Applying aging & degradation science is the only way to stop the 12% annual inventory write-off rate caused by stagnant warehouse stock. Unregulated environmental exposure triggers acid hydrolysis, which destroys cellulose bonds and turns premium bulk rolls into brittle, unsellable waste.

This technical analysis evaluates 100% virgin wood pulp and OBA-free protocols against standard storage stressors. We use specific 13–22g/m² density metrics and FIFO ROI models to help you preserve the tensile strength of your 40HQ shipments until they reach the final consumer.

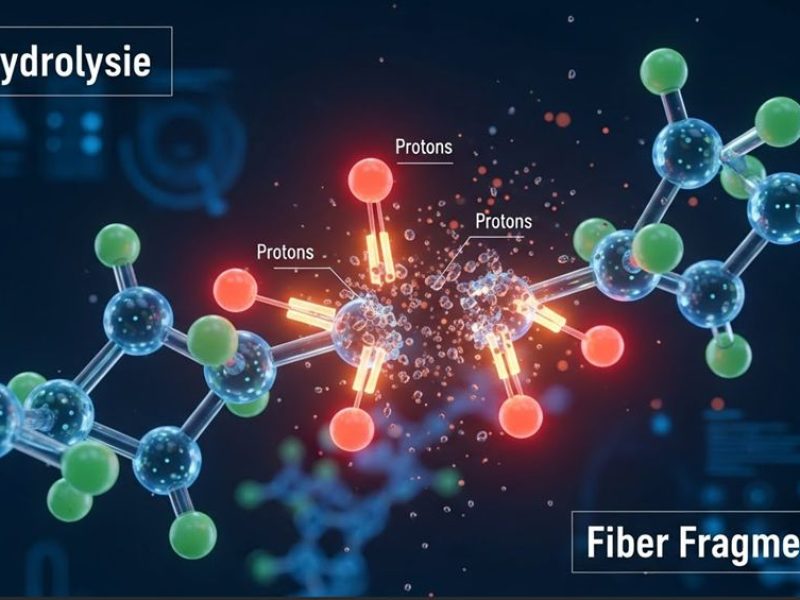

What is the Chemistry Behind Acid Hydrolysis and Paper Aging?

Acid-catalyzed hydrolysis breaks cellulose bonds, shortening molecular chains and destroying paper strength. We mitigate this by using OBA-free, 100% virgin wood pulp to eliminate acidic catalysts.

The Autocatalytic Mechanism of Cellulose Fragmentation

Paper degradation centers on the breakdown of cellulose, which consists of glucose units linked by β(1→4) glycosidic bonds. In acidic environments, protons (H3O+) attack the acetal oxygen bridges within these bonds. This chemical strike splits the long cellulose chains into progressively shorter segments, a process that physically manifests as brittleness and loss of tensile strength.

This reaction is particularly dangerous because it is autocatalytic. As the paper ages, the oxidation of alcohol groups creates carboxylic acids. These new acids increase the proton concentration, which further accelerates the hydrolysis. We also see internal acidification from organic acids that form shortly after manufacturing:

- Formic Acid: Trapped within the fiber structure during aging.

- Acetic Acid: A byproduct of the breakdown of hemicellulose.

- Lactic and Oxalic Acids: Common metabolic byproducts that lower the internal pH.

Preventing Chemical Instability with OBA-Free Virgin Wood Pulp

Standardizing material selection is the most effective way to disrupt the hydrolysis cycle. Our production focuses on 100% virgin wood pulp because the long-fiber integrity provides a much higher initial tensile strength. This gives the paper a robust structural baseline that can withstand some inevitable molecular chain shortening without immediate failure.

Chemical purity is equally vital. We strictly maintain OBA-Free (Optical Brightening Agent-free) protocols for several technical reasons:

- Oxidative Stability: Fluorescent whiteners can trigger photo-oxidation, creating free radicals that feed the hydrolysis loop.

- pH Control: Avoiding aggressive chemical bleaching keeps the paper in a neutral or slightly alkaline range.

- Natural Brightness: By selecting premium fibers, we achieve 85-92% brightness without adding acidic catalysts.

- Fiber Purity: 100% virgin pulp eliminates the recycled waste residues that often harbor residual acids or metal ions.

By controlling these variables at the source, we prevent the “acid-trap” effect common in lower-grade bulk papers. High-purity pulp ensures the paper remains chemically stable even when stored in regions with fluctuating warehouse humidity.

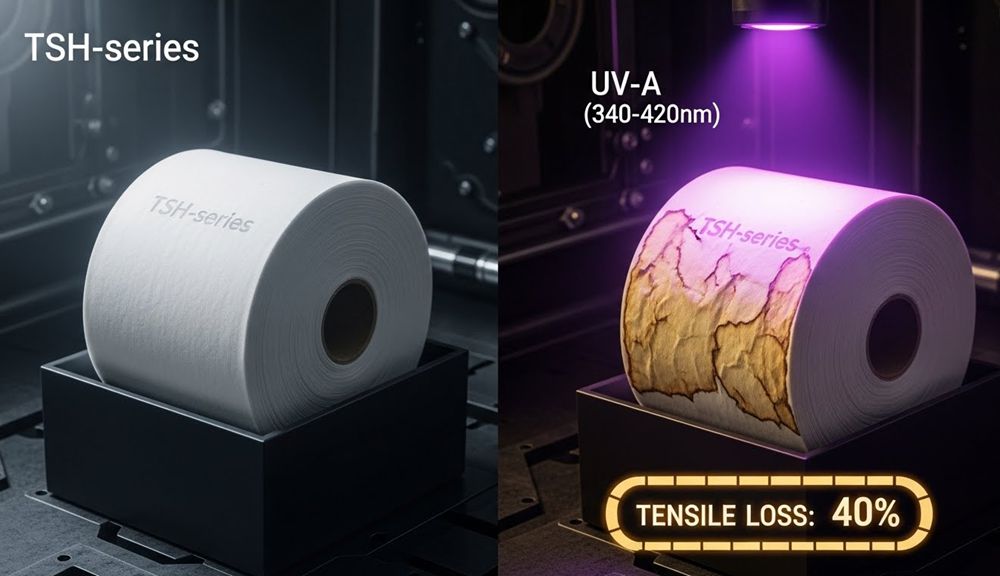

How Does UV Light Impact Fiber Brittleness and Yellowing?

UV radiation triggers photo-oxidation, breaking down wood pulp polymer chains. This chemical degradation destroys structural integrity, causing fibers to become brittle and yellow as internal color molecules decompose.

The Chemistry of Photo-oxidation and Surface Yellowing

UV light initiates a destructive chemical cycle the moment it hits the paper surface. While visible light causes some fading, the real damage comes from specific radiation bands that penetrate the fiber structure and reorganize the material at a molecular level.

- UV-A Wavelengths (340–420 nm): These wavelengths excite photons that generate free radicals, starting the photo-oxidation process.

- Polymer Degradation: Chemical bonds in organic materials weaken as polymer chains break, resulting in surface cracking and a total loss of material flexibility.

- Hydrogen Peroxide Formation: UV rays convert moisture within the fiber into hydrogen peroxide. This acts as an internal bleaching agent that destroys chromophore bonds, leading to the “burnt” look of aged paper.

- Proximity Risk: Direct exposure at close ranges (5–50 cm) increases the yellowing rate by 2.1 times compared to standard ambient warehouse lighting.

Leveraging Long-Fiber Virgin Pulp and OBA-Free Stability

Mitigating UV damage requires a move away from recycled materials and heavy chemical treatments. At Top Source Hygiene, we use specific material engineering to ensure bulk stock maintains its integrity during long-term storage or transit in high-UV regions.

- 100% Virgin Wood Pulp: Our premium long-fiber structures provide significantly higher tensile strength than recycled pulp, resisting the structural snapping caused by UV-induced embrittlement.

- OBA-Free Manufacturing: We eliminate Optical Brightening Agents (fluorescent whiteners). This prevents the rapid chemical breakdown common when these unstable additives meet ultraviolet light.

- Natural Brightness (85-92%): We achieve color stability through rigorous fiber selection rather than chemical bleaching. This preserves the material’s molecular integrity from the start.

- Structural Density: We use high-pressure ply-bonding and mechanical compression during bagging to create a dense paper barrier, limiting light penetration to the outer layers of the stock.

Scale Your Business With Custom Toilet Paper

Why Do Temperature Fluctuations Cause Tensile Strength Loss?

Temperature fluctuations increase atomic mobility, weakening intermolecular bonds and reducing material stiffness. For wood pulp, heat accelerates bond softening and structural degradation, leading to significant tensile strength loss.

Mechanisms of Atomic Mobility and Bond Softening

Heat acts as a catalyst for material instability at the microscopic level. When temperatures rise, the kinetic energy within the material’s structure increases, causing atoms to move more freely. This shift directly impacts the physical integrity of the product during storage and transport.

- Atomic Mobility: Elevated temperatures allow dislocations—structural defects—to bypass obstacles in the lattice, making the material softer and easier to break.

- Bond Weakening: Thermal activation reduces the force of intermolecular bonds, which results in a lower elastic modulus and a loss of overall stiffness.

- Structural Alterations: Fluctuating heat levels trigger microstructural changes like grain growth, which compromise the material’s ability to handle high tensile stress over long periods.

Fiber Stability Through Premium Virgin Wood Pulp Selection

At Top Source Hygiene, we combat thermal degradation by selecting raw materials that offer a higher threshold for stress. Standard recycled papers often fail when temperatures shift because their shorter fibers lack the necessary bonding surface to resist softening.

- Long-Fiber Matrix: We use 100% Virgin Wood Pulp to provide a robust long-fiber structure. This ensures higher initial tensile strength that prevents the paper from tearing even when environmental heat weakens individual bonds.

- High-Pressure Ply-Bonding: Our manufacturing process uses mechanical lamination to bond multi-ply layers. This technology prevents sheets from separating when climate fluctuations soften the fibers.

- GSM Density Buffer: We maintain a strict weight range of 13–22g/m² per ply. This specific density creates a structural buffer, protecting the paper’s integrity as it moves through different climate zones in a 40HQ container.

Wholesalers must recognize that temperature control in the warehouse is not just about comfort; it is about preserving the “cloud-like” softness and strength that defines premium wood pulp products. Using high-purity materials from the Hebei industrial hub ensures the stock remains viable through long-term distribution cycles.

How to Manage Long-Term Stock via “FIFO” ROI Models?

FIFO rotation protects margins by shipping older inventory first, reducing waste by 40% and preserving the tensile strength of 100% virgin wood pulp fibers.

| Performance Metric | Random Stock Rotation | FIFO ROI Model (2026) |

|---|---|---|

| Inventory Write-Off Rate | 8% – 12% annually | 2% – 4% (30-40% reduction) |

| Average Capital Lockdown | High (Stagnant Pallets) | 15-20% reduction in levels |

| Order Fill Consistency | Variable Quality | 5-8% improvement in fill rates |

| Asset Valuation Accuracy | Lagging market prices | Reflects current replacement costs |

Strategic Cost Recovery and Waste Reduction

Standardized inventory rotation directly impacts the bottom line of high-volume paper distributors. By implementing a disciplined age-tracking system, we help partners recover capital that otherwise vanishes into obsolete stock. The 2026 supply chain landscape demands this level of precision to offset inflationary pressures on raw material procurement.

- Obsolescence Control: Disciplined rotation reduces write-offs for aged inventory by 30-40%.

- Capital Efficiency: Average inventory levels decrease by 15-20%, freeing up cash for active 40HQ container cycles.

- Balance Sheet Accuracy: FIFO ensures ending inventory values reflect current market replacement costs.

- Fulfillment Stability: Maintaining a flow of fresh stock increases order fill rates by 5-8% across regional distribution hubs.

Applying FIFO to The Big 10 Strategic Inventory

Bulk paper products are not “indestructible.” Over extended storage periods, even high-purity wood pulp experiences chemical changes like acid hydrolysis. We apply specific FIFO protocols to our Big 10 sell-through models to ensure that the product delivered to the end-user maintains its original factory specifications.

- TSH-2559 and TSH-3396 Integrity: Prioritizing these high-turnover models prevents long-term fiber brittleness and maintains maximum tensile strength.

- Virgin Wood Pulp Preservation: Rotation ensures 100% Virgin Wood Pulp products retain their signature “cloud-like” softness during storage.

- Compression Management: Scheduled movement protects the “loft” of our rolls, preventing permanent flattening from mechanical compression during high-stacking.

- Regulatory Compliance: We move stock quickly to prevent the accumulation of older batches that might deviate from evolving 2026 global hygiene standards.

Using active voice in warehouse management means your team picks the oldest pallet first, every time. This simple operational shift transforms a static warehouse into a dynamic profit center, ensuring Top Source Hygiene products perform exactly as promised upon arrival at the retail shelf.

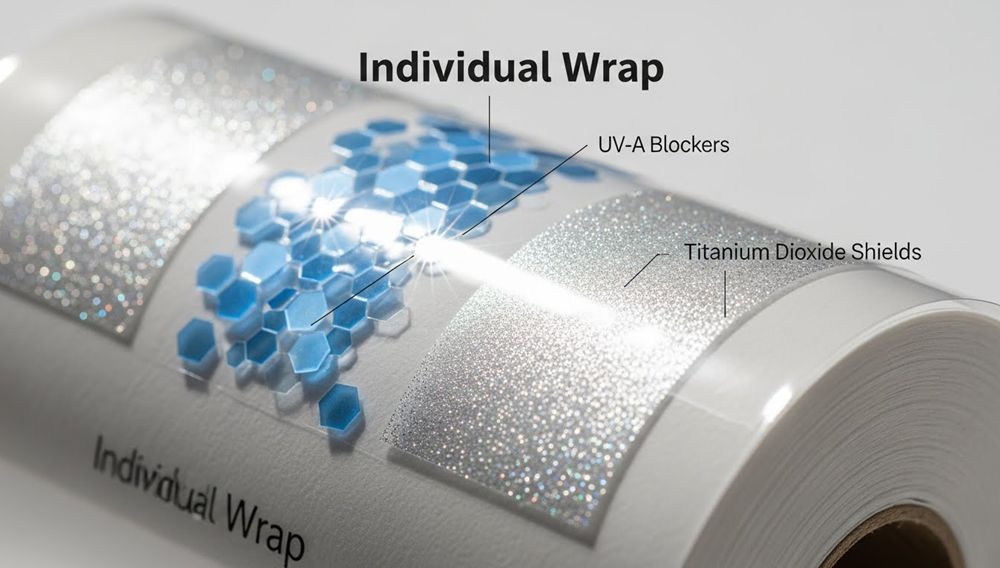

Can Protective Packaging (UV-Blockers) Extend Shelf Life?

UV-blocking barriers prevent photochemical fiber degradation and protein breakdown. By filtering specific wavelengths, these technologies maintain the structural integrity and shelf stability of organic products during long-term storage.

Mechanisms of Photodegradation and Shelf Life Extension

UV light acts as a catalyst for chemical decay rather than just causing surface discoloration. Radiation breaks down polymer chains and triggers photo-oxidation, which transforms ambient moisture into hydrogen peroxide. This process aggressively weakens the molecular bonds in organic fibers and proteins, leading to premature aging and product failure.

- Chemical Absorbers: Benzophenones filter specific wavelengths above 320 nanometers to stop oxidative stress at the molecular level.

- Inorganic Compounds: Zinc oxide and titanium dioxide provide a physical shield that reflects radiation and prevents fiber breakdown.

- Nanomaterials: Carbon-based dots enhance barrier performance while maintaining the transparency required for retail shelf visibility.

- Photochemical Mitigation: Active barriers prevent the degradation of lipids and vitamins, which is critical for maintaining the nutritional value of sensitive goods.

Secondary Protection and Individual Wrap Barrier Strategies

Top Source Hygiene utilizes a multi-layered defense strategy to shield products from environmental light exposure. We focus on high-density materials and structural reinforcement to ensure that bulk inventory maintains its original tensile strength from the factory floor to the final point of sale.

- Format A Individual Wrap: Each roll receives a dedicated light-blocking layer to maintain hygiene and prevent localized fiber yellowing.

- 5-Ply Export Cartons: These reinforced containers serve as the primary UV shield during high-stacking and extended container transport periods.

- Mechanical Compression: Our technology stabilizes internal paper fluffiness while the outer poly bundle blocks light-induced brittleness.

- 100% OBA-Free Materials: We eliminate chemical whitening agents to ensure no fluorescent compounds react with UV light to cause fiber fatigue.

Frequently Asked Questions

Do bulk toilet paper rolls have a formal expiration date?

Toilet paper does not have a formal expiration date because cellulose fibers do not decompose like organic food products. We recommend a shelf life of two to three years for bulk stock. Beyond this window, the paper may lose its optimal softness or absorbency if stored in sub-optimal warehouse conditions.

What are the ideal warehouse conditions to prevent stock degradation?

Store bulk paper in a climate-controlled environment with temperatures between 20°C and 25°C and relative humidity between 35% and 55%. Keeping products in their original sealed poly bundles prevents moisture absorption and paper shock caused by rapid temperature fluctuations.

Why does white toilet paper turn yellow or brittle during long-term storage?

Yellowing and brittleness result from acid hydrolysis or UV light exposure. Internal acids from lignin or manufacturing residues break down cellulose chains over time. Using 100% Virgin Wood Pulp, like our TSH-series, significantly reduces these risks compared to recycled paper options which contain higher levels of impurities.

How do temperature shifts impact the tensile strength of the paper?

Extreme heat causes fibers to swell and warp, while cold environments make the paper brittle. Frequent temperature changes lead to fiber fatigue. This often results in a 10% loss in bursting strength for stock held longer than six months in unregulated warehouses.

Can moisture-barrier packaging extend the shelf life of tissue products in 2026?

High-quality moisture-barrier films and multilayer packaging can extend shelf life to 36 months. These barriers block oxygen and moisture ingress. This protection preserves the structural integrity of the tissue even in high-humidity markets like Southeast Asia or Africa.

What standards are used to test the strength of aged paper stock?

We use TAPPI T 494 or ASTM D828 standards to measure tensile strength and elongation. These tests utilize constant-rate-of-elongation (CRE) equipment. Our laboratory ensures the paper meets the required durability specs before it leaves our Hebei manufacturing hub.

Final Thoughts

Choosing low-grade recycled paper creates a hidden liability through rapid acid hydrolysis and fiber yellowing that destroys retail value. Our 100% Virgin Wood Pulp and OBA-Free standards safeguard your margins by maintaining structural integrity for up to three years in storage. High-purity fibers from our Hebei facility ensure your 40HQ investment retains its softness and tensile strength until it reaches the final consumer.

Verify these material benchmarks by requesting a sample kit of our TSH-2559 or TSH-3396 best-sellers. We recommend starting with a 1 x 40HQ trial order to test our payload optimization and batch consistency firsthand. Contact our supply chain team today to lock in your specifications for the next production cycle.