Optimizing Embossing Technology is a technical requirement to prevent ply separation and poor moisture retention in commercial tissue contracts. Selecting substandard textures leads to high return rates and thin, low-bulk rolls that fail to meet the virgin wood pulp quality standards demanded by tier-one hotel groups.

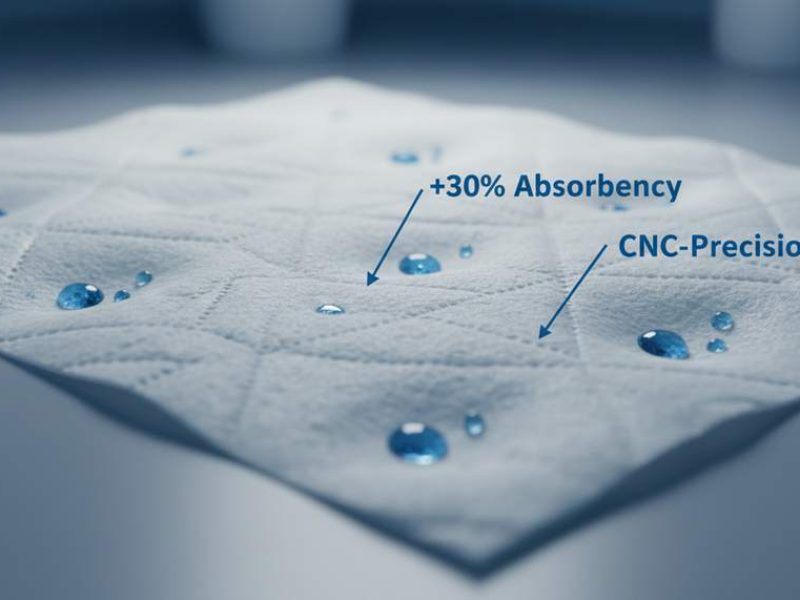

This analysis benchmarks production against the CNC-precision Point-to-Point standard, which increases liquid capture by 30%. We examine how maintaining a 13–22g/m² ply density ensures structural integrity in 40HQ wholesale orders, allowing procurement teams to achieve higher roll volume without increasing raw material costs.

Why Do We Emboss Toilet Paper? (It’s Not Just for Looks)

Embossing creates air pockets for 30% better absorbency while mechanically bonding plies. This ensures multi-ply rolls stay together and feel softer without adding unnecessary weight.

Enhancing Absorbency and Layer Bonding Through Texturing

We transform flat tissue into a three-dimensional surface to trap moisture more effectively. These patterns create small channels and air pockets that significantly increase the surface area of the paper. This physical expansion allows the tissue to capture and retain liquids far better than a flat sheet.

Beyond moisture management, embossing serves as the mechanical “glue” for multi-ply products. We use high-pressure texturing to interlock the paper fibers where they touch. This creates a bond similar to a physical joint, ensuring that 2-ply to 5-ply rolls maintain their integrity and do not peel or separate during use. The process also separates fibers slightly to increase the “fluffiness” and bulk of the roll, providing a softer feel without requiring extra raw material.

CNC-Precision Point-to-Point Embossing for Superior Bulk

Top Source Hygiene utilizes CNC-precision point-to-point (PTP) embossing patterns. This technical approach ensures that the raised points on both rolls align perfectly, creating larger internal air pockets than standard nested embossing. This specific synchronization is a hallmark of professional-grade manufacturing and directly impacts product performance.

- Absorbency: PTP patterns increase liquid capture by up to 30% compared to non-embossed alternatives.

- Ply Density: We maintain a strict 13–22g/m² per ply, ensuring the sheets are thick enough to handle high-pressure bonding.

- Fiber Integrity: Our use of 100% virgin wood pulp allows for deep texturing without breaking the paper web, resulting in a lint-free finish.

- Safety: Every roll is OBA-free, meaning the brightness comes from fiber quality rather than chemical additives.

By controlling the pressure and pattern depth, we balance the need for a soft hand-feel with the mechanical strength required for commercial and retail distribution. This technical precision ensures our rolls meet the high-wet-strength standards necessary for the North American and European markets while remaining septic-safe.

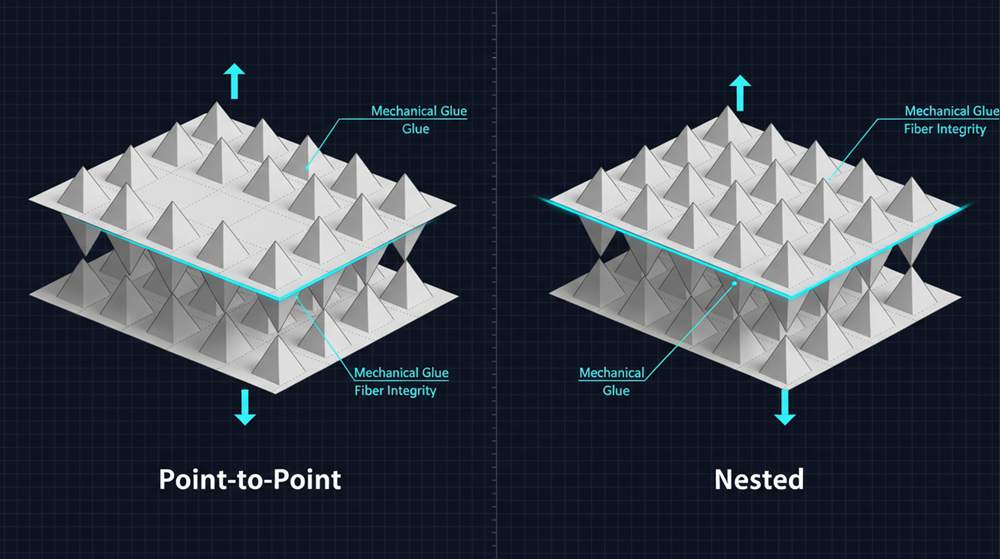

Point-to-Point vs. Nested Embossing: Which Should You Choose?

Point-to-Point (PTP) maximizes absorbency and pattern precision for luxury tiers, while Nested configurations optimize roll bulk and manufacturing speed for high-volume retail markets.

Structural Differences in Ply-Bonding and Absorbency

Point-to-Point (PTP) embossing requires exact synchronization where raised points on both plies meet directly. This alignment creates strong bonding cells that lock moisture inside the sheet. Because the points press against each other, the result is a defined, high-contrast pattern that identifies a product as premium.

Nested embossing takes a different approach by placing the embossed points of one ply into the valleys of the other. This interlocking configuration increases the overall thickness and cushioning of the roll without adding extra fiber. It creates a “fluffy” feel that consumers in North American and European retail sectors often associate with value and comfort.

Luxury hospitality brands usually select PTP technology for 100% Virgin Wood Pulp products. The defined aesthetic patterns reflect the material’s purity and high-end positioning. Nested configurations provide more operational tolerance during high-speed manufacturing, which reduces waste for distributors managing massive retail contracts.

CNC-Precision Technology for Multi-Ply Durability

Top Source Hygiene utilizes high-pressure lamination and CNC-precision embossing to ensure plies do not separate during use. We balance the mechanical deformation of the fiber to maintain tensile strength while achieving deep, tactile patterns. This precision prevents the “shredded edge” effect common in lower-grade alternatives.

- Absorbency Gain: Precision PTP patterns increase liquid retention by 30% compared to basic nested or non-embossed tissue.

- Ply Density: We calibrate our 13–22g/m² ply density to work optimally with nested embossing for maximum bulk.

- Model Integrity: Our TSH-4010 luxury series uses specialized ply-bonding to maintain the structure of 3-ply and 5-ply rolls without sacrificing softness.

- Fiber Protection: CNC-controlled pressure ensures that embossing provides volume without breaking the cellulose bonds of the virgin wood pulp.

Distributors targeting the Middle East or luxury hotel groups benefit most from PTP’s visual sophistication. For high-turnover retail markets in Southeast Asia or Africa, Nested embossing offers the best balance of perceived volume and production cost efficiency. Both methods at our Hebei facility undergo strict pre-shipment visual verification to ensure batch consistency across a 40HQ container.

Custom Wholesale Toilet Paper at Factory Prices

How 3D Embossing Increases Roll Volume and Perceived Value

3D embossing uses deep rollers to trap air, increasing roll thickness by 1mm without adding material. This creates a premium, high-volume look while keeping raw material costs low.

| Performance Metric | Traditional Embossing | 3D Point-to-Point (TSH) |

|---|---|---|

| Pattern Depth | Shallow / Surface level | 0.1mm to 1.0mm |

| Liquid Absorption | Standard baseline | 30% increase |

| Ply Integrity | Nested / Mechanical Press | High-Pressure Lamination |

| Visual Bulk | Compact / Thin | High-Volume / Pillowy |

The Mechanics of Air Pockets and Bulk Enhancement

Physical roll volume depends more on surface geometry than fiber weight. Modern 3D technology uses deeply engraved rollers to reshape 100% Virgin Wood Pulp into pronounced, pillowy textures. This mechanical process creates measurable thickness by expanding the space between individual paper plies.

- Pattern Depth: Technology produces depths from 0.1mm to 1mm for tactile effects.

- Air Entrapment: Fibers trap air to increase sheet thickness without raising GSM or fiber count.

- Shelf Presence: Increased roll diameter makes products look more substantial to retail buyers.

- Material Efficiency: Manufacturers maintain a premium feel while using fewer raw materials per roll.

Leveraging Point-to-Point CNC Precision for Performance

Top Source Hygiene utilizes Point-to-Point (PTP) embossing to solve the common trade-off between softness and strength. While nested embossing remains the industry standard for basic rolls, PTP offers the durability required for high-traffic hospitality and premium retail markets. Our Hebei production facility uses CNC-precision to ensure every roll in a 40HQ container maintains identical pattern alignment.

- Absorbency: PTP patterns increase liquid capture and retention by 30% compared to flat tissue.

- Batch Consistency: CNC-precision floral and dot patterns prevent variation in global wholesale orders.

- Ply Bonding: High-pressure lamination technology prevents layers from separating during use.

- Luxury Indicators: Visible quilted textures correlate with higher guest satisfaction in 5-star hospitality settings.

This technical approach allows distributors to market products like the TSH-4010 or TSH-2269 as high-end solutions. By focusing on volume through geometry rather than raw weight, wholesalers achieve a lower landed cost per roll without compromising the consumer’s perception of quality.

Does Aggressive Embossing Weaken the Tissue Fiber?

Excessive embossing pressure breaks cellulosic fiber bonds, reducing tensile strength. High-quality tissue requires balancing deep aesthetic patterns with the structural resilience of long-fiber virgin pulp.

Mechanical Deformation and Fiber Bond Degradation

The embossing process relies on mechanical stress to reshape the paper web. When sheets pass through embossing nips, the fibers undergo permanent deformation to hold the pattern. If the pressure settings are too aggressive, the process moves beyond simple reshaping and begins to physically damage the sheet structure.

- Fiber Bond Fracture: Excessive compression breaks the connections between cellulosic fibers instead of just bending them.

- Structural Opening: When the paper releases from the nip, the fibrous structure opens up, causing permanent weakening.

- Tensile Loss: Aggressive aesthetic patterns often result in a measurable drop in mechanical properties and tear resistance.

CNC-Precision Point-to-Point Embossing and Long-Fiber Resilience

At Top Source Hygiene, we use specific manufacturing technologies to mitigate strength loss during the embossing phase. By using 100% Virgin Wood Pulp, we ensure the base material has the long-fiber strands necessary for high tensile strength. This allows for deeper patterns without compromising the roll’s integrity.

- Technology: CNC-precision Point-to-Point embossing increases absorbency by 30% without shredding edges.

- Ply Density: Strictly controlled weights between 13–22g/m² per ply.

- Material: 100% Virgin Wood Pulp, OBA-Free, and lint-free.

- Bonding: High-pressure lamination secures layers without destroying the underlying fiber web.

- Compliance: Engineered for rapid disintegration to meet North American and European septic-safe standards.

We manage the tension between volume and strength by optimizing the nip pressure for each specific GSM. This ensures that wholesalers receive a product that feels bulky and soft but remains durable during use.

Custom Logo Embossing: A Branding Tool for Hotels

Luxury hotels use custom 3D embossing to turn standard paper into sensory branding tools, reinforcing identity while improving absorbency through precision CNC patterns.

Enhancing Guest Experiences through Tactile Brand Identity

Guests interact with room amenities more frequently than traditional lobby signage. A raised, 3D logo on a tissue roll creates an immediate physical connection that communicates brand quality every time a guest reaches for a sheet. This tactile experience serves as a subtle but powerful reminder of the hotel’s attention to detail.

Custom patterns align with the high expectations of the boutique and luxury hospitality segments. By replacing standard generic textures with branded relief, hotels transform a basic commodity into a sophisticated brand touchpoint. This creates a memorable sensory interaction that stays with the guest long after they check out.

Consistency matters in premium positioning. When branded amenities are uniform across the property, it reinforces guest loyalty. It signals that the hotel does not cut corners on the small things, which is a hallmark of five-star service standards.

Precision CNC Customization and Functional Absorbency

The technical execution of embossing at Top Source Hygiene relies on CNC-precision patterns. We don’t just stamp the paper; we utilize advanced engineering to ensure the logo is sharp while simultaneously enhancing the paper’s physical performance.

- Material: 100% virgin wood pulp ensures premium long-fiber strength and a lint-free finish.

- Absorbency: Point-to-point embossing technology increases liquid capture and retention by 30%.

- Model Specification: The TSH-4010 luxury hospitality model supports high-ply bonding, preventing layers from peeling apart.

- Hygiene Protection: Format A (Individual Wrap) packaging ensures the embossed logo remains clean and visible at the point of use.

By focusing on high-ply bonding and quilted textures, we maintain a soft, cloud-like feel without sacrificing the integrity of the custom logo. This balance ensures that the branding doesn’t compromise the comfort that guests expect from high-end hospitality supplies.

Frequently Asked Questions

Why do manufacturers emboss toilet paper?

Embossing creates air pockets between paper fibers to increase softness and volume. It also functions as a critical bonding agent for multi-ply tissue. We use high-pressure lamination to fuse layers together at the embossed points, ensuring the sheets do not separate during use while maintaining a quilted, professional texture.

Does the pattern on the tissue affect its absorbency?

Yes. Raised patterns expand the total surface area of the sheet and create tiny channels that trap moisture more efficiently than flat paper. Our CNC-precision Point-to-Point embossing patterns specifically increase liquid capture and retention by 30% compared to non-embossed alternatives.

Is embossed toilet paper safe for septic systems?

Yes. Quality embossing does not hinder the paper’s ability to break down. We engineer our 100% virgin wood pulp rolls to be OBA-free and disintegrate rapidly when submerged. This ensures they meet 2026 global plumbing and septic safety standards for North American and European markets.

Can we request a custom logo or pattern for wholesale orders?

We provide CNC-precision embossing for B2B clients and private labels. This allows you to add specific floral designs, dots, or your own brand logo directly onto the tissue. Custom patterns help distributors and hospitality groups achieve better market differentiation and brand recognition.

How does 3D embossing increase the value of the roll?

3D or sculpted embossing creates a more pronounced tactile relief. This increases the physical thickness and diameter of the roll without adding extra material weight. For retail buyers, this improves shelf presence and perceived luxury while allowing manufacturers to maintain softness with fewer fibers.

Does embossing make the tissue lint-free?

Embossing adds texture, but the lint-free quality depends on the base material. We use 100% virgin wood pulp and high-pressure lamination, which ensures the fibers remain intact at the embossed points. This process provides a soft experience without leaving residue or dust behind.

SEO

Title: Functional Embossing: Beyond Aesthetics to Performance and Grip

Description: Toilet Paper Embossing: CNC point-to-point 100% virgin pulp tech. B2B wholesale factory supply. 40HQ MOQ for global distribution.

URL: toilet-paper-embossing

Keywords: Toilet Paper Embossing