I improve the softness of bamboo tissue?

Softness can be enhanced at the engineering level through three methods:

-

Mechanical Softening: Increasing the “blade impact” during the creping stage to create more micro-folds.

-

Layering: Using a 3-ply or 4-ply configuration to provide more “loft.”

-

PTP Embossing: Utilizing CNC-precision Point-to-Point embossing to create air pockets that soften the overall hand-feel without adding chemicals.

5. Does 3-ply wood pulp feel better than 4-ply bamboo?

It depends on the “Tactile Preference.”

-

3-Ply Wood Pulp: Generally feels more “Plush” and cushioned because wood fibers hold more “bulk.”

-

4-Ply Bamboo: Feels more “Silky” and substantial. Most luxury hospitality buyers in Europe and North America still prefer the 3-ply wood pulp for its classic “cloud-like” cushion, whereas eco-conscious premium brands are shifting toward 4-ply bamboo for its superior strength-to-softness ratio.