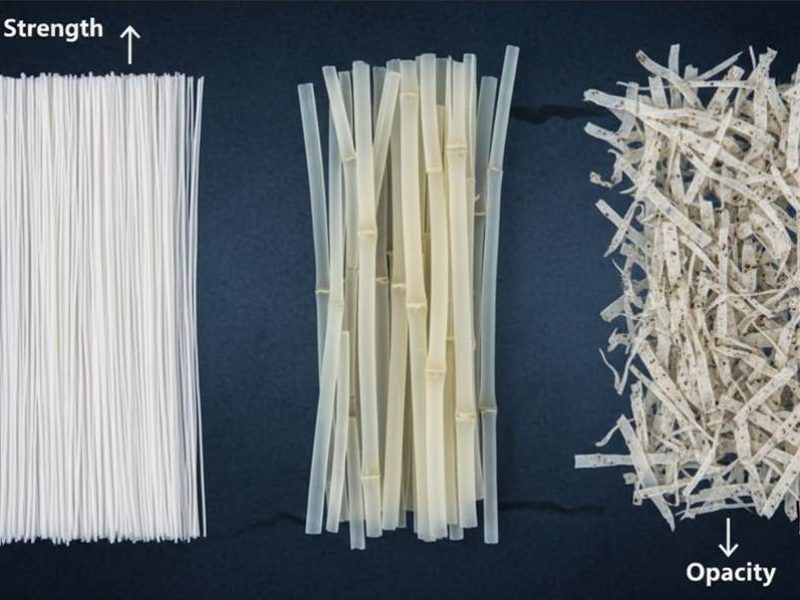

Raw Material Sourcing serves as the foundational metric for determining tissue tensile strength and long-term supply chain viability. Misjudging fiber origins often results in OBA-related safety failures or poor absorbency, costing wholesalers significantly in customer retention and brand equity.

We evaluate 100% Virgin Wood Pulp, bamboo, and recycled stocks against the 13–22g/m² density benchmark. This analysis examines FSC-certified transparency and 40HQ payload optimization to ensure your private label projects meet strict EU and North American hygiene standards.

The Life Cycle of 100% Virgin Wood Pulp Tissue

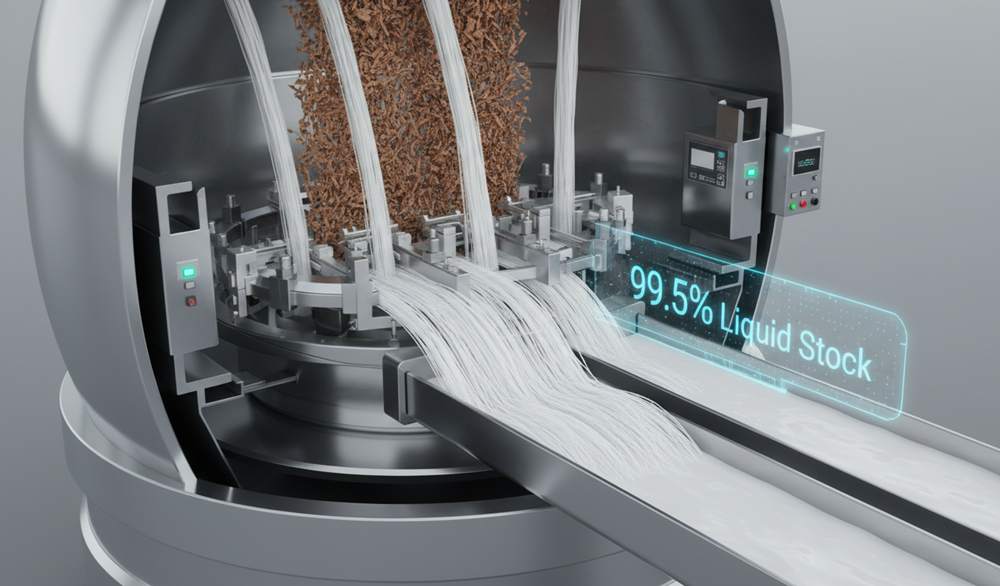

High-purity cellulose is extracted from timber, refined into a 99.5% liquid stock, and transformed into OBA-free, ultra-soft tissue using advanced pressing and embossing techniques.

Harvesting and Refining Raw Cellulose Fibers

The production process starts with the selection of timber, which provides the foundation for the long-fiber strength found in premium tissue products. We focus on isolating high-quality cellulose to ensure the final product meets commercial softness standards.

- Fiber Preparation: Workers harvest timber and strip the bark to prepare the wood for clean chipping.

- Pulping: Wood chips undergo pressure cooking for approximately three hours to dissolve lignin and isolate pure cellulose fibers.

- Purification: The pulp is washed and bleached to strip away residual cooking chemicals and natural impurities.

- Stock Formulation: The refined pulp is mixed into a stock containing 0.5% wood fiber and 99.5% water, a ratio that facilitates rapid dissolution and septic safety.

OBA-Free Processing and Natural Brightness Standards

Manufacturing 100% virgin pulp requires strict adherence to hygiene and safety specifications. We avoid chemical shortcuts, relying instead on raw material quality and mechanical engineering to achieve performance targets.

- Chemical Safety: The process is strictly OBA-Free (No Optical Brightening Agents) to ensure the tissue is safe for sensitive skin and meets international hygiene standards.

- Brightness Levels: We achieve a natural brightness of 85-92% through selective fiber sourcing from the Hebei industrial hub rather than using fluorescent whiteners.

- Ply-Bonding: High-pressure lamination bonds multiple plys together, ensuring the sheets do not separate during use while maintaining a cloud-like texture.

- Precision Embossing: CNC point-to-point embossing patterns increase the surface area, which improves absorbency by 30% compared to non-embossed alternatives.

- Tensile Strength: The use of long-fiber wood pulp creates a sturdy structure that balances high wet-strength with lint-free performance.

Advanced pressing and drying techniques finalize the sheets before they are perforated and wound into rolls. This systematic approach ensures that every batch maintains a consistent GSM and thickness, providing a reliable product for B2B distributors and hospitality groups.

Recycled Paper: Balancing Environmental Gains with Quality Costs

Recycled paper cuts energy use by 68% and saves 17 trees per ton. While matching virgin pulp’s brightness requires extra refining, FSC-certified sourcing ensures B2B compliance and sustainability.

Environmental Resource Conservation and Technical Performance Variables

Manufacturing recycled paper provides quantifiable ecological relief. By diverting fiber from the waste stream, producers significantly lower the burden on local infrastructure and natural resources.

- Landfill Impact: Each ton of recycled paper saves 3.3 cubic yards of landfill space.

- Water Conservation: Processing recovered fiber requires 7,000 fewer gallons of water than virgin wood pulp.

- Atmospheric Emissions: The manufacturing process generates 60 fewer pounds of air pollutants per ton.

Distributors must weigh these gains against physical fiber limitations. Recovered fibers are shorter, which often results in variations in smoothness and consistency. We mitigate these issues through advanced refining stages to ensure the final product meets high-volume retail standards.

Eco-Targeted Project Sourcing and Compliance Standards

B2B procurement increasingly hinges on meeting regional sustainability mandates. For markets in North America and Europe, compliance is the baseline for entry into professional distribution networks.

- FSC Verification: Utilizing FSC-certified recycled pulp satisfies strict hygiene and environmental regulations.

- B2B Customization: We offer tailored recycled options for distributors focused on green procurement and circular economy targets.

- Specification Tuning: Adjusting sheet opacity and thickness helps maintain product performance while managing fiber costs.

Recovered fiber generally carries a higher price point due to complex processing. But the naturally higher opacity of recycled sheets allows for thinner plies that still perform well. This balance helps wholesalers protect their margins while delivering a verified green product in 40HQ containers directly from our Hebei factory hub.

Build Your Premium Toilet Paper Brand

Why Bamboo Is the New Standard for Eco-Conscious Retailers

Bamboo matures in seven years and regenerates naturally, cutting CO2 and chemical use. It meets strict FSC and EU standards, making it the primary choice for 2026 circular retail goals.

Renewable Growth and Natural Carbon Mitigation

Bamboo outperforms traditional hardwood because it reaches harvest maturity in seven years rather than three decades. This rapid growth cycle allows retailers to maintain stable supply chains without contributing to the deforestation of slow-growing forests. The plant’s natural biology allows it to thrive in diverse conditions with minimal human intervention.

- Rapid Maturity: Bamboo reaches full maturity within seven years, compared to the 30-plus years required for traditional hardwood forests.

- Natural Regeneration: The plant regrows from existing root systems after harvesting, which prevents soil erosion and eliminates the need for manual replanting.

- Carbon Sequestration: Bamboo filters CO2 from the atmosphere and produces high levels of oxygen, acting as a highly efficient natural carbon sink.

- Low Resource Dependency: The crop requires no chemical fertilizers, pesticides, or supplemental irrigation, reducing the overall environmental footprint of the raw material.

Technical Compliance of Custom Bamboo Pulp Series

Top Source Hygiene integrates the Custom Bamboo Pulp Series into private label projects to hit specific sustainability KPIs for global distributors. These materials meet the rigorous technical standards required for the North American and European markets, ensuring that “eco-friendly” claims are backed by verifiable data and safety compliance.

- FSC-Certified Sourcing: We utilize materials with full FSC certification to provide wholesalers with total supply chain transparency and verified origin data.

- OBA-Free Production: Our bamboo series is guaranteed 100% free of Optical Brightening Agents, ensuring the final product is safe for sensitive skin and maintains microbiome integrity.

- Plumbing Compatibility: The fibers are engineered for rapid disintegration, meeting North American and European plumbing requirements for biodegradable waste.

- International Hygiene Standards: All products comply with EU hygiene regulations and ISO 9001 manufacturing protocols to ensure batch-to-batch consistency.

Is “Pure Pulp” a Misleading Term in the Industry?

“Pure pulp” is a vague label. Professionals demand specific fiber origins like 100% Virgin Wood Pulp to guarantee tensile strength, OBA-free safety, and consistent production quality.

Technical Ambiguity in Fiber Processing and Sourcing

Pulp is a processed intermediate, not a single raw substance. The term “pure” fails to define the origin or the manufacturing method used to create the fiber slurry. Industry standards recognize that pulp can originate from several distinct sources:

- Wood Fiber: Hardwoods and softwoods providing varying levels of softness and strength.

- Alternative Plants: Bamboo, hemp, flax, and straw with different sustainability profiles.

- Recycled Material: Post-consumer or industrial waste that has undergone previous processing.

Manufacturing methods further complicate the “pure” label. Chemical pulping removes lignin to leave pure cellulose, while mechanical pulping retains all wood components. These two processes create entirely different product grades, yet both could technically be marketed as “pure” to an uninformed buyer. Relying on vague terminology obscures whether the material is virgin or recycled, making sustainability verification nearly impossible for distributors.

Standardizing Quality with 100% Virgin Wood Pulp

Top Source Hygiene eliminates technical uncertainty by adhering to the 100% Virgin Wood Pulp standard. This material utilizes premium long-fiber wood pulp from the Hebei industrial hub to deliver a lint-free texture and superior tensile strength. Unlike mixed “pure” blends, virgin fibers offer the consistency required for high-speed commercial dispensers and premium retail brands.

Safety and compliance rely on specific material data rather than marketing buzzwords. We maintain strict production parameters to ensure every batch meets international hygiene requirements:

- OBA-Free Guarantee: Zero fluorescent whiteners are added, protecting sensitive skin and maintaining microbiome safety.

- Natural Brightness: We achieve an 85-92% brightness level through careful fiber selection rather than heavy chemical bleaching.

- Ply Density: Strictly controlled 13–22g/m² per ply to balance softness with wet-strength durability.

- Septic Safety: Engineered for rapid disintegration to prevent plumbing clogs in high-traffic hospitality environments.

By focusing on 100% Virgin Wood Pulp, we ensure that buyers receive a product with intact molecular chains. This results in higher absorbency and a “cloud-like” softness that recycled or vague “pure” alternatives cannot replicate. For B2B wholesalers, this precision translates to fewer customer complaints and protected profit margins.

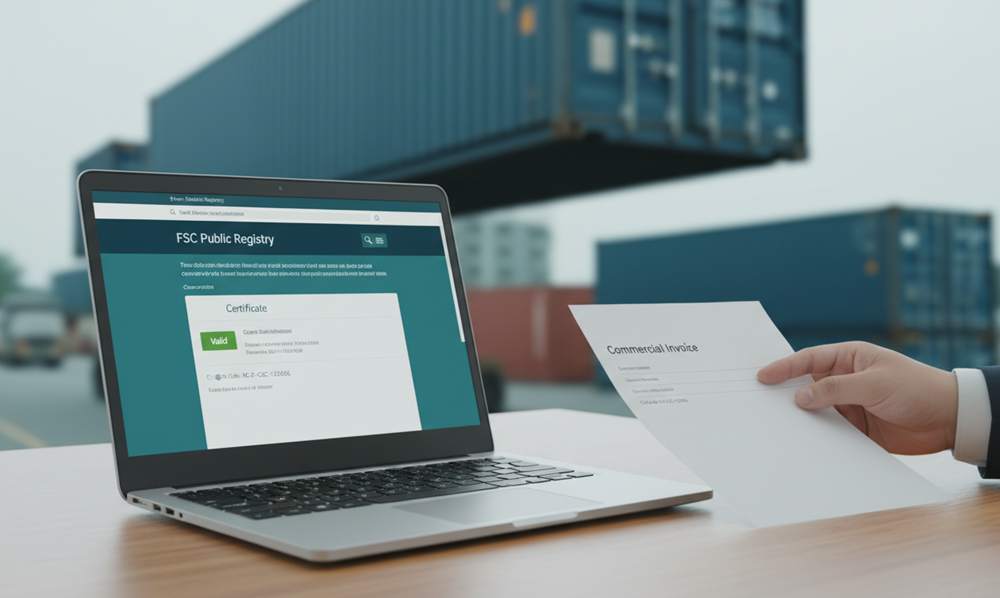

How to Verify Sustainable Sourcing via FSC Certificates

Search the FSC public registry with a supplier’s code to confirm active status. Validate Chain of Custody (CoC) records on all 40HQ shipment documents to ensure traceability.

| Certification Type | Supply Chain Role | Verification Focus |

|---|---|---|

| Forest Management (FM) | Forest Owners/Managers | Environmental and social standards at the raw material source. |

| Chain of Custody (CoC) | Manufacturers/Distributors | Material tracking from the Hebei factory to the final 40HQ container. |

Registry Authentication and Certification Classification

The FSC public database serves as the primary tool for B2B buyers to vet a manufacturer’s sustainability claims. Relying on a PDF certificate provided via email is insufficient; you must cross-reference the unique certificate code against live records to ensure the supplier is not using an expired or suspended credential.

- Search Protocol: Enter the unique FSC certificate code found on Top Source Hygiene commercial invoices into the FSC public registry.

- Classification Check: Differentiate between Forest Management (FM) and Chain of Custody (CoC). Manufacturers typically hold CoC certificates to track processed wood pulp.

- Product Scope: Confirm the certificate explicitly covers categories like “Household Toilet Rolls” or “Jumbo Roll Tissue” (JRT).

- Status Verification: Check the “Certificate Status” field. Ensure it shows “Valid” and covers the current production period.

Chain of Custody Protocols for Virgin Wood Pulp

Maintaining the integrity of 100% Virgin Wood Pulp requires strict adherence to FSC-STD-40-004 standards. These protocols prevent certified materials from mixing with unverified recycled waste during the high-speed lamination and embossing processes in our Hebei facility.

- Shipping Documentation: Audit every delivery note and bill of lading for a 40HQ container to ensure the correct FSC claim and CoC code are listed.

- Standard Compliance: Verify the factory follows FSC-STD-40-004 to maintain a clear line between certified virgin pulp and other materials.

- Annual Surveillance: Request confirmation of yearly third-party audits. These audits ensure the manufacturing site meets EU hygiene and North American OBA-free safety standards.

- Traceability Records: Ask for internal audit summaries or staff training logs. These documents prove the facility maintains a robust system for tracking material batches from intake to final packaging.

Effective verification protects your brand from “greenwashing” risks. By validating the CoC code at the point of shipment, you ensure that high-density products like the TSH-3396 or hotel-grade TSH-4010 meet international sustainability benchmarks before they reach your warehouse.

Frequently Asked Questions

What are the primary differences between virgin wood pulp and recycled tissue?

Virgin wood pulp provides consistent quality, high tensile strength, and superior softness because the long fibers remain intact. Recycled tissue costs less but contains shorter fibers that result in lower mechanical performance. Top Source Hygiene focuses on 100% virgin pulp to ensure OBA-free safety and a lint-free experience for premium markets.

Is bamboo paper more sustainable than traditional wood pulp?

Bamboo matures in 3 to 5 years and regenerates without replanting, making it a highly renewable resource. It requires less water and fewer chemicals during production. Wood pulp remains the standard for softness, but bamboo offers a compostable alternative with high absorbency for eco-conscious retailers.

How does FSC certification impact the sourcing of paper products?

FSC certification verifies that paper products come from responsibly managed forests. This framework ensures compliance with environmental laws, protects indigenous rights, and maintains long-term forest health. FSC standards remain the global benchmark for verifying sustainable sourcing across the entire supply chain.

What exactly is mixed pulp in the context of tissue manufacturing?

Mixed pulp refers to a strategic blend of different fibers, such as virgin wood pulp combined with recycled or mechanical pulp. Manufacturers use these formulations to reach specific cost, opacity, or strength targets. Top Source Hygiene maintains material integrity by avoiding mixed recycled waste in its premium product lines.

Why is virgin wood pulp the preferred choice for luxury hospitality?

Virgin pulp offers superior softness, aesthetic brightness, and reliable durability that enhance guest satisfaction. These attributes reflect a premium brand image. High-end models like the TSH-4010 utilize 5-ply thickness and 100% pure fibers to provide a texture that recycled options cannot match.

Is 100% virgin wood pulp paper safe for sensitive skin and septic systems?

Pure virgin pulp is naturally 100% OBA-free, meaning it contains no fluorescent whiteners. The fibers are engineered for rapid disintegration, making the paper septic-safe for North American and European plumbing standards while ensuring a chemical-free, hypoallergenic experience for users.

Final Thoughts

Choosing between virgin, recycled, and bamboo requires balancing environmental KPIs against consistent product performance. While recycled fibers offer ecological gains, 100% Virgin Wood Pulp remains the only material that guarantees the 13–22g/m² ply density and OBA-free safety required for premium hospitality and sensitive retail markets. Investing in high-density inventory from our Hebei factory protects your reputation by eliminating the linting and strength issues common in low-tier alternatives.

We recommend securing a 40HQ trial order of our “Big 10” best-sellers to optimize your landed costs and test our CNC-embossed absorbency firsthand. Our team provides full pre-shipment visual verification and FSC documentation to ensure your private label meets North American and European compliance. Contact us today to request a technical data manual and discuss your specific wholesale distribution targets.