Selecting the correct Core Sizes & Spindles represents the difference between a high-efficiency facility and a logistical bottleneck involving unusable inventory and frustrated maintenance staff. Ordering the wrong core diameter for your jumbo roll tissue dispensers results in immediate operational downtime, forcing teams to scramble for adapters or leave restrooms unserviced during peak traffic windows. This common procurement oversight wastes thousands in annual supply spend and impacts the hygiene standards of high-traffic commercial environments.

We break down the technical specifications of 2.25-inch and 3.3-inch cores to help you standardize your facility supplies across various restroom configurations. This guide explains how to measure existing dispenser spindle diameters accurately, evaluate core strength for high-speed dispensing, and determine when to use universal adapters. By establishing these technical benchmarks, procurement managers can eliminate sourcing errors and ensure every roll fits the hardware right out of the box.

Why Is Core Size the Most Common Sourcing Mistake?

Purchasing errors regarding core diameter often result in total loss of bulk inventory, as even a 2mm variance prevents mounting on commercial spindles and forces manual product adjustments.

Incompatibility with Installed Dispenser Spindles

Procurement teams often fixate on paper ply and GSM while overlooking the physical dimensions of the internal tube. This oversight creates a critical failure point where the product cannot be mounted on existing hardware. A core diameter even 2mm smaller than the facility’s dispenser spindle renders an entire 40’HQ container of stock unusable for its intended purpose.

- Mismatched sizing causes excessive friction or wobbling, which leads to paper tearing during high-traffic commercial use.

- Facility managers report that core size errors remain the primary driver for bulk returns in the hospitality and office sectors.

- Precision in the internal tube diameter ensures the roll spins freely, preventing the “drag” that causes users to pull excess paper.

Impact on Logistic Efficiency and Shipping Costs

The internal diameter of the core dictates the overall roll volume, which directly influences shipping container capacity. Larger cores increase the “dead air” space inside each roll. This empty space can reduce the total number of rolls per 40’HQ container by 5% to 10%, significantly increasing the landed cost per unit.

Inefficient core selection in 2026 sourcing leads to higher freight costs per sheet, negating savings found in raw material procurement. Top Source Hygiene utilizes strategic core sizing to maximize container density. By balancing core diameter with paper compression, we ensure manufacturers maintain roll integrity while optimizing every cubic meter of shipping space.

Discrepancies Between Metric and Imperial Standards

Global sourcing efforts often fail when regional measurement standards for spindles are not clearly translated during the OEM/ODM design phase. North American buyers typically request a standard 3-inch core, yet variations in manufacturing tolerances can lead to fitment issues with European metric-based spindles.

- Standardizing technical drawings in millimeters prevents the common 1/8th-inch variance that causes roll jams.

- Top Source Hygiene uses precise millimeter measurements to ensure custom-branded rolls meet the specific hygiene compliance standards of Oceania, Europe, and Asia.

- Accurate measurement verification during the prototyping phase eliminates the risk of cross-border equipment incompatibility.

Structural Failure Under High-Capacity Loads

Selecting an incorrect core diameter or insufficient wall thickness for jumbo rolls leads to structural collapse. High-capacity rolls used in airports and malls require reinforced cores to withstand the weight of the paper without deforming. If a core collapses, the roll cannot rotate on the spindle, forcing maintenance staff to manually fix or discard the product.

Selecting the right core strength for 2026 commercial contracts reduces maintenance labor costs and product waste by an estimated 15%. Ensuring the core maintains its circular shape during stacking and transport protects the entire supply chain from downstream mechanical failures at the point of use.

What Is the Difference Between 2.25-Inch and 3.3-Inch Cores?

Selecting the correct core diameter ensures immediate hardware compatibility and dictates the total paper volume available for high-traffic maintenance cycles.

Spindle Compatibility and Dispenser Standards

Facility managers select core sizes based on the specific hardware installed on-site. Most standard Jumbo Roll Tissue (JRT) dispensers utilize a 2.25-inch (57 mm) spindle, which serves as the global benchmark for retail and light commercial environments. Industrial-grade or high-capacity dispensers often feature a 3.3-inch (84 mm) spindle to support larger, heavier rolls without excessive friction or paper tearing. At Top Source Hygiene, we manufacture both sizes to ensure our B2B clients meet regional hardware standards. Mismatching these components leads to immediate operational failure, as a 3.3-inch core will not sit correctly on a 2.25-inch spindle, causing misalignment and paper jams.

| Operational Metric | 2.25-Inch (57mm) Core | 3.3-Inch (84mm) Core |

|---|---|---|

| Hardware Target | Standard/Retail JRT Dispensers | Industrial/High-Capacity Units |

| Facility Fit | Space-Saving Office Restrooms | Airports, Stadiums, and Malls |

| Logistical Edge | Higher 40HQ Container Density | Reduced Refill Labor Costs |

Roll Volume and Maintenance Cycle Impact

Core diameter directly influences the total amount of paper a roll holds and how often staff must perform replacements. Cores with a 3.3-inch diameter typically accommodate longer paper lengths, making them ideal for high-traffic venues where reducing refill frequency is a priority. The 2.25-inch core offers a more compact profile for smaller commercial restrooms that prioritize space-saving over maximum roll longevity. Data from facility managers indicates that switching to high-capacity rolls with larger cores reduces maintenance labor costs by approximately 15% due to fewer service interruptions.

Logistical Footprint and Shipping Density

The internal diameter of the core changes the outer roll dimension and affects how many units fit into a shipping container. Rolls featuring 2.25-inch cores generally allow for higher stacking density in a 40-foot high-cube (40HQ) container, which lowers the landed cost per unit for international importers. Specialized 3.3-inch core products require precise packaging to prevent the core from collapsing under the weight of extra-long paper rolls during transit. We optimize pallet configurations for both core sizes at our Hebei factory to ensure structural integrity throughout the 15-25 day shipping journey to global markets.

Scale Your Brand With Premium Jumbo Rolls

How to Measure Your Existing Dispenser Spindle Diameter?

Precise spindle measurement prevents procurement errors that cause mechanical jams and operational downtime in high-traffic commercial environments.

Accurate verification requires digital calipers or a micrometer to capture the outer diameter of the spindle at its thickest point. We suggest taking measurements at both the base and the tip to identify any tapering or uneven wear that might impede roll rotation. If your dispenser uses a removable sleeve system, verify the bore diameter of the sleeve itself, as this serves as the primary contact point for the Jumbo Roll Tissue (JRT) core.

| Standard Spindle Type | Nominal Diameter | Common Application |

|---|---|---|

| Mini Jumbo Standard | 2.25″ (57mm) | Compact commercial dispensers |

| Large Jumbo Standard | 3.3″ (84mm) | High-capacity industrial systems |

| OEM Specific (e.g. Tork) | 3.8″ (96mm) | Proprietary high-density systems |

Identifying Nominal Diameter Standards

Compare your physical measurements against the two dominant industry standards: 2.25 inches (57mm) and 3.3 inches (84mm). Round your findings to the nearest standard size, as plastic expansion or surface debris can cause minor deviations. You should also check the dispenser housing for manufacturer stamps that explicitly list the required core size for that specific model.

Evaluating Spindle Concentricity and Condition

The physical integrity of the spindle directly dictates how smoothly the paper roll rotates. Inspect the hardware for wobble or warping that causes rolls to snag or tear prematurely. Worn spindles often increase surface friction; in these cases, Top Source Hygiene provides specific core textures via our ODM services to maintain consistent dispensing even on aging hardware. Documenting these signs of degradation early prevents product waste.

Data Integration for OEM Ordering

When you request custom core sizes for jumbo rolls from Top Source Hygiene, provide these precise dimensions to ensure a perfect fit with your infrastructure. Aligning this measurement data with your 2026 maintenance logs helps prevent sourcing errors for high-traffic facilities. We recommend utilizing our free sample rolls to test the fit on-site before committing to a full 40’HQ container order.

- Use digital calipers for ±0.1mm accuracy.

- Match dimensions to 2.25″ or 3.3″ standards.

- Check for spindle warping or debris buildup.

- Submit specific spindle data for custom OEM orders.

Are There Universal Adapters for Different JRT Core Sizes?

Facility managers use modular hardware and snap-in plastic reducers to bridge the 1.05-inch gap between high-capacity 3.3-inch jumbo cores and standard 2.25-inch dispenser spindles.

Functionality of Plastic Core Reducers

Plastic core reducers serve as the primary bridge for facilities with legacy dispenser fleets that cannot natively accept large-diameter cores. These snap-in inserts effectively downsize 3.3-inch or 3-inch jumbo roll cores to fit the standard 2.25-inch spindles commonly found in commercial washrooms. By providing a secure, centered fit, these adapters prevent the “roll jump” and wobbling that occur when a large-core roll is placed on a narrow spindle.

- Maintenance teams clip these adapters into both ends of the cardboard tube before installation to ensure balanced rotation.

- Reducers maintain roll centering, which is critical for consistent tension and preventing paper jams during high-speed dispensing.

- The simple plastic geometry allows for quick removal and reuse, though they are frequently lost during high-volume refills.

Modular Spindle Systems in 2026 Dispensers

Modern dispenser architecture in 2026 has shifted toward integrated flexibility to accommodate global sourcing variations. Newer commercial models often feature interchangeable or telescoping spindle hardware. Instead of relying on external plastic inserts, facility managers swap the central shaft or use spring-loaded mechanisms that automatically expand to grip the internal diameter of the JRT core.

- Modular hardware allows for a “one-dispenser, many-cores” strategy, reducing the need for specific paper proprietary locks.

- Spring-loaded designs adjust to various inner diameters, including the 76mm standard used in many industrial tissue applications.

- Integrated systems eliminate the inventory headache of managing small adapter parts that often end up in the waste bin.

Production-Level Customization for Hardware Alignment

The most reliable method for ensuring compatibility involves aligning the paper core with the dispenser at the point of manufacture. When sourcing from a direct factory like Top Source Hygiene, wholesalers can bypass the need for secondary adapters by specifying the exact core requirements for their client’s existing dispenser fleets. This precision ensures the jumbo rolls spin freely without mechanical drag, which is a frequent cause of paper breakage.

- Top Source Hygiene offers OEM customization for models like the TSH-JRT08, matching core diameters to any global spindle standard.

- Eliminating secondary adapters reduces friction, allowing the 100% Virgin Wood Pulp fibers to maintain their integrity during rapid pulls.

- Tailored core sizes optimize the user experience in high-traffic airports and malls by providing a smooth, snag-free draw.

Why Does Core Strength Matter for High-Speed Dispensing?

In high-traffic commercial environments, a core’s structural integrity determines whether a dispenser functions reliably or becomes a recurring maintenance liability due to mechanical failure.

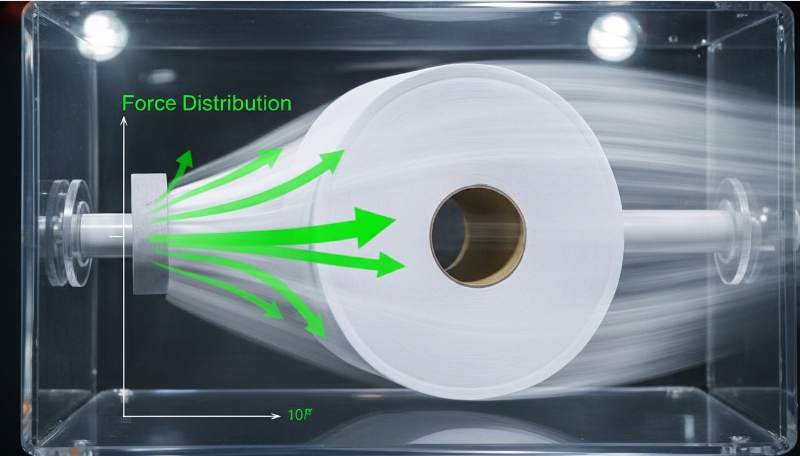

Prevention of Core Collapse Under Centrifugal Force

High-speed dispensing in 2026 commercial environments subjects the cardboard core to intense rotational stress. When a user pulls paper rapidly, the roll spins at high velocity, creating centrifugal forces that can easily deform weak materials. Top Source Hygiene utilizes reinforced virgin wood pulp for cores to ensure they maintain a perfect circular shape even during these rapid rotations.

Structural failure or “ovalization” of the core leads to uneven pulling, which often causes the paper to tear prematurely before the perforation. A rigid core also prevents the roll from flattening under the weight of stacking and transport—vital for maintaining the 2,860-ton monthly production standards our Hebei facility manages.

| Performance Metric | Standard Commercial Core | Top Source Reinforced Core |

|---|---|---|

| Material Base | Mixed Recycled Fiber | 100% Virgin Wood Pulp |

| Deformation Resistance | Low (prone to ovalization) | High (maintains circularity) |

| Humidity Tolerance | Softens in 60%+ Humidity | Moisture-Resistant Bonding |

Maintaining Consistent Spindle Alignment

The interaction between the dispenser spindle and the roll core determines the smoothness of the paper flow. A strong core provides a stable pivot point, reducing friction that can otherwise overheat or wear down dispenser components in 2026 smart-dispensing systems. We engineer core density with precision to ensure the roll stays centered on the spindle, effectively eliminating the “wobble” effect that causes mechanical jams.

- Precision-engineered density prevents the core from expanding or contracting.

- Standardized core strength across 2.25-inch and 3.3-inch options ensures global hardware compatibility.

- Reduced friction extends the lifespan of plastic spindle adapters.

Resistance to Humidity-Induced Softening

Commercial restrooms and industrial kitchens present high-moisture conditions that compromise inferior paper cores. Cores manufactured with moisture-resistant bonding agents prevent the cardboard from delaminating or softening in humid climates like Southeast Asia or South America. By maintaining structural integrity in damp environments, we prevent the core from sticking to the spindle, which is a leading cause of maintenance calls in the hospitality sector.

Impact on Operational Efficiency and Maintenance Costs

Core durability directly influences the total cost of ownership for facility managers. Stronger cores allow for the full depletion of the jumbo roll, eliminating the 10-15% of paper waste typically caused by core failure near the end of the roll. Facilities in North America and Europe report significantly lower maintenance labor costs when using rolls that do not jam due to core deformation.

Predictable dispensing speeds also enable automated facility management systems to accurately track paper consumption. When the core remains stable, sensors can better monitor restock cycles, ensuring that high-traffic zones like airports and malls never run out of supplies.

Conclusion

Matching jumbo roll core sizes to specific dispenser spindles prevents installation failures and ensures smooth operation in high-traffic commercial environments. Accurate sourcing protects your procurement budget by eliminating the need for adapters and reducing paper waste. Professional core alignment remains a critical factor for maintaining efficient facility workflows and equipment longevity.

Review your current dispenser fleet to confirm spindle diameters before placing your next bulk wholesale order. Reach out to our technical team for the Top Source Hygiene official core data manual or to request samples from our JRT inventory.

Frequently Asked Questions

What is the core size of a jumbo roll?

The industry standard for a jumbo roll (JRT) typically features a core diameter of either 2.25 inches (57mm) or 3.3 inches (84mm). While the 3.3-inch core is the most prevalent for high-capacity commercial dispensers, many manufacturers offer adapters to switch between these two primary sizes.

Will a 3.3-inch core fit a 2.25-inch spindle?

Technically, a 3.3-inch core will slide onto a 2.25-inch spindle, but it will not function correctly. The excess clearance causes the roll to wobble, rotate unevenly, and often leads to the paper jamming or unspooling too quickly. For a proper fit, you must use a core-size adapter to bridge the gap.

What size core does tork use?

Tork (an Essity brand) primarily utilizes a 2.25-inch core for their standard jumbo roll tissue (JRT) systems. However, they also produce proprietary systems, such as their coreless and twin-roll dispensers, which utilize specialized spindles designed to fit their specific tissue refills.

How to measure toilet paper core?

To measure a core correctly, you must determine the Inner Diameter (ID). Use a ruler or caliper to measure the straight-line distance across the hollow center of the tube, from one interior wall to the opposite interior wall. Do not include the thickness of the cardboard in your measurement.

Why are jumbo roll cores so big?

Larger cores provide the necessary structural integrity to support the significant weight of high-capacity rolls, preventing the cardboard from collapsing during shipping or use. Additionally, a larger core reduces the inertia needed to pull the first few sheets and allows for smoother dispensing in high-traffic environments.

Do coreless rolls need a spindle?

Yes, coreless rolls still require a spindle, but they necessitate a specific coreless-compatible spindle or mandrel. Unlike standard spindles that hold a cardboard tube, coreless spindles feature a smaller diameter or a specialized “fin” design that grips the tightly wound center of the paper roll.