Absorbency & Efficiency standards dictate whether a facility controls costs or suffers from excessive paper consumption and labor overhead. Low-grade fibers lack the pore structure needed to move liquid instantly, forcing users to pull more sheets and driving up annual disposal fees.

We benchmark 100% Virgin Wood Pulp against bamboo using ISO 12625-8 protocols. This evaluation focuses on how point-to-point embossing increases capacity by 30% and how 13–22g/m² ply density maintains the capillary pressure required for rapid wicking in commercial environments.

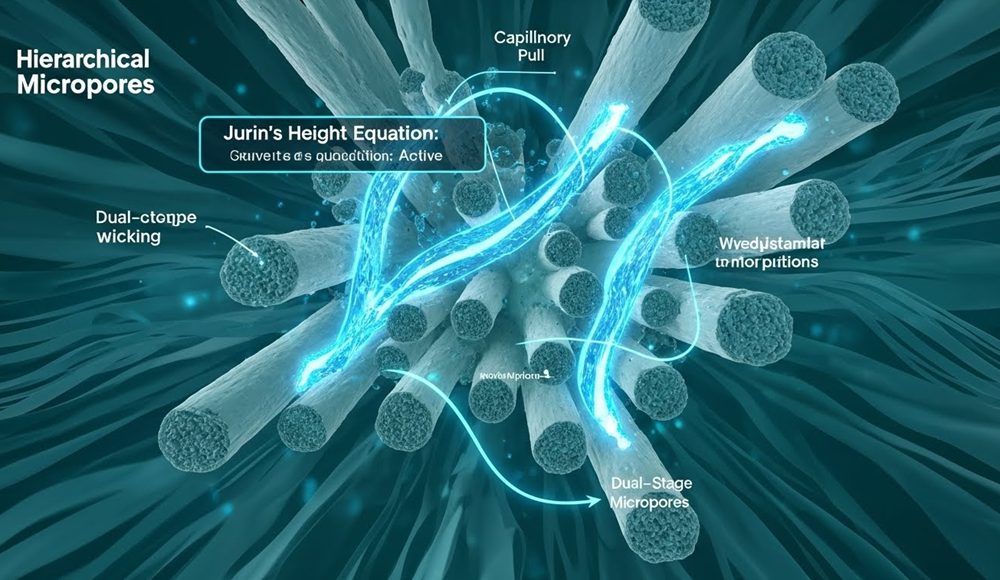

How Wood Pulp’s Pore Structure Facilitates Rapid Wicking

Wood pulp uses hierarchical micropores for capillary pull and macropores for speed. This dual-stage network ensures rapid, high-capacity absorption across the entire surface area.

Capillary Pressure and Dual-Stage Wicking Dynamics

Liquid transport in wood pulp relies on capillary pressure as its primary engine. Smaller micropore radii generate a more powerful pull, effectively moving water upward against gravity according to Jurin’s height equation. This physical mechanism determines how effectively a tissue product handles initial contact with moisture.

- Dual-Stage Flow: Liquid moves rapidly through large macropores during early wetting before shifting to corner-flow transport in partially filled voids.

- Kraft Pulping Impact: Chemical processing removes lignin to establish a uniform, interconnected pore distribution throughout the fiber wall.

- Fiber Swelling: Wetting causes fibers to expand, which can restrict interfiber spaces and potentially reduce the wicking-equivalent radius by up to 44%.

- Pore Interconnectivity: Maintaining open pathways within the cell wall is vital for preventing the wicking speed from plateauing prematurely.

100% Virgin Wood Pulp and Point-to-Point Embossing Efficiency

At Top Source Hygiene, we engineer our products to maximize these natural wicking properties. By utilizing 100% Virgin Wood Pulp, we provide a robust fiber network that resists structural collapse even when fully saturated. This ensures that the macropores remain open for continuous fluid transport.

- Long-Fiber Selection: We use premium virgin strands to maintain a high-integrity pore network that outperforms recycled or short-fiber alternatives.

- Point-to-Point Embossing: Our CNC-precision technology increases absorbency by 30% by creating engineered macropores that trap and distribute liquid instantly.

- Optimized Ply Density: We strictly control weights between 13–22g/m² to balance the wicking radius with the structural strength required for heavy fluid loads.

- OBA-Free Processing: Eliminating synthetic whitening agents preserves the natural cellulose lamellae, keeping pore accessibility unhindered for the user.

Does High Fiber Density in Bamboo Slow Down Initial Absorption?

Higher bamboo fiber density slows absorption rates compared to finer particles, though maximum saturation still occurs within 60 seconds. Strategically managed GSM and embossing mitigate these capacity limitations.

The Inverse Relationship Between Fiber Fineness and Wicking Speed

Fiber coarseness directly dictates how much liquid bamboo can hold. While all densities reach a saturation plateau quickly, the total volume varies based on the particle size within the pulp. Finer fibers provide more capillary pathways than coarser alternatives.

- Coarser Fibers: Exhibit water absorption rates as low as 102.5%.

- Finer Particles: Reach absorption levels between 742.8% and 775.4%.

- Saturation Timeline: Maximum water uptake occurs within the first 60 seconds regardless of fiber density.

Optimizing Bamboo Performance via GSM Control and Point-to-Point Embossing

Top Source Hygiene counters the slower wicking of dense fibers by engineering the physical sheet structure. We manage fiber density to ensure the pulp remains soft without creating a non-porous barrier that blocks liquid penetration.

- GSM Control: We maintain ply density between 13–22g/m² to balance softness with high-wet-strength durability.

- Point-to-Point Embossing: This CNC-precision technology increases the functional surface area, boosting absorbency by 30%.

- Compliance Standards: Strategic use of 100% OBA-free long-fiber pulp ensures rapid disintegration, meeting 2026 global septic safety requirements.

Build Your Unique Premium Toilet Paper Brand

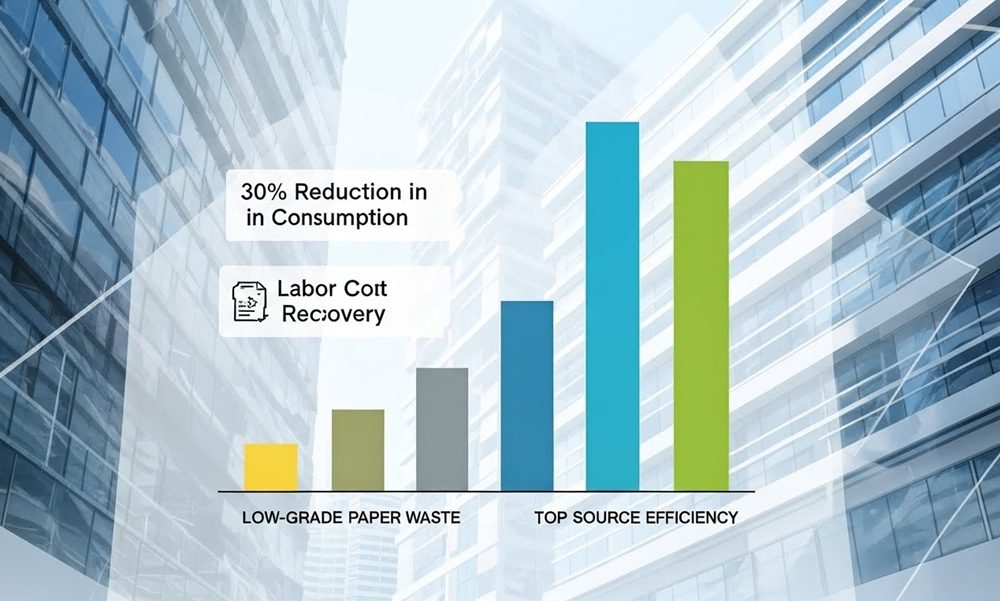

The ROI of Efficiency: Why Superior Sorption Lowers Annual Expenditure

Superior sorption reduces sheet usage and labor costs. 100% virgin wood pulp ensures high absorbency per gram, improving budget performance for commercial buyers throughout 2026.

| Sorption Metric | Technical Specification | Economic Impact |

|---|---|---|

| Initial Wicking Speed | 100% Virgin Wood Pulp | Lowers paper consumption per visit |

| Total Liquid Capacity | Point-to-Point Embossing | +30% absorption per sheet |

| Roll Longevity | TSH-3396 (5000g High-Density) | Reduces dispenser refill labor |

Minimizing Material Waste with Fast-Acting Fiber Structures

Commercial facility managers often overspend on paper because low-grade fibers fail to absorb moisture instantly. When paper lacks an efficient pore structure, users pull multiple sheets to compensate for slow wicking. We address this by utilizing 100% virgin wood pulp, which creates the necessary capillary pressure to move liquid through the sheet the moment it makes contact.

- Fiber Capillary Effect: Long-fibers in virgin wood pulp create a network of micropores that pull moisture deep into the sheet instantly.

- Consumption Control: Higher absorbency rates mean users require fewer sheets per visit, cutting total paper consumption volume across the facility.

- Waste Reduction: Reduced sheet counts per use lower the frequency of trash collection and associated waste disposal fees.

- Perforation Integrity: Precision perforation prevents “shredded edges,” ensuring users take only what they need without accidental roll waste.

Cost Recovery via Point-to-Point Embossing and High-Density Rolls

Manufacturing specifications directly dictate long-term operational savings. We focus on physical structures that maximize the utility of every gram of paper. By combining advanced embossing technology with high-density roll winding, we help distributors and hospitality groups recover costs through better logistics and reduced maintenance cycles.

- Point-to-Point Embossing: This technology increases total surface area to boost liquid absorbency by 30% compared to standard flat sheets.

- Labor Efficiency: High-density models like TSH-3396 (5000g per bundle) maximize paper length, which slashes the labor hours spent on frequent dispenser refills.

- Payload Optimization: Mechanical compression technology allows for a 40HQ payload of up to 9 tons, significantly lowering the landed freight cost per roll.

- Infrastructure Safety: Rapid disintegration technology prevents plumbing clogs, shielding the facility from secondary maintenance expenses and emergency repairs.

Layer Bonding Mechanics and Their Influence on Wet-Strength Retention

Hydrogen bonds and covalent PAE resins enable 20-35% wet-strength retention in 100% virgin pulp, preventing shredding through advanced mechanical ply-bonding and chemical cross-linking.

Cross-Linking Chemistry and Fiber Adhesion

Standard wood pulp fibers connect via van der Waals forces and hydrogen bonds. These bonds break instantly when water penetrates the sheet, causing untreated paper to lose structural integrity. Chemical modification changes this dynamic by introducing water-resistant bridges between fibers.

- PAE Resins: Polyamide-amine-epichlorohydrin additives create permanent covalent crosslinks that resist moisture.

- Cationic Starch: This works with resins to form a hydrophobic network, effectively restricting fiber swelling during saturation.

- Tensile Retention: These chemical modifications increase wet tensile strength retention from a baseline of 4% to over 30%.

High-Pressure Ply-Bonding and Fiber Performance

Mechanical bonding protocols ensure multi-ply tissue remains intact during heavy use. Top Source Hygiene utilizes high-pressure lamination to bond layers without excessive chemical reliance, maintaining the “cloud-like” softness required for premium markets.

- Point-to-Point Embossing: CNC-precision patterns create mechanical interlocks that improve liquid distribution and boost absorbency by 30%.

- GSM Control: We strictly manage ply density between 13–22g/m² to optimize the balance between sheet durability and skin-feel.

- Fiber Morphology: Long-fiber 100% virgin wood pulp provides the surface area necessary for optimal fiber-to-fiber bridge formation.

- OBA-Free Safety: Fiber integrity is achieved through material selection and mechanical pressure rather than fluorescent brightening agents.

How Do We Measure Liquid Sorption Capacity via ISO 12625-8 Standards?

ISO 12625-8 uses basket-immersion to measure saturation speed and total liquid-holding capacity. This ensures consistent absorbency by calculating the mass ratio of absorbed water to dry fiber.

Measuring Absorption Time and Mass Capacity via Basket-Immersion

International B2B trade relies on ISO 12625-8:2010 to standardize how we evaluate tissue performance. This automated protocol eliminates human error and provides a clear benchmark for liquid intake speed and volume across different manufacturing batches.

- Automated Immersion: We submerge a cylindrical test basket containing the tissue sample into demineralized water to prevent mineral interference with wicking speed.

- Precision Timing: Sensors record the exact duration from the first moment of water contact until the sample achieves full saturation.

- Capacity Calculation: We determine the liquid-holding capacity by comparing the dry mass of the sample to its mass after a 30-second submersion and a subsequent 60-second drainage period.

- Standardized Metrics: Results are expressed in grams of water per gram of paper fiber, ensuring transparency for wholesalers comparing 40HQ container specifications.

Improving Liquid Retention Through Point-to-Point Embossing Technology

Raw material quality and mechanical finishing dictate how well a product performs under ISO testing. We optimize these factors at the factory level to ensure Top Source Hygiene products meet high-performance B2B requirements.

- Point-to-Point (PTP) Embossing: Our CNC-precision embossing creates internal air pockets that increase liquid capacity by 30% compared to standard flat-pressed tissue.

- 100% Virgin Wood Pulp: We select premium long-fiber wood pulp to provide the structural integrity needed to survive the basket-immersion drainage phase without shredding.

- GSM Optimization: We maintain a density of 13–22g/m² per ply to balance a soft texture with the durability required for rapid wicking.

- High-Pressure Lamination: This bonding technique ensures plies do not separate during wetting, preserving the hierarchical pore structure necessary for capillary pressure.

Frequently Asked Questions

Does bamboo pulp or virgin wood pulp offer faster wicking speeds for bulk tissue products?

While both materials offer high performance, 100% virgin wood pulp utilizes premium long-fiber structures to facilitate rapid wicking. Bamboo pulp provides high bulk and strength, but its wicking speed depends heavily on fiber coarseness. By 2026, technical benchmarks emphasize fiber morphology over material type to ensure immediate liquid uptake.

How does a 2-ply virgin wood pulp roll compare to a 3-ply bamboo roll in terms of water sorption?

Water sorption capacity depends more on fiber quality and ply construction than ply count alone. A high-density 2-ply virgin wood pulp roll often matches or exceeds the capacity of a standard 3-ply bamboo roll when it utilizes advanced point-to-point embossing and ply-bonding technology to maintain structural voids.

What is the industry standard for measuring tissue absorbency in 2026?

The primary standard is ISO 12625-8, which employs a basket-immersion test method. This protocol quantifies two metrics: water-absorption time (the seconds required for complete wetting) and water-absorption capacity (the mass of water retained per gram of sample).

Can customized embossing patterns improve liquid retention in household rolls?

Yes, 3D embossing patterns increase the surface area of the tissue, which creates more space for liquid retention. Specifically, point-to-point embossing can increase absorbency by approximately 30% by creating quilted pockets that trap moisture without compromising the mechanical strength of the fiber bonds.

Why does over-compressed tissue sometimes fail to absorb liquid effectively?

Extreme mechanical compression collapses the internal pore space between fibers where fluid is normally stored. While compression is necessary for 40HQ container efficiency, we utilize specific bagging technology that maintains paper fluffiness to ensure the internal structure remains open for rapid fluid penetration.

Are Top Source Hygiene products safe for sensitive skin and high-traffic plumbing systems?

Our products are 100% OBA-Free, containing no optical brightening agents or fluorescent whiteners. They are also engineered for rapid disintegration to meet septic-safe requirements in North America and Europe, preventing clogs in high-traffic commercial environments.