In high-capacity manufacturing, custom embossing engineering is a strategic lever for material optimization that can reduce raw fiber weight by 5-10% without sacrificing perceived roll diameter or tactile softness. Achieving this structural “bulk” requires rigid adherence to material constants—ranging from 0.20 for aluminum to 2.00 for stainless steel—and specifying press capacities at 150% of calculated tonnage to prevent mechanical stalling and ensure pattern permanence in high-wear environments.

This article analyzes the mechanical evolution of nested vs. point-to-point systems pioneered by Ernst Nystrand (PCMC) and Charmin (P&G), while providing technical benchmarks for ISO 12625-4 tensile strength standards. We examine the 3D CAD design logic required for custom roller production, covering parametric mapping, 4th-axis CNC machining, and the selection of magnesium or brass dies to maintain a strict 0.015-inch geometric tolerance across 2,860-ton monthly production cycles.

Why Embossing is More Than Just Aesthetic

Embossing uses male-female dies to permanently deform substrates, increasing structural integrity and surface area while ensuring marks withstand high-wear environments through precise tonnage calculations.

Functional Material Deformation and Structural Integrity

Manufacturers use male-female dies to physically displace material rather than applying surface ink. This creates raised characters that resist environmental wear and maintain legibility in harsh conditions. In paper and textile production, this deformation increases the material’s “bulk,” which improves absorbency and reduces fiber costs for OEM products.

Achieving sharp definition on thicker substrates requires a “semi-coining” technique. Engineers double the total calculated pressure to force the material into the die cavities completely. To prevent structural failure, they use locating pins larger than the marking piece to maintain strict alignment and prevent cracking during high-pressure deformation.

Technical Parameters: Tonnage, Die Selection, and Material Constants

Engineering success depends on matching press capacity to material physics. You must spec a press that provides at least 150% of the calculated embossing force to ensure consistent formation across long production cycles. The required tonnage scales based on the substrate’s hardness and thickness.

- Material Constants: Aluminum (3SO) at 0.20, Steel at 1.00, and Stainless Steel at 2.00.

- Magnesium Dies: Cost-effective for short runs; available in 1.63mm to 7mm thicknesses.

- Brass Dies: CNC-engraved for high-detail longevity and precise edge definition.

- Mechanical Limits: Maximum character height, minimum stroke width, and character spacing must all remain at 0.015″ to facilitate material flow.

Selecting the right die material involves balancing run length against detail requirements. While magnesium works for basic etching, brass and copper provide the heat retention and hardness necessary for high-definition CNC engraving. These technical choices ensure that functional marks like serial numbers and logos remain permanent throughout the product’s lifecycle.

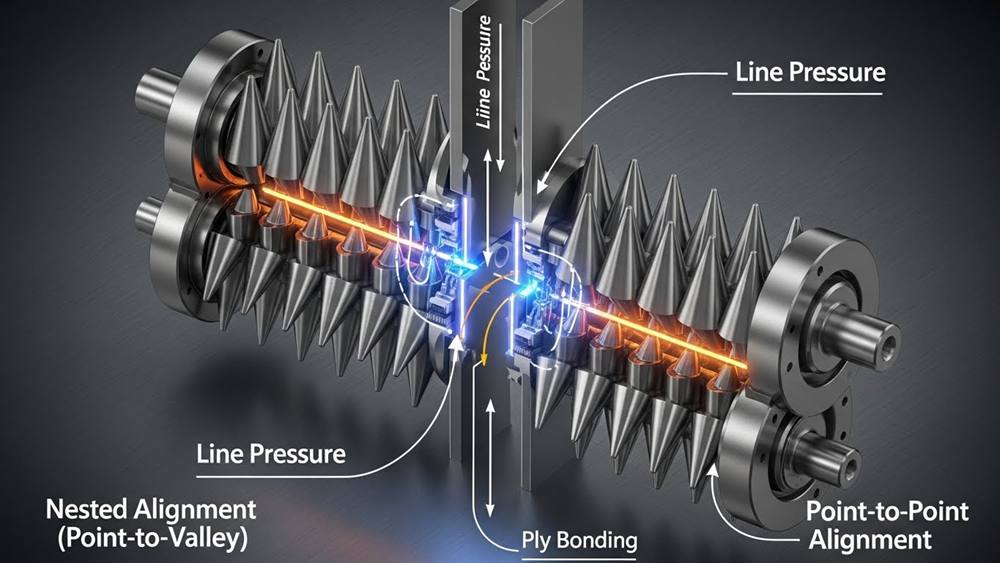

Nested vs. Point-to-Point Embossing Mechanics

Nested embossing uses point-to-valley alignment for higher bulk and operational tolerance, while point-to-point relies on direct protrusion contact for superior pattern definition and bonding strength.

The Mechanical Distinction: Phased Alignment vs. Direct Compression

Ernst Nystrand (PCMC) engineered nested embossing in the 1970s as a mechanical alternative to the P&G “Wells” point-to-point patent. This development shifted the industry toward point-to-valley configurations, allowing for high-speed production without the extreme precision requirements of direct protrusion contact.

- Alignment Logic: Nested rolls fit protrusions from one roll into the recesses of another; Point-to-Point (PTP) matches protrusions directly through the web.

- Operational Tolerance: Nested systems use phased roll synchronization to absorb minor registration errors while maintaining ply lamination.

- Functional Output: PTP yields superior bonding strength and high-definition aesthetics; Nested prioritizes cushion, hand-feel, and fiber efficiency.

Engineering Benchmarks: Pressure, Nip Length, and Protrusion Depth

Advanced embossing performance relies on the interplay between engagement depth and peak pressure. Modern nested configurations, such as MarryShoe systems, use shoe-press mechanics to extend the nip zone and reduce fiber damage during high-speed runs.

- Engagement Depth: Deep-nested embossing requires a protrusion engagement depth exceeding 1.016 mm (0.04 inches).

- Nip Extension: Advanced rolls achieve nip lengths of 31.5 mm at 3 kg/cm line pressure, roughly 4x longer than traditional setups.

- Pressure Distribution: Traditional PTP systems exert 0.85 kg/mm² per point; advanced nested tips operate as low as 0.03 kg per tip.

- Production Velocity: Current roll coverings support stable production speeds up to 800 m/min.

- Precision Limits: Standard 500 mm diameter rolls must maintain a deflection tolerance of 0.25 mm per 0.1 mm of error for uniform lamination.

These technical benchmarks ensure that manufacturers can optimize for bulk and absorbency without sacrificing machine speed. While PTP remains the standard for high-detail decorative patterns, nested configurations dominate in sectors where softness and material efficiency are the primary performance indicators.

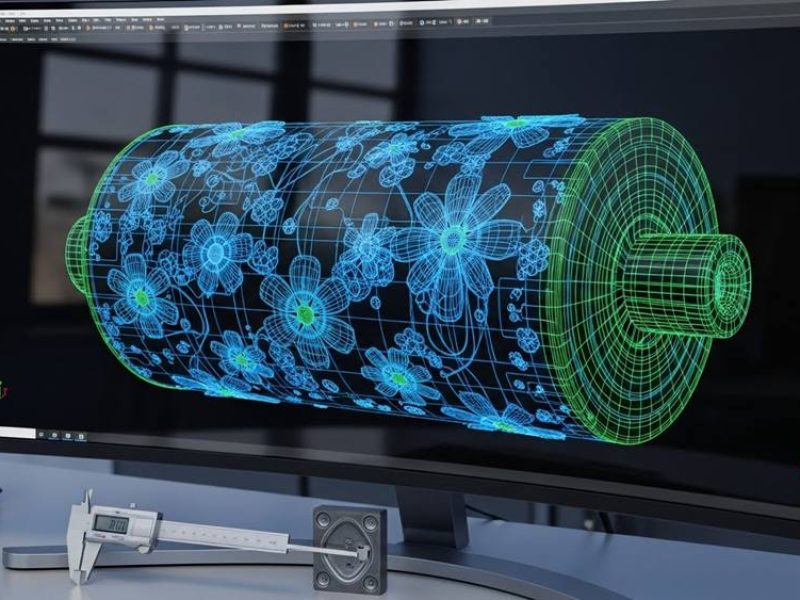

The Engineering of Custom Rollers (3D CAD Design)

Parametric 3D CAD modeling and grayscale-to-surface conversion translate complex textures into precise geometries for 4th-axis CNC machining and high-speed paper production.

| Engineering Parameter | Technical Specification |

|---|---|

| Standard Dimensions | OD: 50 mm | ID: 20 mm | Centerline: 35 mm |

| Wall Thickness | Minimum 6 mm (3 layers at 0.4 mm nozzle) |

| Assembly Tolerances | 0.2 mm radius offset (0.4 mm overall) |

| Embossing Limits | Max height: 0.015″ | Min stroke: 0.015″ |

| Material Constants | Aluminum (0.20), Steel (1.00), Stainless (2.00) |

Parametric Design and Dimensional Logic

Engineers use parametric sketches to define the core structural integrity of the roller. By locking the Outside Diameter (OD) at 50 mm and the Inside Diameter (ID) at 20 mm, the system automatically establishes a 35 mm centerline radius. This mathematical foundation ensures that any change to the roller count—such as moving from an 8-roller to a 12-roller configuration—scales the diameter dynamically to fit the fixed circumference of the machine layout.

Structural durability depends on specific geometry constraints during the CAD phase. For rollers destined for 3D-printed prototyping or heavy-duty CNC milling, engineers maintain a minimum straight section thickness of 6 mm. This thickness accommodates three layers at a 0.4 mm nozzle width, preventing shell failure under the high pressures required for paper embossing.

Texture Mapping and Manufacturing Specifications

Converting flat branding into a cylindrical tool requires wrapping grayscale images into 3D surfaces via Image2Surface add-ins. This process generates the precise peaks and valleys needed for 4th-axis CNC machining. To ensure the final parts fit the OEM production line, CAD files must incorporate a 0.2 mm radius print tolerance. This offset accounts for material expansion and prevents binding in the inner and outer race assembly.

Physics dictates the final tooling design. Total embossing pressure is calculated by multiplying the characters by the tonnage found on character charts, then adjusting for the material constant. Harder substrates like stainless steel require double the force of standard steel. Also, the chosen press must be rated for 150% of this calculated force to ensure clean character formation without stalling the equipment. Key technical specs include:

- Die Materials: Magnesium (short runs), Brass (precise edges/long runs), or Copper (fine detail).

- Geometric Limits: Character height, line width, and spacing must all maintain a 0.015″ minimum to prevent metal fracturing.

- Export Formats: STEP, DWG, SAT, and PDF are required for seamless integration into multi-lane roller layouts.

- Alignment: Locating pins must be larger than the marking piece to ensure perfect male-female die registration.

Build Your Premium Toilet Paper Brand with 30 Years of OEM Expertise

Balancing Surface Texture with Tensile Strength

Embossing enhances texture and bulk but reduces tensile strength. Exceeding 2.8 bar pressure improves softness but risks structural failure and poor machine runnability.

| Material Category | Standard / Protocol | Mechanical Threshold |

|---|---|---|

| Tissue Paper | ISO 12625-4:2005 | 2.8 Bar (Peak Tensile Index) |

| Stainless Steel (304/316) | ASTM A240 | 30–80 MPa (Room Temp) |

| HSLA Steel | ASTM A1011 | 40–90 MPa (Room Temp) |

| Industrial Marking | Process Engineering | ≥1,000 PSI (High Pressure) |

The Inverse Relationship Between Tactile Softness and Fiber Integrity

Softness is never free. Every gain in tactile “hand-feel” or bulk costs you in structural integrity. Embossing patterns fundamentally disrupt the Machine Direction (MD) and Cross Direction (CD) fiber orientation to increase absorption. While this displacement creates the desired texture, it compromises the tensile strength required for high-speed machine runnability. If you push pressure beyond the material’s elastic limit, you risk micro-fractures and structural failure.

- Aluminum (3SO) Constant: 0.20 (Soft material requires lower tonnage).

- Stainless Steel Constant: 2.00 (Twice the force of standard steel).

- Max Character Height: 0.015″ for functional metal marks.

- Warm Embossing: 150–300°C for high-strength steel features.

Metal embossing introduces work hardening. While this increases surface hardness and wear resistance, it simultaneously reduces overall ductility. High-pressure variants exceeding 1,000 psi enable deeper textures but require a press capacity of 150% of the calculated force to account for material resistance and semi-coining requirements.

Technical Quantification and ISO Testing Standards

Calibration requires precision standards to prevent material quality drift. ISO 12625-4 defines the testing of MD and CD tensile strength, often utilizing equipment like the Thwing-Albert VantageNX. Engineers use Ramberg-Osgood modeling to apply stress-strain plastic parameters, predicting how specific materials will behave when subjected to the 14.88–16.14 MD pressure range. These metrics ensure the material survives the converting process without losing its tactile advantages.

- ISO 12625-3:2014: Protocol for thickness and bulk measurement via micrometer.

- ISO 4287: Specifications for quantifying geometrical surface texture.

- ISO 12004-2: Critical standards for setting material forming limits.

- Pressure Calculation: P_min = k * σ_y * ln(t_0 / t_f) (where k = 1.1–1.3).

Tooling choice also dictates the success of this balance. Magnesium dies work for short, economical runs, but high-precision long runs require Brass or Copper. These materials maintain thermal stability and sharp edges, ensuring that even as you push the limits of tensile strength, the resulting surface texture remains consistent across the entire production cycle.

Increasing “Bulk” to Save Fiber Costs

Embossing increases structural volume by trapping air between plies, allowing manufacturers to reduce raw fiber weight by 5-10% without sacrificing roll diameter or perceived softness.

The Mechanics of Air Trapping and Structural Volume

In paper engineering, “bulk” represents the ratio of thickness to weight. High-depth embossing patterns create structural voids between paper plies, physically increasing the sheet’s caliper. This process transforms a standard sheet into a high-volume product by using air as a secondary filler.

The success of this technique depends on the fiber source. 100% virgin wood pulp provides the structural integrity necessary to maintain embossed peaks under the high tension of rewinding lines. Unlike recycled fibers, virgin pulp resists collapsing, ensuring the “hand-feel” remains consistent from the first sheet to the core.

- Die Materials: Magnesium for short-run etching, Brass for CNC-engraved long runs with precise edges, and Copper for high-detail finishing.

- Caliper Expansion: Strategic pattern depth creates the tactile volume of a 4-ply or 5-ply product while maintaining a lower total fiber density.

- Tooling Precision: Die spacing and gaps must be adjusted based on substrate thickness to ensure material flow without cracking.

- Press Requirements: Systems must deliver 150% of calculated embossing force to maintain pattern consistency across high-speed runs.

GSM Optimization for High-Capacity Production

Managing a 2,860-ton monthly production capacity requires aggressive Grams per Square Meter (GSM) optimization. Advanced 3D CAD roller designs allow engineering teams to reduce base sheet weight by 5-10% while preserving the product’s premium tactile standards.

These material savings do not come at the expense of durability. Strict adherence to ISO 9001 and FSC standards ensures that fiber reduction does not compromise the tensile strength or absorbency required for commercial jumbo rolls. Precision engineering ensures the “bulk” remains functional rather than just aesthetic.

- Material Constants: Roller durability is calculated using constants for different metals (Aluminum: 0.20, Steel: 1.00, Stainless: 2.00) to withstand high-tonnage pressure.

- Technical Limits: Maximum character height of 0.015″ and minimum stroke width of 0.015″ for clear, durable markings.

- Compliance Standards: ISO 9001 for quality control and FSC for sustainable fiber sourcing.

- Alignment: Utilization of locating pins larger than the marking piece to ensure zero-defect registration during high-speed production.

Branding via Logo Embossing: Charmin vs. Generic

Logo embossing creates a visual trademark and tactile “bulk” that separates premium brands from generics, increasing customer return rates by 10% in hospitality and retail sectors.

Visual Identity and Consumer Perception in Tissue Branding

Embossing acts as a visual signature. Charmin uses proprietary patterns to signal its “ultrasoft” market position, while generic manufacturers typically rely on simple micro-dots or straight lines to minimize production costs. This visual distinction creates a psychological perception of higher value, even when the base fiber weight (GSM) remains identical to cheaper alternatives.

- Hospitality Returns: Custom patterns drive a 10% increase in guest return rates by reinforcing brand cohesion.

- Satisfaction Scores: ODM services allow private labels to replicate high-end aesthetics, boosting guest satisfaction by 20%.

- Tactile Psychology: Embossed structures increase the physical thickness of the roll, leading consumers to perceive better performance and “bulk.”

Technical Performance: PTP vs. Nested Embossing Mechanics

Point-to-Point (PTP) embossing, pioneered by P&G for the Charmin brand, offers superior liquid absorption. However, this method requires extreme roller synchronization. Most high-volume 2-ply production lines favor Nested embossing because it handles high speeds across 2,860-ton monthly capacities with fewer mechanical failures.

- Tooling Materials: Magnesium for short-run economy; Brass or Copper for high-detail, long-run precision.

- Standard Specs: 2-ply, 450-sheet rolls designed for 4.75-inch core diameter dispensers.

- Force Requirements: Presses must provide 150% of calculated embossing force to ensure consistent 3D structures.

- Operational Efficiency: Optimized roller wear reduces maintenance costs by 15% while maintaining tensile strength in 100% virgin pulp.

Engineering these patterns involves managing material constants. While aluminum requires less pressure, the stainless steel rollers used in tissue production demand specific tonnage to bond plies without compromising the fiber integrity. This technical balance ensures the roll remains soft enough for the consumer but strong enough for high-speed industrial dispensers.

Maintenance and Longevity of Custom Rollers

Standard rollers last 2 to 5 years, requiring reconditioning every 6 to 12 months and monthly lubrication to maintain OEM precision and prevent pattern degradation.

Scheduled Reconditioning and Operational Lifespan

Industrial rollers face high-intensity loads that degrade surface integrity over time. While the mechanical structure may survive up to five years, the embossing pattern begins to lose definition much sooner depending on the abrasiveness of the substrate.

- Standard Lifespan: 2 to 5 years based on load and environment.

- Reconditioning Cycle: Every 6 to 12 months to restore surface integrity.

- Lubrication Frequency: Monthly for ring rollers and high-capacity hydraulic systems.

- Inspection Intensity: High-speed paper manufacturing requires more frequent cycles than light-duty tissue conversion.

Maintaining these intervals minimizes friction and energy consumption. Neglecting monthly lubrication protocols often leads to premature bearing failure and inconsistent texture depth across the web.

Technical Restoration: Advanced Coatings and OEM Conformance

Restoration involves more than simple cleaning; it requires engineering the surface to resist wear and chemical corrosion. Using specialized coatings ensures the roller performs reliably under harsh industrial conditions.

- Wear Coatings: Titanium nitride, diamond-like carbon (DLC), and ceramics.

- Performance Treatments: Urethane coatings and precision regrinding for heat transfer.

- Quality Standards: ISO 9001 compliance and verification against original OEM specifications.

- Storage Protocol: Dry, dust-free environments to prevent oxidation and rust.

Technicians verify reconditioned components through real-world simulations. This ensures that the rejuvenated roller meets the original design’s durability and reliability requirements before it returns to the production line.

Final Thoughts

Embossing slashes fiber costs by 10% via added bulk, yet over-pressuring destroys tensile strength. Balance tactile volume against the material’s elastic limit to avoid structural failure during high-speed production.

Spec your press for 150% of calculated force and prioritize CNC-engraved brass dies. Schedule reconditioning every six months to protect branding precision and prevent costly pattern degradation.

Frequently Asked Questions

Does embossing improve toilet paper absorbency?

No. ISO immersion testing proves that embossing increases bulk and perceived thickness rather than the paper’s actual capacity to hold liquid. It improves the hand-feel, but does not enhance functional absorption.

How do you design a custom embossing pattern for a brand?

Engineers use vector-based software for precision. Production involves CNC engraving to create matched dies: a copper or brass top die (4-6mm thick) and a resin bottom die (1.2-3mm thick) to ensure pattern sharpness and alignment.

What is the cost of a custom embossing roller?

Manufacturers quote rollers individually because costs depend on specific engineering requirements. Pricing scales with roller length (up to 7,000 mm), weight (up to 25 tons), and the complexity of the engraving and tooling investment.

Does embossing affect the ply-bonding of the paper?

Yes. Embossing rollers use pressure—typically 2.0 to 3.6 bar—to create localized bonds between plies. However, exceeding these pressure levels can degrade the final sheet’s softness and reduce its tensile strength.

Can I put my company logo in the embossing pattern?

Yes. Logos are standard in industrial embossing. For clarity, use bold Sans Serif fonts and simple layouts. Intricate details often fail during metal-forming because thick dies cannot capture micro-fine elements effectively.

How long do embossing rollers last during high-volume production?

Chrome or nickel plating extends roller life by 20–50%. Proactive maintenance increases lifespan by 3 to 5 times, while professional refurbishment processes can extend operational use by an additional 30–50%.