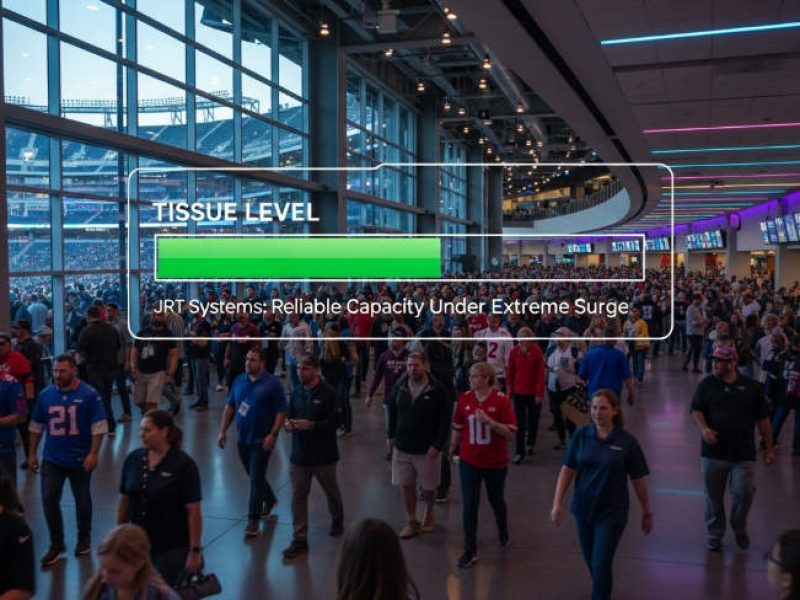

Facility managers often judge a High-Traffic Venue (Solution) by its restroom reliability, as stockouts or plumbing failures directly trigger operational delays and poor public sentiment. When thousands of visitors pass through an airport or stadium hourly, standard commercial supplies fail, creating a direct risk to facility hygiene scores and overall brand reputation. Efficient paper management remains the first line of defense against the high costs of emergency plumbing repairs and excessive labor hours.

This guide serves as a technical standard for selecting high-capacity tissue systems that withstand the unique pressures of mass-scale environments. We analyze how high-capacity jumbo rolls minimize maintenance intervals, the mechanics of anti-theft dispenser integration, and the specific paper dispersion rates necessary to protect stadium plumbing from blockages. By evaluating roll specifications against universal commercial dispenser standards, operations teams can optimize their supply chain to handle extreme peak demand without compromising on durability or cost-efficiency.

Why is High-Traffic Restroom Management Different from Offices?

High-traffic facilities require a shift from comfort-centric office maintenance to high-capacity, vandal-resistant infrastructure capable of handling extreme usage spikes and strict hygiene compliance.

Managing Concentrated Usage Spikes and Rapid Surges

Stadiums, airports, and transport hubs operate on a “pulse” demand model. Unlike the steady, predictable occupancy of a corporate office, these venues face extreme surges where hundreds of users enter facilities simultaneously during event intervals or flight arrivals. This rapid turnover leaves zero room for stockouts. Maintenance teams must deploy high-capacity jumbo rolls (JRT) to ensure that the supply outlasts these peak windows without requiring mid-surge refills.

Operational efficiency in 2026 relies on clustered restroom designs. By grouping facilities, staff can service multiple units quickly between surges rather than traveling across sprawling campuses. This approach focuses on bulk replenishment, where a single jumbo roll replaces several standard rolls, effectively reducing labor-intensive maintenance cycles by up to 30%.

Durability and Resistance to Vandalism or Abuse

Public restrooms face significantly higher rates of intentional damage and accidental misuse compared to private corporate environments. Equipment in these spaces requires heavy-duty materials, such as 12-16 gauge stainless steel, to withstand physical impact and tampering. While office restrooms prioritize employee wellness and aesthetic softness, public-facing stalls must prioritize security and “hardening” to prevent the unauthorized removal of paper supplies.

- Tamper-Proof Design: High-traffic dispensers feature locking mechanisms and secure mounting to prevent units from being torn off walls.

- Distributed Facilities: Smart design choices reduce large congregations, which naturally lowers the wear and tear on individual fixtures.

- Resource Security: Anti-theft strategies, including single-sheet dispensing, discourage users from pulling out excessive lengths of paper or removing entire rolls.

Strict Regulatory Compliance and Hygiene Standards

High-traffic facilities operate under rigorous public health oversight that differs fundamentally from internal office wellness policies. Venues in North America and Europe must meet specific regional hygiene standards, such as ISO 9001 and FDA compliance. Products like the Top Source Hygiene TSH-JRT08 are engineered specifically for these environments, ensuring that 100% virgin wood pulp paper remains OBA-free and safe for sensitive skin across a diverse user base.

In educational environments, managers must balance student privacy with safety. This requires paper solutions that dissolve quickly to prevent intentional or accidental plumbing clogs, which are more frequent in schools than in monitored office settings. Choosing septic-safe, rapid-dispersing paper ensures that high-volume waste management systems remain operational even during peak student activity.

How Do High-Capacity Jumbo Rolls Reduce Maintenance Rounds?

High-capacity jumbo roll systems shift facility management from reactive restocking to planned maintenance cycles by extending the product lifecycle per dispenser by up to 30%.

Extended Sheet Capacity and Refill Frequency

High-traffic environments like airports and shopping malls face concentrated usage spikes that quickly deplete standard toilet rolls. Jumbo Roll Tissue (JRT) fundamentally changes this dynamic by providing significantly more linear footage in a single unit. Top Source Hygiene engineers these rolls to maximize the paper density within the dispenser’s physical footprint, which prevents the common “run-out” scenarios that lead to user complaints and hygiene lapses.

| Roll Specification | Standard Commercial Roll | TSH-JRT08 Jumbo Series |

|---|---|---|

| Total Length | 150 – 400 Feet | 750 – 1,400 Feet |

| Refill Frequency | Daily / Multiple Daily | Reduced by 30% |

| Maintenance Goal | Reactive Response | Strategic Optimization |

Labor Cost Optimization and Operational Efficiency

Facilities using high-capacity solutions in 2026 reported a 15% reduction in overall maintenance costs. This saving stems directly from labor reallocation; when janitorial teams perform fewer restocking rounds, they spend more time on deep cleaning and high-level sanitation. We also see a streamlined supply chain where larger rolls result in fewer internal stock handling movements and reduced delivery frequency to the facility.

Waste Reduction and Sustainability Goals

Jumbo rolls support corporate ESG targets by minimizing packaging waste per sheet of paper used. Top Source Hygiene offers FSC-certified 100% Virgin Wood Pulp options that pair high capacity with responsible sourcing. These systems specifically target “stub roll” waste—the practice where staff discard partially used standard rolls to avoid a run-out before the next shift—by utilizing high-capacity dispensers often equipped with a secondary roll holder to ensure every foot of paper is used.

- Reduced core waste through high-density winding techniques.

- Minimized secondary packaging per metric ton of delivered product.

- Septic-safe engineering ensures rapid disintegration, preventing costly plumbing repairs.

Scale Your Brand With Premium OEM Toilet Paper

What Are the Best Anti-Theft Strategies for Public Restrooms?

Effective anti-theft protocols in high-traffic venues shift the focus from reactive policing to physical hardening and data-driven consumption monitoring.

High-Capacity Jumbo Roll Systems

Standard retail rolls are prime targets for theft because they fit easily into bags and pockets. Transitioning to jumbo roll tissue (JRT) like the TSH-JRT08 series eliminates this incentive through sheer size. These oversized formats require specialized industrial dispensers and are physically difficult to transport discreetly. By utilizing rolls that offer significantly more linear footage, facility managers reduce the number of refill cycles, which limits the time dispensers remain open and vulnerable to tampering during maintenance rounds.

| Security Metric | Standard Retail Rolls | TSH Jumbo Systems |

|---|---|---|

| Theft Vulnerability | High (Easily concealed) | Low (Industrial dimensions) |

| Access Method | Open Spindles | Locking Stainless Steel |

| Maintenance Exposure | Every 2-4 Hours | 24-72 Hours |

Vandal-Resistant Dispenser Integration

Physical hardening of restroom fixtures creates a deterrent against forced entry. High-traffic venues use stainless steel or high-impact ABS plastic cabinets that resist prying. These dispensers feature proprietary locking mechanisms that require specific keys held only by authorized staff. Integrated designs further hide roll edges, making it difficult for users to pull or tear large sections unnecessarily, which prevents the “spooling” theft often seen in unmonitored public stalls.

IoT and Smart Monitoring Solutions

Smart technology allows for proactive prevention rather than reactive damage repair. IoT-enabled dispensers track consumption patterns in real-time and trigger alerts if a roll depletes too rapidly, indicating potential bulk theft. These systems also monitor “open/close” events to ensure cabinets are never left unlocked by accident. Data analytics help identify high-risk times of day when vandalism is most likely, allowing for targeted staff presence.

Operational Oversight and Design

Strategic facility management choices reduce the opportunity for theft while maintaining user privacy. Improving sightlines to restroom entrances increases the perceived risk of getting caught, which serves as a psychological deterrent. Regular maintenance rounds, facilitated by Top Source Hygiene’s 15% reduction in labor requirements through high-capacity products, ensure that security fixtures remain intact and functional across the facility.

How to Balance Softness and Durability in Mass-Scale Venues?

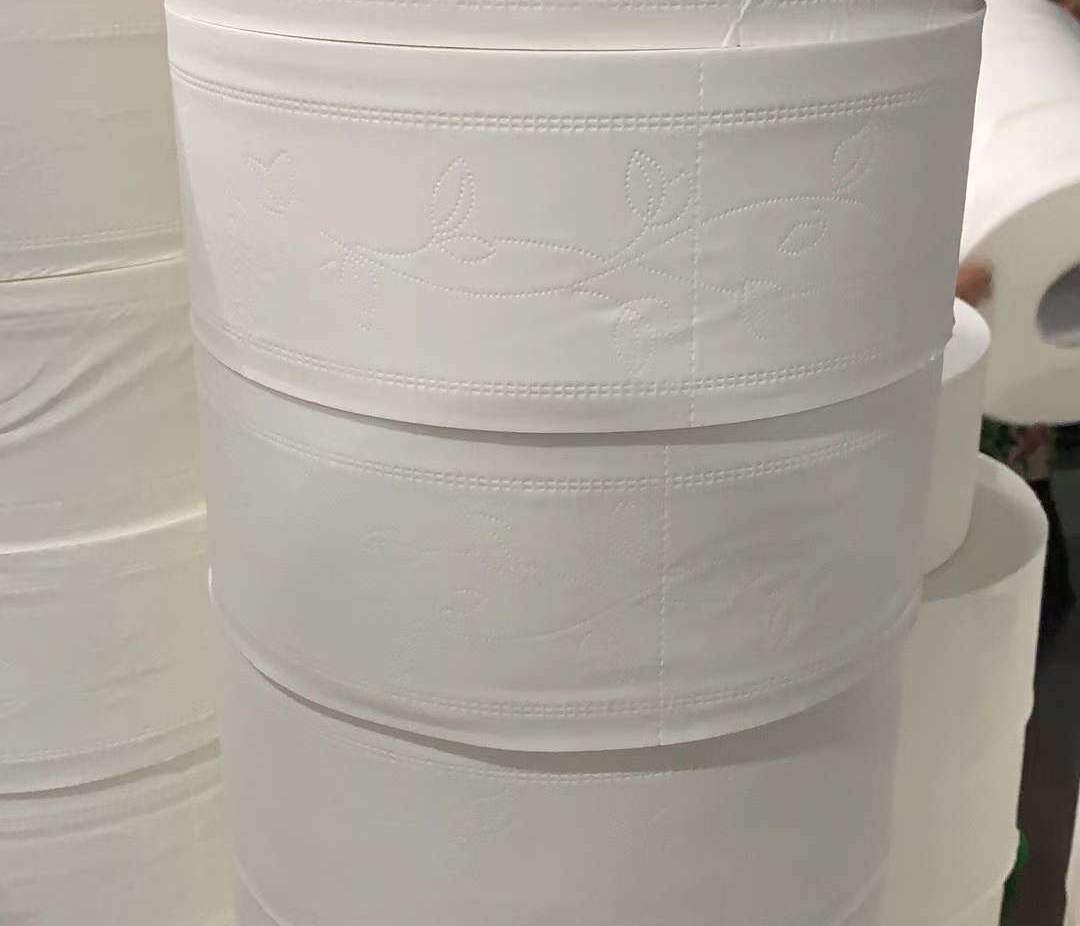

Achieving premium user comfort in high-traffic environments requires a specific engineering balance between long-fiber virgin pulp selection and advanced ply-bonding technology to prevent structural failure under heavy use.

Material Engineering for High-Traffic Comfort

Top Source Hygiene utilizes 100% virgin wood pulp as the primary substrate for venue-grade tissue. Unlike recycled fibers which often feel abrasive and possess shorter fiber lengths, premium long-fiber wood pulp provides a natural, cloud-like softness. This material choice allows us to deliver a gentle skin-feel without relying on chemical softeners that can compromise the paper’s integrity or cause irritation.

By implementing multi-ply configurations, such as 3-ply or 4-ply, we increase the overall thickness and absorbency of the product. This creates a luxury hand-feel even in utilitarian settings like airports or stadiums. We guarantee that all fibers are 100% OBA-free, ensuring that no optical brightening agents or fluorescent whiteners touch the end-user’s skin, meeting the strictest hygiene standards in North America and Europe.

Structural Integrity and Embossing Techniques

Our manufacturing process employs CNC-precision point-to-point embossing to bind layers together. This technique traps air between the plies, which serves a dual purpose: it enhances the plush texture while significantly increasing the tensile strength. In high-traffic venues, paper must resist tearing prematurely during the dispensing process to minimize floor litter and waste.

We calibrate the GSM (Grams per Square Meter) specifically for commercial dispensers, maintaining a range between 13g/m² and 22g/m² per ply. This optimization ensures a substantial hand-feel that signals quality to the user while remaining compatible with high-speed automated dispensers. High tensile strength testing ensures our rolls withstand the rapid “pull” force common in busy public restrooms.

Sustainability Without Performance Trade-offs

By 2026, facility managers no longer have to choose between environmental goals and user experience. We offer FSC-certified paper options that utilize responsibly sourced virgin fibers. This approach maintains the high-performance benchmarks required for durability while satisfying the eco-conscious procurement mandates of modern mass-scale venues.

Every batch undergoes rigorous ISO 9001 quality control to ensure consistency in brightness and texture. For larger hospitality groups and venue operators, we provide customizable solutions that allow for branded, sustainable packaging. This enables venues to communicate their green initiatives directly through the hygiene products they provide, reinforcing their commitment to quality and sustainability.

Why is Quick-Dispersing Paper Crucial for Stadium Plumbing?

Stadium plumbing survival depends on paper that disintegrates within seconds to prevent catastrophic mainline blockages during high-volume peak intervals.

Preventing System Failures During Peak Usage Intervals

Stadium drainage networks face extreme hydraulic stress during halftime or event conclusions when thousands of fixtures cycle simultaneously. Standard toilet paper often clumps under these high-volume surges, forming dense obstructions in the horizontal outflow lines. Quick-dispersing rolls solve this by shedding their fiber structure immediately upon water contact, ensuring waste moves freely even under heavy loads.

| Performance Metric | Standard Commercial Paper | Top Source Stadium-Grade |

|---|---|---|

| Disintegration Time | 60–90 Seconds | <15 Seconds |

| Fiber Composition | Mixed/Recycled Pulp | 100% Virgin Wood Pulp |

| Peak Flush Risk | High (Mainline Damming) | Low (Slurry Conversion) |

- Rapid fiber separation prevents “damming” in main sewer trunks during 15-minute peak windows.

- Top Source Hygiene engineers stadium rolls to liquefy significantly faster than retail alternatives.

- Advanced ply-bonding maintains strength during use but fails instantly once submerged.

Protecting Sensitive Pumping Stations and Sensors

Modern sports venues built for 2026 and beyond utilize sophisticated sensors and pumping stations to manage greywater and sewage. Non-dispersing fibers can wrap around pump impellers, leading to mechanical overheating and expensive system failures. Sensors that monitor flow rates and tank levels often return false readings when caught in clumps of undissolved paper. Using 100% virgin wood pulp products ensures that the material degrades into a fine slurry that current filtration systems process without manual intervention or mechanical strain.

Reducing Venue Operational Costs and Emergency Repairs

Plumbing emergencies during live events cause high costs, negative guest reviews, and potential health code violations. Facility managers report a 15% reduction in maintenance calls when switching to high-dispersing paper products tailored for high-traffic environments. Preventing clogs eliminates the need for emergency plumbing contractors who charge premium rates during nights and weekends. Reliable paper disintegration protects the long-term integrity of the stadium internal drainage infrastructure, extending the lifespan of the entire plumbing network.

How Does Our 2860-Ton Capacity Support Emergency Peak Demand?

Scale-driven production at Top Source Hygiene eliminates the supply chain bottlenecks that typically paralyze large-scale distributors during seasonal spikes or sudden market shifts.

Monthly Output Stability at 2860 Tons

Operating at a monthly capacity of 2,860 tons ensures that large-scale orders for the hospitality and retail sectors move through the pipeline without delay. By utilizing 100% virgin wood pulp as our primary feedstock, we maintain machine efficiency at peak levels, preventing the technical slowdowns often associated with lower-grade materials. This volume allows us to absorb sudden market spikes in 2026, ensuring that high-volume distributors receive their goods regardless of global supply fluctuations.

Dual Factory Operations and Infrastructure

Our two manufacturing sites in the Mancheng production base provide essential redundancy for B2B partners. We can reroute or split massive orders between facilities to bypass potential bottlenecks, ensuring consistent flow for toilet paper and facial tissue lines. This strategic location provides immediate access to raw materials and skilled labor, which are vital for rapid scaling while maintaining ISO 9001 and FDA compliance standards.

Expedited Timelines for Urgent Bulk Orders

Standard 40-foot container orders typically ship within 15 to 25 days, yet we offer flexible manufacturing schedules to address critical inventory shortages. Our logistics team manages established shipping routes to North America, Europe, and Asia to secure fast transit during peak 2026 demand. We expedite free samples to allow clients to verify specifications quickly before we initiate high-speed mass production for their private label brands.

Would you like me to draft a logistics plan for a 40HQ container shipment to your specific region?

What Roll Specifications Best Fit Universal Commercial Dispensers?

Technical compatibility requires aligning core diameter, roll width, and total footage with dispenser tolerances to prevent operational failures and maintenance delays.

We manufacture jumbo rolls to meet diverse international hardware standards across 56 countries. Our 2026 production lines deliver 2,860 tons of monthly capacity, ensuring a stable supply for bulk commercial contracts. Clients maintain full control over GSM and dimensions, allowing the paper to match specific hardware perfectly without compromising performance.

Standard Core Dimensions for Seamless Compatibility

Universal dispensers typically require specific core sizes to ensure the roll spins freely during use. Most commercial systems utilize a standardized core diameter between 1.5 and 2 inches. Selecting these precise sizes prevents loading errors and removes the risk of the roll jamming inside the housing, which preserves the life of the hardware and reduces staff intervention.

Optimized Roll Diameter and Total Footage

Balancing the outer diameter with the total length of the paper determines how often staff must refill the units. A roll diameter between 5 and 8 inches fits the majority of universal commercial cabinets currently in service. High-capacity rolls extending up to 1000 feet help facilities cut maintenance labor and lower overall operational costs by extending the time between technician rounds.

Ply Selection and Material Strength

The physical properties of the paper affect both user experience and the functional limits of the dispenser. Facilities often select 2-ply or 3-ply options to balance softness with the durability needed for high-traffic environments. Adjusting the paper weight through custom GSM settings ensures the paper handles moisture effectively without tearing prematurely or causing clogs in the dispensing throat.

Conclusion

Managing high-traffic restrooms requires a strategic balance between high-capacity jumbo rolls and rapid-disintegration technology to prevent maintenance bottlenecks and plumbing failures. Selecting 100% virgin wood pulp solutions ensures that airports and stadiums maintain hygiene standards while reducing the frequency of refill rounds. These specifications work together to protect infrastructure and lower the total cost of facility operations.

Review your current restroom traffic patterns to see if upgrading to high-density jumbo rolls could streamline your maintenance schedule. You can also reach out to our team for a technical consultation or to request samples from our commercial inventory.

Frequently Asked Questions

Best paper for public restrooms?

For high-traffic public restrooms, Jumbo Roll Tissue (JRT) is the industry standard. It balances durability and capacity, reducing the frequency of run-outs during peak usage spikes. Using a 2-ply 9-inch jumbo roll provides a professional feel while maintaining the high-volume efficiency required for environments like airports and schools.

How to stop toilet paper theft?

The most effective way to prevent theft and vandalism is the installation of locking, high-capacity dispensers. Utilizing proprietary core systems or large jumbo rolls also discourages theft, as these rolls do not fit standard residential dispensers. For high-risk areas, heavy-duty stainless steel housing provides an extra layer of physical security.

What is high-capacity tissue?

High-capacity tissue refers to rolls designed with significantly more linear footage than standard commercial rolls, often achieved through tighter winding or coreless technology. A single high-capacity jumbo roll can be equivalent to nearly 10-15 standard rolls, specifically engineered to handle rapid surges in demand in facilities with concentrated usage.

How to reduce maintenance costs?

Maintenance costs are reduced by implementing “twin-roll” or high-capacity dispensing systems that minimize the frequency of refill trips. Strategically clustering restroom locations allows janitorial staff more efficient access. Furthermore, using durable, vandal-resistant materials reduces the long-term cost of replacing damaged hardware in high-abuse environments.

Does JRT fit all dispensers?

No, Jumbo Roll Tissue (JRT) requires specific dispensers designed for larger roll diameters (typically 9 or 12 inches). Additionally, some manufacturers use “proprietary cores” (unique spindle shapes) to ensure only their specific brand of paper can be used. It is critical to match the roll diameter and core size with the dispenser model.

How much paper does a mall need?

Consumption is calculated based on foot traffic and “dwell time.” On average, a high-traffic retail environment should estimate approximately 2.5 to 3.5 sheets per visitor. For a mall, this necessitates high-capacity systems distributed across multiple facilities to prevent congregation and ensure availability during peak shopping hours and events.