Your Market Positioning Strategy hinges on a cold calculation between wood pulp cost stability and the sustainability premiums of bamboo. Misaligning fiber selection with your target demographic erodes margins by up to 20% or causes inventory stagnation in eco-sensitive retail channels.

We analyze procurement profiles using the 100% OBA-Free and 2.7mm fiber length standards. By benchmarking TSH-2559 wood pulp efficiency against custom bamboo SKUs, this guide helps you secure a scalable 40HQ payload strategy that protects your brand reputation and distribution ROI.

Who Is Your Ideal Customer: The Wood Pulp Purist or the Bamboo Pioneer?

By 2026, the market splits between cost-focused wood pulp purists and ESG-driven bamboo pioneers targeting 25-50% CO2 reduction. Your choice depends on supply chain stability versus renewable marketing goals.

Determining the right inventory mix requires a cold look at operational priorities. Buyers typically fall into two distinct camps: those optimizing for high-speed mechanical performance and those paying a premium for sustainability narratives. Each profile demands specific fiber characteristics and price points to maintain their respective margins.

Procurement Profiles for Established Infrastructure and Cost Efficiency

Organizations that prioritize price stability and mechanical reliability lean toward traditional wood pulp. These buyers usually operate in mature markets where the existing infrastructure and logistics are optimized for wood-based materials.

- Cost Basis: Wood pulp costs approximately $890 per tonne, offering a 20% price advantage over bamboo’s $1,120 per tonne average.

- Tensile Strength: Softwood fibers provide a 2.7mm length, which is necessary for the durability required in high-speed industrial dispensers.

- Regional Logistics: Established wood-based logistics hubs in North America and Europe help wholesalers maintain a lower carbon footprint for local transport compared to long-haul bamboo shipments.

- Chemical Safety: Traditional buyers secure 100% OBA-Free certifications to guarantee a safe, non-fluorescent product for sensitive skin without the premium cost of alternative fibers.

The Virgin Wood Pulp Strategy and Eco-Targeted Material Diversity

Top Source Hygiene caters to both procurement profiles by utilizing flexible manufacturing at our Hebei facility. We lead with virgin wood pulp for maximum softness while offering bamboo integration for brands targeting carbon-sensitive consumer segments.

- Material Integrity: We utilize 100% Virgin Wood Pulp to ensure a lint-free experience and the cloud-like softness required for the premium retail market.

- Carbon Reduction: For projects requiring 25-50% lower lifecycle CO2 emissions, we integrate bamboo pulp to meet specific environmental targets.

- Plumbing Compatibility: TSH-2559 models use rapid-disintegration technology, making them septic-safe for standard residential plumbing in Western markets.

- ESG Reporting: We provide FSC-certified options that align with 2026 ESG reporting requirements and modern sustainability-marketing trends.

Selecting the right material comes down to the end-user’s primary pain point. Wood pulp serves the demand for consistent, high-strength hygiene at the lowest landed cost, while bamboo acts as a strategic SKU for brands looking to differentiate through rapid renewable resource marketing.

The Hospitality Gold Standard: Why Wood Pulp Dominates 5-Star Sourcing

5-star hotels use 100% virgin wood pulp for its natural brightness and long-fiber strength, ensuring a lint-free, absorbent experience that exceeds luxury guest expectations.

Luxury hospitality sourcing revolves around tactile feedback and visual trust. While alternative fibers gain niche traction, 100% virgin wood pulp remains the primary choice for premium suites. This preference stems from the mechanical properties of softwood fibers, which provide the structural integrity required for multi-ply tissue without sacrificing softness.

The Relationship Between Long-Fiber Integrity and Guest Comfort

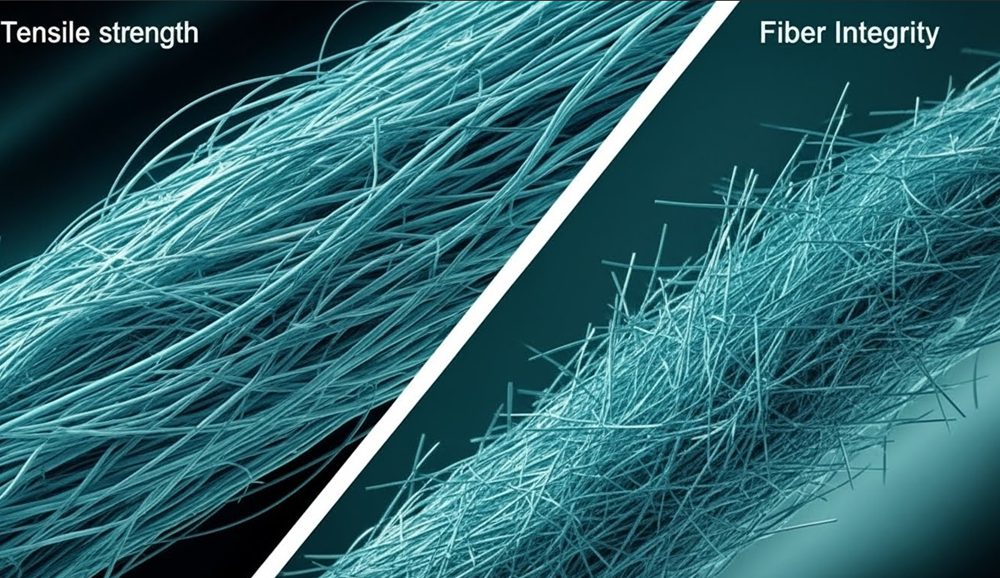

The difference between “economy” and “luxury” lies in the fiber length. Virgin wood pulp, particularly from softwood sources, features fibers averaging 2.7mm. These long-fiber structures create a stronger internal matrix than the 1.2mm fibers found in bamboo or the fractured fibers in recycled stock.

- Fiber Length: 2.7mm softwood fibers provide superior tensile strength and a lint-free surface.

- Brightness Levels: Natural 85-92% brightness eliminates the need for optical brightening agents (OBA).

- Chemical Profile: 100% OBA-free composition ensures safety for sensitive skin and prevents chemical odors.

- Absorbency: High-purity pulp creates “cloud-like” pockets that hold moisture better than coarser recycled alternatives.

By focusing on material integrity, high-end establishments ensure their hygiene products don’t shred or produce dust. This reflects directly on the property’s maintenance standards and the perceived quality of the guest room environment.

TSH-4010 Engineering: 5-Ply Density and Point-to-Point Embossing

For our hospitality clients, we developed the TSH-4010 luxury model to address the specific density and aesthetics required for 5-star suites. The engineering focuses on ply-bonding and surface area to maximize the user experience while maintaining facility efficiency.

- Ply Configuration: 5-ply solid roll design (2500g/18 rolls) provides maximum thickness and hand-feel.

- Embossing Technology: CNC-precision point-to-point patterns increase functional surface area, boosting absorbency by 30%.

- Lamination: High-pressure ply-bonding prevents layer separation without the use of heavy adhesives.

- Disintegration: Engineered to dissolve rapidly in water to meet North American and European plumbing standards, preventing clogs in high-traffic facilities.

This technical approach moves beyond the “commodity” mindset of toilet paper. We treat the TSH-4010 as a functional tool for hotel operators. It reduces consumption through better absorbency while providing the quilted texture that guests associate with premium care.

Premium Custom Toilet Paper at Factory Prices

When Should You Strategically Offer Bamboo as a Complementary SKU?

Introduce bamboo for eco-conscious retail and e-commerce. Use bundling to boost order values by 25-35% while keeping wood pulp for high-volume commercial supply chains.

Aligning Multi-Channel Distribution with Sustainable Consumer Demand

Wholesalers often find that a single-fiber strategy limits growth in diversifying markets. Introducing bamboo alongside wood pulp allows for precise channel segmentation, ensuring high-volume buyers get the cost-efficiency of wood while retail segments get the sustainability they demand.

- Institutional Buyers: We recommend 100% Virgin Wood Pulp models like TSH-2559 or TSH-3396 for price-sensitive bulk contracts.

- Specialty Retail: Deploy premium bamboo pulp rolls to capture eco-conscious households and niche specialty shops.

- Seasonal Timing: Align marketing efforts with 2026 seasonal peaks to attract gift buyers who prioritize environmental credentials.

This segmentation protects your margins. By bundling bamboo rolls with existing bathroom accessories or kitchenware, distributors successfully increase average order value by 25-35% without cannibalizing their existing wood pulp volume.

Utilizing the Custom Bamboo Pulp Series for Eco-Targeted Projects

Top Source Hygiene supports this transition through our Custom Bamboo Pulp Series. We specifically engineered this line for the North American and European markets where environmental and safety certifications are non-negotiable for new B2B projects.

- Material Integrity: Every roll is 100% OBA-Free, ensuring no optical brightening agents or fluorescent whiteners.

- Compliance Standards: The factory maintains material diversity to meet specific project needs for European and North American hygiene standards.

- Inventory Management: We utilize real-time tracking for these complementary SKUs to prevent stockouts that might damage a brand’s reliability promise.

Leveraging these specialized materials allows project managers to meet strict ESG requirements. You can offer a sustainable alternative that remains safe for sensitive skin while maintaining the mechanical strength and lint-free experience expected of professional-grade tissue.

Inventory Turnover ROI: Why Wood Pulp Moves Faster in Bulk Wholesale

Wood pulp essentials drive high liquidity through a 4.35% CAGR and optimized 40HQ payload densities, ensuring faster retail depletion and superior distributor ROI compared to alternative fibers.

| Efficiency Metric | Wholesale Strategy | ROI Impact |

|---|---|---|

| Payload Density | Mechanical compression in 40HQ containers | Reduces landed cost per roll |

| Inventory Velocity | “Big 10” standardized SKU focus | Minimizes dead stock and storage overhead |

| Market Liquidity | 100% Virgin Wood Pulp sourcing | Accelerates retail depletion in premium sectors |

Global Market Liquidity and Demand Velocity

The global wood pulp market scales toward USD 228.21 billion by 2032. This growth ensures a steady pull-through for wholesale stock, as essential hygiene products remain insulated from most discretionary spending dips. High transaction frequency in the market pulp segment, which involves over 73 million metric tonnes, creates a liquid secondary market that protects distributors from inventory stagnation.

- Global Market Scale: Projected growth to USD 228.21 billion by 2032 maintains high wholesale demand.

- Secondary Market Volume: Over 73 million metric tonnes of market pulp production ensures high transaction frequency.

- Regional Preferences: 100% virgin wood pulp remains the standard in North America and the Middle East, driving faster retail turns.

- Supply Concentration: Recent capacity shifts in North America concentrate supply among efficient producers, streamlining the procurement cycle.

40HQ Payload Optimization and The Big 10 Inventory

We focus production on the “Big 10” inventory strategy to maximize distributor profitability. By standardizing high-volume models like TSH-2559 and TSH-3396, we provide ready-to-ship availability that cuts market entry time. Our Hebei manufacturing hub utilizes mechanical compression to pack up to 9,000kg into a single 40HQ container, directly lowering the freight cost allocated to every individual unit.

- Big 10 Strategy: Standardized specifications like TSH-2559 and TSH-3396 ensure faster dispatch and lower storage risk.

- Mechanical Compression: Advanced bagging technology maximizes roll density for a 9,000kg 40HQ payload.

- Hub Logistics: Sourcing from the Hebei Paper Industrial Hub protects dealer margins against raw material price swings.

- Weight Flexibility: Standardized bundle ranges from 780g to 5,000g allow precise alignment with regional price points.

Active inventory management allows wholesalers to optimize working capital. Unlike lower-grade alternatives, 100% virgin pulp maintains consistent tensile strength and softness, properties that prevent retail returns and build brand loyalty. This performance reliability ensures that once the product reaches the warehouse, it moves through the supply chain without the friction common in uncertified or variable-grade stock.

Will Alternative Fibers Ever Fully Replace Wood Pulp in the B2B Sector?

Wood pulp will remain the B2B standard through 2026. Superior tensile strength and established supply chains make full replacement by alternative fibers technically and economically unfeasible.

Structural Barriers to Total Fiber Substitution

Wood pulp continues to dominate the global market because alternative fibers cannot yet match its mechanical performance at scale. In the dissolving pulp sector, wood-based materials maintain nearly an 80% market share. This dominance stems from the physical integrity of the fibers themselves, which determine the final product’s durability and user experience.

The technical gap between wood and alternatives like bamboo is significant for high-performance applications. B2B buyers in the hospitality and retail sectors rely on specific fiber characteristics to ensure quality consistency:

- Fiber Length: Softwood kraft pulp offers fibers averaging 2.7mm, compared to 1.2mm for bamboo, providing the tear resistance required for premium multi-ply products.

- Cost Advantage: Wood pulp currently averages $890 per tonne, while bamboo pulp sits near $1,120 per tonne—a 20% price premium that limits mass adoption.

- Bonding Performance: Softwood fibers create superior hydrogen bonds, essential for the high-ply toilet paper used in high-traffic commercial environments.

Integrating Material Diversity for Eco-Targeted Procurement

Manufacturing strategies are shifting toward a hybrid model rather than a total transition. Top Source Hygiene utilizes 100% Virgin Wood Pulp as the primary standard because it provides the most consistent softness and absorbency. We stabilize the supply chain by focusing on high-purity long-fiber pulp from our Hebei industrial hub.

Strategic material selection allows distributors to meet specific “green” requirements without sacrificing bulk performance. We manage material diversity through strict technical parameters:

- Primary Standard: 100% Virgin Wood Pulp for maximum tensile strength and a lint-free experience.

- Strategic Complements: Bamboo and Recycled Pulp options are deployed specifically for eco-targeted projects and ESG-focused brands.

- Chemical Integrity: All fiber types undergo 100% OBA-Free manufacturing to ensure safety for sensitive skin and compliance with EU/FDA hygiene standards.

- Ply Density: We maintain a strict range of 13–22g/m² per ply across all material types to balance durability with natural brightness.

Alternative fibers will grow in niche segments, but they must compete against entrenched wood pulp supply chains that offer 61% FSC® certified availability. For most high-volume B2B operations, wood pulp remains the most viable platform for maintaining margins and quality through 2026.

Frequently Asked Questions

Why do global hospitality groups favor 100% virgin wood pulp over alternative fibers in 2026?

Luxury hotels prioritize virgin wood pulp for its superior absorbency and soft texture. While bamboo gains traction for niche eco-branding, 100% wood pulp provides the specific tensile strength and lint-free finish required for high-end amenities. This material ensures the batch consistency necessary for multi-property hospitality chains where uniform quality is a non-negotiable standard.

What buying triggers influence premium tissue procurement for B2B distributors?

Environmental safety and performance metrics drive procurement decisions. Buyers look for OBA-free certifications and septic-safe technology to ensure plumbing compatibility in high-density facilities. Professional consumers prioritize products that balance sustainability with technical features like point-to-point embossing and high-density ply-bonding, which enhance the perceived value for the end-user.

How can wholesalers shift their client base from economy rolls to premium wood pulp?

Wholesalers should position premium pulp as a solution for operational efficiency. Highlighting that 100% virgin wood pulp rolls offer better absorbency means users require fewer sheets per visit, which reduces inventory turnover. This shift increases guest satisfaction and lowers long-term maintenance costs for commercial facilities by reducing the frequency of roll replacements and plumbing calls.

Which material options offer the most stable profit margins for new brands?

100% virgin wood pulp offers predictable profit margins due to its established manufacturing infrastructure and high global turnover. While bamboo requires a 20–30% higher capital investment for processing equipment, the reliable supply chains for wood pulp in industrial hubs like Hebei allow new brands to scale quickly with lower initial overhead and more consistent input costs.

What compliance standards are required for exporting toilet paper to North America or Europe?

Importers must ensure products meet ISO 9001 and FDA regulations for North America, or specific EU hygiene standards. Providing OBA-free guarantees and using the correct HS code 4818.1000 streamlines customs clearance. These certifications confirm the product is safe for sensitive skin and compliant with regional environmental laws, protecting the importer from regulatory delays.

Final Thoughts

Choosing 100% Virgin Wood Pulp over lower-grade alternatives ensures consistent tensile strength and skin-safe, OBA-free quality. This reliability prevents the costly retail returns and plumbing claims that erode distributor margins. Standardizing your inventory with our Big 10 models secures a stable supply chain and maximizes your 40HQ shipping ROI.

Request our latest technical datasheet to see how our Hebei manufacturing hub optimizes your landed cost per roll. We recommend a sample kit or a 40HQ trial order to verify our point-to-point embossing and rapid disintegration standards firsthand. Reach out today to start your private label production and secure your supply for the 2026 season.