Implementing a Multi-SKU Portfolio Strategy stops the margin decay caused by single-tier hygiene sourcing. Distributors stuck in the one-product trap face inefficient container utilization and lost revenue in premium hospitality segments, directly increasing the landed cost per roll.

We standardize 100% Virgin Wood Pulp and OBA-free safety across product tiers to solve this. By integrating high-volume TSH-2559 rolls with luxury TSH-4010 variants, we maximize 40HQ payloads to 9,000kg, allowing you to capture diverse market segments within a single logistics stream.

The “Good-Better-Best” Strategy for Hygiene Brands

Tiered pricing captures diverse market segments by offering standard, enhanced, and premium options. This structure drives revenue by upselling clients to high-margin, 5-ply virgin wood pulp specifications.

| Tier | Technical Profile | TSH Model | Target Market |

|---|---|---|---|

| Good | 2-Ply/3-Ply Standard Household Rolls | TSH-2559 | High-volume retail/Supermarkets |

| Better | 4-Ply High-Density Solid Rolls | TSH-2214 | Urban retail & office supply |

| Best | 5-Ply Luxury Solid/Wide-Format Rolls | TSH-4010 / TSH-2269 | Luxury hospitality & VIP clubs |

Segmenting Consumer Markets through Tiered Value

Distributors use the decoy effect to guide buyers toward high-margin premium options. By pricing the “Better” and “Best” tiers within a narrow margin, the premium tier appears to offer significantly more value for a small price increase. This psychological anchor shifts the buyer’s focus from “cheapest price” to “highest value.”

Effective tiering requires clear value gaps. Essential cleaning rolls serve budget-conscious retail needs, while specialized variants target safety and comfort. We establish these gaps using specific differentiators:

- Chemical Safety: 100% OBA-free (no fluorescent whiteners) for sensitive skin.

- Plumbing Compliance: Septic-safe engineering that ensures rapid disintegration.

- Certification: Adherence to ISO 9001 and EU hygiene standards across all mid-to-high tiers.

Aligning TSH Multi-Ply Specs with Portfolio Tiers

Top Source Hygiene provides the technical parameters needed to fill each pricing band. For the core “Good” tier, we deploy TSH-2559. These 2-ply and 3-ply household rolls handle high-volume retail demand in North America and Europe, focusing on septic-safe technology and OBA-free safety.

For the “Best” luxury collections, we utilize high-density solid rolls and wide-format models. These specs justify premium price points through superior fiber performance:

- TSH-4010: A 5-ply luxury hospitality roll designed for high-end hotel chains.

- TSH-2269: A 165mm wide-format 4-ply roll that meets premium comfort standards in the Middle East.

- Material Integrity: 100% Virgin Wood Pulp ensures exceptional tensile strength and cloud-like softness.

- Point-to-Point Embossing: CNC-precision patterns increase absorbency by 30% compared to flat-sheet alternatives.

We manufacture these tiers at our Hebei industrial hub to maintain batch color consistency. Every 40HQ container maximizes payload efficiency, ensuring distributors receive the lowest landed cost per roll across their entire “Good-Better-Best” portfolio.

Balancing Material Costs Across a Multi-SKU Portfolio

Brands balance costs by standardizing core materials across SKU tiers and maximizing 40HQ container payloads to reduce procurement complexity and the landed cost per unit.

Portfolio Segmentation and Bill of Materials Standardization

Managing a diverse hygiene portfolio requires aggressive segmentation. We apply ABC analysis to isolate high-velocity SKUs and concentrate material spending where it generates the most movement. By cutting low-performing variations, we stop bleeding capital on niche materials that complicate the supply chain.

The most effective way to lower expenses is through Bill of Materials (BOM) standardization. Instead of sourcing different fiber grades for every price point, we use standardized 100% Virgin Wood Pulp across our 2-ply and 3-ply tiers. This consolidation allows us to negotiate better raw material rates and simplifies warehouse management.

- Material Base: Standardized 100% Virgin Wood Pulp across economy and premium tiers.

- Production Synergy: Shared embossing patterns and ply-bonding techniques to reduce machine downtime.

- Fiber Standards: 13–22g/m² per ply density control for consistent quality.

- Inventory Logic: Data-driven forecasting to align material purchasing with actual market performance.

Logistics Efficiency Through the Big 10 Inventory Strategy

Inventory complexity is a margin killer. We focus on “The Big 10” core inventory models—high-demand specifications like the TSH-2559 and TSH-3396. This focus ensures high turnover of raw materials and maintains consistent production efficiency at the factory level.

Shipping air is the fastest way to lose money in the paper industry. We maximize 40HQ container payloads, targeting weights between 7,000kg and 9,000kg. By using mechanical compression during the bagging process, we increase roll density and fit more product into every shipment, driving down the freight cost per roll.

- Core Inventory: High-turnover “Big 10” models like TSH-4010 and TSH-3082.

- Container Optimization: Strict 40HQ payload targets of 7-9 tons per shipment.

- Packaging Tech: Mechanical compression to maximize cubic meter utilization.

- Strategic Sourcing: Direct dispatch from the Hebei industrial hub to Tianjin port to minimize domestic transit costs.

Scale Your Brand with Premium OEM Manufacturing

Unified Branding: Maintaining Visual Identity Across Tiers

Successful 2026 branding uses flexible logos and shared color palettes to bridge economy and premium tiers, ensuring recognition through physical signatures like custom embossing across all ply counts.

Designing a Flexible Visual Language for Global Portfolios

Multi-tier portfolios often struggle when the visual connection breaks between a 2-ply value roll and a 5-ply luxury product. Building a scalable system ensures that high-volume distributors recognize the source factory identity instantly, regardless of the price point.

- Logo Scalability: Primary logos and secondary wordmarks must remain legible on both high-end individual wraps and large-format bulk poly bags.

- Core Color Palette: We use 1-3 primary colors across the 2-ply to 5-ply range to establish long-term buyer trust and brand shelf-presence.

- Typography Systems: Maintain font consistency across digital catalogs and 5-ply export cartons to ensure professional presentation in every channel.

- Accessibility Compliance: Visual assets follow 2026 high-contrast standards to ensure readability in diverse international markets.

Using Custom Logo Embossing and Packaging Standards

Physical branding serves as a “silent salesman.” By integrating brand marks into the manufacturing process, Top Source Hygiene helps private label owners protect their market share through distinct tactile features.

- CNC-Precision Embossing: Use point-to-point embossing to press custom logos directly into the paper, creating a permanent physical brand signature.

- Standardized Layouts: Align graphic placement between Format A (hospitality individual wraps) and Format B (retail bundle packs) to maintain a cohesive family look.

- Material Integrity: 100% Virgin Wood Pulp ensures a consistent natural brightness (85-92%) and OBA-free safety across all product levels.

- Batch Uniformity: We monitor color consistency in packaging films to prevent visual drift between separate 40HQ production runs.

Leveraging Shared Logistics for Multiple Product Types

Consolidating household and commercial tissues into single 40HQ shipments reduces landed costs and allows distributors to manage diverse SKUs while maintaining lower individual inventory levels.

Cost Optimization Through Multi-SKU Consolidation

B2B distributors often struggle with high shipping costs when ordering single-product categories. By pooling different paper types into a unified logistics stream, we help wholesalers bypass the inefficiencies of fragmented shipping. This approach spreads fixed warehousing overhead across a wider portfolio, from 100% Virgin Wood Pulp household rolls to industrial jumbo rolls.

- Rate Negotiation: Combining categories like facial tissue and coreless toilet paper allows us to negotiate better carrier rates based on total volume.

- Overhead Reduction: Warehousing expenses are distributed across both high-velocity retail packs and specialized commercial solutions.

- Waste Prevention: Joint inventory coordination reduces redundant transport legs and prevents storage waste in regional hubs.

- Dynamic Fulfillment: Shipment volumes can be adjusted in real-time to match specific demand for economy versus premium product tiers.

High-Payload 40HQ Optimization and Compression Specs

Maximizing container space is the most effective way to lower the landed cost per roll. Our Hebei facility uses specific packing standards designed for mixed orders to ensure that every cubic meter of a 40HQ container is utilized without damaging the product. We prioritize structural integrity so that lighter items, like facial tissues, aren’t crushed by heavy-duty rolls.

- Mechanical Compression: Our bagging technology minimizes roll bulk, increasing units per cubic meter while keeping the paper soft.

- Payload Engineering: We stack high-density solid rolls (like TSH-3396) with lighter products to hit a 7,000kg to 9,000kg total payload in a 40HQ.

- Export Protection: We use reinforced 5-ply export cartons to prevent crushing during high-stacking in long-haul transit.

- Port Proximity: Direct dispatch from our Hebei hub to Tianjin Xingang Port cuts domestic transit time for international buyers.

Cross-Selling Strategies: From Economy Rolls to Premium Wipes

Group high-volume TSH-3396 rolls with premium TSH-4010 variants to maximize 40HQ container efficiency while covering budget retail and luxury hospitality segments in a single shipment.

Strategic Bundling and the Compromise Effect

Wholesalers often face decision fatigue when navigating a massive SKU catalog. Grouping basic household rolls with premium facial tissues or wet wipes simplifies the selection process. This bundling strategy allows distributors to offer a complete hygiene solution to their retail clients without requiring multiple sourcing points.

Psychological anchoring plays a significant role in moving inventory. By presenting high-tier 5-ply options like the TSH-4010 first, we establish a high baseline for quality. This makes mid-range products appear more affordable while encouraging quality-conscious buyers to commit to the premium tier.

- Timing: Introduce kitchen towels or specialty wipes during the container configuration phase to fill remaining space and increase total order value.

- Segmentation: Target upsell opportunities toward established distributors who consistently order 100% Virgin Wood Pulp products.

- Value Positioning: Use the “Good-Better-Best” model to ensure every market tier is covered within a single 40HQ container.

Utilizing the Big 10 Inventory for Tiered Market Alignment

The Big 10 inventory strategy focuses on stocking the most popular global specifications to facilitate immediate mixed loading. Mixing high-density TSH-3396 solid rolls with luxury TSH-4010 hotel-grade rolls allows a single distributor to serve both budget-conscious retail chains and high-end hospitality clients.

Maintaining material integrity across all tiers is vital for brand trust. We use 100% Virgin Wood Pulp for our entire tiered range, ensuring that even the economy options provide superior skin-friendly softness and OBA-free safety. This consistency prevents the “quality gap” that often plagues multi-tier brands.

- Retail Anchors: Use TSH-2559 septic-safe rolls for standard residential retail orders.

- Specialty Markets: Introduce wide-format TSH-2269 rolls (165mm) for markets requiring maximum surface area and comfort.

- Payload Optimization: Combine heavy industrial-grade rolls like the TSH-3082 with lighter, high-margin premium multi-packs to hit the 9-ton payload limit.

- Efficiency: Utilize coreless solid rolls to maximize paper volume per cubic meter, reducing the landed cost for the importer.

Strategic cross-selling relies on logical product relationships. By utilizing our Hebei factory’s specialized loading teams, we ensure that mixed-tier containers are packed to prevent crushing while maximizing every inch of space, protecting both the product and the distributor’s profit margins.

Managing Inventory Complexity for Wholesale Distribution

Integrate AI demand forecasting with high-payload 40HQ container logistics to balance SKU complexity and reduce landed costs for international wholesale operations.

Predictive Demand Planning and Multi-Hub Coordination

Wholesale distributors often face supply-demand imbalances across regional locations. We solve this by using AI-driven forecasting to analyze historical data and market trends, allowing us to predict seasonal shifts in hygiene product demand before they impact your stock levels.

- Real-time Synchronization: Connecting regional hubs prevents localized stockouts and removes the need for expensive internal transfers between warehouses.

- Automated Reorder Points: Replenishment triggers based on actual lead times ensure a consistent supply for high-turnover retail and institutional clients.

- Centralized Visibility: Real-time inventory transparency enables faster order allocation and significantly reduces manual coordination errors.

The Big 10 Strategic Inventory Model for Streamlined Sourcing

Standardizing your sourcing around “The Big 10” core inventory models simplifies global logistics. This approach reduces SKU proliferation and focuses resources on the high-demand products that drive the most volume and profit.

- Standardized Models: Prioritize high-demand models like TSH-2559 (Global Retail Favorite) and TSH-3396 (Maximum Efficiency) to simplify warehouse management.

- Logistics Speed: Strategic stocking of these ready-to-ship models allows for a 10-15 day dispatch lead time from our Hebei facility to Tianjin Xingang Port.

- Container Optimization: Our teams maximize 40HQ container payloads to reach 7,000kg–9,000kg, ensuring you get the highest freight value and the lowest landed cost per roll.

A leaner, rationalized portfolio enhances supply chain flexibility. By focusing on high-velocity SKUs and utilizing precision loading, we help you respond faster to market shifts while keeping operational waste to a minimum.

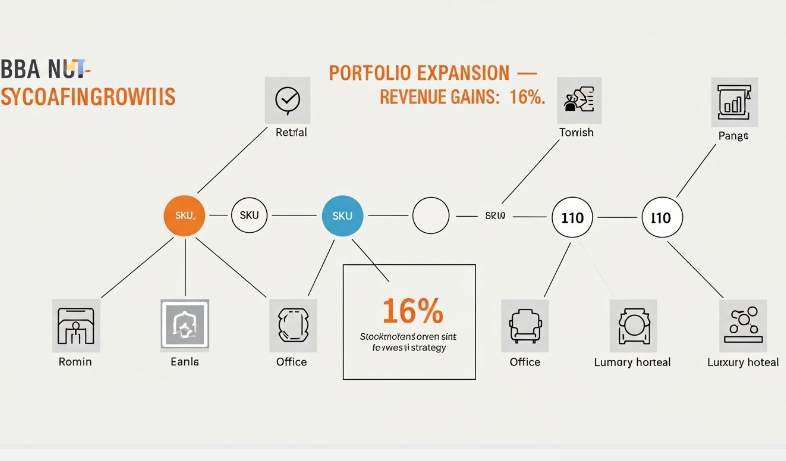

Case Study: Scaling from 1 SKU to a 10-SKU Brand Family

Scaling to 10 SKUs balances diversity and efficiency. Brands see 16% revenue gains per SKU by standardizing manufacturing and consolidating shipping to manage growth complexity.

The Strategic Framework for Portfolio Expansion

Scaling from a single product to a 10-item family requires a systematic approach to SKU selection. We identify high-demand, low-competition private label items to repeat the successful market entry process used for the lead product. This data-driven replication ensures that each new addition contributes to the bottom line without cannibalizing existing sales.

To maintain production speed, we distinguish between “below-the-skin” manufacturing complexity and “above-the-skin” retail variety. A brand might offer ten different packaging options while using the same base paper specifications and core materials. This maintains high throughput at our Hebei facility while providing the variety retail buyers demand.

Distribution channels have physical limitations that dictate SKU priority. A convenience store shelf cannot hold the same variety as a warehouse club pallet. We conduct channel-specific analysis to determine which SKUs fit best in specific retail and warehouse environments, preventing stockouts of top-performing items.

Standardizing packaging and material specifications can reduce complexity costs by up to 45%. By eliminating redundant items and focusing on core materials, brands streamline their procurement and free up working capital for marketing and expansion.

Standardizing with the Big 10 Global Inventory

Inventory stability drives rapid scaling. We select from the Top Source Hygiene “Big 10” core inventory to ensure products remain ready-to-ship during growth spurts. This includes high-demand models designed for specific market needs.

- Core Models: TSH-2559 (Standard 2/3-Ply Retail) and TSH-3396 (5-Ply High-Density Solid Roll).

- Payload Optimization: 7,000kg to 9,000kg of mixed SKUs per 40HQ container to achieve the lowest landed cost.

- Material Integrity: 100% Virgin Wood Pulp with guaranteed batch color consistency across all 10 tiers.

- Safety Standards: 100% OBA-free and septic-safe certifications for North American and European compliance.

Mixing different product tiers in a single container allows brands to test new SKUs without committing to massive individual volumes. Our loading teams in Hebei maximize container space, ensuring every cubic meter of the 40HQ is utilized for maximum profitability.

We use high-pressure lamination and CNC-precision embossing to maintain brand trust. Whether a customer buys the economy roll or the luxury hotel-grade option, the technical quality—from tensile strength to fiber performance—remains uniform across the entire brand family.

Frequently Asked Questions

How should I structure a multi-tier toilet paper brand portfolio?

Successful brand architecture segments products into Value, Standard, Premium, and Specialty tiers. Direct your efforts toward niche differentiation by positioning Value rolls for cost-conscious buyers and Premium rolls for those seeking 100% virgin wood pulp or OBA-free safety. Younger audiences specifically favor sustainability-focused premium options, making eco-friendly materials a high-value anchor for the top tier.

What are the benefits of sourcing all SKUs from a single manufacturer?

Consolidating your supply chain with one factory like Top Source Hygiene reduces administrative overhead and increases negotiating leverage for bulk pricing. This single-source strategy simplifies logistics through consolidated deliveries in 40HQ containers, shortens lead times by removing multi-vendor coordination, and ensures consistent quality control and batch color uniformity across your entire product range.

How can I differentiate economy and premium rolls through branding?

Differentiation relies on distinct messaging and genuine quality gaps. Economy rolls should emphasize reliability and everyday value through practical, volume-driven packaging. Premium rolls require aspirational language like “Hotel-Grade” or “Ultra-Soft” and must feature substantive upgrades, such as moving from 2-ply to 5-ply thickness or using 100% virgin wood pulp materials to justify the price point.

Can I mix different product tiers in a single shipping container?

Yes, load mixing is a cost-effective way to maximize container capacity and reduce transportation expenses. By combining various SKUs, such as standard household rolls and jumbo commercial rolls, you achieve better space utilization. Our Hebei loading teams use specific stacking protocols to ensure heavy high-density rolls do not crush softer retail packs, protecting the payload during transit.

How do I maintain brand consistency across different price points?

Establish logical pricing relationships using coefficients so that price shifts in one tier adjust the entire portfolio automatically. Consumers trust brands with consistent vertical chaining, where unit prices follow a predictable pattern across sizes and plies. Maintaining this discipline even during economic shifts helps preserve your brand’s reputation for reliability and prevents consumer confusion.

Which product tiers offer the highest profitability for distributors?

High-margin profitability is often found in specialized tiers like 5-ply luxury rolls and eco-friendly bamboo pulp options. While standard retail rolls drive volume, premium items like the TSH-4010 for hospitality or the TSH-3396 for industrial efficiency command higher prices due to their specialized performance, high density, and unique market positioning.

Final Thoughts

Wholesalers often fail by chasing the lowest unit price, only to face high returns and lost retail trust due to inconsistent material quality. We recommend anchoring your portfolio with 100% Virgin Wood Pulp and OBA-free certifications to ensure technical integrity across every price point from economy to luxury. This tiered strategy protects your dealer reputation and turns a single-product commodity into a resilient, high-margin brand family.

Start optimizing your landed costs by consolidating a mixed-tier trial order into a single 40HQ container today. We suggest reviewing our Big 10 core inventory to identify the high-velocity models, such as the TSH-2559 or TSH-3396, that best match your regional demand. Contact our technical team in Hebei to request a sample kit and begin the private label design process for your 2026 portfolio.