Digital 3D mockups now replace up to 50 physical iterations, accelerating development cycles by 50% and reducing initial prototyping costs by as much as 80%. Despite these efficiencies, relying exclusively on virtual models creates significant brand risk, as digital twins cannot replicate the material weight or tactile fidelity required to serve as an essential quality benchmark for high-volume production runs.

This guide establishes a technical framework for the prototyping lifecycle, from managing cumulative lead times that can reach 26 days to the final sign-off of the “Golden Sample.” We analyze procurement protocols used by suppliers like Top Source Hygiene and outline the testing parameters necessary to maintain ISO 9001, FDA, and FSC compliance across the global supply chain.

The Importance of Physical Samples in B2B Sourcing

Physical samples provide the final tactile validation for texture and durability that digital twins cannot replicate, serving as the essential quality benchmark for high-volume production runs.

Tactile Validation and Material Fidelity

Digital 3D twins now replace 20 to 50 physical iterations, which accelerates development cycles by up to 50%. Even with this efficiency, virtual models cannot communicate the “hand-feel” or material weight. Procurement teams use physical samples as the final checkpoint to verify suitability for bespoke upholstery, industrial textiles, or drapery.

For a sample to be operationally valid, it must mirror the exact technical specifications of the intended production run. Modern B2B protocols require these physical benchmarks to meet specific criteria:

- Material Metrics: Direct evaluation of texture, color accuracy under varied lighting, and GSM.

- Traceability: Samples must match production batch IDs or lot numbers to ensure they accurately represent the final manufacturing quality.

- Performance: Physical testing for durability and material tolerances that virtual simulations might overlook.

The Economic and Logistical Impact of Sampling

Physical sampling carries significant overhead that creates friction in the procurement cycle. Warehousing and international shipping costs accumulate quickly, often causing buyers to hesitate on high Minimum Order Quantities (MOQs). Managing these costs requires lean sampling protocols and reliable supplier lead times.

The financial and logistical data points for sampling include:

- Storage Costs: Monthly fees range from $2 to $5 per unit.

- Warehouse Fees: Large collections typically incur quarterly charges between $200 and $500.

- Stock Lead Times: Suppliers like Top Source Hygiene deliver stock samples in 2 to 3 days.

- Custom Lead Times: Bespoke or custom-designed samples require approximately 10 days for production.

Effective sampling prevents mismatched expectations that lead to costly errors in high-MOQ orders. By validating materials early, companies avoid delayed seasonal drops and protect their merchandising calendars from production instability.

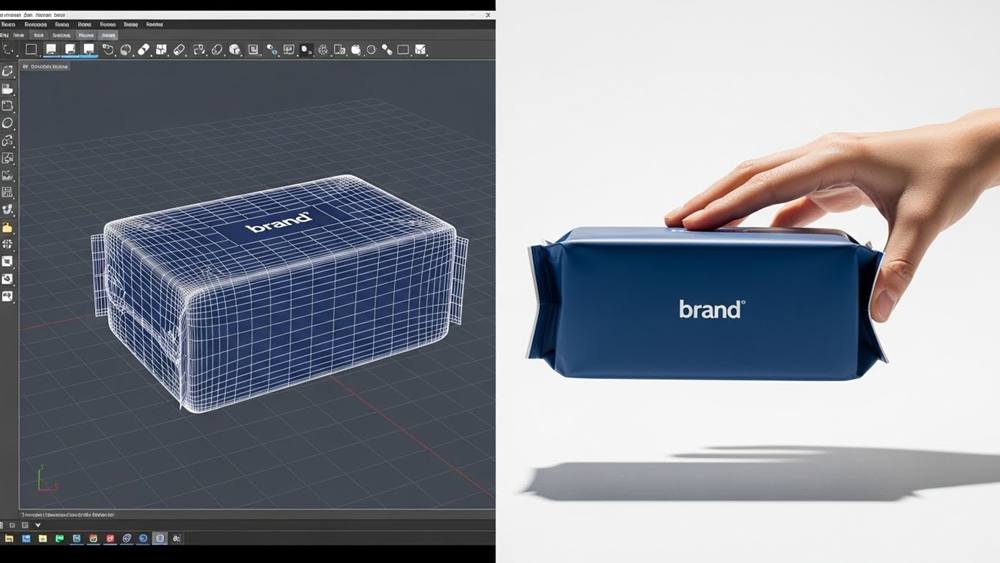

Phase 1: Digital 3D Mockups and Artwork Proofs

3D digital twins replace up to 50 physical samples, cutting production costs by 80% and accelerating development cycles by 50% through early-stage virtual validation.

Digital Mock-Ups (DMU) act as the primary filter for design integrity. Instead of shipping physical prototypes back and forth, engineers use virtual assemblies to interrogate the product structure. This process identifies geometric conflicts and assembly errors before any raw material is wasted or production lines are scheduled.

Virtual Prototyping via Digital Mock-Ups (DMU)

DMU integrates CAD data with metadata to create a master digital standard. This allows for simultaneous loading of native files from different systems, ensuring the virtual prototype matches the intended production output without translation errors.

- Scalability: Supports native 3D CAD data for assemblies ranging from hundreds to millions of components.

- Data Integration: Consolidates Product Manufacturing Information (PMI) and metadata into a single source of truth.

- Performance: Uses triangular patch compression to visualize complex packaging assemblies without hardware lag.

- View Validation: Compares “as-designed” versus “as-planned” views to confirm virtual space allocation.

Technical Analysis and Simulation Parameters

Simulation bridges the gap between a visual sketch and a functional product. By inputting specific manufacturing variables, manufacturers predict how products will behave in real-world commercial environments.

- Automated Functions: Collision detection, wall thickness measurement, and neutral fiber computation.

- Material Math: Volume and surface area calculations to determine GSM (grams per square meter) consistency.

- Operational Inputs: Cycle times, defect rates, Mean-Time-To-Failure (MTBF), and Mean-Time-To-Repair (MTTR).

- Performance Modeling: Validation of kinematics and thermal simulations for hardware like branded dispensers or industrial equipment.

This rigorous digital interrogation reduces the reliance on physical iterations. B2B buyers use these proofs to validate suitability and performance metrics early, stripping out the costs of warehouse storage and unnecessary shipping emissions.

Phase 2: Physical Paper and Embossing Hand-Samples

Hand-samples transform digital designs into tactile prototypes, validating micron-level embossing depths and material durability through rigorous thermal and friction testing before scaling to mass production.

Validating Tactile Quality: The Role of Physical Prototypes

Digital mockups cannot simulate material tension or the way light hits a physical texture. Physical hand-samples bridge the gap between 3D visuals and mass production by allowing teams to check for pattern blur, deformation, or missing corners in the raised design. These prototypes confirm that the paper maintains surface flatness without wrinkling during the pressing process.

- Embossing Depth: Typically 15 to 25 microns (0.25 thousandths of an inch).

- Margin Clearance: Embossed areas must sit 0.25 to 0.5 inches from margins to prevent distortion.

- Sample Timeline: Physical prototypes ready in roughly 10 days to verify GSM and softness.

Engineering the Impression: Technical Specs and Fastness Testing

Engineers use male and female counter dies to sandwich the paper under high pressure. This mechanical bond must withstand friction and moisture without losing pattern definition. Every sample undergoes a battery of stress tests to ensure the finished product survives the logistics chain and end-user handling.

- Die Materials: Engraved magnesium, copper, or brass plates.

- Press Temperature: Up to 200°F (93°C) to set the impression.

- Quality Benchmarks: Friction fastness (white cloth rub test), stretching fastness (tensile resistance), and thermal stability.

- Regulatory Compliance: ISO 9001 and FDA standards to confirm the absence of heavy metals or formaldehyde.

Validating these technical parameters at the hand-sample stage prevents costly rejections during full-scale production runs. If a sample fails the friction or wet stability test, the die pressure or paper coating is adjusted before the master standard is signed off.

Scale Your Brand with Premium, Factory-Direct Custom Toilet Paper

Phase 3: Packaging Prototypes (BOPP/Paper Wrap Trials)

Trials validate BOPP films and paper wraps for moisture resistance, heat-seal strength (≥300g), and high-speed production durability, ensuring product protection and international shipping readiness.

Material Selection: Evaluating BOPP and Eco-Friendly Paper Wraps

Material choice dictates shelf-life and brand positioning. We prioritize Biaxially Oriented Polypropylene (BOPP) for technical performance, while prototyping FSC-certified paper alternatives for brands targeting the sustainable retail sector in Europe and North America.

- BOPP Density: 0.90 g/cm³ for high-yield, lightweight protection.

- Moisture Barrier: Water vapor permeability rates of ≤10 g/m²/24 hours.

- Sustainable Options: FSC-certified paper wraps tested for grease and oxygen resistance.

- Visual Clarity: High-transparency films for premium retail visibility.

Technical Calibration: Thickness, Heat-Sealing, and Durability Specs

Prototypes must survive high-speed automated lines without tearing or losing seal integrity. We calibrate thickness based on the specific mechanical requirements of the bundling and wrapping machinery used in the production run.

- Thickness Ranges: 15-30 µm for flexible household wraps; 30-50 µm for heavy-duty laminates.

- Heat-Seal Strength: Minimum ≥300 g at temperatures not exceeding 180°C.

- Mechanical Resilience: Material stiffness ≥11 mm and biaxial stretch of 300%-400%.

- Regulatory Compliance: All materials meet FDA and EEC hygiene and safety standards.

These trials prevent commercial losses by identifying film failures before the factory initiates a full-scale production run. We verify that the selected gauge can withstand the tension of machine-direction orientation without sacrificing the clarity required for retail shelf appeal.

Managing Sample Lead Times and International Shipping

Total lead times range from 14 to 26 days, combining fixed setup, variable production rates, and transit variability across global regions.

Understanding Fixed, Variable, and Cumulative Sample Lead Times

Manufacturing lead times are mathematical outputs of fixed and variable cycles, not just guessed delivery windows. For paper products, the timeline splits between active processing and unavoidable queue times. Queue and wait times typically dominate the cycle, often exceeding the time spent on actual fabrication.

- Fixed Lead Time: Setup-independent manufacturing portions calculated by scheduling zero-quantity jobs.

- Variable Lead Time: Scales based on production rates; for example, a rate of 10 assemblies per hour results in a 0.0125-day variable offset.

- Cumulative Total: The sum of item processing and maximum component offsets. A 10-day processing window plus a 16-day component wait equals a 26-day total production cycle.

- Product Benchmarks: Stock samples ship within 2–3 days, while custom OEM prototypes requiring specific GSM or ply adjustments take roughly 10 days.

Buyers should calculate the baseline using the formula: Delivery Date minus Order Date. For prototypes, the lot size is usually one, meaning the lead time lot size must match the specific routing to avoid inaccurate delivery projections.

Logistics Management and Regional Shipping Variability

Shipping is the most volatile variable in the B2B procurement cycle. While internal facility processing can be optimized through fast-track lanes with 24–48 hour targets, international transit depends entirely on regional infrastructure and distance from the manufacturing hub.

- North America & Europe: 7–14 days transit.

- Asia & Oceania: 10–20 days transit.

- Africa & South America: 15–25 days transit.

- Digital Substitution: One 3D digital twin can substitute for 20–50 physical samples, potentially reducing shipping emissions and sample-production costs by 50–80%.

Efficient suppliers use lot size matching for prototypes to provide “see it first” windows. This phase also serves as a critical quality checkpoint where samples must match specific batch IDs or lot numbers. This ensures that the prototype accurately represents the final production run according to ISO 9001 and FSC requirements.

Feedback Loops: Adjusting GSM and Softness After Testing

Testing physical samples identifies discrepancies between digital designs and real-world feel, enabling precise adjustments to GSM and ply before committing to mass production.

| Technical Metric | Adjustment Range | Target Performance |

|---|---|---|

| GSM (Grammage) | 13g/m² – 45g/m² | Thickness & Absorbency |

| Ply Configuration | 2-ply to 5-ply | Softness & Tensile Strength |

| Prototyping Lead Time | 10 Business Days | Specification Validation |

The Prototyping Loop: From Initial Hand-Samples to Specification Adjustments

Sourcing teams use physical prototypes to bridge the gap between technical spreadsheets and actual user experience. Digital mockups provide visual data, but they cannot simulate the tactile response of 100% virgin wood pulp or recycled fibers.

- Tactile Evaluation: Testing 100% virgin wood pulp samples to confirm softness aligns with premium brand positioning.

- 10-Day Sampling: Using the custom window to catch hand-feel discrepancies before high-volume runs.

- Regional Standards: Adjusting for African public facility capacity needs versus European eco-friendly requirements.

- Stress Testing: Validating absorbency and durability through physical usage on initial prototypes.

While 3D digital twins can substitute for up to 50 physical samples and reduce initial costs by 80%, the final physical iteration remains the industry standard for verifying texture and weight.

Technical Calibration: Quantifying Changes in GSM, Ply, and Texture

We translate tactile feedback into hard engineering metrics. This phase ensures production stability and protects profit margins by balancing material weight with the perceived luxury required for the target market.

- GSM Optimization: Adjusting grammage to find the peak efficiency between material cost and premium thickness.

- Ply Refinement: Scaling from 2-ply jumbo rolls for industrial use to 5-ply configurations for luxury hospitality.

- Compliance Check: Ensuring all technical tweaks maintain ISO 9001 and FDA hygiene certifications.

- Packaging Fit: Finalizing embossing patterns and wrap dimensions based on the adjusted paper volume.

Suppliers must provide batch IDs and lot verification for these samples. This ensures that the final mass-produced goods match the performance metrics and tolerances established during the feedback phase.

Approving the “Golden Sample” for Production Stability

The golden sample is the definitive pre-production benchmark. It locks material specifications and tolerances into a physical contract, preventing quality drift during high-volume manufacturing runs.

| Parameter | Technical Requirement | Production Role |

|---|---|---|

| Material Specs | Virgin pulp type, GSM, ply thickness | Ensures long-term tactile consistency |

| Dimensions | CAD-defined tolerances | Validates assembly and packaging fits |

| Storage | $2–$5 per unit/month warehouse fee | Maintains physical reference integrity |

Defining the Golden Sample as an Objective Quality Benchmark

The golden sample signals the end of the prototyping phase. It functions as a physical contract between the buyer and supplier. Without a signed, dated master reference, production specifications often diverge, creating “the golden sample trap” where bulk orders fail to meet initial expectations.

- Formal Sign-off: Buyers and factory managers must sign and date the sample to track revisions over the product lifecycle.

- Acceptance Criteria: Documentation defines allowable tolerances and surface imperfections to eliminate subjective interpretation by QC teams.

- Digital Substitution: One 3D digital twin can substitute for 20–50 physical samples, reducing sample production costs by 50–80%.

Technical Rigor and the Dual Sample Protocol for Long-Term Consistency

Physical samples remain critical for evaluating texture, weight, and durability—properties digital files cannot fully communicate. Managing these samples requires strict logistics and technical documentation to ensure every production batch matches the original intent.

- Dual Sample Protocol: The factory keeps one sample for production reference while the external QC team holds a second identical sample to prevent tampering.

- Material Verification: Records include specific batch IDs, lot numbers, and fiber counts for virgin wood pulp or non-woven substrates.

- Regulatory Compliance: Samples must meet ISO 9001, FDA, and FSC standards to maintain global market access.

- Functional Stress Testing: Validates performance under real-world conditions before the supplier starts bulk manufacturing.

While virtual configurations accelerate the buying cycle, physical validation at the “golden” stage remains the final safeguard. High-volume paper and hygiene manufacturers rely on these physical standards to catch quality drift early, preventing costly rework and shipment rejections.

Final Thoughts

Virtual mockups cut 80% of development costs, but digital perfection is often an illusion. Only a physical “Golden Sample” prevents catastrophic quality drift in high-volume, 40-foot container orders.

Finalize 3D designs now to filter errors. Then, secure three signed, dated “Golden Samples” to legally bind the factory to your exact GSM and tactile specifications before mass production begins.

Frequently Asked Questions

How do I request a custom sample for my private label paper brand?

Provide high-resolution artwork at 300 DPI in PDF or JPEG format with outlined fonts. Select your specifications, including pulp type (virgin or recycled), dimensions, and ply. Custom samples take roughly 10 days to produce, while stock samples ship within 48 to 72 hours.

What is the typical timeline for the prototyping process in China?

The full cycle generally spans 2–8 weeks depending on complexity. Paper products move faster, with custom prototypes ready in about 10 days. If you choose sea freight over air express, add 15–45 days to your final delivery schedule.

Are there setup costs associated with custom printing and embossing samples?

Setup fees cover plate creation, color calibration, and press warm-up, usually charged per color. While these are industry standard, Top Source Hygiene provides free samples to qualified B2B clients to verify quality before committing to 40’HQ container orders.

How can I scientifically test the absorbency and softness of a paper sample?

Verify absorbency using AATCC 79-2014 for wetting time and ASTM D4772 for percentage capacity. Evaluate softness through instrumental methods or subjective panel testing to ensure the 100% virgin wood pulp meets hospitality or retail standards.

What is a ‘Golden Sample’ and why is it necessary for production?

A Golden Sample is the final approved version made with mass-production machinery and materials. It acts as the quality benchmark. You should have three copies: one for the buyer, one for the factory floor, and one for third-party inspectors.

How much does it cost to ship samples internationally and how is it calculated?

Express shipping for 1–5 kg parcels costs between $20 and $150 USD. Carriers charge based on the greater of actual weight or dimensional weight (L × W × H / 5000). Many suppliers cover these shipping costs for vetted B2B inquiries.