Navigating the technical specifications of JRT Senior vs. Junior (Sizes) prevents the procurement errors that lead to dispenser incompatibility and unnecessary facility downtime. Facility managers who overlook these dimensional differences often face increased labor costs and maintenance bottlenecks when rolls fail to fit existing hardware.

This guide details the critical variations in roll diameter, linear footage, and dispenser compatibility to help you standardize your restroom supplies. We analyze the exact dimensions for each size and provide a practical framework for selecting the roll that matches your specific traffic patterns and storage capacity.

What Defines the Difference Between JRT Senior and Junior?

The primary distinction between JRT Senior and Junior classifications lies in the outside roll diameter, which dictates both the total paper capacity and the physical footprint required for the dispenser unit.

Roll Diameter and Physical Dimensions

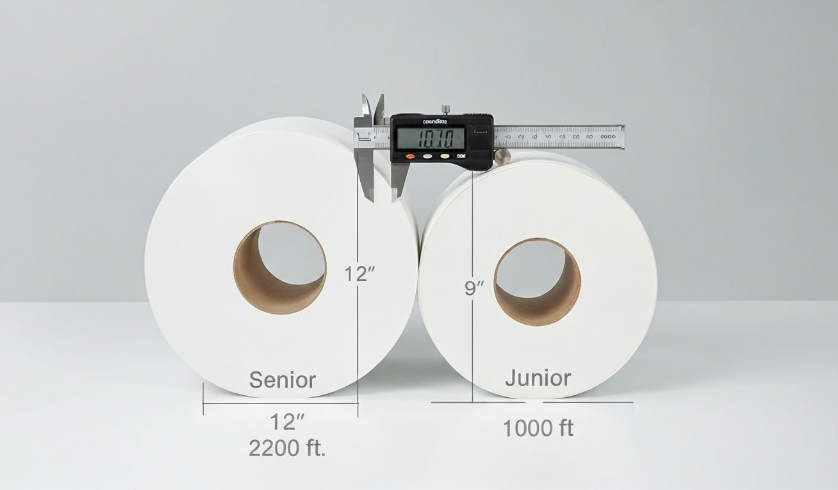

Roll diameter serves as the defining metric for equipment compatibility. Senior JRT rolls typically maintain a 12-inch outer diameter, whereas Junior variants are standardized around 9 inches. This 3-inch variance allows facility managers to optimize space in smaller stalls while maintaining a consistent sheet width between 3.3 and 3.8 inches. Maintaining these specific tolerances ensures that rolls spin freely within the dispenser cabinet without friction against the lid or backing plate.

| Technical Specification | JRT Senior (Large) | JRT Junior (Standard) |

|---|---|---|

| Roll Diameter | 12 – 13 Inches | 9 – 9.4 Inches |

| Linear Footage (2-Ply) | 1,000 – 1,400 Feet | 500 – 1,000 Feet |

| Primary Use Case | Airports / Stadiums | Offices / Retail |

Linear Footage and Paper Volume

Volume capacity directly affects maintenance cycles and labor costs. A Senior roll often holds up to 2,000 feet of 1-ply tissue, which is double the capacity of many Junior rolls. High-traffic environments, such as transit hubs or large-scale manufacturing plants, prioritize Senior rolls to minimize the frequency of refill checks. For mid-range traffic, Junior rolls offer a compact solution that still outperforms standard household rolls by a significant margin.

- Senior Rolls: Optimized for maximum uptime in 24/7 high-volume facilities.

- Junior Rolls: Balanced for professional office environments with regular cleaning rotations.

- TSH-JRT08 Series: We utilize 100% Virgin Wood Pulp to ensure high tensile strength across these high-capacity formats.

Dispenser Cabinet Compatibility

Hardware requirements are rigid. A Junior-sized dispenser cannot physically house a Senior roll because it lacks the 12-inch clearance necessary for the roll to rotate. While some modern “combo” dispensers use adjustable mandrels to fit both sizes, most installations are fixed. We recommend that facility managers verify their current dispenser’s maximum outside diameter (OD) before finalizing bulk procurement to prevent inventory mismatch. Using a Junior roll in a Senior dispenser is possible but often leads to paper wastage if the unit lacks proper tension control.

Why Is Roll Diameter the Most Important Factor in Naming?

Diameter serves as the ultimate physical constraint in facility management, dictating whether high-capacity paper can actually function within the existing hardware footprint.

Compatibility with Fixed Dispenser Constraints

Commercial dispensers are rigid structures. Unlike flexible packaging, the internal housing and closure mechanisms of a Jumbo Roll Tissue (JRT) dispenser provide zero tolerance for oversized rolls. If the outside diameter (OD) exceeds the cabinet’s internal depth, the lid will not lock and the paper cannot rotate. This physical limit makes diameter the primary filter in procurement; a roll with the wrong diameter is functionally useless regardless of its paper quality or price point.

- Dispensers feature fixed internal dimensions that restrict the maximum allowable roll size.

- Top Source Hygiene engineers JRT rolls specifically to match these hardware constraints, ensuring the roll rotates freely without jamming.

- Exceeding the maximum diameter prevents the dispenser from functioning, making it the first compatibility check in modern facility planning.

Interplay Between Paper Thickness and Total Volume

Diameter acts as a consolidated metric that reflects the combined impact of paper grade, ply count, and total sheet volume. Variations in GSM (grams per square meter) and ply counts—ranging from 2-ply to high-density 5-ply options—directly alter the outer diameter even when linear footage remains the same. A 1,000-foot roll of premium 3-ply wood pulp will naturally have a larger diameter than a 1,000-foot roll of standard 1-ply recycled tissue.

- Ply counts and density alter the outer diameter even when linear footage is constant.

- Outer diameter fluctuates based on the density and softness of the virgin wood pulp used, unlike standardized core sizes.

- Naming conventions prioritize diameter because it accurately represents the physical space the product occupies in storage and on the rack.

Diameter as a Primary Selection Metric

Facility managers use diameter as the definitive checkpoint to avoid procurement errors and operational downtime. Ordering based on diameter allows teams to verify fit before evaluating secondary specifications like footage or weight. This is particularly critical in global supply chains where regional dispenser standards may vary by fractions of an inch.

- Specifying by diameter allows procurement teams to verify fit before assessing secondary specs.

- Top Source Hygiene provides precise diameter specs to help global clients across 56 countries align inventory with regional standards.

- Consistent diameter measurements streamline the transition between different product lines, such as moving from standard tissue to high-capacity jumbo rolls.

Premium Custom Toilet Paper at Factory Prices

How to Choose Between Senior and Junior Rolls for Your Facility?

Matching JRT roll diameter to specific facility traffic volume and dispenser clearance is the most effective way to optimize janitorial labor costs and procurement efficiency.

Analyze Foot Traffic and Usage Patterns

High-traffic environments like airports, shopping malls, and large stadiums require Senior rolls to prevent frequent run-outs during peak hours. These 12-inch diameter rolls provide the necessary volume to handle hundreds of users per stall without daily monitoring. In contrast, Junior rolls serve low-to-medium traffic areas such as small offices, boutique hotel rooms, or private clinics where space is at a premium and usage is predictable. Data from Top Source Hygiene suggests that matching roll size to traffic volume helps maintain a consistent supply without overstocking individual stalls.

| Specification | JRT Senior (Large) | JRT Junior (Small) |

|---|---|---|

| Standard Diameter | 12 – 13 Inches | 9 – 9.4 Inches |

| Linear Footage | 2,000 – 4,000+ Feet | 500 – 2,000 Feet |

| Ideal Application | Stadiums, Hubs, Public Parks | Offices, Retail, Clinics |

Evaluate Restroom Wall Space and Dispenser Size

Physical constraints within a facility often dictate which JRT size is viable. Maintenance teams must measure the clearance in smaller restroom stalls where a large Senior dispenser might obstruct movement or interfere with ADA accessibility requirements. Junior rolls offer a compact solution that maintains a streamlined aesthetic while still providing significantly more paper than standard household rolls. We recommend consulting with Top Source Hygiene regarding custom dimensions for OEM orders to ensure rolls fit specific legacy dispensing hardware already installed in the facility.

Calculate Maintenance Labor and Refill Intervals

Choosing the right roll size impacts the operational budget by reducing the time janitorial staff spends on refills. Implementing Senior rolls can achieve up to a 15% reduction in maintenance costs because larger rolls require fewer technician interventions. In 2026, where labor costs continue to rise, Senior rolls allow staff to focus on deep cleaning and sanitation rather than constant paper monitoring. Reviewing facility logs helps identify if Junior rolls are being replaced too frequently, which indicates a need to upgrade to a higher-capacity Senior system.

Review Long-term Procurement and Storage Goals

Facility managers must balance the benefits of high-capacity rolls with available storage and shipping logistics. Senior rolls take up more warehouse volume per unit, which affects the storage footprint of 40’HQ container orders. We leverage 30 years of manufacturing experience to determine the most cost-effective shipping configuration for bulk Senior roll orders, optimizing the 7,000kg to 9,000kg payload typical of our Hebei production facility. Always factor in the 20-25 day production lead time for custom-branded rolls when planning transitions between Junior and Senior systems to ensure uninterrupted supply.

- Verify dispenser diameter limits before switching sizes to avoid equipment jams.

- Use Senior rolls for high-traffic zones to cut labor costs by 15%.

- Opt for Junior rolls in boutique or low-traffic settings to save wall space.

Are Junior Rolls Compatible with Standard Senior Dispensers?

While physical space allows Junior rolls to fit within Senior dispenser cabinets, the resulting spindle gap and diameter mismatch frequently trigger mechanical jams and excessive paper waste.

Physical Diameter Constraints in Standard Units

Standard JRT Senior dispensers are built specifically for 12–13 inch rolls, creating a large internal cavity. While a 9-inch Junior roll physically fits inside this space, the spindle hardware often differs in width or tension requirements. Without the proper fit, the smaller roll lacks the stability needed for smooth rotation, which often causes the paper to drag against the dispenser housing.

- Senior dispensers possess a larger internal cavity that physically accommodates smaller Junior rolls, but the spindle size often differs.

- Junior rolls placed in Senior dispensers may spin unevenly, leading to paper waste or difficulty in dispensing.

- Top Source Hygiene provides precise roll diameters to ensure its OEM products match specific dispenser requirements across 56 countries.

Performance Issues and Maintenance Impact

Operational costs climb when facilities use mismatched sizes. Maintenance crews spend significantly more time clearing jams or replacing exhausted Junior rolls in high-traffic zones designed for Senior-level capacity. We have observed that mismatched fits frequently lead to rolls falling off the spindle entirely, rendering the dispenser useless until a janitorial intervention occurs.

- Junior rolls in high-traffic Senior dispensers require more frequent refills, increasing labor hours for janitorial staff.

- A mismatched fit can lead to rolls falling off the spindle or jamming the dispensing mechanism.

- Facilities in North America and Europe often see a 15% reduction in maintenance costs when rolls are correctly paired with dedicated dispensers.

Universal and Combo Dispenser Solutions

The commercial market has moved toward combo dispensers that eliminate compatibility risks. These units utilize adjustable spindles or specialized internal brackets to secure both 9-inch and 12-inch rolls. This flexibility allows procurement managers to hedge against supply chain fluctuations by switching between Senior and Junior rolls based on current market availability.

- Combo dispensers use adjustable spindles or specialized brackets to secure both 9-inch and 12-inch rolls.

- Standardizing on versatile equipment allows procurement managers to switch between Senior and Junior rolls based on market price and availability.

- By 2026, many global facilities are expected to adopt these flexible systems to simplify tissue procurement.

Custom Manufacturing for Equipment Alignment

Top Source Hygiene leverages 30 years of manufacturing expertise to bridge the gap between paper and hardware. We allow clients to specify exact GSM, ply, and diameter through our OEM and ODM services. By tailoring the roll to the existing dispenser infrastructure, we ensure that every sheet dispenses correctly without requiring a complete hardware overhaul.

- Clients can specify GSM, ply, and roll diameter through OEM and ODM services to guarantee compatibility with existing hardware.

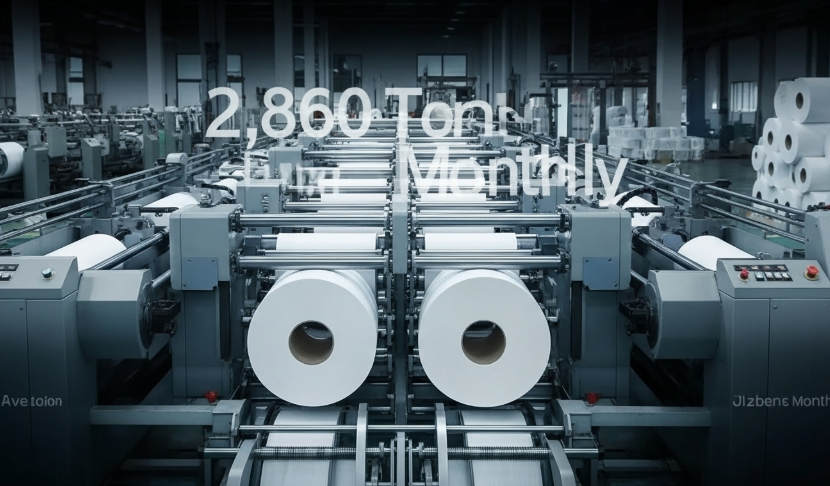

- The company produces 2,860 tons of paper monthly, allowing for high-volume custom orders that meet ISO 9001 and FDA standards.

- Direct factory production ensures that custom-sized rolls maintain consistent quality and absorbency for commercial use.

What Are the Linear Footage Standards for Both JRT Sizes?

Linear footage acts as the primary metric for calculating janitorial maintenance cycles, with 9-inch Junior rolls providing up to 1,000 feet and 12-inch Senior rolls doubling that capacity to minimize refill frequency in high-traffic zones.

Junior JRT Roll Lengths for 9-Inch Dispensers

Junior jumbo rolls (JRT Jr.) serve as the industry standard for medium-traffic commercial restrooms. These rolls balance high capacity with a compact dispenser footprint. While a standard 9-inch diameter junior roll typically offers between 700 and 1,000 linear feet for 2-ply tissue, single-ply variants can reach up to 2,000 feet. The actual length depends heavily on the paper’s GSM (thickness) and the winding tension applied during manufacturing.

| JRT Size Category | Roll Diameter | Avg. 2-Ply Linear Footage |

|---|---|---|

| Junior (JRT Jr.) | 9.0 Inches | 700 – 1,000 ft |

| Senior (JRT Sr.) | 12.0 Inches | 2,000 – 2,200 ft |

| Standard Retail Roll | 4.5 – 5.0 Inches | 75 – 125 ft |

Top Source Hygiene manufactures junior rolls to meet 2026 facility requirements, ensuring total compatibility with universal 9-inch dispenser cores. We prioritize 100% virgin wood pulp to maintain high tensile strength, preventing the paper from snapping even when users pull from a high-capacity, heavy roll.

Senior JRT Roll Lengths for 12-Inch High-Traffic Systems

Senior jumbo rolls maximize linear footage to reduce maintenance frequency in high-volume environments like airports, stadiums, and large transit hubs. A standard 12-inch diameter senior roll provides approximately 2,000 linear feet for 2-ply configurations. Higher capacity options for 1-ply senior rolls can exceed 4,000 feet, which drastically lowers the labor costs associated with manual refills by janitorial staff.

This increased diameter requires specific heavy-duty dispensers capable of supporting the weight of a full virgin pulp paper roll. We utilize high-pressure lamination and precision perforation to ensure these massive rolls dispense smoothly without “shredding” or causing clogs in high-use municipal plumbing systems.

How Ply Density Influences Total Linear Footage

The relationship between paper thickness (GSM) and roll diameter dictates the final footage available on each jumbo roll. Adding plies increases the thickness of the paper, which naturally reduces the total linear footage that can fit within a 9-inch or 12-inch diameter limit. We offer custom GSM settings from 2-ply to 5-ply, allowing clients to choose their priority:

- 2-Ply Efficiency: Optimized for length (up to 1,000ft in Jr. rolls) to reduce maintenance frequency.

- Luxury Multi-Ply: 3-ply to 5-ply options provide superior softness for hospitality settings but result in shorter total footage.

- 100% OBA-Free: All our JRT options guarantee no optical brightening agents, ensuring safety for sensitive skin across all footage tiers.

Facility managers often calculate the trade-off between the luxury of higher ply counts and the labor costs associated with more frequent roll changes. By utilizing Top Source Hygiene’s 100% virgin wood pulp, facilities can often use a lower GSM while maintaining the strength and perceived quality of a thicker, recycled-fiber alternative.

Conclusion

Selecting the right jumbo roll size depends on balancing daily foot traffic with specific dispenser dimensions. Understanding the roll diameter and linear footage standards prevents maintenance delays and ensures a seamless fit within commercial restrooms. Choosing the correct JRT specification reduces labor costs and guarantees a consistent supply for high-volume environments.

Review your current dispenser specifications to determine if a Senior or Junior roll best optimizes your facility maintenance schedule. Contact our team to request a technical datasheet or a custom quote for bulk 100% virgin wood pulp JRT orders tailored to your distribution needs.

Frequently Asked Questions

What size roll is jumbo jr toilet paper?

A Jumbo Junior (JRT Jr.) roll typically features a 9-inch diameter. It is designed with a standard 3.3-inch core to fit universal commercial dispensers. This size is the industry standard for high-traffic restrooms that require a balance between high capacity and space-saving dispenser footprints.

What is the difference between jumbo and mini jumbo?

The primary difference lies in the roll diameter and total capacity. A standard “Jumbo” roll (often called a Senior roll) usually has a 12-inch diameter, making it ideal for extremely high-volume areas like stadiums or airports. A “Mini Jumbo” or “Junior Jumbo” roll has a 9-inch diameter, making it more versatile for standard commercial office restrooms and retail environments.

How many feet are in a junior jumbo roll?

Capacity varies based on the ply, but a standard 2-ply Jumbo Junior roll typically contains 1,000 feet of paper. For 1-ply variants, the length can increase to 2,000 feet per roll. This high footage significantly reduces the frequency of maintenance checks compared to standard residential-style rolls.

Is a mega roll the same as a jumbo roll?

No, they are different product categories. A “Mega Roll” is a consumer-grade product designed to fit standard residential spindles, albeit with a tighter fit. A “Jumbo Roll” is a commercial-grade product with a much larger diameter (9–12 inches) that requires a specific industrial dispenser and cannot be used on a standard home toilet paper holder.

What are the dimensions of a jumbo roll?

A standard Jumbo Junior roll measures approximately 9 inches in diameter and roughly 3.5 to 3.8 inches in width. A Senior Jumbo roll measures approximately 12 inches in diameter. Most jumbo rolls are engineered with a 3.3-inch core to ensure compatibility with universal commercial dispensing systems.

How many rolls in a jumbo junior case?

The standard packaging for Jumbo Junior (JRT Jr.) toilet paper is 12 rolls per case. This configuration is the industry benchmark for facility management, providing a total of 12,000 linear feet of paper (at 1,000 feet per roll) per unit of sale.