Prioritizing 2-Ply JRT Strength serves as a primary defense against rising maintenance labor costs and the negative guest feedback associated with low-quality facility supplies. Weak paper leads to mid-roll tearing and dispenser jams, forcing janitorial staff to spend more time on basic refills and floor cleanup rather than high-value cleaning tasks. Poor tensile performance creates a ripple effect that damages a facility’s reputation and increases annual product waste.

We analyze the specific technical factors that contribute to roll durability, including the role of multi-ply bonding and the use of 100% virgin wood pulp. This breakdown provides a clear standard for balancing industrial tensile strength with the softness expected in professional environments. By understanding these manufacturing specifications, facility managers can optimize sheet usage and lower the total cost of ownership for high-traffic restrooms.

What Makes 2-Ply JRT Superior for Guest Experiences?

2-ply jumbo roll tissue (JRT) bridges the gap between commercial high-capacity needs and the tactile expectations of modern hospitality, delivering a premium feel while significantly reducing maintenance overhead.

Guest satisfaction in high-traffic environments often hinges on the small details of facility amenities. While single-ply options focus strictly on volume, 2-ply JRT integrates comfort and durability. This configuration provides a noticeable upgrade in texture and performance, reflecting positively on hotel and commercial facility standards.

Enhanced Softness for Improved Comfort

The perceived quality of toilet tissue directly impacts customer perception and employee morale. By layering two sheets, manufacturers create internal air pockets that increase the plushness and compressibility of the roll. This structural design results in a gentle feel against the skin that single-ply products cannot replicate.

- Laminating multiple layers traps air between fibers, significantly increasing softness and the cushion-like feel of the tissue.

- Top Source Hygiene utilizes 100% virgin wood pulp to ensure a premium, long-fiber texture that eliminates the scratchiness associated with low-grade recycled paper.

- Refined surface textures reduce mechanical irritation, making these rolls suitable for sensitive skin in professional hospitality environments.

Superior Absorbency and Functional Strength

Functional reliability is paramount in commercial restrooms where tearing or insufficient absorption causes guest frustration. 2-ply JRT offers a higher tensile strength than single-layer alternatives, ensuring the paper holds up during use. This structural integrity prevents the tissue from falling apart when wet, which is a common complaint with cheaper industrial products.

- High-pressure ply-bonding technology keeps the layers fused, providing a stronger sheet that reduces the need for guests to double up on paper.

- Increased liquid retention capacity allows the tissue to manage moisture efficiently, ensuring high performance per sheet.

- Consistent strength across the roll prevents premature shredding or “shingling” during dispensing, maintaining a clean and professional restroom environment.

Reduced Maintenance for High-Traffic Facilities

Facility managers must balance quality with operational costs. High-capacity jumbo rolls are specifically designed to reduce the labor expenses associated with frequent roll changes. By providing a superior 2-ply product in a jumbo format, facilities can offer a luxury experience without the high maintenance costs of standard household rolls.

- Large roll diameters replace 10 to 12 standard rolls, drastically lowering the frequency of run-outs in busy locations like airports and malls.

- Top Source Hygiene leverages its Hebei manufacturing hub to provide high-volume JRT solutions that meet strict global supply chain requirements.

- Efficient sheet usage leads to fewer dispenser refills, saving significant staff time and lowering total operational expenses over the fiscal year.

How Does Multi-Ply Bonding Prevent Tearing During Dispensing?

Multi-ply bonding transforms independent tissue layers into a unified structural composite, neutralizing the shearing forces and tension imbalances common in high-capacity commercial dispensers.

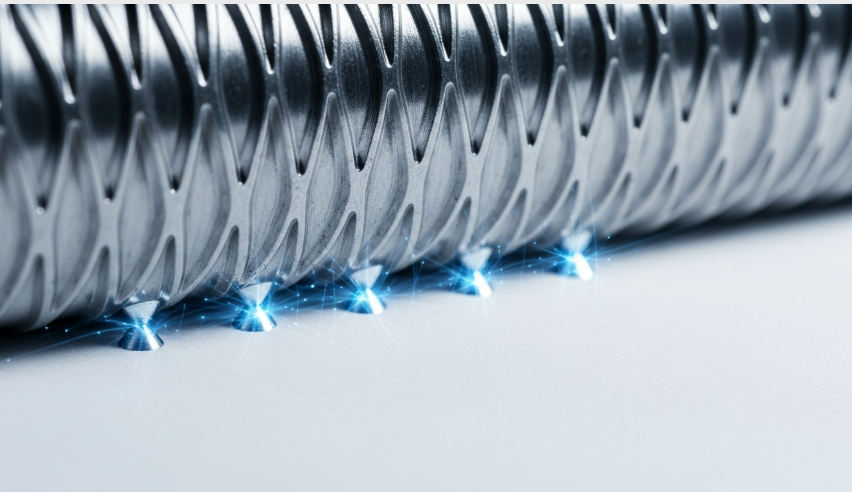

Mechanical Interlocking through Precision Embossing

Top Source Hygiene utilizes CNC-engraved steel rollers to execute mechanical interlocking between paper plies. This process creates nested physical bonds at specific pressure points, forcing the fibers of separate layers to weave into one another. Unlike basic pressing methods, precision embossing ensures the plies function as a single unit during the dispensing cycle. This prevents layers from sliding or delaminating when users pull the tissue from high-tension industrial dispensers.

These precision patterns maintain the structural integrity of the sheet while preserving the quilted texture required for hospitality environments. By locking the plies together, the roll maintains a consistent caliper (thickness), which prevents the “starring” or internal collapsing that often leads to mid-roll tearing.

| Performance Metric | Standard Recycled 2-Ply | TSH 100% Virgin 2-Ply |

|---|---|---|

| Bonding Method | Friction / Light Pressure | CNC Mechanical Interlock |

| Ply Delamination | High Risk under Tension | Zero Layer Separation |

| Tear Cleanliness | Frequent Shredding | Precision Perforation |

Ply Adhesion and Surface Tension Management

Our automated production lines apply eco-friendly, micro-dot adhesives that secure the plies without reducing the absorption capacity of the virgin wood pulp. Controlled adhesive application manages surface tension across the entire width of the Jumbo Roll Tissue (JRT). This uniformity prevents the “ply separation” effect that causes dispenser jams in high-traffic restrooms.

When the paper reaches the perforation line, the consistent bonding ensures it tears cleanly. Without this adhesive management, one ply often breaks before the other, resulting in “shredded edges” that frustrate users and increase waste. Our bonding technique ensures that the pull force is distributed equally, maintaining a professional appearance in the stall.

Tensile Strength Distribution in Multi-Layer Formats

Bonding multiple layers together allows the product to distribute pulling force across a higher fiber density. By integrating 100% virgin wood pulp fibers, we achieve superior fiber-to-fiber bonding compared to recycled alternatives. This increased structural stability enables 2-ply and 3-ply JRT rolls to withstand the high-torque environments of modern 2026 industrial dispenser models.

- Multi-ply bonding increases the total GSM (Grams per Square Meter) strength at critical stress points during dispensing.

- Virgin long-fiber structures provide the necessary elongation to prevent air shear bursts during high-speed unwinding.

- Structural integrity is maintained even when the roll is near the core, where winding tension is most volatile.

Premium Jumbo Rolls at Factory-Direct Prices

Why Is 100% Virgin Wood Pulp Crucial for 2-Ply Strength?

Virgin wood pulp provides the long-fiber architecture necessary to maintain high tensile strength in 2-ply jumbo rolls, effectively preventing the shredding and linting common in recycled fiber alternatives.

Long-Fiber Architecture and Tensile Resilience

Virgin wood pulp naturally contains long, intact fibers that create a robust internal network during the paper-making process. These fibers interlock more effectively than recycled pulp, which undergoes structural degradation and fiber shortening every time it is reprocessed. In 2-ply configurations, this fiber length is the primary determinant of “wet strength” and pull-resistance.

Commercial environments in 2026 demand tissue that survives the mechanical stress of high-capacity dispensers. When a user pulls a jumbo roll, the paper must resist snapping under tension. Top Source Hygiene utilizes this material integrity to ensure their 2-ply rolls perform reliably under heavy use, reducing the frustration of “stub-roll” tearing or mid-dispense shredding.

| Performance Metric | 100% Virgin Wood Pulp | Recycled/Mixed Pulp |

|---|---|---|

| Fiber Integrity | Long, flexible fibers | Short, brittle fibers |

| Tensile Strength | Superior (Low break rate) | Average to Poor |

| Chemical Safety | 100% OBA-Free | Often contains whiteners |

| User Experience | Lint-free & Ultra-soft | Prone to dusting |

Structural Consistency in High-Volume Manufacturing

Using 100% virgin pulp allows for a predictable and uniform production process. Recycled batches often vary in quality based on the source material, which can lead to thin spots or weak points in the finished roll. Stable raw materials are a prerequisite for maintaining the 2,860-ton monthly capacity required to meet international ISO 9001 standards.

- Uniform fiber distribution prevents premature tearing during the dispensing phase.

- Consistency in pulp quality reduces machine downtime and manufacturing defects.

- Global partners benefit from a reliable supply chain with batch-to-batch uniformity.

Enhancing Softness Without Sacrificing Durability

Virgin wood pulp enables manufacturers to achieve a premium texture while maintaining industrial-grade strength. Because the fibers are naturally flexible, the tissue provides a soft feel that improves guest satisfaction in the hospitality sector. This balance of comfort and strength helps facilities reduce sheet waste; a more effective “single-wipe” experience means users pull less paper from the dispenser.

The absence of brittle recycled fibers ensures the tissue stays intact when wet. We optimize the GSM (typically 13.5 to 17 for 2-ply JRT) to ensure the paper dissolves quickly in septic systems while remaining tough enough for commercial use. This engineering prevents the frequent plumbing clogs associated with low-quality, high-binder recycled tissues.

FSC-Certified Sourcing and Market Positioning

Adopting 100% virgin pulp from responsible sources aligns with global sustainability mandates. FSC-certified virgin pulp ensures raw materials come from responsibly managed forests. For retailers and hotel chains in North America and Europe, these certifications are necessary to meet strict environmental compliance and premium branding requirements.

Purity also translates to health safety. Virgin pulp is naturally bright, reaching 85-92% brightness without the need for fluorescent whiteners or Optical Brightening Agents (OBAs). This makes the product safe for sensitive skin and appeals to the health-conscious consumer base that drives the premium B2B hygiene market today.

Does 2-Ply JRT Actually Save Money by Reducing Sheet Usage?

Transitioning to 2-ply jumbo roll tissue shifts the focus from price-per-case to total cost of ownership by slashing maintenance labor and curbing excessive user consumption.

Lowering Maintenance Labor and Refill Frequency

High-traffic commercial environments in 2026 demand operational efficiency to stay profitable. Facility managers often find that labor represents a larger portion of the restroom budget than the paper itself. By moving to 2,000-foot jumbo rolls like the TSH-JRT08, maintenance teams drastically reduce the number of daily rounds required to check and restock dispensers.

- Switching to 2,000-foot rolls minimizes staff intervention time, allowing maintenance crews to focus on higher-priority sanitation tasks.

- Data from large-scale facilities indicates up to a 15% reduction in overall maintenance costs when restocking frequency drops.

- Longer roll lengths decrease the frequency of “runouts,” which directly correlates to higher guest satisfaction scores and fewer complaints.

Improving Absorption to Minimize Per-Use Waste

The double-layered construction of 2-ply JRT handles moisture more effectively than thin single-ply alternatives. When paper feels substantial, users naturally pull fewer sheets. Top Source Hygiene uses 100% virgin wood pulp to ensure that the ply-bond remains intact during use, preventing the paper from shredding or becoming unusable when wet.

- Higher tensile strength in 2-ply sheets prevents accidental tearing at the dispenser, which often leads to piles of wasted paper on the floor.

- Premium long-fiber wood pulp creates a thicker feel, reducing the psychological urge for users to “over-compensate” by pulling massive amounts of paper.

- Precision perforation ensures a clean break, giving users exactly what they need without trailing excess sheets from the roll.

Analyzing Total Cost of Ownership vs. Standard Rolls

The economic benefits of jumbo rolls extend into logistics and waste management. A single jumbo roll replaces roughly 10 to 12 standard rolls. This consolidation reduces the volume of cardboard cores and outer plastic packaging that facilities must process and discard.

- Consolidating inventory into 40’HQ containers lowers per-unit transportation costs for global hospitality and retail groups.

- We optimize the GSM (grams per square meter) between 13g and 22g to provide the exact weight needed for durability without paying for unnecessary bulk.

- Using high-density coreless or jumbo formats maximizes the payload in every shipment, ensuring the lowest possible landed cost per meter.

Direct Factory Sourcing for Enhanced Long-Term Savings

Eliminating intermediaries through direct OEM/ODM partnerships provides a distinct financial advantage for procurement. When you source directly from the Hebei paper industrial hub, you remove distributor markups that can inflate costs by 20-30%. This direct line also ensures a consistent supply chain, protecting you from price volatility in local spot markets.

- Factory-direct sales allow for precise customization of roll length and ply to match specific foot traffic patterns.

- Our manufacturing capacity of 2,860 tons per month guarantees a steady flow of product, preventing costly emergency purchases from local retailers.

- Direct sourcing allows for private label branding, which builds your brand equity while maintaining professional-grade quality standards.

How to Balance Softness with Industrial Tensile Requirements?

Advanced chemical integration and topical application methods allow manufacturers to decouple tensile strength from material stiffness, ensuring 2-ply JRT survives high-torque dispensers without sacrificing skin-contact comfort.

Integrating Dry Strength Resins

Traditional manufacturing relies on heavy mechanical refining to increase fiber bonding, but this process often results in a brittle, “sandpaper” texture. To counter this, professional-grade production now utilizes dry strength resins. These chemical additives enhance the paper’s resistance to pulling forces by creating additional hydrogen bonds between the wood fibers. Because these resins provide the necessary structural support, we can reduce mechanical refining intensity, which naturally preserves the material’s soft, airy texture.

- Dry strength resins maintain high tensile ratings without increasing the thickness or stiffness of the individual plies.

- Reducing refining prevents fibers from becoming short and brittle, ensuring a lint-free user experience.

Surface Spraying Techniques

The method of applying softening agents determines the final durability of the jumbo roll. Mixing softeners into the initial pulp slurry—the “wet-end” approach—interferes with fiber-to-fiber bonding, often leading to a 25% to 40% loss in total strength. High-performance 2-ply JRT avoids this by using surface spraying. By applying softeners directly onto the finished paper web at the final production stage, the core structural integrity of the virgin wood pulp remains untouched.

| Performance Metric | Wet-End Mixing (Recycled) | Topical Surface Spraying |

|---|---|---|

| Tensile Strength Retainment | 60% – 75% | 95% – 98% |

| Softness Hand-Feel | Inconsistent/Waxy | Premium/Velvet-like |

| Fiber Shedding (Lint) | High | Minimal/Lint-Free |

Optimizing Elongation and Ductility

Industrial dispensing environments subject toilet tissue to sudden, high-torque pulling forces. If a paper is strong but rigid, it will snap under the tension of a commercial dispenser. We focus on maximizing the “stretch” capability, or elongation, of the 2-ply tissue. Strategic engineering creates a balance where the paper can deform and stretch before reaching its breaking point. This ductility ensures the tissue withstands aggressive use while maintaining the comfort levels expected in professional and hospitality settings.

- Optimal ductility allows the tissue to absorb energy during the “snap” pull common in high-traffic restrooms.

- Combining 100% virgin long-fibers with precise creping ratios produces a sheet that is both flexible and remarkably durable.

Conclusion

Selecting 2-ply jumbo rolls made from 100% virgin wood pulp provides the tensile strength needed to prevent tearing and shredding in high-traffic dispensers. Advanced ply-bonding technology maintains layer integrity and softness, ensuring a professional experience for every user while protecting plumbing systems. These technical standards lower operational costs by reducing paper waste and maintenance frequency across your facility.

Review your current supply specifications to see how high-density jumbo rolls can optimize your restroom maintenance. Contact our team to request technical data sheets or a product catalog tailored to your bulk procurement requirements.

Frequently Asked Questions

Is 2 ply jumbo toilet paper better?

Yes, 2-ply jumbo roll tissue (JRT) is considered the industry standard for professional environments. It provides a superior balance of softness and strength compared to 1-ply options, directly improving guest satisfaction and perceived value. Additionally, the dual-layered construction offers better absorbency, which often leads to reduced consumption per use.

Why does my jumbo roll keep tearing?

Frequent tearing is typically caused by improper dispenser tension or low-quality perforations. If the roll is too large for the dispenser housing, excessive friction creates “shredding.” Environmental factors, such as high humidity in the restroom, can also weaken the paper fibers, making the roll prone to tearing before it fully unspools.

What is the softest jumbo toilet paper?

The softest jumbo toilet papers are premium 2-ply rolls manufactured using Through-Air-Dried (TAD) technology or high-quality virgin pulp. These products feature “point-to-point” embossing, which creates air pockets between the plies to enhance bulk and plushness.

Is 2-ply JRT septic safe?

Yes, most professional-grade 2-ply JRT is engineered to be septic safe. It is designed to rapidly break down and disperse when agitated in water, preventing clogs in high-traffic plumbing systems and septic tanks.

What is the GSM for commercial 2-ply?

Standard commercial 2-ply tissue typically ranges from 13 to 15 GSM (grams per square meter) per ply. This results in a combined total weight of 26 to 30 GSM for the finished product, providing the necessary tensile strength for dispensers.