The “Invisible” Detail That Defines Restroom Efficiency

In modern restroom management, even advanced IoT-enabled smart restrooms depend on fundamental compatibility between dispensers and consumables. When toilet paper tube dimensions don’t align with dispenser specifications, operational problems emerge.

While facility managers budget for major infrastructure like handwashing stations and drainage systems, the cardboard tube holding toilet paper receives minimal attention despite its operational impact. Mismatched tubes cause jams, slipping, and dispensing gaps, leading to maintenance calls, increased labor costs, and user complaints—problems that multiply across institutional settings replacing thousands of rolls monthly.

Standard Consumer Commercial Cores

Understanding the precise dimensional standards for both consumer and commercial toilet paper cores is fundamental for ensuring proper dispenser functionality and operational efficiency across different environments.

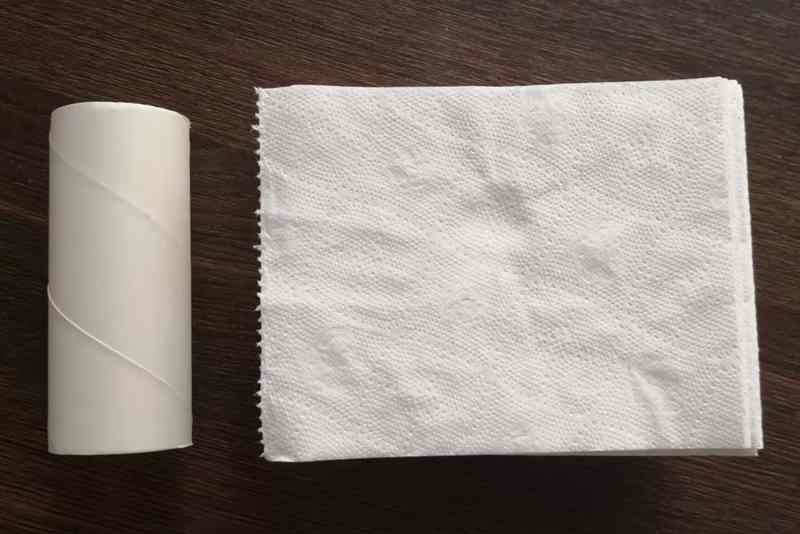

Consumer Roll Standards

Standard household toilet paper cores maintain consistent specifications that accommodate residential dispensers and storage requirements. The core diameter typically measures 1.5 to 1.75 inches (38-44 mm), with most manufacturers settling on 1.5 inches as the industry baseline. Tube length generally corresponds to paper width, measuring 4 to 4.5 inches (100-114 mm), ensuring complete sheet coverage without overhang.

-

Core diameter: 1.5-1.75 inches (38-44 mm)

-

Tube length: 4-4.5 inches (100-114 mm)

-

Sheet dimensions: 4.5 x 4.5 inches (11.4 x 11.4 cm)

-

Typical sheet count: 200-500 sheets per roll

The outer diameter of consumer rolls averages 4.5-4.7 inches when fully wound, providing optimal balance between capacity and residential dispenser compatibility.

Tailor Your Toilet Paper Brand to Fit Your Needs

With over 30 years of experience in toilet paper manufacturing, Top Source Hygiene offers customized solutions, ensuring quality and sustainability for your brand. Whether you're in hospitality, retail, or other sectors, we provide a range of options to suit your market requirements.

Industrial & Jumbo Roll Standards

Commercial applications demand significantly different core specifications to support high-volume usage and reduce maintenance frequency in institutional settings. Jumbo roll cores feature enlarged diameters ranging from 2.25 to 3.3 inches (57-84 mm), specifically engineered for heavy-duty commercial dispensers.

-

Small jumbo cores: 2.25 inches (57 mm) diameter

-

Large jumbo cores: 3.3 inches (84 mm) diameter

-

Roll width: 3.5-4 inches (89-102 mm)

-

Outer diameter: 8-12 inches (203-305 mm)

-

Sheet capacity: 1,000-4,000 sheets per roll

Engineering Rationale Behind Size Differences

The dimensional disparity between consumer and commercial cores reflects fundamental engineering principles for different usage environments. Larger commercial cores provide structural integrity necessary to support massive paper volumes—some jumbo rolls contain over 4,000 sheets compared to 500 in standard rolls. The increased core diameter distributes weight more effectively, preventing collapse under the substantial mass of industrial-grade paper quantities.

High-capacity dispensers require robust core dimensions to maintain smooth rotation under continuous use, while the larger diameter creates mechanical advantage for easier unwinding in high-traffic scenarios where users may pull paper more aggressively than in residential settings.

Regional Variations in Toilet Paper Tube Dimensions

Despite widespread globalization, toilet paper tube dimensions remain surprisingly fragmented across international markets, with regional preferences and regulatory standards creating distinct manufacturing specifications that challenge multinational facility management and procurement strategies.

Regional Dimensional Standards by Market

| Region | Core Diameter | Tube Length | Paper Width | Regulatory Framework |

|---|---|---|---|---|

| North America | 1.5-1.75″ (38-44mm) | 4.5″ (114mm) | 4.5″ (114mm) | ANSI/TAPPI standards |

| Europe | 1.57-1.73″ (40-44mm) | 3.94-4.33″ (100-110mm) | 3.94-4.33″ (100-110mm) | EN ISO specifications |

| Asia-Pacific | 1.38-1.65″ (35-42mm) | 3.54-4.13″ (90-105mm) | 3.54-4.13″ (90-105mm) | JIS/GB national standards |

| Latin America | 1.5-1.75″ (38-44mm) | 4.13-4.33″ (105-110mm) | 4.13-4.33″ (105-110mm) | Regional adaptations |

Commercial Consistency vs. Consumer Variation

While commercial jumbo rolls maintain relatively standardized 2.25″ and 3.3″ core diameters globally due to international dispenser manufacturers, consumer products exhibit significant regional variation driven by cultural preferences and local manufacturing traditions. European markets typically favor narrower 100-110mm tube lengths reflecting space-conscious bathroom designs, while North American specifications emphasize the familiar 4.5″ standard established by early 20th-century manufacturers.

Global manufacturers like Top Source Paper address these challenges through regional specification databases and flexible production capabilities, enabling consistent dispenser compatibility across international operations while maintaining local sourcing relationships and regulatory compliance in each market.

Looking for Affordable and Reliable Hygiene Products in Africa?

Top Source Hygiene provides customizable hygiene solutions including toilet paper, napkins, and more, designed to meet the unique challenges of African businesses. Our products combine quality and affordability to elevate your brand while addressing local demands.

The Link Between Tube Length and Dispenser Compatibility

Mechanical incompatibility between tube dimensions and dispenser spindles creates a cascade of operational failures that extend far beyond simple inconvenience. When tubes exceed dispenser length specifications by even a few millimeters, the resulting compression stress can cause cardboard deformation, preventing smooth rotation and creating binding points that tear paper during use. Conversely, undersized tubes create excessive play within the dispenser mechanism, allowing rolls to shift laterally and jam against internal components, particularly in spring-loaded commercial dispensers where precise tolerance is critical for proper tensioning.

The financial implications of dimensional mismatches compound rapidly across institutional settings, where dispensing difficulties increase paper consumption by an estimated 15-30% as users compensate for tearing and incomplete sheets. Installation failures force maintenance staff to modify dispensers or source alternative products, creating unplanned procurement costs and inventory complications. Beyond operational concerns, visible gaps between tubes and dispenser housings project an image of poor facility management, while repeated jamming can damage dispenser springs and spindle mechanisms, requiring costly repairs or replacements that could be avoided through proper dimensional compatibility from the outset.

Customization is Key: Achieving a Perfect Fit with Top Source Paper

Custom manufacturing capabilities address dimensional challenges in today’s diverse dispenser landscape through Top Source Paper’s OEM and ODM services. These services provide tailored core diameters (1.2 to 3.5 inches), customized tube lengths, and optimized roll configurations to eliminate compatibility issues and prevent costly operational failures.

As your reliable OEM & ODM partner, Top Source Paper’s core strength lies in providing fully customized solutions.

We can tailor the following to your specific proprietary or standard dispenser systems:

- Core diameter and length

- Paper width and ply count

- The length or sheet count per roll

The process includes dispenser analysis, free compatibility samples, and design services covering tube specifications, paper width adjustments, sheet count optimization, and cardboard density modifications. This ensures seamless integration with existing infrastructure while meeting high-traffic performance requirements.

Premium Jumbo Roll Tissue for Your Business Needs

Our jumbo roll tissue is crafted from high-quality materials, ensuring efficiency and convenience for busy commercial environments. With customization options and strict quality control, we deliver solutions that meet your specific requirements.

Conclusion

Strategic procurement in facility management must consider mechanical engineering principles in dispenser-consumable integration beyond traditional factors like absorbency and cost. Precise tube-to-dispenser alignment delivers measurable results: 40% fewer maintenance calls, 15-30% reduction in paper waste, and improved user satisfaction. This transforms reactive management into proactive optimization where dimensional precision drives cost containment.

Proper compatibility ensures professional-grade dispensers operate at peak efficiency with dimensionally accurate consumables, maximizing infrastructure ROI while minimizing operational disruption. Organizations should partner with manufacturers who understand these requirements, ensuring seamless performance rather than mechanical conflicts from poorly-specified products.