A rigorous Sampling & Prototyping Workflow serves as the primary defense against quality drift and costly plate remakes in high-volume paper procurement. Failing to validate physical specs before committing to a 40HQ container often results in shipments that miss softness benchmarks or violate chemical safety regulations, leading to immediate rejection at the distribution level.

We examine the 14-day lifecycle from digital 3D artwork to the final golden sample. By prioritizing 100% Virgin Wood Pulp verification, 13–22g/m² ply density checks, and OBA-free purity audits, you establish a non-negotiable technical standard that protects brand reputation across North American and European markets.

Why Physical Samples are the Foundation of B2B Sourcing

Physical samples bridge the gap between 3D renders and reality. They allow volume buyers to verify material GSM, texture, and chemical purity before committing capital to production.

Mitigating Procurement Risk Through Direct Quality Assessment

Digital mockups serve a purpose for layout and design approval, but they cannot simulate the physical performance of a high-density tissue roll. A physical sample provides the only definitive proof that the goods will meet the technical requirements of your specific distribution channel or hospitality group.

- Tactile Verification: Evaluate the actual texture and GSM thickness—Top Source Hygiene maintains a strict 13–22g/m² range per ply—which digital files cannot convey.

- Operational Testing: Confirm product behavior under real-use conditions, such as rapid disintegration rates to ensure the paper remains septic-safe for North American and European plumbing.

- Supplier Calibration: Validate that our Hebei-based factory accurately translates your technical requests into a physical prototype before the full 40HQ container run.

Verifying OBA-Free Purity and Ply-Bonding Integrity

For importers targeting the EU and North American markets, chemical safety and material purity are essential for regulatory compliance. Hand-samples allow your quality control team to perform lab audits on the raw materials used in our production process.

- Chemical Safety Audit: Inspect samples to confirm 100% OBA-Free status, ensuring no optical brightening agents are used, which is critical for skin-safe certifications.

- Structural Lamination: Test the durability of multi-ply sheets bonded with our high-pressure lamination technology to ensure layers stay intact during use without separating.

- Fiber Performance: Compare 100% Virgin Wood Pulp samples against local benchmarks to verify the lint-free experience and the 85-92% natural brightness we achieve through fiber selection.

Phase 1: Digital 3D Mockups and Artwork Proofs

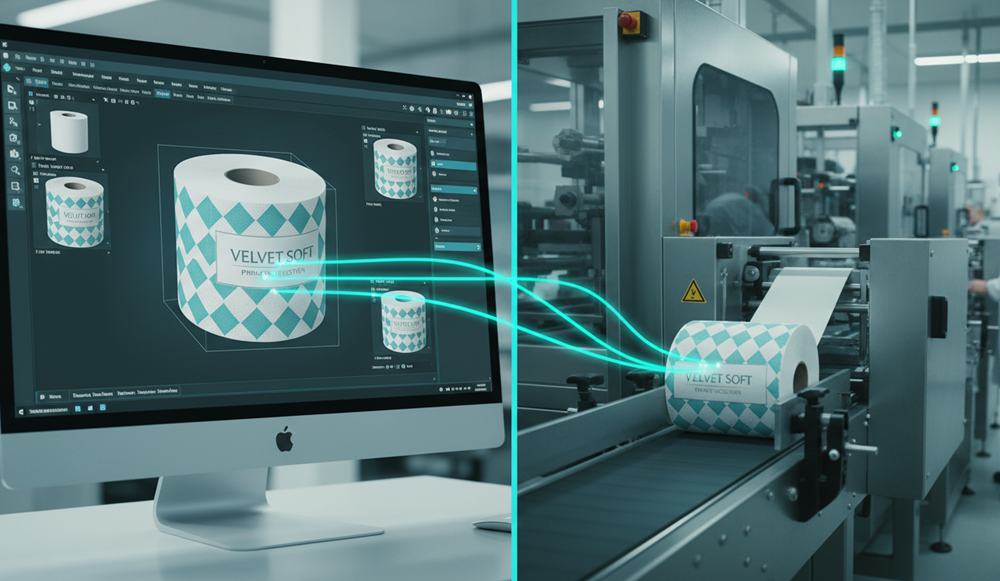

Digital 3D mockups visualize designs early, catching text distortion and alignment errors on curved packaging to speed up approval before starting physical production.

Digital 3D mockups bridge the gap between a design concept and the manufacturing floor. In the private label hygiene sector, flat 2D artwork often hides alignment issues that only become visible once wrapped around a cylindrical roll or a high-density bundle. By generating 3D visualizations, we verify how logos and legal text interact with the physical product geometry before committing to plates or physical samples.

Accelerating Design Approval with 3D Rendering

Most B2B sourcing delays happen during the “back-and-forth” of artwork revisions. We use three-perspective rendering to show exactly how a brand’s aesthetic holds up on curved surfaces. This process allows for instant adjustments in software like Adobe Illustrator or Esko Studio, cutting weeks off the traditional approval timeline.

- Geometric Accuracy: Visualizing design interaction with roll dimensions through three-perspective rendering.

- Distortion Control: Identifying text stretching or misaligned graphics on curved packaging surfaces early.

- Rapid Iteration: Using Esko Studio and Adobe tools to perform instant digital revisions and reduce time-to-market.

Validating CNC Embossing and Private Label Artwork

At Top Source Hygiene, digital proofs serve as the technical blueprint for our manufacturing equipment. We use this phase to confirm the exact placement of CNC-precision embossing patterns. This is critical for ensuring point-to-point ply-bonding in our multi-ply virgin wood pulp rolls, which keeps the layers from separating while increasing absorbency.

- CNC Precision: Reviewing embossing patterns to ensure functional ply-bonding and quilted texture.

- Packaging Verification: Confirming branding for both individual hygiene wraps and large-scale retail bundle packs.

- Batch Uniformity: Locking in digital color standards to guarantee consistency across full 40HQ container orders.

By finalizing these details digitally, we protect the production cycle from the high costs of plate remakes. Once the 3D mockup is approved, it establishes the visual baseline that the factory must match during mass production.

Scale Your Brand With Premium OEM Tissue

Phase 2: Physical Paper and Embossing Hand-Samples

Physical sampling verifies wood pulp purity, ply strength, and embossing depth. This stage confirms tactile quality and technical performance before moving to full-scale production.

Digital proofs show the layout, but they cannot simulate the tactile experience of premium tissue. We use physical hand-samples to bridge the gap between a design file and a finished product. This phase allows buyers to verify the fiber integrity and skin-feel of the material before the factory commits to a full 40HQ container run.

Tactile Validation of Fiber Strength and Ply Density

We focus on the raw material foundation during this stage. Since we exclusively use 100% virgin wood pulp, the sample must demonstrate the specific long-fiber strength that prevents linting. We test the physical sheets to ensure they meet the density requirements for your specific target market, whether you need a lightweight 2-ply retail roll or a heavy-duty 5-ply luxury option.

- Fiber Purity: Verification of 100% virgin wood pulp to guarantee a lint-free, cloud-like softness.

- Ply Density: Precise measurement of 13–22g/m² per ply to balance mechanical durability with user comfort.

- Safety Standards: Evaluation of natural brightness (85-92%) to confirm the product is 100% OBA-free and safe for sensitive skin.

- Septic Compliance: Assessment of rapid disintegration and tensile strength to meet 2026 septic-safe standards.

CNC Point-to-Point Embossing and Ply-Bonding Integrity

Embossing serves both functional and aesthetic purposes. We apply CNC-precision patterns to the hand-samples to check how the design affects liquid retention and layer adhesion. This technical verification ensures the multi-ply sheets stay bonded through high-pressure lamination and do not separate during use.

- Absorbency Boost: Application of CNC-precision patterns designed to increase surface area and improve absorbency by 30%.

- Lamination Testing: Verification of high-pressure ply-bonding to ensure layers remain intact during dispensing and use.

- Pattern Customization: Review of floral, dot, or custom logo embossing to align with hospitality or retail branding requirements.

- Perforation Accuracy: Confirmation of clean-cut perforation lines to ensure smooth tearing and prevent shredded edges.

By finalizing these physical details now, we eliminate the risk of material dissatisfaction during mass production. We provide clear visual and tactile evidence that the paper meets the rigid specs required for international distribution.

Phase 3: Packaging Prototypes (BOPP/Paper Wrap Trials)

Physical prototypes validate film barrier strength, print accuracy, and roll fit to ensure hygiene and integrity during international shipping in 40HQ containers.

Physical packaging trials bridge the gap between digital artwork and real-world performance. We run these tests to confirm the material survives high-pressure palletization and varying humidity levels during sea freight.

Functional Testing for Film Integrity and Dimensional Fit

Our lab subjects every prototype to a battery of stress tests. These evaluations ensure that the BOPP films or paper wraps do not fail when thousands of kilograms are stacked in a single container.

- Dimensional Validation: Ensures the bag or wrap size accurately fits the roll volume and weight without tearing.

- Drop Tests: Finished goods must withstand the rigors of manual handling and automated palletization.

- Color Accuracy: Spectrophotometer validation ensures printed branding matches digital artwork across entire 40HQ batches.

- Lamination Strength: Peel and shear force testing prevents packaging delamination in humid climates.

Individual Wrap and Bundle Format Optimization

Top Source Hygiene trials specific wrapping formats to balance luxury feel with logistics efficiency. We adjust the mechanical tension during the bagging process to protect the specific fiber structure of our 100% Virgin Wood Pulp rolls.

- Format A Trials: Focuses on individual roll wrapping in paper or film to maintain hygiene standards for premium hospitality markets.

- Mechanical Compression: Minimizes roll bulk while preserving paper softness, allowing for higher 40HQ payload optimization.

- Direct Bundle Pack (Format B): Optimizes roll counts for high-volume supermarkets using reinforced 5-ply export cartons.

- BOPP Surface Treatments: Prepares the film for high-speed automated packing lines to ensure consistent output for large-scale orders.

These trials finalize the technical specifications before we commit to the golden sample. By verifying these physical details early, we eliminate the risk of packaging failure during the final production run.

Managing Feedback Loops and Revision Cycles

Systematic feedback loops convert stakeholder input into production-ready specs, using visual audits to ensure mass-produced paper matches approved golden samples with 100% transparency.

Implementing a Systematic Framework for Iterative Refinement

Raw data from the field only becomes useful when you structure it. We move beyond casual communication to a rigorous loop that identifies technical deviations before they reach the production line. This process ensures that the final product meets the specific demands of your local market.

- Data Capture: We store input from distributors and quality control teams to identify recurring technical pain points.

- Prioritization: We apply an Impact vs. Effort Matrix to rank revisions for critical specs like perforation precision and ply-bonding strength.

- Version Control: Our team maintains strict logs across digital artwork and physical embossing hand-samples to prevent design drift.

- Verification: We close the loop with post-implementation reviews to confirm the paper achieved the required tactile or absorbent properties.

Closing Revision Cycles with Pre-Shipment Visual Verification

Transparency is the only way to protect your margins during large-scale B2B imports. We utilize digital audits to bridge the gap between our Hebei manufacturing hub and your warehouse, ensuring the bulk order matches the tactile quality of the initial approved sample.

- Digital Audits: We provide high-definition photos and videos of finished goods for a final review before you release the balance payment.

- Brightness Standards: We verify that batch color consistency meets the 85-92% natural brightness levels of the golden sample.

- Label Validation: Our team double-checks private label packaging layouts and barcode placements during the final review phase.

- Logistics Audit: we verify 40HQ container loading density to ensure physical revisions did not negatively impact your landed costs.

Approving the “Golden Sample” for Production Stability

A golden sample provides the final physical benchmark for mass production, locking in texture and ply-bonding standards to ensure 40HQ container consistency and eliminate quality disputes.

| Quality Metric | Golden Sample Standard | Production Tolerance |

|---|---|---|

| Material Purity | 100% Virgin Wood Pulp | Zero recycled waste allowed |

| Natural Brightness | 85% – 92% (OBA-Free) | +/- 2% variance |

| Ply Density | 13 – 22g/m² per ply | Strict adherence to GSM spec |

| Embossing | Point-to-Point CNC Precision | 30% absorbency boost maintained |

Establishing an Objective Standard through Physical Approval

We use the golden sample to move beyond digital mockups and create a tangible baseline that the factory must replicate. This physical unit represents the exact tactile feel, embossing depth, and perforation strength required for the final product. By having a signed reference on the factory floor, we remove subjective opinions about whether a roll is “soft enough” or “strong enough.”

- Traceability: We sign and date every approved sample to ensure the production team never uses an outdated prototype during setup.

- Integrity: Sealing the approved sample prevents environmental humidity or dust from degrading the paper fibers, keeping the benchmark accurate for months.

- Third-Party Inspection: We distribute identical sets of signed samples to both our production leads and independent inspectors to ensure unified evaluation criteria.

- Standardization: The sample establishes a measurable baseline for perforation strength, ensuring a clean tear that prevents “shredded edges” in retail packs.

Batch Consistency and Pre-Shipment Visual Verification

Mass production for a 40HQ container involves handling 7,000kg to 9,000kg of paper. We utilize the golden sample to maintain uniformity across these massive payloads, particularly for multi-ply products where lamination strength is critical. Our team compares the high-pressure ply-bonding of the production run against the sample to ensure layers do not separate during use.

- Chemical Safety: We verify the 85-92% natural brightness against the sample to confirm no Optical Brightening Agents (OBA) were introduced.

- Transparency: Our Pre-Shipment Visual Verification process involves taking photos and videos of the finished goods alongside the golden sample before you pay the 70% balance.

- Weight Accuracy: We check rolls ranging from 780g to 5000g bundles against the sample density to prevent fluctuations in paper softness.

- Disintegration Testing: We ensure the production batch matches the rapid-dissolve properties of the golden sample, meeting septic-safe standards for North American and European markets.

Once we approve the golden sample, we treat the specifications as non-negotiable. This prevents “quality drift” where the first few thousand rolls look great but the end of the batch begins to deviate. By anchoring the entire 40HQ run to a single physical master, we protect your margins and your brand reputation.

Shipping Samples Internationally: Timeline and Costs

International sample shipping typically takes 3 to 15 days. We dispatch stock inventory within 3 days, while custom prototypes require a 10-day production window before express courier pickup.

Courier Service Tiers and Associated Freight Costs

Carrier selection determines the landed cost and speed of your evaluation process. High-priority projects benefit from expedited tiers, while standard options suit routine inventory planning for distributors.

- Express Couriers: DHL, FedEx, and UPS provide the fastest turnaround, delivering samples in 1-3 business days.

- Standard Priority: This tier balances cost and speed, reaching 180 countries within 6-10 business days.

- Economy Logistics: Services offer lower rates starting near $17 for parcels under 4 lbs, with delivery windows of 5-18 days.

Customs processing and destination geography remain the primary variables that can extend these timelines beyond initial carrier estimates.

Factory Turnaround Times for Stock and Custom Samples

Preparation at our Hebei facility follows specific protocols based on your customization needs. Top Source Hygiene provides free samples to help global clients verify the 100% Virgin Wood Pulp quality before committing to a 40HQ container order.

- Stock Dispatch: Ready-to-ship models from our “Big 10” inventory, such as the TSH-2559, leave the facility within 2-3 days.

- Custom OEM/ODM: Prototypes involving specific CNC-precision embossing patterns or private label packaging require approximately 10 days for production.

- Pre-Shipment Verification: We provide visual confirmation through photos and videos to ensure the prototype meets your brand specifications before dispatch.

This internal rigor ensures the physical sample matches the digital requirement, preventing delays in the international shipping loop and protecting your project timeline.

Frequently Asked Questions

How long does the custom sampling process take for paper products?

Standard custom samples from Top Source Hygiene typically take 10 days. For complex projects that require new CNC molds for embossing or specialized material sourcing, the timeline ranges from 15 to 60 days. The final duration depends on revision cycles and when the tech pack is officially finalized.

Are there setup costs for custom printing and packaging samples?

Yes. Setup costs or plate fees apply to custom printing to cover screen creation, color calibration, and ink mixing. These charges act as one-time fees per design and remain valid for reorders within a two-year window.

Can 3D digital mockups replace physical prototypes in 2026?

Digital 3D mockups serve as realistic prototypes to validate artwork and geometry, which reduces early development costs. But physical samples remain essential for verifying tactile qualities like softness and 100% Virgin Wood Pulp fiber integrity before mass production.

What is the purpose of a Golden Sample in B2B sourcing?

The golden sample acts as the final, non-negotiable benchmark for mass production. Both the manufacturer and buyer sign off on this sample to ensure every roll in a 40HQ container matches the approved brightness, ply density, and perforation quality.

What are the typical international shipping costs for paper samples?

Top Source Hygiene covers shipping costs for qualified B2B partners. In the general market, shipping a 5 lb sample parcel to the US or EU via express carriers like DHL or FedEx typically costs between $50 and $155 depending on urgency.

How do buyers test the softness and absorbency of hand-samples?

Buyers use subjective hand panel testing following AATCC procedures or objective instruments like the ELMOGAHZY-KILINC method. these tests quantify hand force and surface friction to ensure the paper meets high-end hospitality or retail standards for premium 100% Virgin Wood Pulp.