Advanced Die-Cutting & Shapes provide the technical escape from the margin-killing commodity trap of standard tissue rolls. Sticking to traditional rotary die limits creates structural bottlenecks and wasted container air, which directly inflates freight overhead for high-volume distributors.

This analysis focuses on bypassing fixed-tooling constraints through CNC Point-to-Point embossing and coreless engineering. We evaluate performance benchmarks like the TSH-3396 high-density build and 40HQ payload optimization to ensure custom silhouettes maintain 100% Virgin Wood Pulp strength across global logistics chains.

Breaking the Cylinder: Why Shape Innovation Matters

Digital cutting and CNC embossing bypass rotary die limits, enabling coreless high-density rolls and custom widths that maximize shipping efficiency, absorbency, and brand differentiation in competitive B2B markets.

Limitations of Rotary Dies and the Shift to Digital Precision

Traditional manufacturing relies on cylindrical rotary dies that roll over materials at high speeds. While effective for standard volumes, this fixed-tooling approach creates a massive bottleneck for innovation. Every design change requires expensive physical tool fabrication and significant machine downtime, which limits how quickly a factory can respond to specific buyer requests.

The industry is moving toward digital precision to eliminate these physical constraints. Computer-controlled cutting systems allow us to skip the metal die phase entirely. This shift provides the flexibility to produce complex shapes and customized widths that were previously impossible to manufacture at a competitive price point.

- Digital Cutting Systems: These use software-driven patterns instead of physical dies to enable rapid prototyping and small-batch customization.

- Laser Technology: Non-contact cutting prevents material stress on delicate virgin wood pulp fibers, ensuring clean edges without fraying.

- Tooling Efficiency: Decoupling design from fixed cylinders reduces lead times and allows for non-standard geometric components.

CNC Point-to-Point Embossing and Coreless Roll Engineering

Shape innovation isn’t just about the outer dimensions; it also applies to the internal structure of the roll. At Top Source Hygiene, we use CNC-precision Point-to-Point embossing to improve the physical performance of the paper. This process uses high-pressure lamination to bond plies together, creating a quilted texture that stays intact during use.

Engineering the shape of the roll itself allows for significant logistical advantages. By moving to coreless, high-density designs, we eliminate the wasted air space found in traditional cardboard tubes. This results in a more compact product that lowers the landed cost per roll for international distributors.

- Absorbency Gains: CNC Point-to-Point patterns increase surface area and liquid retention by 30% compared to standard flat sheets.

- TSH-3396 Specification: This coreless model uses high-density engineering to provide 5000g of 100% usable paper per bundle, maximizing warehouse space.

- Mechanical Compression: Our bagging systems use mechanical pressure to reduce roll bulk. This optimization ensures a 40HQ container carries the maximum possible payload without crushing the fibers.

- Fiber Integrity: Despite high-pressure embossing, the 100% virgin wood pulp maintains a natural fluffiness and high wet-strength.

By focusing on these technical shape innovations, we help B2B wholesalers offer a product that feels more premium on the shelf and costs less to transport across the globe.

Engineering the Interfolded (Pop-up) Tissue Box

Interfolded tissue boxes use mechanical interleaving to create interlocked patterns. Sequential dispensing relies on high-speed folding where one sheet pulls the next into position automatically.

Mechanical Interleaving and Folding Dynamics

The pop-up function depends on how sheets interact within the stack. Machines must maintain extreme precision at high volumes to prevent dispensing failures or jams.

- Mechanical Interleaving: This process creates an alternating, interlocked pattern where one side of a sheet sits inside the fold of the next.

- Folding Velocity: Industrial converting machines process up to 16 folds per second to meet global B2B throughput requirements.

- Automated Sizing: Computer-controlled circular saws cut these interfolded stacks at exact 8-inch intervals for dimensional uniformity.

Precision Perforation and Ply-Bonding Standards

Material integrity determines if a tissue survives the mechanical pull. We prioritize specific bonding techniques and fiber selections to ensure a smooth user experience.

- Strategic Perforation: Precision lines use specific unperforated segments that are weak enough to allow clean separation but strong enough to pull the next sheet up.

- Ply-Bonding Technology: High-pressure lamination bonds multiple plies together, preventing layer separation when the tissue is pulled through the carton slit.

- 100% Virgin Wood Pulp: This material provides the high tensile strength necessary to withstand the friction of high-speed mechanical converting.

Scale Your Brand With Premium Custom Tissues

Custom Core Shapes: Oval, Square, and Hybrid Designs

Non-cylindrical cores maximize container space by eliminating dead air, allowing high-density 40HQ loading that directly lowers landed costs per roll for global wholesalers.

| Core Geometry | Space Utilization | Structural Benefit |

|---|---|---|

| Standard Round | Standard (Air Gaps Present) | Conventional Nesting |

| Oval / Square | High (Zero-Gap Stacking) | Anti-Roll Stability |

| Solid Coreless | Maximum (100% Paper Volume) | High Crush Resistance |

Geometric Stability and Anti-Roll Dynamics

Manufacturers are shifting toward non-cylindrical profiles to solve the “dead air” problem in high-volume logistics. Oval and square cores create flat surfaces that stop rolls from shifting or nesting unevenly during transit. This stability is vital for maintaining the integrity of 40HQ container loads.

Standard round cores often leave gaps that reduce total payload efficiency. By contrast, geometric innovation increases the contact area between stacked rolls. This structural shift provides several mechanical advantages:

- Payload Support: Non-cylindrical designs handle the weight of a 9-ton payload without core collapse.

- Stacking Integrity: Square cores prevent the “bottom-heavy” crushing often seen in lower layers of high-stack containers.

- Retail Optimization: Hybrid shapes allow for “flat-pack” supermarket configurations, maximizing shelf space in urban retail environments.

Mechanical Compression and High-Density Coreless Solutions

Modern production lines use mechanical compression to shrink the roll profile while keeping the paper fibers soft. This technology works best with high-density solid models that remove the center tube entirely. We focus on maximizing paper length per bundle to optimize 40HQ freight value.

By removing the core, models like the TSH-3396 and TSH-3082 deliver significantly more usable product per cubic meter. These solid rolls leverage 100% Virgin Wood Pulp to maintain structural strength without the need for a cardboard insert.

- TSH-3396 & TSH-3082: High-density solid rolls achieving up to 5000g per bundle.

- Width Customization: Core shapes support specialized widths from 102mm to 132mm for commercial dispensers.

- Compression Efficiency: Mechanical bagging minimizes bulk while ensuring the paper retains its 13-22 GSM fluffiness.

- Safe Dissolution: Engineered for rapid disintegration to meet septic-safe standards in North America and Europe.

The Physics of “Flat-Pack” Tissue for Space Saving

Interfolded engineering couples precision friction control with mechanical compression to maximize container payloads, ensuring lower landed costs for high-volume distributors.

Flat-pack tissue engineering moves away from the bulk of traditional rolls to focus on high-density stacking. This requires a sophisticated “tug-and-present” mechanic where the extraction of one sheet automatically positions the next. At the factory level, we achieve this through high-speed mechanical interleaving that creates a continuous chain of 100% virgin wood pulp sheets.

Folding Dynamics and Slit-Based Friction Control

The primary challenge in flat-pack dispensing is preventing “streaming,” where multiple sheets exit the box simultaneously. Our production lines use a specific mechanical interaction between the interlocked stack and the dispenser interface to regulate flow. The clear plastic separator slit serves as the primary regulator, creating the necessary friction to hold the remaining stack in place while allowing a single sheet to pass through.

- Interfolding Speed: Machines execute 16 folds per second to create the alternating Z-fold or V-fold patterns.

- Friction Coefficient: The plastic slit aperture provides a calculated resistance that separates sheets at their perforation lines without tearing the 13–22g/m² fibers.

- Ply Integrity: We utilize high-pressure ply-bonding lamination to ensure 2-ply and 3-ply configurations stay unified during the high-velocity extraction process.

Mechanical Compression and 40HQ Loading Efficiency

Shipping air is the biggest margin-killer in the tissue industry. Our Hebei facility uses industrial-grade mechanical compression during the bagging stage to eliminate excess air gaps between sheets. This process reduces the physical footprint of the product without damaging the tensile strength or “cloud-like” softness of the wood pulp fibers.

- Container Optimization: Compression technology allows our loading teams to reach payloads of 7,000kg to 9,000kg per 40HQ container.

- Lamination Stability: Point-to-point embossing increases absorbency by 30% and provides structural pillars that prevent the stack from collapsing under high-stacking pressure.

- Model Specification: The TSH-2214 Urban Compact is specifically designed for this high-density format, offering a 4-ply configuration that maximizes paper volume within a minimized retail footprint.

By focusing on the mechanical density of the stack, we provide distributors with a product that fits easily into drawers and cabinets while significantly reducing the logistics overhead associated with traditional, uncompressed paper goods.

Tooling and Die-Cutting Costs for Unique Product Shapes

Custom die tools range from $350 to $1,500. Scaling production to 40HQ levels absorbs these costs by slashing unit prices via high-speed automation and material efficiency.

Tooling costs represent the primary upfront investment for any custom tissue project. These expenses cover the physical dies used to cut, score, or emboss the raw 100% virgin wood pulp into specific geometries. While initial costs appear significant, the price per unit drops drastically as volume increases toward full container loads.

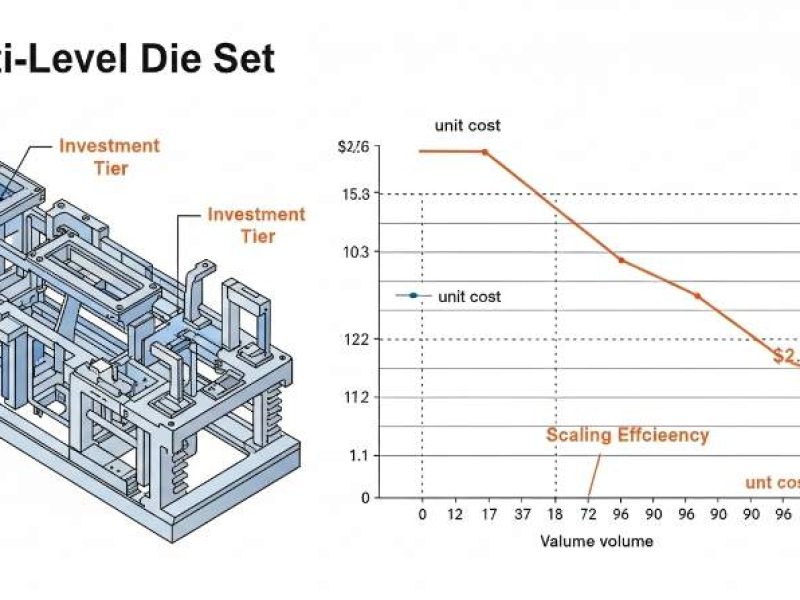

Investment Tiers for Custom Die-Cutting Tools

The complexity of the product shape determines the tier of the manufacturing die. Simple designs use basic blades, while intricate branding or functional shapes require multi-level tool sets.

- Single-level dies: $350 minimum; used for basic scoring or simple straight cuts.

- Double-level dies: $800–$1,500; handles complex shapes and simultaneous operations like cutting and scoring.

- Triple-level dies: $1,500+; rare configurations for highly specialized industrial or medical-grade tissue products.

- Scaling Efficiency: Unit costs drop from $24.75 to $2.07 when moving from 1,000 units to 100,000 units.

We focus on high-volume production to ensure these fixed costs do not inflate your margins. For distributors, an annual production cycle often yields over $200,000 in savings by optimizing design precision and reducing material waste to near 1%.

CNC Precision Perforation and Custom Embossing Specs

At Top Source Hygiene, we integrate tooling costs directly into high-performance specs. This ensures that custom shapes do not compromise the structural integrity of the 13–22g/m² ply paper.

- CNC-Precision Embossing: Custom die sets create patterns that increase absorbency by 30%.

- Precision Perforation: Engineered blades ensure clean-cut, smooth tears even in ultra-soft 5-ply luxury rolls.

- Payload Optimization: Tooling is calibrated for 40HQ containers to hold 7,000kg to 9,000kg, reducing landed costs.

- OBA-Free Integration: Custom branding is stamped directly into 100% virgin wood pulp without chemical brightening agents.

Our Hebei loading teams maximize container space during the production of these custom shapes. By matching tool dimensions to 40HQ shipping constraints, we protect your cash flow and ensure batch color consistency across every pallet.

Branding via Structural Design: The “Unique Factor”

Structural design creates permanent brand signatures through custom silhouettes and CNC embossing, ensuring immediate retail recognition and tactile value that distinguishes premium OEM products from generic alternatives.

Shape-Based Differentiation in Modern Paper Retail

Custom structural silhouettes function as permanent brand signatures. In a crowded retail shelf, consumers identify these physical forms faster than they read printed logos. This physical permanence ensures brand recognition continues throughout the entire product lifecycle, from initial purchase to final disposal.

We use precision die-cutting to enable irregular shapes and “peek-a-boo” windows in packaging. These structural elements increase perceived value for hospitality groups and premium retail brands by creating a high-end unboxing experience. The tactile connection formed during handling builds a stronger emotional tie than flat graphics alone.

Custom CNC Embossing and High-Pressure Ply-Bonding

Top Source Hygiene utilizes CNC-precision embossing to create floral patterns and custom logos that serve both aesthetic and functional goals. These technical patterns are a hallmark of our premium 100% Virgin Wood Pulp models, such as the TSH-4010 luxury hotel rolls.

- Absorbency: CNC-precision patterns increase surface absorbency by 30% compared to non-embossed sheets.

- Lamination: High-pressure ply-bonding technology ensures 3-ply to 5-ply sheets remain bonded without separation.

- Density: Strictly controlled 13–22g/m² GSM per ply balances softness with high-wet-strength durability.

- Perforation: Precision lines prevent shredded edges, ensuring a clean-cut tear that reinforces professional manufacturing standards.

Advanced ply-bonding maintains structural integrity in high-density models like the TSH-3396 and TSH-3266. This process prevents the “paper separation” common in lower-tier manufacturing. By combining high-purity long-fiber pulp with these mechanical bonding techniques, we deliver a quilted feel that remains consistent across 40HQ container orders.

Balancing Novelty with Dispenser Compatibility

Compatibility in 2026 relies on .937-inch die height standards and adapter systems, allowing novelty formats like Top Source Hygiene’s high-density rolls to fit existing commercial fixtures.

Standardized Baseline for Global Equipment Compatibility

Most commercial die-cutting presses and tissue converting lines maintain fixed technical baselines to prevent hardware obsolescence. By adhering to global geometric standards, manufacturers produce unique paper shapes that remain functional across various equipment brands without requiring custom-built machinery for every new product iteration.

- Steel-Rule Heights: Industry baselines stay at .937 inches to ensure 2026 cross-brand compatibility for die-cutting presses.

- Universal Plates: Adapter-based systems allow manual machines like the Sizzix Big Shot Pro to process diverse formats without legacy hardware becoming obsolete.

- Registration Pins: Specialized blades and pins allow equipment to cut novelty shapes while strictly respecting width limitations.

- Cost Control: Standardized die specifications ensure that custom-shaped tissues do not require high-cost, proprietary dispensing units.

Tailored Specifications for Specialized Commercial Units

Top Source Hygiene solves compatibility issues for high-capacity environments by engineering specific product dimensions that match the mechanics of specialized commercial dispensers. We focus on maximizing paper volume while maintaining the structural integrity needed for high-traffic use in airports and malls.

- Model TSH-3099: Features a 235mm wide format engineered specifically for specialized dispensers that standard retail rolls cannot service.

- High-Density Builds: Solid rolls like the 5000g TSH-3396 provide 100% paper utilization for 2026 high-traffic requirements.

- Ply Density: Strictly controlled 13–22g/m² density balances the structural strength of unique shapes with the performance of 100% Virgin Wood Pulp.

- Mechanical Compression: We use specialized bagging technology to ensure novelty-sized bundles fit efficiently into 40HQ containers for global distribution.

Frequently Asked Questions

Can manufacturers produce toilet paper in shapes other than standard rolls?

Most industrial production focuses on cylindrical rolls, but advanced converting machinery allows for alternative formats like interfolded sheets and coreless high-density bundles. We produce these specialized geometries, such as the TSH-3396 coreless series, to satisfy market needs for higher paper volume or specialized dispensing in tight spaces.

How does the interfolded tissue system work?

This format uses a mechanical interleaving process where sheets are folded in an alternating pattern. When a user pulls one sheet, the friction automatically pulls the next sheet into the dispensing slot. This design improves hygiene by ensuring users only touch the sheet they use while also preventing the over-consumption common with standard rolls.

What are the estimated costs for developing a custom tissue shape?

Developing a unique product shape involves concept design, engineering, and tooling. Basic 3D mockups are relatively inexpensive, but setting up a production line for a new geometry typically requires an investment starting at $30,000. This covers the professional die-cutting setup and manufacturing engineering needed for high-volume output.

Are custom-shaped tissues compatible with standard restroom dispensers?

Compatibility is a challenge because most dispensers use fixed dimensions for roll diameter and core size. Non-standard shapes or oversized rolls, like our 235mm wide TSH-3099 model, often require proprietary dispensers or specific hardware to ensure smooth tearing and prevent the paper from jamming.

What logistical advantages does flat-pack packaging provide?

Flat-pack designs minimize the volume of air transported during shipping. This efficiency allows us to maximize the payload in 40HQ containers, often reaching 9,000kg. For international B2B buyers, this significantly reduces the landed cost per unit and optimizes limited warehouse storage space.

How does die-cutting precision affect the final product quality?

High-precision die-cutting ensures clean edges and consistent ply-bonding without fraying. At our Hebei factory, we use CNC-guided tools to maintain dimensional accuracy across large batches. This precision is essential for ensuring the tissues fit perfectly within their packaging and dispense reliably without tearing prematurely.

Final Thoughts

Low-cost alternatives often sacrifice fiber density and structural integrity, leading to crushed rolls and high return rates. Selecting 100% Virgin Wood Pulp and coreless engineering like the TSH-3396 ensures a 9-ton payload while protecting your brand’s reputation for premium quality. Superior shape innovation effectively lowers your landed cost per unit by eliminating wasted air in every 40HQ container.

Eliminate the guesswork in your supply chain by verifying our technical specs firsthand. Contact us to request a sample pack or a detailed quote for your private label project. We recommend a trial 40HQ order to see how our mechanical compression technology maximizes your warehouse efficiency.