From hotels to public facilities, selecting the right toilet paper requires balancing softness, strength, and sustainability with the demands of your market. This guide examines material options—virgin wood pulp, recycled fibers, and rapidly renewable bamboo—alongside the impact of chemical treatments on performance. You’ll learn how blends influence durability, why sourcing decisions affect brand positioning, and which additives can refine texture or enhance environmental credentials.

What’s Really in Your Toilet Paper?

When sourcing toilet paper for commercial or retail markets, fiber composition and production methods directly affect quality, sustainability, and cost. By understanding fiber types, pulp-to-roll conversion steps, and environmental impact, procurement teams can position their brands effectively and select the right suppliers. This knowledge supports stronger negotiations, reliable supply, and alignment with the expectations of eco-conscious customers.

Key Raw Materials Used in Toilet Paper

Premium toilet paper typically uses virgin wood pulp from managed softwood and hardwood forests—softwood for tensile strength, hardwood for surface softness. Recycled paper pulp from sources like office paper or newsprint offers cost and sustainability gains but requires extra processes such as de-inking to meet cleanliness and softness standards. Alternative fibers including bamboo, sugarcane bagasse, and hemp grow quickly, demand fewer resources, and signal environmental commitment; select based on market priorities and supplier capabilities.

How Is Toilet Paper Made: A Process Overview

Pulping separates fibers using water and chemicals; recycled pulp requires de-inking to remove inks and contaminants. Sheet formation spreads slurry onto mesh, presses out water, then dries on heated cylinders—precision here affects uniformity and texture. Bleaching, often needed for recycled pulp, ensures consistent whiteness; validate chemical processes for compliance. Finishing embosses, perforates, cuts, and rolls sheets, shaping hand-feel, tear performance, and brand differentiation.

Material Choices and Their Impact on Quality and Sustainability

Virgin wood pulp delivers maximum softness, strength, and durability for premium lines but at higher cost. Recycled fibers lower cost and environmental impact yet need more refining to meet premium standards. Bamboo and bagasse offer rapid renewability and strong sustainability appeal, acting as differentiators in eco-focused markets. Across all sources, fiber type and processing determine absorbency, softness, and tensile strength—align these attributes to customer expectations to sustain quality and repeat orders.

Considerations for B2B Buyers and Sourcing Managers

Begin by assessing a supplier’s fiber sourcing—can they deliver virgin pulp for premium applications or integrate recycled and alternative fibers without losing efficiency? Evaluate operational capacity, fiber specialization, facility scale, and certifications such as FSC or ISO 9001 to ensure consistent quality and rapid scalability. In markets with strict ESG mandates, verified environmental credentials add leverage in negotiations. Finally, test sample batches in real-world conditions to confirm softness, strength, and absorbency before finalizing contracts.

The Core Materials: Virgin Pulp, Recycled Paper, and Bamboo

In toilet paper manufacturing, material choice directly impacts product quality, unit cost, and sustainability outcomes. For procurement teams, understanding the virgin pulp vs recycled toilet paper debate helps align product specifications to brand positioning

Virgin Pulp: Quality and Consistency from Wood Fibers

Virgin pulp is sourced from selected softwood species such as pine and spruce, blended with hardwoods like oak and eucalyptus for balanced performance. Softwoods deliver tensile strength, while hardwoods provide the softness premium markets demand. Mills apply Elemental Chlorine-Free bleaching with agents such as chlorine dioxide or hydrogen peroxide to meet brightness targets without breaching environmental standards. For high-end segments, virgin pulp ensures consistent softness and durability across production cycles—reducing complaint rates and safeguarding quality under long-term hospitality, retail, or healthcare contracts.

Recycled Paper: Sustainable and Cost-Effective

Recycled paper blends post-consumer waste from offices and households with pre-consumer offcuts from printing operations. The pulp is deinked using mild surfactants, cleaned, and sometimes lightly bleached to achieve safe, neutral characteristics. Performance depends on the incoming fiber mix, so requesting pilot runs before large-scale commitments is essential. While it cannot match virgin pulp’s premium finish, recycled content delivers strong sustainability credentials and cost savings—critical for public facilities, value retail, or corporate ESG programs, where minor texture variations are acceptable trade-offs.

Bamboo: Rapidly Renewable and Eco-Friendly

Bamboo pulp originates from fast-growing grass that regenerates within a few years, offering a renewable fiber supply with long, sturdy strands that produce tissue both strong and soft. Processing, part of the bamboo toilet paper manufacturing process, typically uses fewer chemicals and less water than conventional wood pulping, lowering environmental impact. For brands targeting eco-conscious consumers, bamboo’s sustainability narrative and hypoallergenic properties support differentiation and align with FSC or equivalent certifications—helping meet strict procurement requirements in regions such as Northern Europe and premium hospitality markets.

Balancing Performance and Sustainability Through Material Blends

Manufacturers often blend virgin pulp, recycled fibers, and bamboo to fine-tune softness, strength, absorbency, and unit cost, meeting diverse market needs from luxury hotels to high-volume public facilities while staying within sustainability targets. Buyers should evaluate suppliers not only for material composition but also for supply stability and certification compliance. Controlling inputs and processing ensures product consistency, mitigates disruption risks, and keeps quality aligned with corporate sustainability commitments.

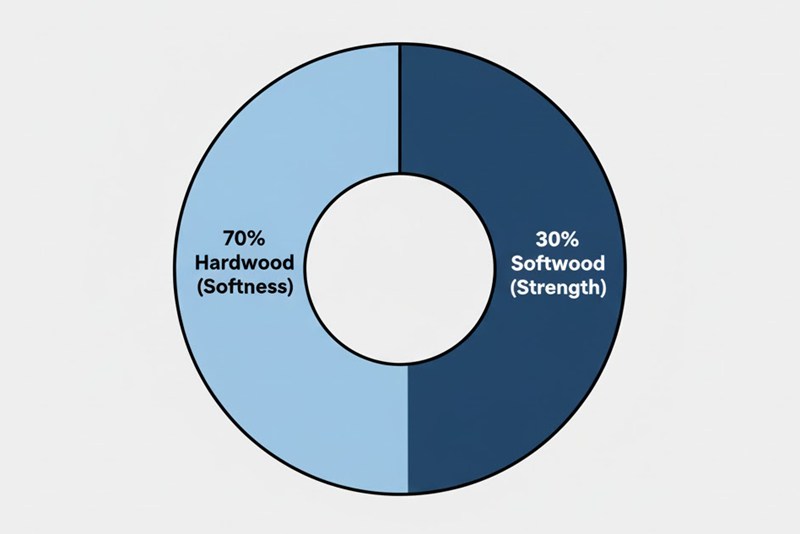

The 70/30 Recipe: The Hardwood vs Softwood Pulp Toilet Paper Balance

Balancing hardwood and softwood pulp in toilet paper production is a strategic lever that impacts feel, durability, and unit economics. For procurement leads in private label or institutional supply, mastering this ratio ensures end-user satisfaction and operational resilience. A well-structured blend delivers softness without losing tensile strength, while securing sourcing stability and sustainability credentials that directly influence brand equity.

The Role of Hardwood and Softwood Fibers

Hardwood pulp from eucalyptus, maple, or acacia produces shorter fibers for a smooth, soft touch—critical in hospitality and premium segments where comfort drives loyalty. Softwood pulp from pines or spruces provides long fibers for strength and wet-sheet integrity. A 70/30 hardwood-softwood mix hits the sweet spot: meeting guest expectations while reducing wastage and complaint rates, protecting both margins and brand perception.

Optimizing the 70/30 Blend for B2B Clients

Manufacturers can adjust ratios and incorporate additives like lotion or fragrance to target distinct markets. Urban retail programs may demand ultra-soft textures; institutional contracts often prioritize cost efficiency and strength. Experienced suppliers apply automated blending and rigorous quality checks to lock in consistent ratios and performance, preventing off-spec batches that disrupt distribution and erode profits.

Sourcing and Sustainability Considerations

Hardwood and softwood pulps come from distinct geographies with different forestry models and risk profiles. Buyers should weigh supply stability against sustainability mandates, favoring FSC-certified or eco-conscious sources in regulated markets. Partnering with suppliers who diversify sourcing and transparently document ethical compliance safeguards continuity while reinforcing marketing narratives where eco-labels influence purchase decisions.

Innovations and Alternatives to the Traditional 70/30 Recipe

Beyond hardwood and softwood, bamboo and recycled pulp enable niche and sustainable lines that meet environmental objectives without sacrificing function. With tailored additives—softness enhancers, scents, or lotion—suppliers can calibrate tactile qualities to align with brand positioning. For B2B portfolios, these innovations open agile pathways to address shifting consumer preferences or compliance changes without reengineering the entire supply chain.

Build Your Brand with Custom Toilet Paper Solutions

Top Source Hygiene offers 30 years of expertise in tailoring toilet paper products to your exact needs. From eco-friendly materials to premium softness and global delivery, create a unique product line that stands out in homes, hotels, and commercial spaces worldwide.

The Assembly Line: Understanding the Chemicals in Toilet Paper Manufacturing

In large-scale toilet paper production, chemical processes are as critical as mechanical operations. For procurement teams, mastering these steps enables sharper supplier evaluation and ensures products meet performance and compliance benchmarks. Strategic chemical choices dictate softness, strength, brightness, and environmental footprint—factors that directly influence customer experience and regulatory clearance.

Raw Material Selection and Chemical Pulping

Secure consistent, high-grade pulp sources to avoid variability. Blending hardwood and softwood balances softness with tensile strength. Logs are chipped and processed via chemical pulping—typically the Kraft process—using caustic soda and sodium sulfide to remove lignin and release cellulose fibers, delivering a clean pulp with superior bonding. When recycled paper enters the mix, additional washing and targeted de-inking chemicals improve fiber quality but may extend lead times. Always verify pulp origin and processing to safeguard uniformity and confirm the supplier can meet custom specs without sacrificing performance.

Bleaching and Chemical Treatments for Quality

Bleaching sets visual quality. Mills may deploy chlorine compounds, hydrogen peroxide, ozone, or sodium-based agents to strip color and residual lignin. Method choice has regulatory consequences; chlorine-based systems can produce restricted dioxins. Post-bleaching, additives like formaldehyde (for wet strength) and calcium carbonate (for texture and fiber bonding) refine performance. Some mills add PFAS for liquid resistance despite tightening oversight. Demand complete chemical disclosure to weigh functional gains against compliance risks.

Pressing, Drying, and Converting to Final Product

After chemical treatment, pulp is pressed and dried into thin, uniform sheets. Precision in these stages governs softness and thickness—critical B2B differentiators. Modern lines adjust easily to different ply counts or regional preferences. Sheets are rolled into master logs, cut to length, and packaged for retail or high-traffic commercial use. Maintaining tight process control here confirms a supplier’s ability to meet exacting specs while balancing cost efficiency, product appeal, and environmental compliance.

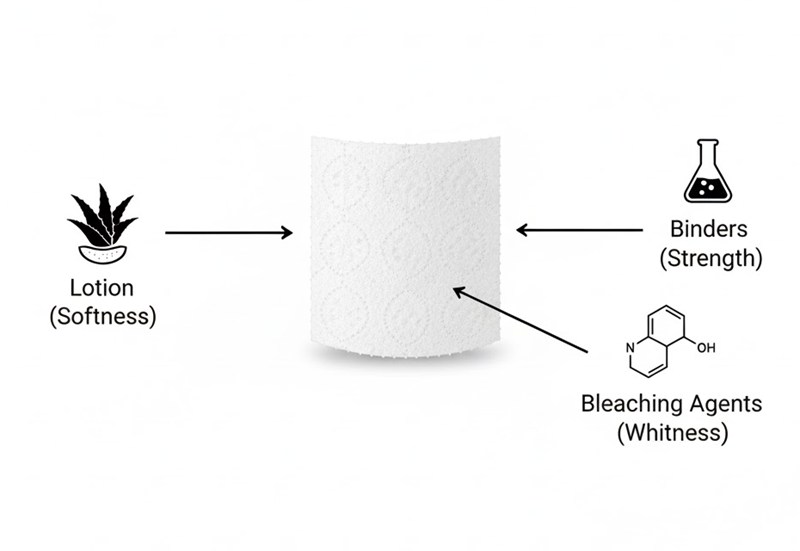

Optional Upgrades: Lotions, Scents, and Binders

Optional additives deliver targeted functional and sensory advantages, allowing you to position toilet paper for high-value niches. For B2B buyers, knowing how each upgrade impacts performance, compliance, and customer perception is essential to align procurement choices with brand positioning and end-user preferences.

Lotions: Enhancing Softness and Skin Comfort

Lotions improve tactile quality by integrating conditioning agents such as aloe vera, vitamin E, or mineral oils via precision coating systems, ensuring even distribution without weakening sheet integrity. Selecting lotion-treated products enables supply to premium hospitality or healthcare markets where comfort drives loyalty. Factor the modest cost increase against differentiation potential and the ability to command higher service or retail rates.

Scents: Masking Odors and Improving User Experience

Fragrances are applied through scented microcapsules or aromatic compounds during finishing, with profiles like floral, citrus, or fresh linen tailored to complement the setting and discreetly mask odors. Calibrate scent intensity to remain pleasant and compliant with regulations. For boutique hotels or upscale facilities, pilot batches and on-site trials help verify consumer acceptance before large-scale procurement.

Binders: Strengthening and Improving Durability

Binders—starches, synthetic polymers, or natural gums—boost tensile strength and tear resistance, affecting recyclability and compatibility with other enhancements. In high-traffic contracts, stronger binders reduce wastage and maintenance. Balance these gains with production costs, especially in competitive tenders where pricing pressure is high.

Tailoring Upgrades for Market Needs

Combining lotions, scents, and binders can align products with luxury hospitality, healthcare, or eco-conscious retail requirements, driving brand distinction and meeting sector-specific standards. Matching upgrade strategy to end-user profiles and regional preferences accelerates contract approvals and reduces returns. Include these options in tender specifications to strengthen bids in competitive markets.

FAQs About Toilet Paper Ingredients

Buyers in hospitality, retail, and commercial supply frequently field inquiries about toilet paper composition. Knowing the fibers, chemical treatments, and certifications involved enables faster, more confident procurement decisions that balance performance with environmental requirements.

Is there plastic in toilet paper?

Mainstream toilet papers use natural fibers such as virgin wood pulp or recycled paper and avoid plastic to ensure quick biodegradation. Some specialty products may include coatings or binders, though these are uncommon in high-volume commercial supply. For eco-conscious markets, review product specifications and confirm credible “plastic-free” certifications before bulk purchasing.

What trees are used to make toilet paper?

Virgin pulp typically comes from fast-growing softwood and hardwood species such as pine, spruce, fir, and eucalyptus, selected for fiber strength and consistent supply. Source species affect softness, absorbency, and pricing. Sustainable brands often procure wood from certified forests—critical when supplying regions where eco-label compliance drives purchasing decisions.

Are there harmful chemicals in toilet paper?

Manufacturers may use regulated bleaching agents to achieve a white, soft finish, but reputable suppliers operate within strict FDA and FSC limits to protect end users. For sensitive markets, prioritize products free from fluorescent whiteners, dyes, and fragrances to minimize irritation risks and align with clean-label trends.

What’s the difference between virgin and recycled pulp?

Virgin pulp, derived from fresh wood fibers, delivers a softer, stronger, and more absorbent product—ideal for premium hospitality supply. Recycled pulp, sourced from recovered paper, reduces environmental impact but may sacrifice some softness and strength. Blended options can balance quality with sustainability objectives in mixed-use markets.

Is bamboo toilet paper really made from bamboo?

Genuine bamboo toilet paper uses fibers processed from bamboo plants, which grow rapidly and require less water and pesticides than many tree species—making it a strong proposition in sustainability-focused supply chains. Quality varies by processing method, so confirm bamboo content percentage and manufacturing process before procurement.

Is bamboo toilet paper better?

‘Better’ depends on your goals. For sustainability, bamboo is an excellent choice due to its rapid renewability. For sheer softness, premium virgin pulp often still has an edge. However, high-quality bamboo toilet paper manufacturing now produces products that are both soft and strong, making it a competitive, eco-friendly option.

Your Conclusive Toilet Paper Sourcing Guide

Fiber choice drives product performance, cost control, and sustainability positioning. Virgin pulp ensures consistent softness and tensile strength for premium ranges, recycled fibers cut environmental impact and expense but need extra refining to meet standards, while bamboo and other fast-renewable fibers offer strong eco differentiation when supply chains are reliable. Manage fiber ratios, chemical treatments, and optional upgrades like lotions or binders to meet exact end-user profiles, and vet suppliers for sourcing integrity, processing strength, and certification compliance to protect brand equity and maintain flexibility in changing markets.