Traditional retail packaging is a structural liability in the Amazon ecosystem, where failing the mandatory 3-foot drop test results in immediate inventory disposal and costly prep fees. By January 1, 2026, Amazon will terminate all manual labeling services, forcing sellers to migrate FNSKU application and 1.5 mil polybag compliance upstream to the factory floor or risk total shipment rejection at the fulfillment center dock.

This analysis provides a technical framework for Amazon FBA optimization, navigating the rigorous ISTA 6-Amazon testing protocols and the shift from Tier 2 SIOC to Tier 1 Frustration-Free Packaging (FFP) standards. We evaluate high-volume production economics involving partners like Top Source Hygiene and detail how auditing the 139 DIM divisor can slash fulfillment overhead by over 60% per unit.

Why Traditional Retail Packaging Fails in E-commerce

Retail packaging prioritizes shelf appeal over transit durability. It fails e-commerce because it lacks the rigidity, material thickness, and impact resistance required for automated sorting and multi-drop logistics.

Standard retail boxes rely on palletized transport for stability. In e-commerce, every unit acts as its own shipping container. If a box is not a six-sided Regular Slotted Carton (RSC) sealed with an H-pattern, it often bursts on the conveyor. Retail packs use lightweight materials that collapse under the medium pressure of automated sorting systems.

Structural Vulnerability and the Mandatory 3-Foot Drop Test

Automated fulfillment centers subject packages to intense physical stress. Retail designs optimize for shelf-space efficiency rather than individual transit durability. Most fail the mandatory 3-foot drop test, which simulates falls on sorting machines and delivery trucks.

- Drop Test: Units must survive five 3-foot drops (base, top, longest side, shortest side, and corner) without collapsing.

- Dimensions: Boxes must stay under 25 inches per side and maintain at least 5.9” x 3.9” x 0.9”.

- Weight Limits: Maximum 50 lb. Units exceeding this require “Team Lift” or “Mechanical Lift” labels.

- Sealing: Traditional tape patterns fail; use an H-pattern seal for structural reinforcement.

Material Compliance: Polybags, Cushioning, and Prohibited Fillers

Retailers use thin films and cheap fillers to cut costs. Logistics facilities reject these because they do not prevent leaks or punctures. Non-compliance leads to FBA prep fees or inventory disposal. You must replace common retail aesthetics with specific technical barriers.

- Polybags: Use transparent bags with a minimum 1.5 mil (0.0254 mm) thickness. Openings over 5 inches must include a suffocation warning.

- Cushioning: Fragile items require 2 inches of bubble wrap or foam inserts inside a rigid box.

- Liquids: Double-seal all containers. Products over 16 oz require polybagging even if they have double seals.

- Prohibited Fillers: Do not use Styrofoam peanuts, shredded paper, or biodegradable crinkle wrap. Use air pillows or bubble wrap.

- Inventory Tracking: Use 36-point font for expiration dates. Ensure FNSKU barcodes are scannable without opening the pack.

Retail packaging rarely qualifies for “Ships in Own Container” (SIOC) certification. Without modifications, these packs increase damage rates and shipping costs. Switching to FBA-optimized rigid corrugated boxes prevents the logistics failures inherent in retail-first designs.

ISTA-6 Testing: Passing the “Drop Test” from China

ISTA 6-Amazon testing uses a 10-drop sequence from up to 36 inches to certify packaging for direct shipping, eliminating over-boxing fees and reducing transit damage.

ISTA 6-Amazon.com-SIOC (Ships in Own Container) is a technical protocol that validates packaging specifically for the Amazon fulfillment network. Passing this test proves a product can survive the journey from a Chinese factory to a customer’s doorstep without an additional outer shipping box.

Understanding SIOC and ISTA-6 Classifications

Testing requirements shift based on the physical profile of the parcel. Amazon categorizes these into specific types to determine the level of stress the packaging must endure during automated sorting and transit.

- Type A: Parcels under 50 lbs with a girth under 165 inches.

- Type B: Parcels weighing 50 to 100 lbs.

- Type C: Parcels exceeding 100 lbs.

- Pass Criteria: Zero visible damage to product functionality; minor exterior corner crushing is acceptable.

Novice sellers often ignore these standards, resulting in “over-boxing” fees where Amazon adds a second box at the fulfillment center. Aggregators mandate ISTA-6 compliance to protect margins and ensure guest satisfaction by preventing “Dead on Arrival” returns.

Technical Execution: Drop Sequences and Height Calibration

China-based labs perform a rigid 10-drop sequence using pneumatic actuators. They target the weakest structural points: one corner, three edges originating from that corner, and all six flat faces of the carton.

- 1-9kg Parcels: 76cm (approx. 30 inches) drop height.

- 10-18kg Parcels: 61cm (approx. 24 inches) drop height.

- 19-27kg Parcels: 46cm (approx. 18 inches) drop height.

- Pre-conditioning: 12-24 hours at 26℃ and 38% relative humidity to simulate transit environments.

- Equipment: innDrop pneumatic actuators and 450kg machine weight testers for rotational impacts.

These heights simulate real-world hazards like falling off a high-speed conveyor or tumbling during manual sorting. If the internal product shifts or the corrugated cardboard collapses under medium pressure, the packaging fails. Labs typically use Regular Slotted Cartons (RSC) sealed with an H-pattern tape method to maximize structural integrity during these freefall impacts.

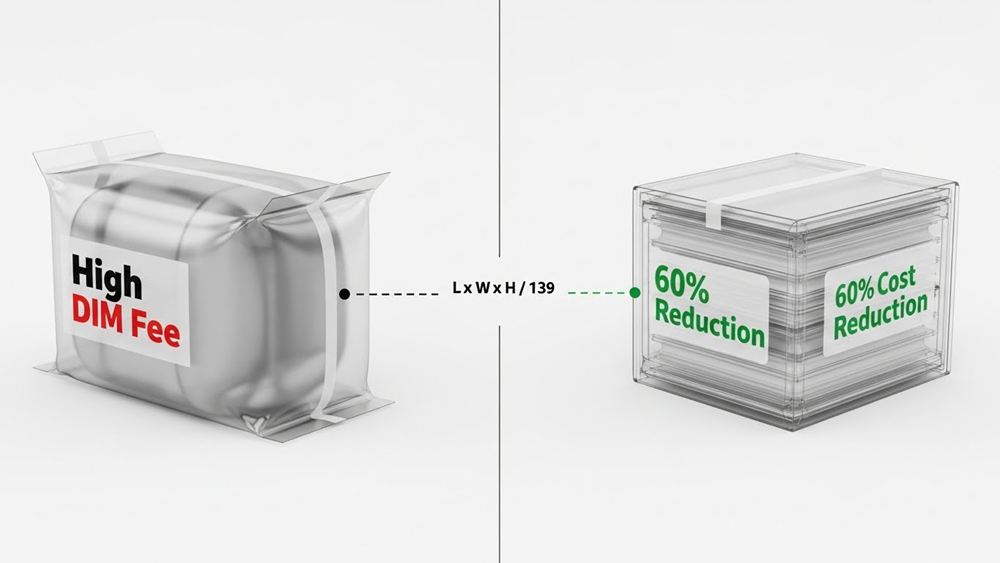

Reducing Dimensional Weight (DIM) Fees via Compression

Amazon bills by volume or weight, whichever is higher. Compression removes dead air to shrink package dimensions, qualifying items for lower size tiers and cutting fulfillment costs.

| Metric | Standard Value / Calculation |

|---|---|

| US DIM Divisor | 139 in/lb |

| EU DIM Divisor | 5,000 cm³/kg |

| Max Box Side (Standard) | 25 inches (63.5 cm) |

| Billable Weight Formula | (L x W x H) / 139 |

The 139 Divisor: Calculating the Financial Impact of Volumetric Air

Shipping air is an expensive mistake in the Amazon FBA ecosystem. Carriers use dimensional weight to ensure they are paid for the space a package occupies on a truck or plane, not just its mass. If your product is light but bulky, the carrier applies a math-based weight penalty that can triple your fulfillment overhead.

- US Divisor: Every 139 cubic inches of package volume equals one billable pound.

- EU Metric: Fulfillment calculations use 5,000 cm³/kg as the threshold.

- Inflation Risk: Air-filled polybags and oversized retail boxes can inflate dimensions by 3x compared to the actual product size.

- Low-Density Penalty: Sellers pay a premium whenever the volume-equivalent weight exceeds the physical mass.

Volume Reduction Techniques and FBA Size Tier Optimization

Optimization is about hitting the “sweet spot” where physical weight and DIM weight match. High-density packing and mechanical compression allow products to drop from expensive “Oversize” surcharges into “Large Standard” tiers. This shift is critical for maintaining margins as Amazon continues to hike storage utilization fees for low-density inventory.

- Vacuum Sealing: Removes dead air from textiles and apparel, often reducing volume by 50% or more.

- Target Box Ratios: An 18x18x16 inch box creates a 38 lb DIM weight; you should fill it to at least 38 lbs of actual weight to maximize value.

- Standard Tier Compliance: Keep all box sides under 63.5 cm and total weight under 23 kg to avoid heavy/bulky surcharges.

- High-Density Methods: Use tight-rolling for paper goods and mechanical compression for soft products to optimize storage utilization metrics introduced in 2023.

Eliminating just one inch from a box’s height can save thousands in annual fulfillment fees across high-volume SKUs. If you aren’t auditing your DIM weight versus actual weight, you are likely overpaying for shipping air.

Your Custom Toilet Paper Brand Starts Here

Frustration-Free Packaging (FFP) vs. SIOC Standards

FFP (Tier 1) mandates 100% recyclable materials and easy-open designs, while SIOC (Tier 2) focuses on shipping durability without Amazon overboxes for larger or heavier items.

| Requirement | FFP (Tier 1) | SIOC (Tier 2) |

|---|---|---|

| Material Type | 100% Curbside Recyclable | Standard Protective Packaging |

| Opening Time | Max 120 Seconds | Not Mandated |

| Minimum Dimensions | 8″ x 4.7″ x 0.375″ | 6″ x 4″ x 0.375″ |

| Overbox Required? | No | No |

Material and Experience Requirements for FFP Tier 1

FFP removes unboxing friction and plastic waste. You must use 100% curbside-recyclable corrugated or paper-based materials. Prohibited components include plastic inserts, filler chips, and paper shreds. Any necessary plastics require specific labeling for consumer recycling clarity.

- Approved Plastics: Must be marked SPI codes 1 (PET), 2 (HDPE), or 5 (PP).

- Opening Speed: Design must allow full access within 120 seconds.

- Tool Restrictions: Minimal use of scissors or box cutters; no “clamshell” plastic heat-sealing.

Technical Specifications and Mandatory Certification Thresholds

Amazon triggers mandatory certification based on package bulk and weight. Engineers must optimize the box-utilization score to meet minimum efficiency standards and pass rigorous physical stress tests. Failure to certify large items results in per-unit financial penalties.

- Mandatory Threshold: Any item exceeding 18″ x 14″ x 8″ or weighing 20 lbs or more.

- Box-Utilization Score: Minimum 50% for non-fragile goods; 30% for fragile items.

- Testing Protocol: ISTA 6-Amazon.com-SIOC (Includes nine drop-shock sequences and random vibration profiles).

- Weight Limits: Maximum box weight is 50 lbs without specialized “Team Lift” labeling.

Source-Side Labeling: FNSKU and Warning Requirements

Amazon ends all labeling services on January 1, 2026. Sellers must apply 1″ x 2.625″ FNSKU barcodes and 1.5 mil polybag warnings at the factory to avoid rejection.

FNSKU Fundamentals and the 2026 Labeling Mandate

FNSKU barcodes, identifiable by their “X” prefix, are the only way Amazon tracks your specific inventory. Without them, your goods are commingled with every other seller using the same UPC, making it impossible to protect your brand or inventory health. The era of paying Amazon to fix your labeling at the dock is ending.

- Hard Deadline: January 1, 2026, is the final cutoff for U.S. FBA prep and labeling services.

- Label Content: Every unit requires a scannable barcode, the exact product title, and the condition (e.g., “New”).

- Inventory Risk: Shipments arriving without source-applied labels face immediate rejection, unplanned service fees, or being marked as “stranded” without reimbursement.

This shift forces sellers to move prep operations upstream. If your factory doesn’t integrate these labels into the production line now, you face significant logistics bottlenecks and cost spikes when the mandate takes effect.

Technical Print Specifications and Warning Standards

Amazon warehouse scanners require high contrast and specific “quiet zones” to function. If your factory uses glossy paper or places labels over seams, the automation fails, and your inventory gets flagged as a defect.

- Label Dimensions: Minimum size is 1″ x 2.625″. The standard range is between 1″ x 2″ and 2″ x 3″.

- Quiet Zones: Maintain 0.25 inches of white space on the sides and 0.125 inches on the top and bottom.

- Polybag Safety: Bags must be at least 1.5 mil thick and transparent.

- Suffocation Warnings: Required on any polybag with an opening of 5 inches or larger.

- Material Specs: Use black ink on white, non-reflective labels with removable adhesive.

Labels must completely obscure any existing UPC or EAN barcodes. Apply them only to flat exterior surfaces—never on corners, curves, or box flaps. These tolerances ensure your inventory moves through high-volume fulfillment centers without manual intervention.

Bundling Strategies: From 2-Pack to 48-Pack ROI

Bundling increases average order value and slashes per-unit fulfillment fees. This strategy secures 30-40% margins while clearing slow-moving stock to protect your Inventory Performance Index score.

Maximizing ROI via Virtual and Physical Bundles

Virtual bundles are the lowest-risk entry point for margin growth. They allow you to group up to five existing FBA ASINs into a single listing without touching physical inventory or paying for new packaging. This setup lets you test market demand for complementary pairings before committing to a factory-level multipack.

Sellers targeting products in the $15 to $50 range often see the best results. By consolidating individual shipments into a single bundle fulfillment, you bypass multiple “pick and pack” fees, directly inflating your bottom line.

- Target Profit Margins: 30% to 40% for mid-tier price points.

- Sales Volume: Ideal for products moving 300-400 units monthly.

- Data Validation: Amazon Brand Analytics identifies “frequently bought together” items for documented $24,000 sales lifts.

Inventory Velocity and Volume Pack Economics

Scaling to large physical bundles, such as 24-packs or 48-packs, is essential for high-demand household goods. This approach leverages the massive manufacturing capacity of facilities like Top Source Hygiene to move volume quickly. High turnover prevents the dreaded 365-day storage fee threshold that kills profitability on slow-moving SKUs.

Physical bundles must meet strict FBA durability standards to avoid rejection at the warehouse. If you are shipping bulk paper products or liquids, the packaging must survive automated handling without leaking or collapsing under pressure.

- Maximum Box Weight: 50 lbs (requires “Team Lift” labels if exceeded).

- Box Dimensions: Maximum 25 inches per side.

- Drop Test: Must pass a 3-foot drop on all sides and corners.

- Polybag Specs: Minimum 1.5 mil thickness with suffocation warnings.

- Cushioning: 2 inches of bubble wrap or foam for fragile items.

Pricing also plays a role in velocity. Use psychological price breaks—pricing a bulk set at $99 instead of $100—to drive conversions. Pairing your “dead stock” with bestsellers as a discounted bundle clears shelf space and improves your overall Inventory Performance Index (IPI) score, unlocking higher storage limits.

Integrating with 3PLs and Amazon Fulfillment Centers

Direct API links between WMS and Seller Central automate inventory syncing and FBA prep, maintaining the sub-1% Order Defect Rate required to avoid account suspension.

WMS and Seller Central: Automating Real-Time Inventory Sync

API connectivity between a 3PL’s Warehouse Management System (WMS) and Amazon Seller Central replaces manual spreadsheets. This link pulls orders and updates inventory levels across sales channels in real time. Tech integration provides the visibility needed to manage stock levels without operational silos.

- Data Flow: Automated shipment plans transfer SKU quantities and fulfillment center assignments directly to the warehouse floor.

- Logistics Proximity: 3PL hubs near major Amazon fulfillment centers in North America and Europe minimize transit times and freight costs.

- Workflow: 3PLs receive inventory, create the FBA shipment plan, pack to spec, and upload tracking data to trigger “in transit” status.

FBA Prep Compliance: FNSKU Labeling and ODR Management

Amazon enforces strict physical standards for inbound goods. 3PLs act as the final quality gate to keep the Order Defect Rate (ODR) below 1%. If the ODR exceeds this threshold, Amazon suspends the seller account. Compliance requires precision in both individual unit prep and bulk palletization.

- Labeling Specs: Mandatory FNSKU application for all items and 36-point font for expiration dates on food products.

- Box Limits: Maximum dimensions of 25 inches per side and 50 lbs total weight; “Team Lift” labels required for boxes over 50 lbs.

- Unit Protection: 1.5 mil polybags with suffocation warnings for openings over 5 inches and 2-inch cushioning for fragile items.

- Durability Standards: Shipping cartons must pass a 3-foot drop test (5 drops) without collapsing or damaging contents.

- Palletization: Stacks must be shrink-wrapped, meet height limits with no leaning, and include accurate Bill of Lading (BOL) documentation.

Traditional retail packaging often fails these requirements because it lacks the corrugated rigidity needed for automated sorting. 3PLs mitigate this by converting retail units into e-commerce-ready packs using H-pattern tape sealing and approved fillers like air pillows, as Styrofoam peanuts are prohibited.

Final Thoughts

Retail-first packaging is a margin killer. While it saves cents at production, it loses dollars through FBA surcharges, DIM weight penalties, and high return rates.

Move all prep upstream immediately. Audit every SKU for ISTA-6 compliance and source-side FNSKU labeling now to beat Amazon’s 2026 prep-service shutdown.

Frequently Asked Questions

What are the specific Amazon FBA packaging requirements for tissue products?

Tissue products require a sealed, transparent polybag with a minimum thickness of 1.5 mil. Any bag opening 5 inches or larger must display a printed suffocation warning. Shipping boxes must be six-sided corrugated cardboard, stay under 25 inches on any side, weigh less than 50 lbs, and pass a 3-foot drop test.

How does ISTA-6 testing ensure paper product safety in the Amazon network?

The ISTA 6-Amazon.com-SIOC protocol simulates 18-inch free-fall drops, random vibrations, and compression. This testing validates that packaging survives Amazon’s automated logistics chain, preventing high return rates and damage-related chargebacks.

Can custom packaging help avoid high ‘Oversized’ FBA fees?

Optimizing dimensions through custom packaging moves products into lower size tiers to slash fulfillment costs. Shrinking a package from the extra-large to the large-bulky tier cuts fees by over 60%. Reducing the longest side from 20 to 18 inches saves approximately $4.44 per unit.

What is the ideal bundle size for household paper products on Amazon?

Amazon Virtual Bundles require a minimum of 2 and a maximum of 5 items. For physical multipacks, keep dimensions within the standard size tier (max 18 x 14 x 8 inches) to maximize ROI and avoid oversized surcharges.

Should tissue products be shipped in poly-bags or corrugated boxes via UPS?

Corrugated boxes are superior. UPS requires rigid packaging and at least 2 inches of cushioning to protect goods. Poly-bags lack the structural integrity to prevent soft tissue products from being crushed during transit.

Will the manufacturer apply FNSKU labels at the factory level?

OEM factories typically handle FNSKU labeling during production. Sellers provide barcodes in 3 1/3 x 4 inch or 4 x 6 inch PDF formats, and the factory applies them to the outermost packaging to ensure the product is ready for fulfillment upon arrival at the Amazon warehouse.