Core & Inner-Tube Branding captures the user’s attention at the moment of product exhaustion, preventing lost revenue from missed reorder cycles. While consumers discard external wrappers instantly, the inner core serves as a final touchpoint to secure brand recall and long-term loyalty.

We examine how CNC-precision printing on 100% Virgin Wood Pulp rolls maintains OBA-free safety and premium aesthetics. By leveraging 40HQ payload optimization and high-density white board, we help wholesalers achieve luxury retail standards and superior logistics efficiency.

Why is the Inner Core Your Brand’s Most Underutilized Billboard?

The inner core offers 100% visibility during the final usage stage, turning a discardable item into a high-value touchpoint for repeat orders and brand recognition.

Maximizing Brand Recall During the Final Usage Phase

Most branding disappears the moment a custodian or consumer removes the outer plastic wrap. The cardboard tube remains in the dispenser until the very last sheet is used, making it the only part of the product that stays in the user’s hand during the entire lifecycle.

This space creates a captive audience during the final ten percent of product consumption. In hospitality settings, guests judge quality by these small details. A branded core signals a premium experience that persists throughout the stay, ensuring the brand stays top-of-mind exactly when the roll needs replacement.

- Logo Visibility: Strategic placement inside dispensers after the outer wrap is discarded.

- End-User Engagement: Direct contact during the final sheets of consumption.

- Hospitality Standards: Association of quality with detailed, finished aesthetics.

Leveraging Premium White Board and Custom Inner Printing

The choice of core material dictates the perceived value of the entire roll. While many manufacturers use recycled gray board to save costs, Top Source Hygiene utilizes high-density White Board to maintain a medical-grade, professional appearance that matches our 100% Virgin Wood Pulp paper.

We apply CNC-precision printing on the inner tube surface to ensure logos and QR codes remain crisp. This is vital for distributors who use QR codes to drive repeat B2B orders or loyalty program sign-ups. Because our materials are 100% OBA-free, the white core maintains its natural brightness without chemical bleaching, ensuring safety for sensitive skin across the entire product.

- Material Selection: High-density White Board instead of recycled gray board.

- Printing Tech: CNC-precision inner surface branding for high-resolution graphics.

- Compliance: OBA-free materials ensuring hygiene and skin safety.

- Aesthetic: Bright, clean finish that complements premium hotel-grade tissue.

Can Custom Printing on the Tube’s Inner Surface Drive Repeat Purchases?

Interior tube printing creates a post-purchase surprise that boosts social sharing and brand recall, turning the core into a persistent marketing touchpoint that triggers timely reorders.

The Psychological Impact of Interior Storytelling on Brand Recall

Most marketing budgets focus on the outer poly bundle, but that packaging usually hits the trash can seconds after the customer gets home. The inner core is the only part of the product that stays in the line of sight until the very last sheet is used. This makes it an underutilized billboard for high-frequency branding.

- Organic Exposure: Unique packaging designs featuring interior details have a 90% probability of being shared on social media, providing free organic growth for private labels.

- Retention Triggers: Placing a “Time to Reorder” message or a brand logo inside the tube captures the consumer’s attention at the exact moment of product depletion.

- Quality Perception: Subtle design elements inside the core signal a commitment to detail and premium craftsmanship that justifies a higher retail price point.

- Extended Interaction: Internal branding provides a marketing space that survives the entire product lifecycle, unlike external wrappers.

Applying CNC-Precision Printing to Custom Private Label Cores

Top Source Hygiene uses CNC-precision technology to solve the technical challenge of printing on curved, narrow surfaces. We ensure that logos and intricate patterns remain crisp and legible, preventing the “smudged” look common in low-tier manufacturing. For B2B distributors, this capability is a strategic necessity rather than a luxury.

- Hospitality Branding: In hotel settings, staff remove outer wrappers before placing rolls in dispensers; custom core printing ensures the hotel or brand identity remains visible to the guest.

- Design Synergy: We match inner core designs with our point-to-point embossing patterns to create a unified aesthetic that stands out in premium retail markets.

- MOQ Efficiency: Our 40HQ container strategy allows private label owners to integrate custom core printing without inflating the landed cost per roll.

- Technical Precision: CNC-driven applications guarantee batch-to-batch consistency, even for complex 5-ply household rolls like our TSH-4010 luxury model.

By moving the brand message from the disposable exterior to the permanent interior, wholesalers can reinforce quality every time a sheet is pulled. This creates a feedback loop where the consumer associates the premium feel of our 100% Virgin Wood Pulp with the visible brand on the core, driving higher loyalty and repeat container orders.

Build Your Premium Toilet Paper Brand

How to Effectively Use QR Codes on Cores for Direct-to-Consumer Loyalty?

Inner core QR codes link physical tissue usage to digital rewards, driving repeat sales through one-tap reordering and collecting vital first-party data for private label brands.

| Digital Strategy | Core Implementation | Business Outcome |

|---|---|---|

| Subscription Anchor | Scan-to-reorder links on tube interior. | Reduced friction in household procurement. |

| Trust Verification | Direct links to FSC/OBA-Free reports. | Built-in credibility for premium labels. |

| Loyalty Enrollment | Exclusive rewards for batch-specific scans. | Direct ownership of consumer data. |

Digital Lifecycle Integration and Consumer Rewards

The shift from industrial batch tracking to consumer-facing digital engagement turns a disposable cardboard tube into a persistent branding billboard. By 2026, smart packaging strategies move beyond the outer plastic wrap. Placing a QR code on the inner core captures the user’s attention at the moment of product exhaustion—the exact second the reorder decision happens.

Retailers use these codes to incentivize repeat scans through tiered rewards programs. Instead of generic marketing, the scan provides an immediate path to action. For household management, we integrate scan-to-reorder features that link the physical core directly to the buyer’s preferred subscription platform or e-commerce cart.

- Transparency Links: Scans verify 100% OBA-Free and FSC-certified sourcing, proving the material is 100% Virgin Wood Pulp.

- Subscription Reduction: One-tap reordering minimizes the steps between noticing an empty roll and completing a new purchase.

- Data Collection: Brands collect first-party usage data to refine inventory forecasts and regional marketing spend.

Leveraging TSH Custom OEM Printing for Code Integrity

Scannability depends entirely on print precision and surface contrast. Standard brown recycled board often suffers from ink bleeding, which renders complex QR codes unreadable by smartphone cameras. To solve this, we utilize high-contrast printing on premium white board cores, specifically for luxury models like TSH-2559 and TSH-4010.

We manage batch color consistency at our Hebei industrial hub to ensure every roll meets the 100% scannability threshold. This requires specialized surface preparation of the inner tube to prevent the ink from spreading into the paper fibers. High-resolution graphics stay sharp, ensuring the digital bridge remains functional throughout the product’s shelf life.

- Model Compatibility: Optimized for TSH-2559 (Retail) and TSH-4010 (Luxury Hospitality) white-core specifications.

- Bleed Prevention: Specialized coating on the inner core surface ensures sharp edges for camera recognition.

- High-Contrast Output: Bright white board substrates provide the maximum possible contrast for CMYK or monochrome QR printing.

Should You Choose Recycled Core Board or Premium White Board for Branding?

Recycled cores cut costs by 30% for eco-conscious brands, while premium white virgin pulp ensures 92% brightness and zero color shift for luxury hospitality and high-end branding.

Balancing Cost Efficiency and Environmental Narratives with Recycled Board

Recycled core board (CRB) provides a natural, slightly textured finish that reinforces a brand’s sustainability story. It allows distributors to lower material costs by 10% to 30% without sacrificing structural integrity. This substrate appeals directly to mass-market retail sectors where eco-labels drive consumer purchasing decisions.

- Carbon Footprint: Reduces packaging-related CO2 emissions by up to 25%.

- Print Output: Maintains 95% of premium print clarity while utilizing post-consumer waste.

- Market Compliance: Meets North American and European regulations, including California’s SB 54 requirements for recycled content.

Enhancing Luxury Positioning Through High-Brightness Virgin Wood Pulp Cores

Premium white boards utilize 100% virgin wood pulp to achieve a high-end aesthetic. Top Source Hygiene maintains a natural brightness level of 85-92% by selecting high-quality long fibers rather than using chemical bleaches or optical brightening agents (OBAs). This ensures the product remains safe for sensitive skin while providing a pristine canvas for branding.

- Advanced Craftsmanship: The smooth surface supports CNC-precision embossing and foil stamping, as seen in the TSH-4010 Luxury Hospitality series.

- Batch Consistency: Virgin pulp eliminates the color shifting common in recycled materials, ensuring uniformity across full 40HQ container orders.

- Material Integrity: 100% OBA-Free and lint-free composition meets strict EU and North American hygiene standards.

How to Engineer Core Strength for High-Pressure Container Stacking?

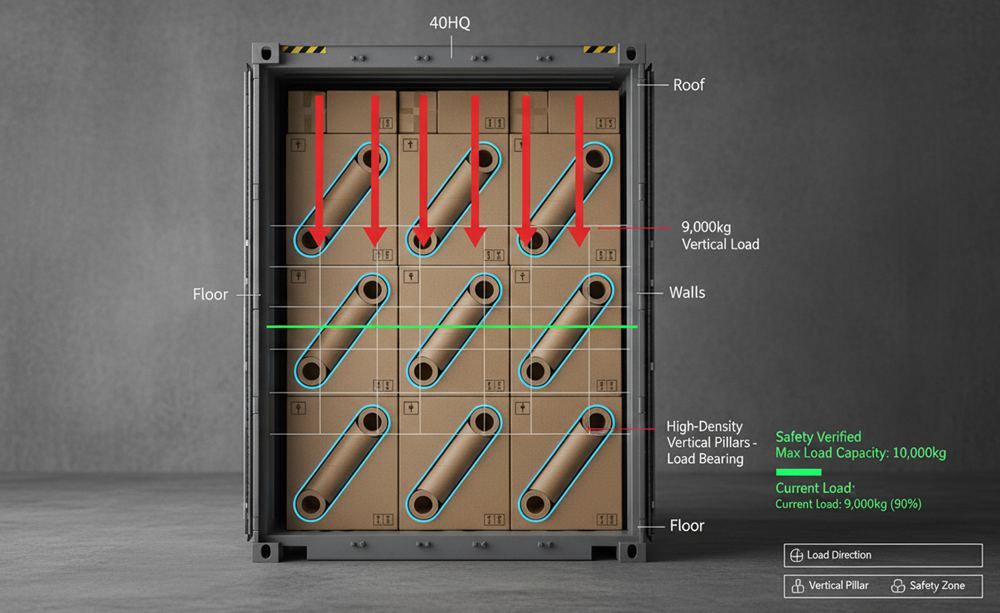

Engineers calculate vertical load and ship motion while utilizing 5-ply cartons and high-density rolls to protect 9,000kg payloads in 40HQ containers during maritime transit.

Structural Load Mechanics and Dynamic Ship Motion

Engineers analyze vertical load distribution using finite element methods to assess how heave and pitch impact stacked inventory. We focus on the physics of maritime transit to ensure the bottom tier of a 40HQ container withstands the weight of the entire stack during long-haul 2026 routes.

- Transverse Wave Effects: We calculate roll angle and angular acceleration to prevent lateral shifting inside the container.

- Metacentric Height (GM): Stowage arrangements account for GM values to keep weight distribution stable even in heavy seas.

- Lashing Stiffness: Our teams evaluate the stiffness of lashing systems and corner casting support to preserve structural integrity under high pressure.

- Vertical Forces: Calculations incorporate heave acceleration and pitch angle effects to determine the actual load-bearing requirements for export.

Top Source 5-Ply Reinforcement and High-Density Roll Engineering

Manufacturing specifications solve stacking challenges before the product ever reaches the port. We engineer the rolls and the secondary packaging to act as a unified support structure that resists crushing without adding unnecessary bulk.

- TSH-3396 Technology: This model utilizes a high-density coreless design to maximize internal resistance to vertical pressure.

- 5-Ply Export Cartons: We use reinforced 5-ply cartons to create a rigid external skeleton for soft tissue products.

- Mechanical Compression: Our Hebei factory uses compression bagging to remove excess air, optimizing 40HQ payloads up to 9,000kg while keeping paper fluffy.

- Visual Verification: We provide pre-shipment photos and videos of the loading process to ensure every bundle meets North American and European load standards.

Hebei loading teams maximize every inch of the 40HQ container space. This precision ensures the lowest landed cost per roll for international buyers while protecting the material integrity of the 100% virgin wood pulp fibers from batch to batch.

Does Scenting the Core Provide a Higher ROI Than Scenting the Paper?

Core-scenting maximizes ROI by slashing fragrance costs 20%, extending shelf life during 40HQ shipping, and keeping 100% Virgin Wood Pulp OBA-free and safe for sensitive skin.

Cost-Efficiency and Fragrance Diffusion Longevity

Scenting the cardboard tube creates a steady diffusion system that outperforms surface-sprayed paper. When we treat the core, the fragrance evaporates slowly from the center outward, ensuring the aroma lasts until the customer uses the very last sheet. This method addresses a common complaint in bulk wholesale: paper-scented rolls often lose their scent before they even reach the retail shelf.

- Oil Consumption: Manufacturing data confirms core-scenting requires 15-20% less fragrance oil than treating thousands of sheets per roll.

- Logistics Stability: Core-infused rolls retain their scent profile during 40HQ container shipping and long-term storage in Hebei-based hubs.

- Brand Presence: The fragrance remains active in the bathroom environment even as the roll diameter decreases.

Maintaining 100% OBA-Free Safety in Premium Rolls

Applying fragrance directly to tissue fibers can compromise the material’s technical performance. For distributors targeting the North American or European markets, maintaining the purity of 100% Virgin Wood Pulp is a major selling point. Scenting the core allows us to offer a luxury sensory experience without introducing chemical additives to the paper that the end-user actually touches.

- Purity Standards: Ensures the paper remains 100% OBA-free (No Optical Brightening Agents) and safe for users with sensitive skin.

- Fiber Integrity: Avoiding direct chemical application prevents negative changes in paper absorbency and tensile strength.

- Model Example: Our TSH-4010 luxury hospitality rolls use core-infusion to provide high-end branding while meeting 2026 safety compliance.

- Certification: Helps products meet ISO 9001 and FDA hygiene standards by keeping synthetic perfumes away from the wood pulp fibers.