For facility managers creating a janitorial training guide, a jammed toilet paper dispenser is a top issue that can disrupt operations and leave a poor impression on visitors. Every minute it remains out of service invites complaints and damages the professional image you work to uphold. By applying a universal, five-step method for both jumbo roll and center-pull models, you can resolve jams quickly without harming the unit. This guide provides precise, damage‑free troubleshooting to keep your dispensers reliable and restrooms running smoothly.

Why Quick Fixes Protect Your Business

Impact on Customer Satisfaction

In hospitality and retail, restroom condition communicates how much you value your customers. Properties that keep dispensers stocked and operational consistently enjoy better reviews, stronger repeat business, and longer guest stays. By contrast, a single encounter with an empty or jammed dispenser can undermine the positive impressions built elsewhere in the service experience. Reliable functionality is therefore not just a convenience—it’s a tangible driver of loyalty and competitive advantage.

Cost of Maintenance Downtime

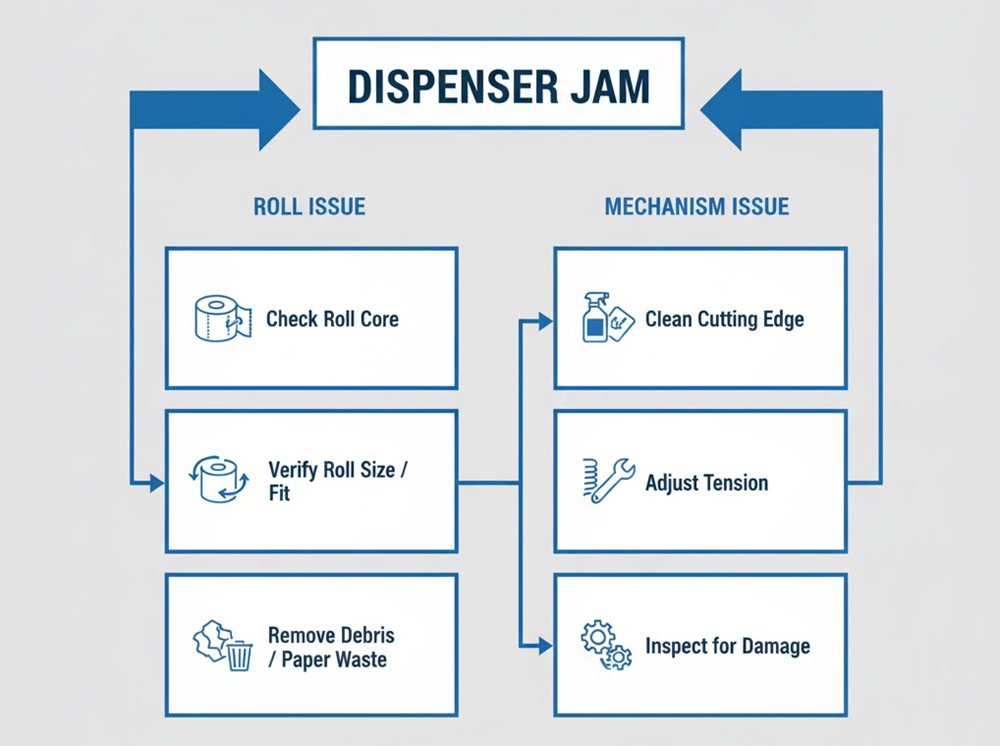

The primary goal is to reduce restroom maintenance calls, because every jam consumes resources. Staff must spend extra time clearing obstructions, sometimes making unscheduled trips to storage or vendors when paper isn’t accessible. Clearing jams improperly—by forcing parts rather than adjusting tension or checking roll compatibility—accelerates wear on mechanisms and shortens unit lifespan. In high-traffic sites, these small disruptions can quickly add up to significant labor hours and replacement costs, reducing operational efficiency and straining budgets.

Brand Reputation in Shared Spaces

In public venues and corporate campuses, dependable restroom supply is essential for maintaining trust and meeting facility standards. Visitors frequently cite cleanliness and supply reliability in feedback, so recurring dispenser issues create a gap between brand promise and delivery. Consistently functional dispensers signal attention to detail, reinforcing a quality-focused image from the main lobby to individual stalls.

Tools and Materials You Need

Basic Hand Tools

Equip maintenance teams with a compact kit so they can respond immediately when a dispenser jams. A flathead and Phillips screwdriver will open most casings, while certain premium models—such as those from Bobrick or Bradley—may also require Allen keys for precise internal adjustments. If mounting brackets loosen, a small adjustable wrench allows quick tightening without waiting for specialized tools. Having these essentials readily available minimizes downtime, keeps restrooms operational, and reduces repeat service calls.

Cleaning and Safety Gear

Safeguard both personnel and equipment during repairs. Rubber gloves protect against contamination when removing blocked paper or handling internal mechanisms. A microfiber cloth cleans cutter edges and feed tracks without scratching surfaces, and a mild, non‑corrosive cleaning solution removes residue without damaging stainless steel finishes. Routine cleaning not only prolongs the dispenser’s life but also ensures smoother operation, reducing user frustration in high‑traffic facilities.

Replacement Parts

Keep an inventory of the right consumables to speed repairs and avoid recurring jams. Stub‑roll spindles maintain smooth operation in dual‑roll systems, preventing short‑roll misalignment—a frequent cause of blockages. Manufacturer‑specific tension springs matched to your dispenser model preserve correct feed pressure so paper releases consistently. Always stock rolls in the exact size and core type specified by the manufacturer; mismatched dimensions are a leading cause of jams, service interruptions, and increased maintenance costs.

Tailored Toilet Paper Solutions for Your Brand

When rolls jam or run out at the wrong time, the impact is felt in both user experience and maintenance budgets. We prevent these issues by supplying paper precisely matched to dispenser specifications, avoiding common problems with roll diameter or core size. With Top Source Hygiene’s OEM program, every element—from ply count to wrap quality—can be customized so your supply chain supports uptime, hygiene, and sustainability goals.

How to Fix a Jammed Toilet Paper Dispenser: A 5-Step Guide

Step 1: Open the Dispenser Safely

Use the model-specific key supplied by the manufacturer to release the cover without applying force, which can crack plastic or deform stainless steel panels. If the key is missing, follow your facility’s approved override process—If you’re missing a Bobrick dispenser key, for example, the manufacturer can provide spares or built-in release mechanisms. Avoid improvised tools like screwdrivers, as they can damage locks and void warranties. For keyed models, check the lock housing for tamper seals before opening to ensure compliance with facility standards.

Step 2: Remove the Roll

Lift the roll from the spindle using both hands to apply even pressure, preventing core bending or stress on the spindle assembly. Look for crushed or folded paper layers, which are common causes of jams. For heavy jumbo rolls in Kimberly-Clark or GP PRO dispensers, support their weight carefully. Place the roll on a clean, dry surface for inspection; if intact, reshape or trim damaged sections to maximize use and minimize waste.

Step 3: Inspect and Clean Cutting Edges

Locate the tear-off or cutting edge at the paper exit. Wipe it with a microfiber cloth to remove dust, fibers, or residue that interfere with clean tearing. In stainless steel models like Bobrick or Bradley, check for early signs of rust and address them promptly to avoid replacement costs. On plastic units, verify teeth alignment has not shifted. Test with a scrap strip—smooth tearing confirms readiness and ensures consistent dispensing in high-traffic areas.

Step 4: Perform a Toilet Paper Dispenser Tension Adjustment

Identify the tension spring or guide panel inside the dispenser and set it according to the manufacturer’s recommendations for the roll size in use. Incorrect tension is a frequent cause of feed resistance. In coreless systems such as GP PRO’s, ensure guides are not pressing excessively on the roll. Adjust so paper feeds steadily without free-spinning. Proper tension extends component life, reduces jams, and keeps service interruptions to a minimum.

Step 5: Test and Refill

Before securing the cover, pull several sheets to confirm a smooth feed. Ensure the lock or latch engages without resistance. If your facility logs maintenance, record the action and note any unusual wear or repeat issues for procurement review. Refill with the roll size and quality specified for your dispenser. This routine safeguards supply availability and minimizes urgent maintenance requests.

Preventing Future Jams

Choose the Correct Paper Size

Stock only rolls that meet the dispenser’s specified diameter and core type. This prevents excessive tension, a leading cause of feed stalls during use. Oversized rolls can drag or lock inside the housing, while undersized rolls may shift and catch on internal parts—both increase downtime and labor costs. In multisite facilities with varied dispenser models, clearly label storage shelves with each unit’s compatible paper size. This simple measure reduces troubleshooting and keeps high-traffic restrooms operating without interruption.

Implement a Routine Cleaning Schedule

As part of any comprehensive facility maintenance checklist, a routine cleaning schedule is essential. Paper fibers, dust, and moisture inside dispensers. In busy locations, schedule weekly internal wipe-downs using a mild, non-corrosive cleaner suitable for both plastic and stainless steel. Record each cleaning in a maintenance log to highlight gaps and track service consistency. Regular cleaning extends equipment lifespan, prevents friction-related jams, and ensures smooth roll movement—reducing the time staff spend on reactive repairs.

Train Staff on Proper Roll Loading

Incorrect roll installation is one of the most frequent causes of jams, making staff training essential. Demonstrate correct orientation for each dispenser type, including dual-roll and stub-roll designs, and have staff verify tension settings before closing the cover. If tension is misaligned, adjust immediately to maintain consistent feed. Refresh training at regular intervals to reinforce best practices, especially after team changes or product updates. Accurate loading lowers maintenance calls, safeguards brand presentation, and keeps budgets focused on customer-facing priorities rather than avoidable repairs.

Expert Tips & Common Mistakes

Expert Tips

Store a clearly labeled set of spare dispenser keys in a secure but quickly accessible location to prevent access delays during maintenance. When ordering components such as tension springs or spindles, purchase only from the manufacturer or an authorized distributor to ensure precise fit and function—mixing brands often creates poor alignment and recurring jams. Keep an up-to-date record of each dispenser’s serial number; this streamlines warranty claims and allows service teams to identify exact configurations, reducing repair time and eliminating costly ordering errors.

Common Mistakes and Fixes

Trying to force a roll to turn before removing an obstruction can damage internal mechanisms. Always take out the roll first, clear the spindle or feed path, and reassemble only once the area is clean. Avoid loading more than the manufacturer’s stated capacity, as compressed rolls increase friction and disrupt smooth feeding—always follow roll diameter guidelines. Another frequent oversight is neglecting to clean the cutting blade or paper guide during refills; even light dust or adhesive buildup can impede paper flow. A quick wipe with a mild cleaner at every service keeps dispensing consistent and reduces avoidable downtime.

Frequently Asked Questions

How can I open a dispenser without a key?

If your dispenser uses a universal commercial lock, check onsite for spare keys or request replacements from the manufacturer. In urgent situations, contact your supplier—never force the lock, as this can damage the unit and void the warranty.

Which roll type is least likely to jam?

Jumbo rolls from reputable suppliers, correctly sized to match dispenser specifications, are less prone to jamming. Ensuring the roll’s core diameter aligns with manufacturer guidelines prevents tension issues that cause misfeeds.

Why do center pull dispenser jams happen so often?

Center-pull systems depend on accurate pull angles and paper quality. Loading off-center or using rolls with weak perforations increases the risk of bunching, particularly in high-traffic environments.

Can using the wrong paper size damage a dispenser?

Oversized rolls can strain the spindle and housing, accelerating wear. Undersized rolls may shift during use, catching on internal components and increasing the risk of jamming.

How often should maintenance staff clean a dispenser?

In busy facilities, inspect and clean dispensers weekly to remove dust, paper fragments, and residue that impede movement. Routine cleaning minimizes downtime and helps extend the unit’s service life.

Your Takeaway

Following the five-step process—freeing the jam, confirming correct roll size, checking spindle tension, using the specified paper type, and securing the cover—restores dispenser function quickly while preventing recurring issues. These actions help control maintenance spending, keep restrooms operational, and protect the user experience.

With consistent application, you can address jams confidently, even when keys are unavailable or rolls vary in quality. Embedding these preventive habits into routine maintenance keeps dispensers running reliably, extends service life, and ensures every visitor encounters a fully stocked, functional unit.