Choosing between 1000ft vs. 2000ft rolls determines whether a facility manager controls maintenance labor costs or falls victim to constant, reactive restroom service calls. Relying on vague roll counts instead of precise linear footage creates gaps in supply management that lead to premature run-outs and frustrated building occupants. When staff spend excess hours on repetitive refills, the business loses productive time that should go toward preventive maintenance and safety inspections.

This guide provides a technical breakdown of jumbo roll efficiency to help you refine your facility procurement strategy. We examine the relationship between roll density and maintenance cycles, calculate monthly footage requirements for various traffic volumes, and address the physical storage constraints of higher-footage options. These insights serve as a framework for selecting the right paper capacity to streamline restroom operations and stabilize your supply chain expenses.

Why Is Linear Footage the True Measure of JRT Value?

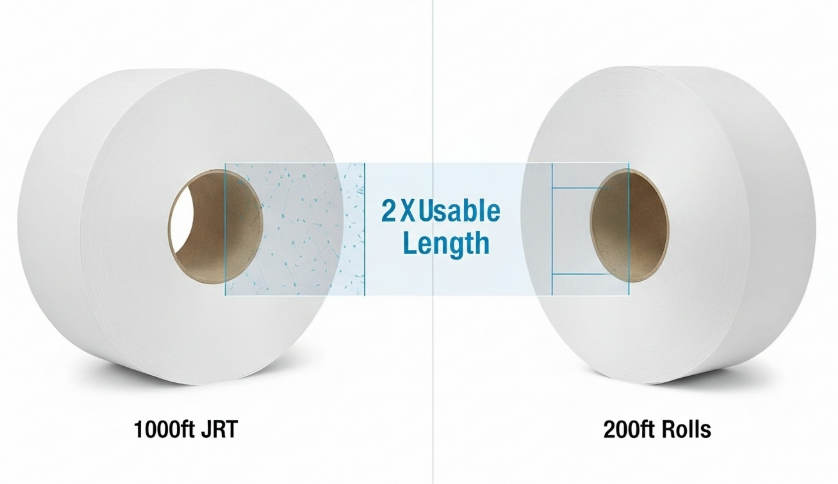

Purchasing jumbo roll tissue based on roll diameter or case price alone ignores the mechanical variables of winding tension and core size that dictate the actual volume of usable paper.

Roll Diameter vs. Total Usable Length

External dimensions often deceive buyers because winding tension and core size vary significantly between manufacturers. A roll that appears thick may simply be loosely wound, creating “false bulk” that takes up dispenser space without providing extra length. Specifying linear footage ensures facility managers receive a guaranteed amount of product regardless of visual bulk or roll thickness.

- Tighter winding creates a compact roll that contains more paper than a loosely wound, larger-looking competitor.

- Top Source Hygiene uses precision winding technology to maintain consistent footage across high-volume 2026 production runs.

- Standardized footage allows for predictable inventory forecasting in high-traffic environments like airports or malls.

Cost-Per-Foot Efficiency in Commercial Procurement

Evaluating Jumbo Roll Tissue by the case price hides the actual price of the paper being consumed. Calculating the cost per linear foot allows for a direct comparison between different brands and varied roll sizes, revealing the true operational cost. High-footage rolls often carry a higher upfront price but offer a lower cost per individual use over time because they minimize packaging waste and logistics overhead per foot of paper.

| Performance Metric | Standard 1000ft JRT | TSH High-Footage Series |

|---|---|---|

| Total Linear Footage | 1,000 Feet | 2,000+ Feet |

| Standard Roll Equivalent | ~4.5 Rolls | ~9.5+ Rolls |

| Maintenance Frequency | Moderate | Ultra-Low (50% reduction) |

Commercial buyers in 2026 prioritize linear length to optimize annual hygiene budgets and reduce the frequency of procurement cycles. By focusing on footage, distributors can offer more competitive pricing to large-scale institutional clients who track every penny of their facility management expenses.

The Transparency of Length Over Weight and Ply

Paper weight and thickness can fluctuate based on pulp quality and different embossing techniques. Embossing adds air between layers, which makes rolls look thicker without actually increasing the amount of usable paper. Linear footage remains a constant metric that stays reliable even if the GSM (grams per square meter) of the paper is adjusted to meet specific softness or strength targets.

- Precision Perforation ensures that linear footage translates into consistent sheet counts for end-users.

- OEM clients use specific footage requirements to maintain strict quality control across different product tiers like 2-ply or 3-ply jumbo rolls.

- We guarantee 100% OBA-Free materials, ensuring that high-footage rolls are safe for sensitive skin across all markets.

How Does a 2000ft Roll Impact Your Maintenance Schedule?

Transitioning to 2,000ft jumbo rolls effectively cuts restroom maintenance touchpoints by 50% compared to standard 1,000ft commercial formats, allowing facility managers to reallocate labor hours toward high-value deep cleaning.

Reducing Refill Frequency in High-Traffic Facilities

High-traffic hubs such as international airports and metro-center shopping malls in 2026 prioritize 2,000ft jumbo rolls to maintain service continuity during peak hours. Doubling the linear footage from standard 1,000ft rolls directly halves the physical interventions required by janitorial staff. This capacity extension prevents “run-out” scenarios, which Top Source Hygiene clients identify as the primary cause of emergency maintenance calls and service complaints.

- Strategic use of the TSH-JRT08 model ensures dispensers remain operational throughout 12-hour shifts without requiring mid-shift restocking.

- Facility managers in developing markets like Nairobi report that high-capacity rolls have cut labor requirements for restroom maintenance by nearly a third.

- Reducing the number of “empty roll” alerts allows onsite managers to focus on broader facility security and hygiene standards.

| Performance Metric | Standard JRT (1,000ft) | High-Capacity (2,000ft) |

|---|---|---|

| Service Interval | Daily / Twice Daily | Every 48-72 Hours |

| Roll Weight (2-Ply) | Approx. 1.5 lbs | Approx. 3.0 lbs |

| Labor Cost Impact | Baseline | 15% Reduction in Overhead |

Optimizing Labor Allocation for Facility Staff

Top Source Hygiene data indicates that high-capacity systems contribute to a 15% reduction in overall maintenance costs by streamlining restroom service routes. The shift to 2,000ft rolls allows management to transition staff from repetitive restocking tasks to high-value sanitation and deep-cleaning duties. Predictable maintenance cycles reduce the need for constant inventory checks, allowing teams to follow a structured schedule rather than reacting to depletion alerts.

In commercial property management, labor efficiency serves as a critical metric for reducing overhead without sacrificing service quality. Using 2,000ft rolls ensures that staff spend less time in transit between storage rooms and restroom stalls. This optimization is particularly valuable in multi-story office complexes where vertical travel time for maintenance personnel can account for a significant portion of the hourly wage.

Minimizing Mechanical Wear on Dispensing Systems

Every time a janitor opens a dispenser to replace a roll, the locking mechanisms, hinges, and housing are subjected to physical stress. By increasing the footage per roll, facilities reduce the frequency of these manual interventions, effectively preserving the structural integrity of the hardware. Fewer roll changes mean less mechanical wear on the plastic or stainless steel units typically used in high-traffic environments.

Consistent use of 2,000ft rolls supports a preventative maintenance model. Hardware stays intact longer because it is handled less frequently. Over a five-year building lifecycle, this reduction in manual handling can extend the operational lifespan of dispensing units by up to 25%, further lowering long-term capital expenditure on restroom fixtures.

Scalable Jumbo Roll Manufacturing for B2B

What Are the Storage Requirements for High-Footage Rolls?

High-footage jumbo rolls require climate-stabilized, elevated storage environments to prevent fiber degradation and compression damage that compromises dispensing efficiency.

Maintaining the technical integrity of 100% virgin wood pulp requires strict environmental parameters. Since high-capacity rolls like the TSH-JRT08 contain significantly more material than standard rolls, even minor atmospheric shifts can lead to substantial inventory loss through moisture absorption or fiber brittleness.

Climate Control and Humidity Management

Standard warehouse operations in 2026 must prioritize a stable moisture baseline. We recommend keeping relative humidity (RH) between 45% and 65%. Exceeding this range causes the paper to absorb ambient moisture, increasing the roll weight and potentially triggering mold growth, while levels below this range make the fibers brittle and prone to snapping during high-speed dispensing.

- Maintain storage temperatures between 20°C and 25°C to preserve the natural elasticity of the wood pulp.

- Position rolls away from active heat sources like radiators or steam pipes that dry out the outer layers and cause uneven tension.

- Deploy dehumidifiers in tropical climates to stop the growth of mildew on bulk inventory before it reaches the facility.

Stacking Protocols and Structural Integrity

Heavy jumbo rolls exert significant static pressure on the bottom tiers of a stack. Improper positioning leads to “flat-spotting” or edge distortion, which prevents the roll from turning smoothly inside its dispenser. For facilities managing high-capacity warehouses, horizontal orientation remains the industry standard for stability.

- Store wide-format and jumbo rolls horizontally to avoid toppling and edge deformation.

- Limit stack heights to 6–8 cartons to prevent the bottom rolls from crushing under the weight of the upper tiers.

- Elevate the lowest storage shelf at least 6 inches above the floor to protect products from potential water damage or floor moisture.

- Organize rolls by footage length to ensure older inventory moves through the facility first, maintaining fresh stock levels.

Environmental Protection and Contamination Defense

Shielding rolls from light and dust maintains the hygiene standards required for hospitality and healthcare sectors. Exposure to UV rays can degrade the natural brightness of the 100% virgin wood pulp, leading to yellowing that suggests poor quality to the end-user.

- Use opaque packaging or cardboard covers to protect paper from direct sunlight.

- Keep rolls in their original factory-sealed plastic until the moment of installation to ensure they remain OBA-free and lint-free.

- Store products in closed cabinets or covered shelving units to minimize dust accumulation on the dispensing edges.

- Ensure the storage area remains clean and free of pests that could compromise FSC-certified materials.

How to Calculate Your Facility’s Monthly Footage Consumption?

Predictive inventory modeling relies on converting raw occupancy data into precise linear footage requirements to eliminate the guesswork inherent in traditional roll-count ordering.

Determine Daily Occupancy and Foot Traffic

Effective procurement starts with hard data. We monitor space utilization through badge swipes or infrared sensor data to establish a reliable baseline of daily active users. This empirical approach separates full-time staff from transient visitors, who typically consume resources at different rates in high-traffic common areas.

- Track peak usage hours to identify when depletion occurs most rapidly.

- Establish a 2026 occupancy forecast that accounts for seasonal spikes or planned building expansions.

- Differentiate between low-utilization executive wings and high-utilization public lobbies.

Standardize Consumption per Square Foot

Facility managers isolate core consumption areas by calculating usable square footage, specifically focusing on restrooms and breakrooms. We apply industry benchmarks of 15–20 linear feet of paper per user visit to the average daily traffic count. This metric allows us to identify specific departments or zones with higher-than-average depletion rates that may require high-capacity Jumbo Roll Tissue (JRT) solutions.

| Facility Zone Type | Usage Benchmark (Linear Ft) | Recommended TSH Model |

|---|---|---|

| High-Traffic (Airports/Malls) | 18–22 ft per visit | TSH-JRT08 (Jumbo Roll) |

| Corporate Office Units | 12–15 ft per visit | TSH-2559 (Household Standard) |

| Industrial/Manufacturing | 15–18 ft per visit | TSH-3082 (Industrial Value) |

Apply Load Factors for Common Areas

Rentable square footage calculations include load factors to account for shared spaces where consumption intensity typically exceeds standard office zones. We integrate these factors into the procurement model to ensure shared lobbies and public restrooms remain fully stocked without constant manual intervention. Using data-driven space optimization, we allocate more 100% virgin wood pulp jumbo rolls to these high-load zones to maximize the interval between maintenance cycles.

- Adjust footage requirements based on the proportional usage shared by multiple tenants.

- Analyze traffic flow to place high-capacity dispensers in the most efficient locations.

- Monitor the impact of load factors on monthly logistics and 40HQ container payload optimization.

Aggregate Data for Monthly Inventory Planning

The final calculation merges occupancy data, area metrics, and safety stock into a single monthly order volume. We multiply the daily linear footage per user by the number of operating days, then include a 10% waste buffer to account for roll remnants and maintenance overlaps. This ensures a seamless supply chain that syncs with 2026 lead times, preventing stockouts while maintaining a lean inventory profile.

- Calculate total monthly footage: (Daily Users × Avg Footage) × 30 Days.

- Add the 10% safety buffer to handle unexpected visitor surges.

- Convert total footage back into case counts based on specific TSH model specifications (e.g., 12 rolls per case).

Does Higher Footage Affect the Ease of Paper Dispensing?

High-capacity rolls require a specific balance of tensile strength and mechanical braking to prevent paper breakage and unspooling during the initial pull phase.

Initial Pull Force and Roll Inertia

Heavy 2000ft rolls generate significant inertia, requiring more manual force to start the rotation compared to standard rolls. If the paper winding is too tight or the roll sits too close to the dispenser housing, the increased friction often leads to paper snapping before the roll actually begins to turn. This is particularly common in high-traffic environments where users pull the paper sharply rather than with steady pressure.

- Heavy rolls (like TSH-JRT08) demand higher torque to overcome standing inertia.

- Friction between the paper surface and the dispenser wall causes premature tearing.

- Top Source Hygiene manages roll density during the winding process to ensure smooth release at maximum capacity.

Core Integrity and Spindle Alignment

Maintaining a perfectly circular core is essential for consistent rotation in high-capacity systems. High-footage rolls put extreme pressure on the inner core, which must remain rigid to prevent the roll from wobbling or jamming on the spindle. A deformed core causes the roll to spin unevenly, leading to a “herky-jerky” dispensing experience that frustrates users and leads to waste.

- Reinforced cores prevent the weight of the paper from crushing the center tube.

- Precision-engineered core diameters allow the roll to sit correctly within the dispenser braking mechanism.

- Proper spindle alignment ensures the roll continues to spin freely as the weight shifts and diameter decreases.

Tensile Strength Requirements for High-Capacity Rolls

The physical properties of the paper must support the tension required to rotate a larger, heavier roll. Higher footage necessitates a higher tensile strength to prevent the paper from snapping before the roll starts moving. We utilize 100% Virgin Wood Pulp with long fibers to provide the necessary durability without sacrificing the cloud-like softness required for premium B2B applications.

- Customized GSM (13–22g/m²) balances user comfort with industrial-grade durability.

- High-wet-strength technology ensures the paper maintains integrity under various humidity levels.

- Top Source Hygiene tests paper performance across the entire 2000ft length to ensure consistency from the first sheet to the core.

Dispenser Braking Systems and Footage Compatibility

Modern 2026 commercial facilities use dispensers with integrated tension controls to manage high-volume rolls. These dispensers often feature gravity-fed or spring-loaded brakes that control the rotation speed. This prevents the “bird-nesting” effect, where excess paper unspools inside the cabinet because the roll continues to spin after the user stops pulling.

- Braking mechanisms prevent waste by stopping the roll rotation immediately after the pull.

- Properly matched footage avoids paper jams caused by over-spinning inside the dispenser.

- Customized roll diameters allow facility managers to maximize volume without replacing existing hardware.

Conclusion

Choosing the right jumbo roll footage allows facility managers to reduce labor hours spent on refills and minimize product waste. While 2000ft rolls offer maximum efficiency for high-traffic zones, verifying dispenser compatibility and storage capacity prevents logistical bottlenecks. Focusing on total linear footage provides a more accurate metric for cost-per-use than simply counting rolls.

Evaluate your monthly consumption patterns and current dispenser inventory to choose the roll length that best supports your maintenance goals. Contact our specialists to request a quote or samples of our virgin wood pulp commercial solutions.

Frequently Asked Questions

How long is a 1000 ft toilet paper roll?

A 1000 ft toilet paper roll measures exactly 1,000 linear feet, which is equivalent to 12,000 inches or approximately 304.8 meters. This is the industry standard size for Jumbo Roll Tissue (JRT) used in commercial and high-traffic environments.

How many regular rolls are in a 1000 ft roll?

One 1000 ft jumbo roll is equivalent to approximately 10 to 12 standard residential rolls. Since a typical household roll contains between 75 and 100 feet of paper, moving to a jumbo format significantly reduces the frequency of refills and maintenance labor.

What is the longest roll of toilet paper available?

The longest commercially available rolls are typically 2,000-foot 2-ply rolls or 4,000-foot 1-ply rolls. These ultra-high-capacity “Super Jumbo” rolls are designed for massive venues like airports and stadiums to minimize the risk of run-outs during peak usage.

How much does a 2000 ft jumbo roll weigh?

A 2000 ft jumbo roll generally weighs between 4.5 and 5.5 pounds. The exact weight fluctuates based on the paper’s basis weight (GSM) and whether it is a 1-ply or 2-ply configuration.

Is longer paper always better for dispensers?

Not necessarily. While longer rolls decrease maintenance cycles, they require specific high-capacity dispensers. If a roll is too large for the housing, it creates excess friction that prevents the paper from dispensing, and the increased weight can put undue stress on mounting hardware.

How to calculate feet per roll?

To calculate the footage, multiply the total number of sheets by the length of a single sheet in inches, then divide by 12. For non-perforated commercial rolls, linear footage is a fixed specification provided by the manufacturer based on the outer roll diameter and paper thickness.