Septic Safe Toilet Paper: Rapid Disintegration & Plumbing Safety Guide

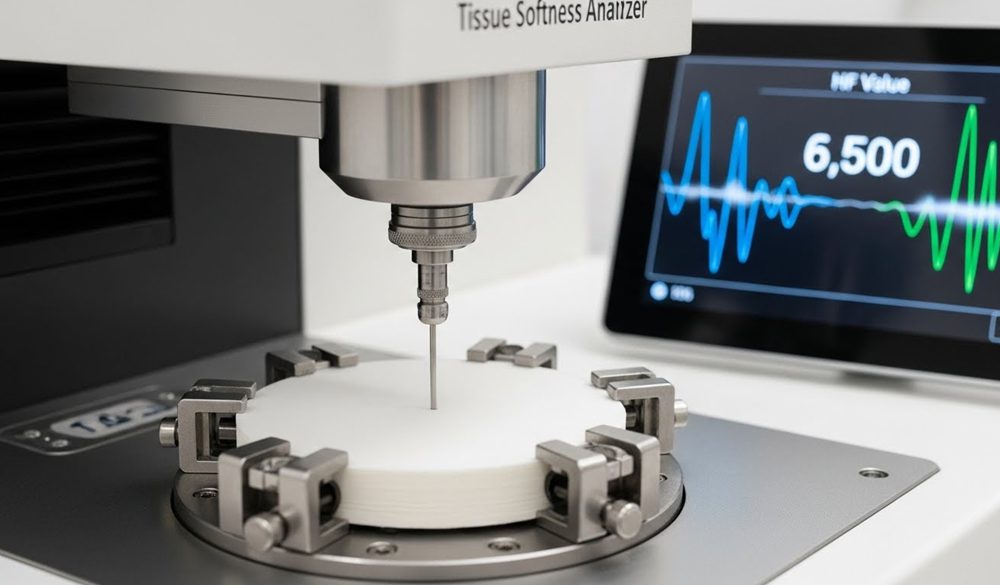

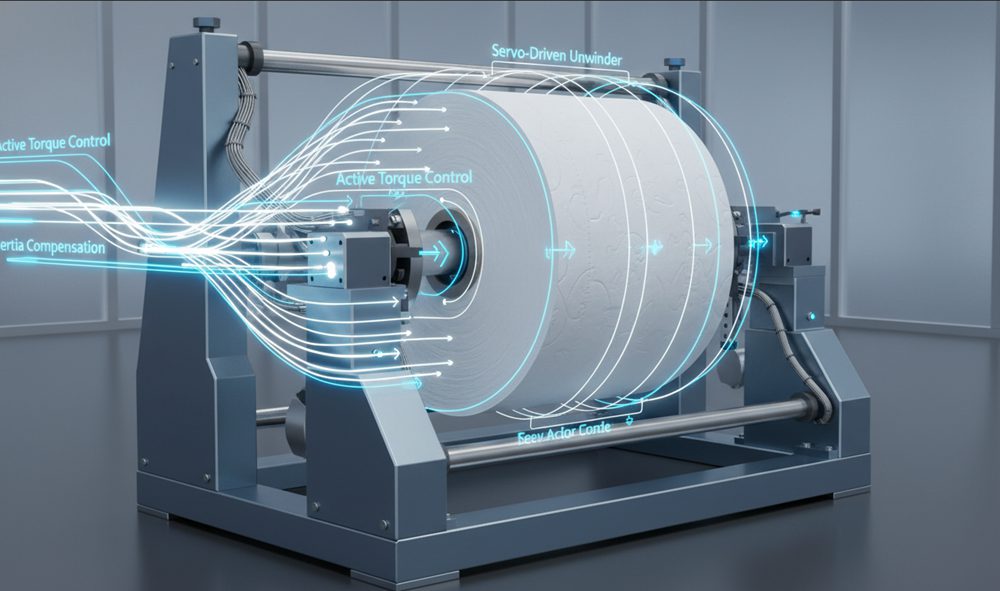

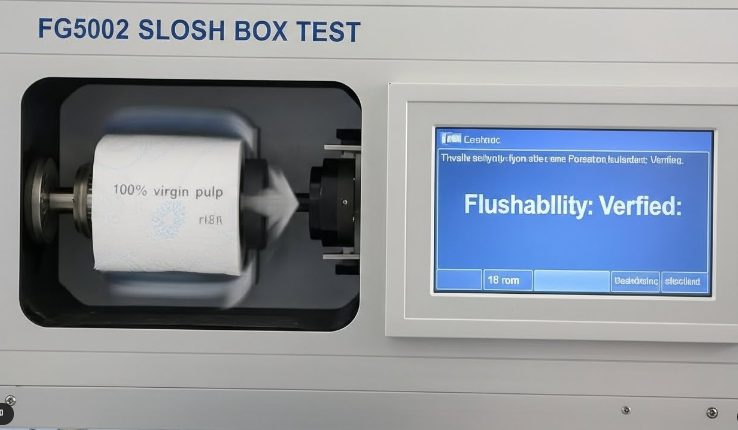

The Physics of Disintegration: Protecting Facility Infrastructure through Engineered Flushability. In high-traffic commercial environments, the wrong choice in tissue grade is the primary driver of plumbing failures and costly emergency repairs. This technical report deconstructs the mechanics of rapid fiber fragmentation in 100% Virgin Wood Pulp, benchmarking it against aging infrastructure requirements. Explore the science behind the FG502 Slosh Box Test, the impact of 13–22g/m² ply density on dissolution speed, and why maintaining a 20-minute disintegration threshold is essential for safeguarding maintenance budgets and tenant productivity in the 2026 global market.