Marine & RV Toilet Paper sits at the frontline of operational resilience for boat fleets, rental RV parks, and charter operators — when the wrong tissue clogs a macerator or fouls a holding tank, businesses face unplanned downtime, emergency haul-outs, and repair bills that quickly run into the hundreds or thousands per incident. Owners and maintenance managers see the same pattern: a soft household roll that looks customer-friendly ends up as long fibers and bonded layers that resist break-up, collect on pump inlets, and compact in narrow risers. That small choice multiplies across dozens of units: more pump failures, more service calls, and more lost bookings or charter days. Beyond immediate repair costs, frequent blockages drive whipsaw maintenance schedules, inflate spare-parts inventories, and erode the predictability of service-level agreements that marinas and rental fleets sell to customers.

This guide serves as a technical standard for procurement, spec writing, and product-development decisions around Marine & RV Toilet Paper. Read on for a clear, step-by-step SOP: what differentiates mobile septic tissue from household rolls; the real-world failure modes to avoid; how fiber selection and bonding affect dissolvability; and why 15-second disintegration benchmarks matter for macerator and gravity systems. You’ll get practical test protocols to require of suppliers, pass/fail criteria to put into contracts, and a short procurement checklist for lab and field verification. The guide also explains tradeoffs — how manufacturers balance rapid solubility with acceptable softness — and outlines messaging and packaging claims that align with technical data so B2B buyers can safely market a clog-free promise. Use these checkpoints to reduce emergency service events, lower operating cost per unit, and make buying decisions based on measurable dissolution and particle-size outcomes rather than subjective softness alone.

What Makes Marine and RV Toilet Paper Different from Household Tissue?

Rapid, predictable disintegration keeps holding tanks, pumps, and sensors working—cut service calls and protect fleet uptime.

Preparation: Define system constraints and target dissolution performance

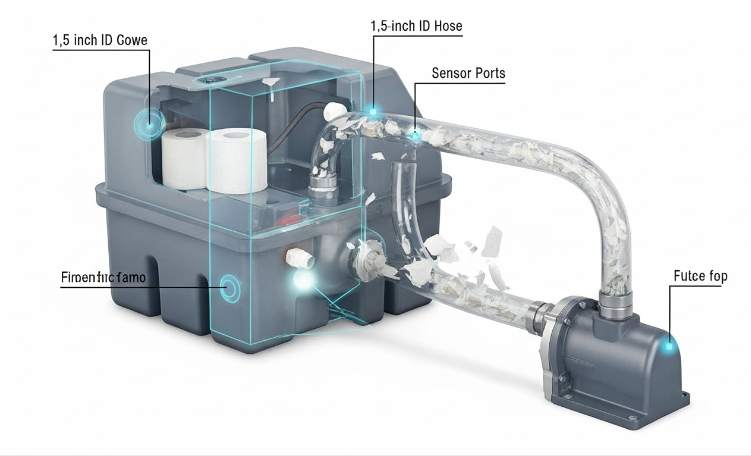

Start every sourcing or specification activity by recording the sanitation system parameters that determine acceptable paper behavior. Note whether the installation uses a macerator or gravity-flush head, measure holding-tank volume, log pump capacity and typical pump cycles, and record hose inner diameter and critical bends so you can match sheet size and roll format to flow constraints.

Specify sensor locations and types—float, pressure, or ultrasonic—so buyers define acceptable residue thresholds. Set material targets: aim for 1–2 ply with ply GSM in the lower range (13–16 g/m² per ply) to maximize breakup while preserving usability. Require OBA-free fibers and third-party rapid-disintegration certification that meets North American and EU septic standards. Finally, capture packaging rules (individual wrap versus bundle) and storage limits to avoid moisture pickup during transit.

Material and construction parameters that improve rapid disintegration

Specify 100% wood pulp or engineered recycled blends formulated for fast fiber separation; avoid heavy lamination and high wet-strength chemistries that keep sheets intact. Control embossing: prefer point-to-point CNC embossing to raise absorbency without dense quilting that bonds plies into a water-resistant block. Use low-pressure ply-bonding so layers stay intact for handling but separate quickly under agitation.

Make perforation a procurement spec: precision perforation ensures clean tearing and prevents long contiguous sheets that hang up in 1.5″–2″ ID marine hoses. Choose roll formats to match dispensers—narrow widths (102–132 mm) for compact heads, and coreless solid or heavy bundles (examples: 5000g/28) for high-volume service areas.

- Fiber: 100% virgin wood pulp or fast-separating recycled blend

- Ply/GSM target: 1–2 ply, 13–16 g/m² per ply

- Embossing: point-to-point CNC; avoid dense quilting

- Perforation: precision cut to prevent long sheets

- Roll formats: 102–132 mm widths for heads; 5000g coreless for service stock

Selection and sourcing checklist for OEMs and fleet managers

Require hard certifications and measurable specs on every PO. Ask suppliers for ISO 9001, FDA and EU hygiene compliance, and documented OBA-free claims. Put technical data on the commercial sheet: ply count, gsm-per-ply, roll width, roll weight range (780g–5000g per bundle), roll length in meters, and explicit disintegration targets tied to accepted tests.

Specify logistics terms up front: private-label MOQ typically equals 1 × 40HQ container; in-stock lead time 10–15 days and production lead time 20–25 days. Use HS code 4818.1000 for customs. Require pre-shipment visual verification, batch color consistency records, and a sample validation run matched to your regional model needs—heavy solid rolls for wholesale markets, low-GSM options for RV/marine septic-safe use.

- Certificates: ISO 9001, FDA, EU hygiene, OBA-free documentation

- Purchase specs: ply, gsm-per-ply, width, weight (780g–5000g), disintegration target

- Logistics: MOQ = 1 × 40HQ; in-stock 10–15 days; production 20–25 days; HS 4818.1000

- Quality controls: pre-shipment photos/videos and batch brightness records

- Product-match: choose roll type by dispenser and service cadence

Onboard and RV operational practices to minimize blockages

Set a clear usage policy: ask users to follow a single-sheet-per-flush habit and limit excess paper in the bowl. Post visible signage at dispensers that forbids wipes, sanitary products, and paper towels. Stock dispenser-specific rolls—narrow-width rolls for compact heads and coreless heavy rolls in service areas—to reduce restock frequency and user substitution.

Specify dosing and plumbing routines: use approved holding-tank treatment fluids that lower surface tension and speed microbial breakdown, flush hoses with freshwater immediately after emptying, and inspect hoses and fittings for constriction points such as tight elbows or reduced-diameter connectors. Train crews to add extra water per flush where practical to aid flow.

- User rule: single-sheet habit; ban wipes and sanitary items

- Treatment: use approved tank fluids to improve dispersion

- Hose care: flush with freshwater after emptying; inspect for constrictions

- Stocking: match roll formats to dispenser and service model

Verification and QC: practical dissolution and septic-safety tests

Build a two-stage test program: bench disintegration followed by field validation. For bench tests, submerge a defined sheet count in a fixed-volume container, agitate mechanically and time fragmentation. Use the slosh-box-style benchmark: agitate up to 60 minutes and require >60% of dry mass to pass a 12.5 mm sieve for comparable flushability assessments. Record time-to-fragmentation and residual mass in grams.

Run a 30–90 day field trial on representative vessels or RVs and monitor tank sensors, pump draw current, and hose flow during service cycles. Keep batch metrics—ply GSM, roll diameter, roll length (m), brightness—and archive QC photos and videos for pre-shipment verification. If a batch fails, change one variable at a time (reduce ply GSM, alter embossing pattern, or refine perforation), then re-test before authorizing full production release.

- Bench test: fixed volume, mechanical agitation, time-to-fragmentation, residual mass

- Pass criteria: no large fragments; residuals must pass device inlet dimensions

- Lab benchmark: 60-minute slosh with >60% mass through 12.5 mm sieve

- Field validation: 30–90 day monitoring of sensors, pump strain, and hose flow

- Corrective actions: adjust GSM, embossing, or perforation and re-test

Why Should Boat and RV Owners Avoid Standard Household Paper?

Choosing fast-disintegrating paper prevents costly macerator failures and downtime in confined holding-tank systems.

Dissolution-rate requirements and how to verify paper will fragment in holding tanks

Household toilet paper often uses construction that resists immediate break-up, so it can form clumps that block holding tanks, discharge lines and macerators. Industry testing treats papers that dissolve within roughly 39 seconds to 1 minute as acceptable for sensitive systems, while purpose-built rapid-dissolve products can break apart in under 6 seconds; papers that remain intact after 60–120 seconds represent a higher clog risk.

Run a field verification: drop one sheet in ~1 L room-temperature water, agitate vigorously for 60–120 seconds and confirm the sheet fragments into small pieces. You can also use the three-quarter glass jar shake test (two sheets, 30 seconds) as a quick pass/fail. If the sample stays as a glob or large ribbon after these checks, do not specify that brand for fleet or marine use.

Mechanical weak points in boats and RV systems that household paper stresses

Mobile sanitation plumbing contains several choke points that household paper stresses quickly: narrow-diameter hoses and small through-hull/discharge lines trap consolidated fibers, macerator impellers jam on cohesive clumps, and waste-tank level sensors foul when fibers build around ports. Those failures produce immediate operational impact—blocked discharge during pump-out, failed macerator motors, and false full-tank readings.

Reduce risk with procedural controls and routine inspection. Limit sheets-per-flush, avoid multi-sheet wiping, and flush an extra bowl of water when feasible. Specify macerator-safe or rapid-disintegration paper where macerators or small-diameter hoses are present, and run a monthly inspection cycle to spot early build-up before a full blockage occurs.

- Common failure points: narrow hoses, macerator impellers, small discharge lines, and tank-level sensor ports.

- Operational safeguards: limit sheets-per-flush, flush additional water, and specify rapid-disintegration paper for macerator systems.

- Maintenance actions: inspect hoses, valves and impellers monthly; clear sensor ports and strainers to detect fiber build-up early.

Material and product selection checklist for safe marine/RV toilet paper

Specify products with explicit rapid-disintegration or septic-safe claims and confirm OBA-free formulation to protect skin and downstream treatment processes. Require documentary proof of compliance with relevant hygiene and flushability standards (FDA/EU where applicable) and preference for INDA/EDANA or IWSFG test data when available.

Prefer 1–2 ply or low-GSM multi-ply constructions designed for fast break-up; use ply density as a selection cue — target the Top Source spec range of 13–22 g/m² per ply and review wet-strength data before approving a SKU for fleet use. For practical alignment, choose products engineered for holding-tank systems (example SKUs: TSH-2559 for North American septic-safe needs; TSH-3396 coreless where storage density matters) and store rolls dry and protected to preserve performance.

- Must-have specs: explicit “rapid disintegration” or “septic-safe” label, OBA-free, and certification or test reports (INDA/EDANA, IWSFG, FDA/EU evidence).

- Preferred construction: 1–2 ply or low-GSM multi-ply; verify ply density 13–22 g/m² per ply and temporary wet-strength performance.

- Product alignment: select holding-tank-engineered SKUs (TSH-2559 for septic-safe retail; TSH-3396 coreless for space-constrained storage) and store rolls in dry, protected packaging.

Scale Your Toilet Paper Brand Fast

Fiber Selection: Why Short-Fiber Ratios Prevail in Mobile Septic

Higher short-fiber content and lower per-ply GSM accelerate sheet break-up, cut clog risk and simplify certification for RV and marine toilet papers.

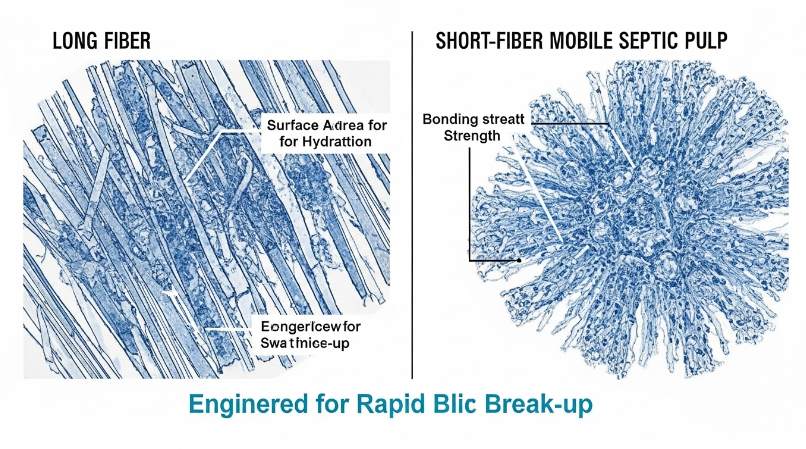

Fiber morphology and how short fibers accelerate dissolution

Short fibers raise exposed surface area, reduce inter-fiber bonding and let water wet and separate the sheet faster than long-fiber constructions. That faster hydration drives mechanical fragmentation during flushing and in macerators, so furnishes with a higher short-fiber fraction consistently produce smaller particle sizes under agitation.

Measure fiber length distribution with a fiber analyzer, record pulp freeness (Canadian Standard Freeness — CSF) and quantify porosity to predict disintegration behavior. Use those three metrics to build a furnish target: characterize incoming pulps for short-fiber fraction and adjust the hardwood/recycle blend to meet your septic-safe specification rather than guessing by supplier label alone.

- Fiber length distribution — run routine fiber analyzer scans and track short-fiber % trends.

- Pulp freeness (CSF) — use CSF to correlate hydration speed with expected disintegration.

- Porosity — measure to estimate liquid uptake and initial sheet weakening under agitation.

Manufacturing levers — furnish, GSM, ply bonding and chemical controls

Shift furnish weight toward hardwood or selected recycled pulp to raise the short-fiber ratio when you design mobile-septic SKUs; avoid making long-fiber virgin pulp the dominant component for those grades. Engineer sheets with lower per-ply GSM — target a 13–16 g/m² range where feasible — and limit total plies to one or two to keep fragmentation fast while preserving acceptable comfort.

Cut high-pressure ply lamination and reject permanent wet-strength chemistries that lock sheets together. Keep OBA-free practice to meet sensitivity and regulatory needs. Consider Temporary Wet Strength (TWS) only after lab validation that it releases under septic conditions; otherwise rely on mechanical emboss and controlled perforation to tune performance. Point-to-point embossing can raise absorbency by roughly 30%, and perforation pattern alters tear behaviour and disintegration pathways.

- Furnish: increase hardwood/recycle share to boost short-fiber fraction; avoid dominant long-fiber blends for septic SKUs.

- GSM & plies: aim 13–16 g/m² per ply and 1–2 plies for fastest break-up without unacceptable user experience loss.

- Bonding & chemistry: eliminate permanent wet-strength; validate any TWS formulations under disintegration tests; remain OBA-free.

- Embossing & perforation: use point emboss to boost absorbency (~30%) and set perforation to promote controlled disintegration.

- Pilot trials: vary furnish ratio, GSM and embossing parameters and record disintegration outcomes for each batch.

Acceptance testing and on-vehicle simulation protocols for septic compatibility

Build an acceptance test matrix that mirrors field stresses: run soak-and-agitate disintegration trials with time-series sampling (measure remaining mass and particle-size distribution at fixed intervals), track wet-tensile decline and execute pumpability/hose-flush trials to catch real clog modes. Use the 30-second jar shake as a quick screen, then move qualifying samples into full slosh-box and drain-line rigs for quantitative results.

Require lab benchmarks aligned with industry standards: the slosh-box disintegration method (60 minutes agitation) should pass >60% dry-mass through a 12.5 mm sieve, drain-line rigs should demonstrate ≥98% clearance, and sedimentation tests should meet a sinking rate >0.1 cm/s. Compare batches to marine/RV control products and certify to INDA/EDANA or IWSFG guidelines before shipment. Capture batch-level disintegration reports and perform pre-shipment visual verification to enforce consistent short-fiber performance across containers.

- Screen: jar shake test — 30 seconds; reject sheets that remain intact.

- Quantify: slosh-box disintegration (60 min) — require >60% dry mass through 12.5 mm sieve.

- Clearance: toilet bowl and drain-line rig — target ≥98% clearance under simulated use.

- Settle & biodegrade: meet sedimentation and biodisintegration thresholds (e.g., sink rate >0.1 cm/s and IWSFG/INDA criteria).

- Field validation: run holding-tank simulations and real-world RV/marine flushing cycles to check sensor interference and hose behavior.

- Documentation: attach batch disintegration reports and pre-shipment photos/videos for traceability and distributor QA.

The Science of Disintegration: 15-Second Dissolve Benchmarks

Hitting a verified 15-second dissolution target cuts field clogs, reduces service calls, and protects warranty exposure for marine, RV, and compact-plumbing customers.

Controlled dissolution test protocol — 15‑second benchmark method

Run tests on representative production sheets: use full-size roll sheets as produced and test at least three replicates per formulation to capture process variance. Use 1 L of deionized water held at 20 ± 2 °C, immerse a single sheet, and apply controlled agitation with a magnetic stirrer; record RPM and stir bar type so laboratories can reproduce results. Start the timer at immersion and stop when no visible intact fragments remain and more than 95% of the original sheet area has dispersed; acceptance for 2026 supply is complete dispersion ≤ 15 seconds.

Complement the visual end point with objective metrics: record the turbidity rise in NTU, pass the test slurry through a 1 mm sieve to quantify residual mass, and capture high-speed video to extract time-to-first-tear and full-disintegration timestamps. Preserve raw video and sieve residuals in the test record for supplier audits and buyer verification.

- Sample: full-size roll sheet; minimum three replicates per formulation.

- Medium/conditions: 1 L deionized water at 20 ± 2 °C; magnetic stirrer (document RPM and stir bar).

- End point: >95% area dispersed; target ≤ 15 seconds.

- Alternate metrics: NTU turbidity curve, 1 mm sieve residual mass, high-speed video.

- Reporting: include sample ID, ply count, per-ply GSM, emboss pattern, bonding method, water temp, RPM, time-to-dispersion, raw video, and sieve mass.

Material variables that determine 15‑second break‑up

Fiber selection drives the trade-off between hand and breakup. Long-fiber virgin wood pulp gives tensile strength and a premium feel but increases resistance to rapid breakup; shorten effective fiber bonding or introduce controlled mechanical debonding to accelerate disintegration without sacrificing perceived softness. Target per-ply GSM within the production range of 13–22 g/m² and bias designs toward the lower half (for example, ≤ 18 g/m² per ply) when aiming for sub-15 s performance while holding tensile and hand-feel specs.

Bonding, embossing, and additives change wet cohesion. High-pressure lamination and permanent wet-strength chemistries increase layer cohesion and slow breakup, so avoid permanent wet-strength resins when you need sub-15 s results or switch to temporary/water-soluble bonding profiles. CNC point-to-point embossing raises absorbency by about 30% and promotes water penetration; tune emboss depth and pattern to speed breakup while maintaining sheet integrity during use. Keep formulations OBA-free and avoid hydrophobic finishes; achieve natural brightness of 85–92% through fiber selection rather than optical brighteners to preserve dissolution characteristics.

- Fiber: 100% virgin long-fiber wood pulp for premium feel; adjust bonding to reduce breakup resistance.

- GSM: design target ≤ 18 g/m² per ply for 15 s benchmark (production range 13–22 g/m²).

- Bonding: avoid permanent wet-strength chemistries; prefer water-soluble/TWS approaches if chasing ultra-fast dissolution.

- Embossing: use CNC point-to-point patterns to increase absorbency ~30% and speed wetting.

- Additives: maintain OBA-free, avoid hydrophobic coatings; target 85–92% natural brightness via fibers.

Field acceptance criteria and compliance for septic‑safe rapid‑dissolve tissue

Specify products to the end-system. Marine and RV holding tanks and macerators need faster breakup than municipal sewer systems; require validated sub-15 s products for marine/RV deployments to reduce clog and sensor-failure risk. Validate at system level by running sensor-operation checks, full pump-out flow trials under expected loads, and sewer-hose emptying cycles to confirm no mid-transfer blockages.

Embed regulatory and packaging checks into acceptance. Align test records with buyer and regional requirements and cite ISO 9001 manufacturing control plus FDA or EU hygiene compliance where relevant; reference HS code 4818.1000 for customs. Watch compressed and coreless formats: high-density rolls (for example 5000 g bundles) change initial fluff and wetting kinetics, so include final-user wetting performance in acceptance testing. Require each manufacturing batch to meet documented 15 s lab results, supply pre-shipment test records and raw video, and verify batch color consistency and OBA-free status before release.

- System compatibility: mandate sub-15 s validation for marine/RV distribution.

- Operational checks: sensor operation, sewer-hose emptying, and pump-out flow trials.

- Regulatory markers: ISO 9001, FDA/EU hygiene compliance, HS code 4818.1000 for customs.

- Packaging effects: test compressed/coreless rolls (e.g., 5000 g) for wetting performance before acceptance.

- Release criteria: batch-level 15 s lab results, pre-shipment videos, sieve residuals, and OBA-free verification.

Can We Balance Rapid Solubility with Premium Softness?

Tune long‑fiber virgin pulp, sheet architecture and validated lab-to-field tests to deliver fast breakup without sacrificing premium handfeel or regulatory compliance.

Pulp and fiber formulation: tune long‑fiber virgin pulp for faster breakup

Select 100% long‑fiber virgin wood pulp as the baseline to preserve tensile strength and a premium handfeel while keeping all chemistry OBA‑free to protect sensitive skin. Target per‑ply GSM between 13–22 g/m²; treat GSM as your primary control knob—lower GSM speeds wet fragmentation and dissolution but reduces dry strength, so balance by adjusting ply count and converting settings.

Run pilot fiber blends that introduce measured short‑fiber or bamboo/recycled inputs to accelerate wet breakup; track lint, brightness and strength simultaneously. Maintain natural brightness in the 85–92% window through fiber selection rather than optical brighteners to meet skin‑safety and EU/North American hygiene expectations. Actionable pilot plan below ensures you capture both breakup and softness data.

- Create three pilot pulps: (A) high‑softness virgin, (B) balanced virgin + controlled short fiber, (C) fast‑dissolve mixed pulp with bamboo/recycled fraction.

- Measure: wet breakup time, residual fiber mass, dry tensile and wet tensile; record brightness and lint counts for each batch.

- Compare results against targeted dissolution benchmarks (aim for visible fragmentation under 60 seconds; use stricter targets where customers require 15–39 second performance).

Sheet architecture and converting settings: embossing, ply‑bonding, ply count and perforation

Offer 2–5 ply SKUs while recognizing tradeoffs: add plies to improve perceived softness, but reduce plies and per‑ply GSM to improve breakup in holding tanks. Set ply‑bonding pressure high enough to keep layers secure during use, and iterate down from maximum lamination pressure to avoid over‑bonding that blocks interlayer separation when wet. Use point‑to‑point CNC embossing to increase absorbency by roughly 30% and to create designed stress points that aid wet breakup without roughening the surface.

Standardize clean‑cut perforation settings and edge finishing checks to prevent ragged tears that form clumps in drains. Test coreless high‑density rolls versus cored designs: coreless maximizes meters per roll and freight value but raises pack density and can alter wet breakup—adjust compression and packaging to preserve breakup performance. Below are the converting tests you should run to quantify tradeoffs.

- Run a converting matrix varying emboss depth (low/medium/high), bond pressure (nominal ±10%), and ply count (2,3,4,5); record perceived softness, wet disintegration time and lint generation.

- Validate perforation tolerance with QC checks for tear uniformity; reject settings that produce >2% ragged tears per 1,000 rolls.

- Measure roll density effects: compare coreless compression levels to cored rolls and map wet breakup delta versus meters per roll and pack compression.

Validation, target metrics and market mapping: test protocols and recommended SKUs

Establish a lab protocol that uses timed dispersion tests with simulated holding‑tank agitation and flow; report time‑to‑dispersion, residual fiber mass and clogging tendency for every batch. Use slosh‑box style agitation and quantify mass passing through a 12.5 mm sieve after 60 seconds as a baseline; set pass/fail windows that align with INDA/EDANA and IWSFG guidance for mobile plumbing.

Define client‑facing pass criteria tied to region: North America and Europe should meet stricter septic‑safe expectations (target fragmentation in the 39s–1min range or better; flag >3 minutes as unacceptable), while specialized rapid‑dissolve SKUs may aim for sub‑15 to sub‑6 second performance where systems demand it. Map SKUs to markets directly: recommend TSH‑2559 for North America (septic‑safe focus), TSH‑3396 for SEA (coreless freight efficiency), TSH‑4010/TSH‑2269 for GCC hotels (luxury with tuned embossing), and TSH‑3082/TSH‑JRT08 for Africa (high‑volume durability). Follow the release checklist below before full production.

- Lab dissolution report: timed dispersion curve, residual mass %, photos and video of breakup sequence for the batch.

- Converting QC logs: emboss depth, bond pressure, perforation tolerances and roll compression data signed off.

- Market signoff: SKU approved for target region (TSH mapping) and documented pass against regional pass criteria.

- Field pilot: ship 1–2 container pilot runs for new formulations, collect tank performance feedback, then iterate pulp mix or converting parameters before scaling.

Marketing the “Clog-Free” Guarantee to Niche Outdoor Brands

A measurable, lab-backed clog-free claim reduces warranty risk and protects distributor margins for outdoor and marine channel partners.

Set measurable ‘Clog‑Free’ criteria and lab dissolution protocol

Define technical pass/fail criteria that align with current mobile-plumbing science: target rapid disintegration (aim for product sheet metrics in the 15–60 second range for best-in-class items, with <6 seconds achievable for TWS chemistries and 39–60 seconds representing a robust commercial threshold). Specify residual particle limits for holding‑tank systems and require percentage-through metrics consistent with IWSFG/INDA guidance (for example, >60% mass through a 12.5 mm sieve in a standardized slosh-box). Require an ISO 17025 third‑party lab report for each batch and include the report ID on shipment documents.

- Standardized test method: agitation dissolution test — define sample size (minimum 5 sheets per run), water volume (1 L per sheet equivalent), agitation time (30–60 seconds for jar/shake screening; 60 minutes for full slosh-box), and residual screening (12.5 mm sieve and dry-mass retention).

- Target sheet construction: prioritize 1–2 ply formats for fastest breakup; set ply GSM per layer at 13–22 g/m² to balance breakup and wet strength.

- Material mandates: OBA‑free pulp and 100% Virgin Wood Pulp by default; allow bamboo or recycled only with a signed composition certificate and clear labeling.

- Regulatory and certification evidence: require ISO 9001, FDA or EU hygiene compliance, and an explicit “Septic‑Safe / Rapid Disintegration” statement on technical files as of 2026.

- QC operationalization: add dissolution-test lot acceptance criteria to the QA checklist and attach result sheets and lab certificates to pre‑shipment documentation.

Map SKUs and packaging to outdoor system requirements and dispenser compatibility

Match product SKUs to actual field use cases so purchasers buy the correct SKU for their infrastructure. Position TSH‑3396 (coreless, 5000g) for high‑volume RV fleets and campgrounds where transport efficiency matters; recommend TSH‑2559 (2/3‑ply) when North American septic sensitivity and customer comfort both matter; and specify TSH‑3082 or TSH‑JRT08 for institutional dispensers and high‑traffic outdoor facilities. Confirm dispenser compatibility—check roll widths and core format before committing—rather than assuming fit.

- Roll and dispenser specs: support standard widths 102–132 mm and offer wide options to 165 mm; verify coreless vs cored compatibility with the dispenser vendor prior to shipment.

- Packaging formats by channel: Format A — individual wrap for hygiene-sensitive hospitality and premium outdoor retail; Format B — direct bundle for park and campground procurement.

- Logistics and bundle technicals: configure bundle weights from 780g to 5000g; use mechanical compression to improve container density while preserving sheet structure and perforation integrity.

- Field validation: ship sample kits that include labeled dimensions, ply, GSM, SKU number, and documented dissolution results for on-site testing in marine/RV holding tanks.

- Labeling and customs: require product labels to list ply, GSM, base material, a “Septic‑Safe / Fast Dissolve” claim, and HS code 4818.1000 for customs clearance.

Build technical marketing assets and distributor enablement for outdoor channels

Create practical, co‑brandable assets that prove performance. Deliver a technical data sheet that lists composition (100% Virgin Wood Pulp default), OBA‑free declaration, ply/GSM, roll dimensions, and a concise third‑party dissolution-summary with test conditions and numeric results. Equip partners with a short field protocol (jar/shake and 60‑minute slosh check), a pass/fail template, and a simple data capture form so distributors collect repeatable evidence during trials.

- Field test protocol: two‑sheet jar test — fill 750 mL water, add two sheets, shake 30 seconds; pass if sheets shred immediately. For fuller verification, run a 60‑minute slosh with a 12.5 mm sieve and record % mass passing.

- Sales enablement priorities: train reps on rapid disintegration metrics, septic‑safe labeling, batch color consistency, and clear compatibility limits (advise against 4–5 ply in sensitive systems).

- Commercial terms to state on offers: MOQ = 1 x 40HQ (private label same), in‑stock lead time 10–15 days, production lead time 20–25 days, payment T/T 30% deposit, 70% pre‑shipment balance (terms current for 2026).

- Supply transparency: commit to pre‑shipment visual verification (photos/videos) and attach lot traceability documents to each B2B shipment to protect distributor margins and reduce disputes.

- Launch packs: ship labeled sample cartons, technical sell sheets, and recommended reorder volumes aligned to a 40HQ payload (typical 7–9 tons) to keep landed-cost math predictable for partners.

Conclusion

Choosing fast-dissolving, short-fiber tissue and verifying 15-second disintegration benchmarks prevents clogged marine and RV plumbing, reduces pump and macerator wear, and keeps holding tanks sanitary. These technical checks lower maintenance costs, minimize guest complaints, and protect fleet uptime. Specifying products with clear dissolution data and septic-safe certification also simplifies procurement and compliance.

Start by auditing your fleet’s current toilet tissue against dissolution and fiber specs, or request field samples to confirm performance in representative systems. Contact Top Source Hygiene to get technical data sheets, certified samples, and OEM options tailored to marine and RV channels.

Frequently Asked Questions

Is RV toilet paper really different from regular toilet paper?

Yes. Marine and RV toilet paper is specifically engineered to dissolve much more rapidly and to be compatible with delicate holding-tank systems. Household toilet paper is biodegradable but breaks down slowly in traditional sewage systems, which can lead to clumping and blockages in mobile plumbing.

How fast should marine toilet paper dissolve in a holding tank?

It should dissolve rapidly — fast enough to break apart within the short timeframes required by holding tanks. Marine/RV paper is engineered for rapid dissolution because household tissue breaks down too slowly and can accumulate in clumps that clog systems.

Can I use bamboo toilet paper in an RV septic system?

The research does not mention bamboo specifically. The critical factors are 100% biodegradability and rapid dissolution; if a bamboo product is labeled and proven to dissolve as quickly as marine/RV paper and is rated safe for mobile sanitation, it may be acceptable. Otherwise using non‑marine-labeled paper risks inconsistent dissolution and clogs.

Why does household toilet paper clog boat toilets so easily?

Because household toilet paper is designed to break down slowly in larger sewage or septic systems, it can accumulate into clumps in compact boat and RV sanitation systems. Those systems are more delicate, with small pipes, sensors and limited capacity, so slow‑dissolving household tissue clogs hoses, tanks and sensors more easily.

Is 1-ply or 2-ply better for marine and RV applications?

Both 1‑ply and 2‑ply marine/RV products exist. The key is formulation and rapid dissolution: 2‑ply household tissue is often too heavy for mobile systems, while some inexpensive 1‑ply household papers can perform similarly to marine paper in dissolution tests. Prefer products engineered and labeled for marine/RV use.

What are the best ways to test flushability for mobile plumbing?

Use dissolution/flushability testing to compare brands and verify rapid breakdown before relying on a product. Studies and practical tests identify how quickly paper disintegrates; because household brands vary, testing (or using products specifically engineered for marine/RV systems) reduces the risk of clogs.