Mastering crepe ratio and bulk is the primary technical threshold for distributors moving away from low-margin, flat-sheet commodities. Improperly managed ratios cause structural snap during converting or produce a coarse texture that alienates premium hospitality buyers. If production engineers fail to balance mechanical expansion with tensile strength, the resulting product loses the volume required to justify premium pricing and professional-grade performance.

Top Source Hygiene benchmarks these processes against a strict 13–22g/m² per ply density standard using 100% Virgin Wood Pulp. We analyze how mechanical bond disruption generates a 350% increase in volume while maintaining the structural backbone needed for high-speed dispensing. This empirical breakdown helps you secure a supply chain that delivers consistent tactile softness without compromising 40HQ container payload efficiency.

Why is Creping Considered the “Mechanical Heart” of Softness?

Creping mechanically disrupts fiber bonds to increase tissue volume by up to 350%, trading raw tensile strength for the superior bulk and skin-friendly softness required in premium hygiene products.

The creping process occurs at the exact moment the paper sheet impacts the stationary doctor blade on the rotating Yankee cylinder. This high-speed energy transfer physically reconfigures the paper’s internal architecture, turning a flat, dense web into a functional tissue product.

Mechanical Energy Transfer and Fiber Bond Disruption

When the sheet hits the blade, the mechanical force breaks the tight hydrogen bonds that hold fibers in a flat plane. This energy-driven delamination is what allows the paper to expand in the Z-direction, effectively “exploding” the structure to create void volume.

- Z-Direction Expansion: The impact transforms a compressed 7–9 fiber layer into a vertically expanded, voluminous structure.

- Absorbency Gains: By disrupting internal bonds, the process creates pockets that increase total liquid absorbency by up to 200%.

- Micro-fold Generation: The blade creates high-frequency micro-folds that establish the base tactile softness before any secondary embossing or converting steps occur.

Balancing GSM Density and Long-Fiber Structural Integrity

Top Source Hygiene engineers maintain strict control over material specifications to ensure the paper web survives this high-impact stage. A sheet that lacks sufficient tensile strength would disintegrate at the blade, while a sheet that is too dense would lose its ability to generate bulk.

- Density Specifications: We strictly maintain 13–22g/m² per ply to ensure the sheet remains durable enough for the creping stage without becoming overly rigid.

- Fiber Selection: We utilize 100% Virgin Wood Pulp long-fibers to provide the backbone needed to survive a 40–80% reduction in total sheet strength during the creping process.

- Targeted Performance: High-density models like TSH-4010 rely on this structural integrity to achieve the thickness and comfort standards expected in luxury hospitality.

- Blade Engineering: Blade geometry is precisely calibrated to control fold frequency, ensuring the substrate meets 2026 global hygiene standards for skin-contact smoothness.

How Does Crepe Ratio Impact Paper Elasticity?

Crepe ratio drives elasticity by breaking hydrogen bonds and forcing fibers to buckle. This creates microfolds that allow the sheet to expand under tension without snapping.

| Physical Property | Impact of Creping Process |

|---|---|

| Bulk/Volume | +200% to +350% increase |

| Absorbency | +200% increase |

| Sheet Strength | -40% to -80% reduction |

| Basis Weight | +10% to +35% increase |

Mechanics of Fiber Buckling and Microfold Frequency

Creping acts as the mechanical heart of tissue production. When the dried paper web impacts the stationary crepe blade, the energy transfer disrupts the hydrogen bonds holding the fibers together. This allows the sheet to expand in the Z-direction, transforming a flat layer into a voluminous structure.

- Bond Disruption: Breaking hydrogen bonds between fiber layers facilitates vertical thickness expansion.

- Fiber Buckling: Mechanical force creates a folded architecture that enables the sheet to stretch and compress.

- Microfold Formation: High-frequency small folds produce a more flexible and softer tissue surface.

The speed differential between the Yankee dryer and the reel determines the frequency of these folds. A higher ratio typically creates larger macrofolds, while lower ratios can be calibrated to produce the finer microfolds required for premium hand-feel.

Leveraging 100% Virgin Wood Pulp for Enhanced Stretch Integrity

Top Source Hygiene utilizes long-fiber 100% Virgin Wood Pulp to withstand the intense mechanical stress of the creping stage. Short or recycled fibers often fail to maintain integrity when the crepe blade forces the sheet to buckle, leading to dust and tearing.

- Material: 100% Virgin Wood Pulp provides the tensile strength necessary for deep crepe folds.

- Density Control: We maintain a strict 13–22g/m² per ply to ensure consistent elasticity across production runs.

- Ply-Bonding: High-pressure technology keeps layers aligned while allowing for mechanical expansion.

Controlling the moisture levels during this process is also vital. By adjusting adhesion uniformity on the Yankee dryer, we maximize “internal stretch.” This allows the paper to achieve elongation values that exceed the base crepe ratio, resulting in a more resilient product for B2B distributors and professional hospitality clients.

Professional OEM Toilet Paper Production Experts

How to Design the “Doctor Blade” Angle for Specific Textures?

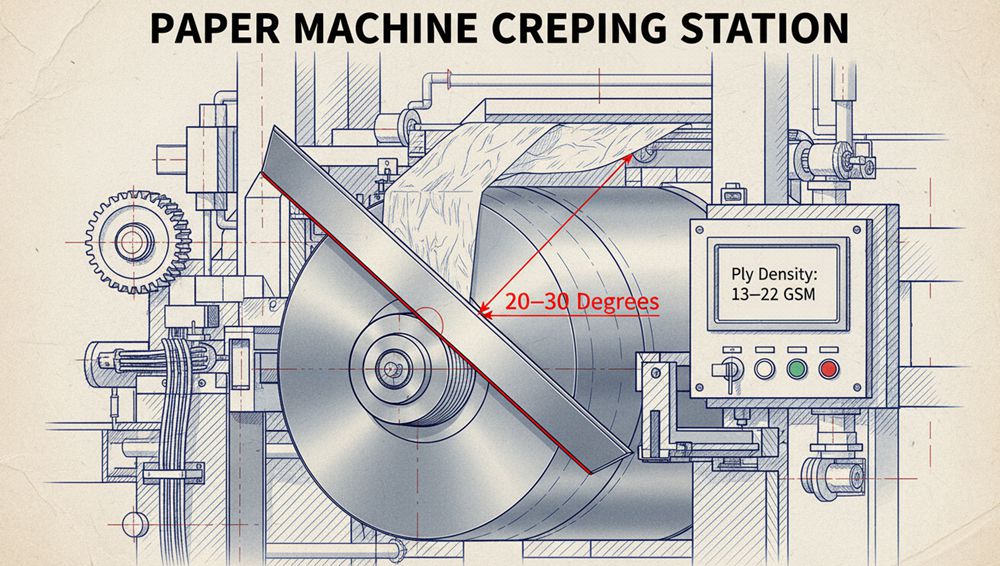

Tissue engineers set doctor blades at 20–30 degrees to optimize creping, directly controlling mechanical impact to define final softness, thickness, and absorbency in high-volume production.

Adjusting the Contact Angle for Surface Softness

The doctor blade serves as the mechanical heart of tissue production. By scraping the paper web from the Yankee dryer, the blade disrupts fiber bonds and forces the sheet to expand vertically, creating bulk and tactile softness.

- Standard Range: Operators maintain a contact angle between 20 and 30 degrees for industrial paper machines.

- Functional Deflection: Blade pressure under load creates a distinct difference between static set angles and functional contact angles during high-speed operation.

- Bulk Generation: Shallow angles generate thicker coatings and significantly increase the bulk of premium tissue rolls.

- Pattern Consistency: Variations in roller diameter and blade wear impact the regularity and frequency of the final crepe pattern.

Matching Blade Precision with 22 GSM Virgin Wood Pulp

High-purity wood pulp requires precise mechanical calibration to maintain long-fiber strength while achieving luxury-grade softness. We synchronize blade settings with specific material weights to ensure consistent output without compromising sheet integrity.

- Load Calibration: Technicians adjust blade pressure for 13 to 22 GSM ply density to avoid tearing the paper web during high-speed runs.

- Material Integrity: Stable angle settings preserve the tensile strength inherent in 100% virgin wood pulp.

- Absorbency Optimization: Precise creping angles combine with point-to-point embossing to increase liquid absorbency by 30 percent.

- Lint Reduction: Maintaining sharp blade edges matched with high-purity pulp eliminates dust and linting during the manufacturing process.

Can We Create More Volume with Less Fiber via Density Control?

Manufacturers increase tissue volume by 200-350% through density control and internal stretch, creating a thick structure with lower basis weight for optimized efficiency.

Creping serves as the mechanical heart of softness and volume. The process transforms a flat, compressed sheet into a high-bulk product by disrupting the hydrogen bonds between fibers. When the paper web hits the stationary doctor blade on the rotating Yankee dryer, the energy transfer forces the fiber structure to expand vertically. This delamination creates the “exploded” texture that B2B buyers and end-users associate with premium quality.

Internal Stretch and Fiber Bond Disruption

The goal is to generate bulk that survives the converting process rather than relying on temporary mechanical stretch. We achieve this by managing how the fibers slip and buckle at the microscopic level.

- Adhesion Uniformity: Consistent coating on the Yankee dryer ensures the sheet adheres firmly, allowing the blade to create a uniform, exploded fiber structure with high void volume.

- Internal Stretch: This mechanism allows fiber-to-fiber bonds to slip and elongate. It increases the physical thickness of the sheet without requiring additional raw material.

- Moisture Optimization: Adjusting creping moisture levels controls the intensity of the fiber separation. Lower moisture increases the sheet’s internal explosion and perceived hand-feel.

Precision Ply Density and High-Capacity Solid Rolls

Density control directly impacts the bottom line for wholesalers. By balancing fiber weight against structural volume, we maximize the paper length per roll while maintaining the high-wet-strength durability required for international hygiene standards.

- Ply Density Standards: We strictly manage density between 13–22g/m² per ply to ensure material savings do not compromise tensile strength.

- TSH-3396 Efficiency: This model utilizes 5000g of high-density paper in a solid (coreless) format to maximize volume and transport efficiency for high-turnover retail.

- Mechanical Compression: Our Hebei facility uses specialized bagging compression to minimize roll bulk for 40HQ container loading, ensuring the lowest landed cost per roll without crushing the paper’s original fluffiness.

This technical approach allows us to deliver 5-ply luxury feel even at optimized weights. By focusing on internal stretch rather than just adding more fiber, we protect dealer margins while meeting the 2026 standards for material efficiency and sustainability.

What is the Synergy Between Creping and Embossing Patterns?

Creping breaks fiber bonds to create foundational volume, while CNC embossing adds 30% absorbency and structural stability. This combination ensures high-bulk tissue remains soft yet durable during use.

How Creping Establishes the Foundational Bulk

Creping serves as the mechanical engine of tissue production. It transforms a flat, compressed sheet into a high-volume substrate by impacting the paper against a stationary blade on the Yankee dryer. This process physically disrupts the hydrogen bonds between fibers, allowing the sheet to expand vertically in the Z-direction. This transformation is necessary to prepare the paper for secondary texturing.

- Bulk Generation: Increases the base sheet bulk by 200-350% through mechanical fiber delamination.

- Wave Formations: Determines the initial elasticity and thickness through the creation of micro and macro folds.

- Bond Disruption: Strategically breaks fiber-to-fiber bonds to reduce sheet strength, optimizing the material’s softness before it reaches the embossing rolls.

CNC Point-to-Point Embossing and Ply-Bonding Stability

Embossing works downstream to refine the raw bulk created during creping. At Top Source Hygiene, we utilize CNC-precision point-to-point embossing to ensure the patterns are functional rather than just decorative. This stage is critical for multi-ply products where structural integrity and liquid management are the priorities. High-pressure lamination ensures these layers stay together without the need for excessive chemical adhesives.

- Absorbency Gain: CNC-precision patterns increase liquid absorbency by 30% compared to unembossed sheets by creating specific void volumes.

- Lamination Integrity: Bonds multi-ply layers, from 2-ply up to 5-ply (such as our TSH-4010 series), ensuring they do not separate during heavy use.

- Thickness Compensation: Calibrated embossing depth fixes the natural loss of thickness that often occurs within the 2026 converting line.

The relationship between these two processes is balance. While creping provides the “cloud-like” volume, embossing provides the “quilted” strength. By coordinating the crepe ratio with the embossing nip pressure, we produce a roll that satisfies the high-end Asian and Middle Eastern standards for thickness while maintaining the rapid disintegration required for North American plumbing.

Frequently Asked Questions

How does the creping process transform flat paper into soft tissue?

Creping acts as the mechanical heart of production. A doctor blade scrapes the dried paper from a Yankee dryer, disrupting hydrogen bonds and creating internal folds. This process increases bulk by 200% to 350% and transforms dense fibers into a three-dimensional, absorbent structure without adding extra material.

Does a higher crepe ratio result in a softer hand-feel?

Not necessarily. While a higher crepe ratio increases mechanical stretch, it often creates a coarser texture. Premium 100% Virgin Wood Pulp tissues often utilize a lower crepe ratio to produce a finer, high-frequency crepe structure that feels smoother and more luxurious to the touch.

Why do 4-ply and 5-ply toilet papers offer better elasticity?

Multi-ply construction creates air pockets between the bonded layers. These pockets provide cushioning and allow the paper to flex under tension. Using long-fiber wood pulp in these layers enhances this elastic quality, making the paper feel thicker and more robust during use.

How do manufacturers increase bulk without increasing the fiber weight?

Production teams use the doctor blade to manipulate the paper structure. By adjusting the impact and pocket angles, they create macro and micro-crepes that expand the sheet’s volume. This structural deformation generates significant thickness (caliper) while maintaining a consistent GSM, ensuring a plush feel without wasting resources.

Is creping the only factor that determines liquid absorbency?

Creping is essential because it increases surface area, but it works as part of an integrated system. We optimize crepe recovery alongside fiber distribution and point-to-point embossing patterns. This combination ensures the tissue can trap and hold liquid effectively, meeting high-traffic commercial and hospitality standards.

How is tensile strength maintained when the paper is made extra soft?

Softness involves breaking fiber bonds, which naturally reduces strength. We balance this tradeoff by using 100% OBA-free virgin pulp and precise ply-bonding technology. Engineers calibrate embossing pressure to reach the ‘sweet spot’ where the paper remains gentle on sensitive skin while retaining the tensile strength needed for high-speed dispensers.