Regional compliance branding acts as the primary gatekeeper for global trade, where a single labeling error leads to immediate market expulsion. Ignoring localized mandates like the 2028 FDA compliance date or AU flushability symbols creates inventory bottlenecks that destroy first-mover advantages and trigger heavy legal fines.

We simplify entry by aligning 100% OBA-free, virgin wood pulp products with regional benchmarks. This review evaluates septic-safe engineering for the TSH-2559 model and GS1 barcode standards to help you secure a legally sound, high-margin private label presence.

Why Regional Compliance is Your First Marketing Hurdle

Compliance is the primary 2026 market gatekeeper. Resolving technical specs like FDA and FSC requirements before marketing prevents legal fines and avoids costly entry delays.

The Impact of Regulatory Complexity on Marketing Speed

Compliance research forms the foundation of every international market entry. It must precede all creative and strategic marketing efforts. If you launch a brand without verifying local paper standards, you risk more than just a failed campaign; you face immediate market expulsion. We see many brands prioritize aesthetics while ignoring the legal baseline required to clear customs.

A massive disconnect exists between marketing and compliance teams. Industry data shows 80% of compliance experts feel marketing undervalues regulatory importance. This friction delays product launches and creates operational bottlenecks. When marketing treats compliance as an afterthought rather than a core spec, the resulting delays can destroy a first-mover advantage.

Non-compliance leads to concrete business threats. Global giants have faced ten-figure fines and permanent reputational damage for regulatory oversights. Operating in multiple jurisdictions means navigating a minefield of governing bodies simultaneously. Whether it is the SEC in the US or regional health ministries in the Middle East, each body has specific demands that dictate how a product is packaged, labeled, and sold.

Leveraging OBA-Free and FDA-Compliant Materials for Seamless Entry

North American markets demand strict adherence to FDA regulations and septic-safe technology. At Top Source Hygiene, we engineer our household toilet rolls to ensure rapid disintegration in plumbing systems. This technical alignment prevents the clogs common with lower-grade materials and meets the primary requirement for US residential distribution.

European markets prioritize skin safety and environmental integrity. EU hygiene standards and FSC certifications drive the demand for 100% OBA-Free materials. We guarantee that no Optical Brightening Agents or fluorescent whiteners are used in our production. This technical purity allows distributors to pass regional chemical safety audits without friction.

Our commitment to 100% Virgin Wood Pulp provides a significant advantage for global importers. Unlike mixed recycled waste, which often carries contaminants, our high-purity long-fiber pulp ensures consistent quality that satisfies strict international inspectors. We focus on these core standards to streamline the auditing process:

- Chemical Safety: 100% OBA-Free (No fluorescent whiteners) for sensitive skin safety.

- Plumbing Compatibility: Septic-safe engineering for rapid water disintegration (FDA/EU compliant).

- Material Purity: 100% Virgin Wood Pulp (85-92% natural brightness) avoiding recycled waste contaminants.

- Verification: Pre-shipment visual verification and batch color consistency documentation for customs.

Using these technical specifications as your marketing foundation eliminates the guesswork from market entry. Providing batch consistency records and visual loading verification directly to customs and quality inspectors satisfies the burden of proof required in regulated regions like the GCC or the EU. This proactive approach turns compliance from a hurdle into a competitive asset.

US Market: FDA, Weight/Measure, and Warning Labels

US importers face a 2028 FDA compliance deadline and specific state labeling mandates. We provide OBA-free, septic-safe virgin pulp products designed for immediate regulatory alignment.

| Regulatory Category | Key Requirement | Factory Solution |

|---|---|---|

| Federal FDA Compliance | Uniform compliance date: January 1, 2028. | Pre-updated labeling for 2026/2027 shipments. |

| State Mandates (TX/LA) | Additive warnings and QR ingredient links. | Integrated QR code printing on master packs. |

| Material Safety | 100% OBA-Free & Septic-Safe certification. | TSH-2559 Model: Rapid-dissolve virgin pulp. |

| Product Measurement | FPLA-compliant net weight declarations. | Precision weighing (780g-5000g bundles). |

Navigating Federal Compliance Dates and State Warning Mandates

The FDA established January 1, 2028, as the uniform compliance date for food and sanitary labeling regulations published between 2025 and 2026. This timeline allows manufacturers to sync updates across product lines, but regional requirements often move faster. For instance, Texas now mandates warnings on specific additives, with compliance required by the start of 2027. Louisiana requires QR codes on packaging that link directly to full ingredient disclosures.

We manage these divergent rules by embedding compliance early in the design phase. Our production lines in Hebei support custom regional printing to ensure products sold in different states meet localized transparency standards without interrupting the main supply chain.

- QR Technology: We integrate high-resolution QR codes on PE bags for instant ingredient access required by regional mandates.

- FPLA Standards: All retail packaging includes accurate net weight and measurement declarations to comply with the Fair Packaging and Labeling Act.

- Transition Support: Our team updates labeling templates to align with the 2028 federal window, preventing retail chargebacks.

FDA-Compliant Material Selection and Septic-Safe Engineering

North American residential plumbing requires paper that disintegrates rapidly to prevent blockages. We engineer our TSH-2559 model specifically for this market, using premium long-fiber wood pulp that maintains high wet strength during use but dissolves quickly once flushed. This ensures compliance with septic-safe standards common in US residential systems.

Safety extends to chemical purity. US skin-safety standards are increasingly focused on the absence of harsh chemicals. We guarantee 100% OBA-Free materials, meaning we use no optical brightening agents or fluorescent whiteners. The brightness is achieved naturally, ensuring the product is safe for sensitive skin.

- Material: 100% Virgin Wood Pulp for lint-free performance and superior tensile strength.

- Brightness: 85-92% natural level achieved through fiber selection rather than chemical bleaching.

- Disintegration: High-pressure lamination and precision perforation ensure sheets dissolve rapidly in standard septic systems.

- Density Control: Strictly maintained 13–22g/m² per ply to balance luxury softness with functional durability.

Boost Your Margins With Custom Manufacturing

EU Market: REACH, FSC, and Multi-Language Requirements

Exporting to the EU in 2026 requires strict REACH compliance, 100% OBA-Free materials, and FSC certification to meet legal safety and sustainability mandates across the Eurozone.

Navigating 2026 REACH Updates and FSC Sustainability Standards

The European regulatory landscape is shifting toward the “REACH 2.0” framework. This update increases the pressure on chemical transparency and environmental reporting for all household paper products. Importers must track microplastic emissions and prepare for digital product passports that verify the entire supply chain from the forest to the final roll.

- Regulation (EU) 2025/2573: Requires updated chemical test methods and a transition to non-animal testing assays for material safety.

- Microplastic Reporting: May 31, 2026, marks the first mandatory reporting window for synthetic polymer microparticle emissions under REACH exemptions.

- Digital Product Passports: Future REACH 2.0 revisions include electronic safety data sheets to ensure transparent polymer notification.

- FSC Certification: FSC-certified wood pulp is essential for European retail shelf placement to prove ethical and sustainable forestry practices.

Implementing OBA-Free Virgin Wood Pulp for EU Hygiene Compliance

Top Source Hygiene provides specific models like the TSH-1071 to meet the high-purity requirements of the German and French markets. These regions demand strict adherence to microbiome safety and specific plumbing standards. We optimize every 40HQ container to ensure these compliant products reach EU ports with the lowest landed cost per unit.

- 100% OBA-Free Guarantee: We use no fluorescent whiteners (Optical Brightening Agents), ensuring the paper is safe for sensitive skin and compliant with EU hygiene laws.

- HS Code 4818.1000: Proper customs classification ensures efficient clearance through major European logistics hubs like Rotterdam or Hamburg.

- Multi-language Strategy: We implement packaging that includes English, German, and French to satisfy local consumer protection and labeling laws.

- Septic-Safe Engineering: Our 100% Virgin Wood Pulp disintegrates rapidly in water to comply with European environmental infrastructure and plumbing regulations.

AU/NZ Market: Water-Saving and Flushability Disclosures

Australia and New Zealand use AS/NZS 5328:2022. Compliant toilet paper passes six laboratory tests and uses clear visual symbols to prevent sewage blockages.

Compliance with AS/NZS 5328:2022 Labeling Standards

Australia and New Zealand introduced the AS/NZS 5328:2022 standard to stop sewer blockages caused by non-flushable materials. If you market a product as “flushable” in this region, meeting these benchmarks is a requirement for market access and consumer trust. The framework ensures that items disposed of in toilets do not damage wastewater infrastructure.

- Six-Test Protocol: Products must pass rigorous laboratory evaluations that simulate real-world sewage conditions to verify mechanical disintegration.

- Visual Disclosures: Packaging must display the official flushable symbol or a mandatory “Do Not Flush” logo to eliminate consumer confusion at the point of purchase.

- WSAA Collaboration: The Water Services Association of Australia (WSAA) leads this initiative to protect environmental health and reduce municipal utility costs.

Rapid Disintegration Engineering and Material Safety

Top Source Hygiene builds toilet rolls specifically to meet these regional plumbing safety requirements. We focus on fiber length and ply density to ensure the paper provides a premium experience during use but breaks down immediately once it enters the drainage system. This balance prevents clogs in both municipal lines and private septic systems.

- Material Integrity: We use long-fiber 100% virgin wood pulp to guarantee rapid breakdown in water while maintaining high tensile strength and soft texture.

- Ply Density Control: We strictly maintain a density of 13–22g/m² per ply, aligning with international septic-safe benchmarks for Oceania and North America.

- OBA-Free Composition: Every roll is guaranteed free from Optical Brightening Agents, ensuring that disintegrated fibers do not release chemical whiteners into the water filtration process.

Designing Packaging for Global Compliance vs. Aesthetics

Successful packaging bridges cultural design—like European minimalism or US bold graphics—with mandatory compliance data to ensure products are both distributor-ready and legally sound.

Balancing Regional Aesthetic Values with Informational Layouts

Visual preferences vary by border. Brands must adapt their color palettes to meet regional expectations to gain shelf traction. For Asian markets, red and gold symbolism often signals quality and prosperity. Conversely, Scandinavian markets respond better to muted, “eco-minimalist” tones that communicate environmental responsibility without visual noise.

Whitespace is a technical requirement, not just a design choice. Designers must manage layout density to accommodate multi-language text and large-format warning labels. This ensures the brand identity remains clear even when regional laws require extensive fine print on the primary display panel.

Retail visibility in North America relies on high-contrast typography. While designers focus on bold brand names, they must also ensure font sizes for weights and measures meet strict legal legibility standards. Integrating these early avoids costly reprints or retail rejections.

Cultural coding often dictates how technical data is presented. In the German market, Bauhaus-influenced precision is highly valued. On these packs, technical icons representing the following attributes serve as design elements:

- Paper Ply: Clear 2-ply to 5-ply indicators.

- Roll Length: Specific meter or sheet counts.

- Fiber Source: 100% Virgin Wood Pulp labeling.

- Texture: Icons for point-to-point embossing.

Integrating Material Disclosures into Premium Packaging Formats

Material safety is a primary selling point in developed markets. Top Source Hygiene utilizes specific badges on Format A (Individual Wrap) packaging to satisfy North American transparency needs. These include:

- OBA-Free: Confirming no optical brightening agents.

- Septic Safe: Certifying rapid disintegration for plumbing health.

- FDA Compliance: Validating hygiene standards for sensitive skin.

For high-volume retail, Format B (Direct Bundle Packs) prioritizes immediate data verification. The design places the GSM weight and roll count prominently alongside the brand logo. This helps wholesalers and warehouse club buyers verify value at a glance without searching through fine print.

Mechanical compression technology is used to maximize container payloads, but it can distort packaging graphics. We position regulatory barcodes on flat, stable zones of the poly bundle to ensure they remain scannable even after high-density packing. This prevents scan failures during automated warehouse sorting.

Instead of hiding certifications, we use ISO 9001 and EU hygiene symbols as trust-building anchors. On bulk poly bundles, these marks are positioned to validate the factory-direct source, signaling to international distributors that the product meets high-tier manufacturing benchmarks before the pack is even opened.

Managing UPC, EAN, and Barcode Placement Standards

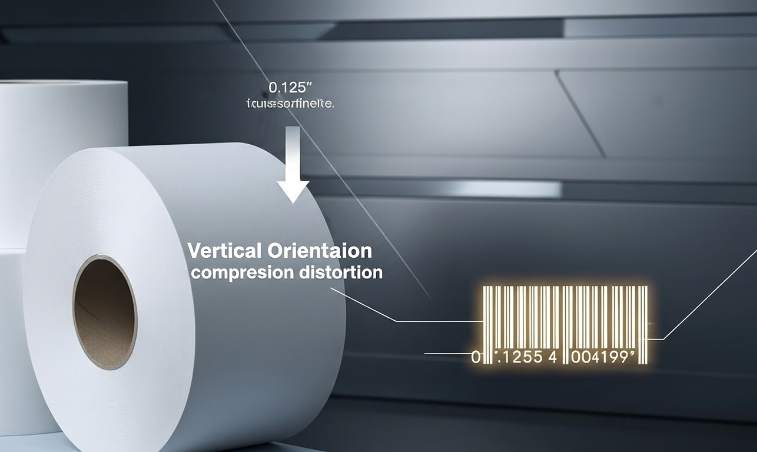

Global standards require GS1 placement guidelines, a 0.125-inch quiet zone, and lower-right quadrant positioning. We prioritize vertical orientation on rolls and stable placement on poly bags to prevent compression distortion.

GS1 Placement Principles and Quiet Zone Requirements

Standardized barcode positioning eliminates scanning failures at the point of sale. We follow GS1 protocols to ensure that every roll or bundle leaving our facility integrates with international retail systems. Technical precision during the design phase prevents costly chargebacks and logistics delays.

- Quadrant Placement: Position barcodes in the lower-right quadrant of the back panel to align with global retail scanning habits.

- Quiet Zone: Maintain a mandatory 0.125-inch (3.175mm) buffer of empty space around the symbol so scanners can detect the start and stop patterns.

- Symbol Scaling: Set magnification between 80% and 200% of the standard 1.469-inch width to ensure legibility across various scanner types.

- Surface Integrity: Print only on smooth, continuous surfaces to avoid the “laddering” effect that occurs on uneven textures.

Implementing Barcodes on Flexible Poly Bags and Individual Wraps

Bulk tissue products present unique packaging challenges due to the flexible nature of PE bags and the mechanical compression used for 40HQ container efficiency. We apply specific orientation rules to maintain code geometry even under high-pressure loading conditions.

- Vertical Orientation: Apply barcodes vertically along the height of cylindrical rolls. This prevents the “picket fence” distortion caused by the natural curve of the product.

- Compression Stability: Locate codes on central, stable areas of poly bags. This avoids placement near seams or gussets where mechanical compression during bagging often warps the film.

- Curvature Limits: Ensure the scanner tangent line remains below 30 degrees on individual wraps to keep the full bar height visible to the laser.

- Secondary Syncing: Match EAN symbols on secondary 5-ply export cartons with internal bundle barcodes to maintain 100% traceability from the Hebei factory to the warehouse shelf.

We verify scannability before shipment. Our quality teams provide visual verification of barcode clarity during the 40HQ loading process to ensure every batch meets regional retail expectations in North America, Europe, and the Middle East.

Batch Coding for Traceability: Global Best Practices

Global batch coding uses unique identifiers and real-time scanning to enable rapid recalls and production accountability. These systems create the audit trails required for ISO 9001 and FDA compliance.

Standardizing Identifiers through Real-Time Event Capture

Traceability depends on the integrity of the data captured at the factory floor. We eliminate manual entry gaps by establishing a digital genealogy for every roll of tissue. This process ensures that if a quality issue arises, we can isolate the specific hour and machine responsible within minutes.

- Global Standards: We implement Global Trade Identification Numbers (GTINs) to maintain barcode consistency across international supply chains.

- Automated Capture: Scan-driven checkpoints at receiving, packaging, and shipping remove human error from the data log.

- Facility Infrastructure: Wireless LAN systems across our Hebei production lines correlate inventory movement with quality control decisions in real time.

- Process Interlocks: System-enforced hard gates prevent a batch from moving to the next stage until the required data event is recorded.

Applying Batch Color Consistency and Pre-Shipment Verification

For high-volume distributors moving 40HQ containers, visual uniformity is a commercial requirement. We link our raw material fiber lots directly to production codes to ensure that the 85-92% brightness level remains identical from the first roll to the last.

- Visual Proof: We provide Pre-Shipment Visual Verification, including photos and video of batch codes, so you see the product before the balance payment.

- Fiber Linking: Our system matches 100% Virgin Wood Pulp lots to specific batch codes to maintain color and texture consistency across 9-ton shipments.

- Private Label Integration: We align batch-level genealogy with your custom packaging to simplify regulatory audits and mock recalls planned for 2026.

- Loading Transparency: We verify that physical batch labels on every bundle match the digital manifest, preventing delays during international customs clearance.

Frequently Asked Questions

What are the mandatory labeling requirements for toilet paper in the US?

The FDA does not regulate toilet paper as a consumer product, which keeps federal labeling requirements minimal. Specific states like California mandate disclosures if the product hits the 45% post-consumer recycled fiber weight threshold. Most professional brands adopt voluntary standards like Green Seal GS-1 or Ecologo to verify quality. As a factory, we ensure our 100% Virgin Wood Pulp products remain OBA-free to meet safety expectations across all US jurisdictions.

Does EU packaging require multiple languages?

Yes, EU member states require labeling in their specific national language for products sold to final users. Many brands use multi-language labels covering the six most common EU languages to streamline inventory. A major shift is coming on 12 August 2026, when the new EU Packaging Regulation introduces uniform pictograms for material composition and recyclability across all member states, simplifying the visual layout for international exporters.

What specific data is required for global retail barcodes?

Global retail distribution requires EAN-13 or UPC-A formats containing a Global Trade Item Number (GTIN). This identifier includes your GS1-assigned company prefix, a specific product number, and a check digit. To prevent scanning failures, barcodes must feature high-contrast colors like black or dark blue and maintain clear “quiet zones” of at least 0.125 inches on all sides.

How can a brand legally display FSC logos on custom packaging?

You must hold a valid Chain of Custody (CoC) certification and sign a trademark license agreement. The logo itself has technical requirements, including a minimum height of 6mm and the inclusion of your specific license code. Every placement on custom packaging requires direct approval from an accredited certification body before you can start mass production.

Are suffocation warnings mandatory for toilet paper poly-bags?

There is no US federal law, but five states—including New York and California—mandate suffocation warnings on plastic bags thinner than 1 mil with openings larger than 5-7 inches. Major retailers like Amazon and Target enforce these safety requirements globally for any poly-bagged product to mitigate risks for children. We apply these warnings to all regional bundle packs to ensure cross-border retail compliance.

How does Top Source Hygiene support regional compliance audits?

We provide transparent access to all manufacturing documentation, including ISO 9001 quality logs and material safety certifications. Our Hebei facility facilitates on-site inspections and worker interviews to verify labor compliance. This ensures all private label products meet the strict REACH and FDA standards required by international importers for seamless market entry.

Final Thoughts

Cheap recycled alternatives risk customs seizures and retail chargebacks that immediately erase your profit margins. Our 100% Virgin Wood Pulp and OBA-free standards eliminate these regulatory hurdles before your shipment leaves the Hebei industrial hub. Investing in compliant inventory secures long-term distribution rights and buyer trust in highly regulated markets like the US, EU, and Australia.

Eliminate the guesswork by starting with a 40HQ trial order of our TSH-2559 series to verify our septic-safe engineering firsthand. We provide full batch documentation and pre-shipment visual verification to ensure your private label meets every 2026-2028 mandate. Contact our production team today to sync your packaging design with regional legal requirements.