Finding faulty products after arrival creates logistical nightmares and financial losses. A Pre-Shipment Inspection (PSI) acts as a safeguard, so you can confirm quality at the source before goods leave the factory.

This article outlines how inspection firms apply ISO 17020 standards and ISO 2859-1 sampling to evaluate shipments. We examine the use of ASTM E84 burn tests for material purity and the 2.5% AQL limit for major defects to help you maintain high standards across your 2026 production runs.

The Role of Third-Party Inspection Agencies (SGS, Intertek, V-Trust)

Third-party agencies provide neutral product verification to ensure goods meet international safety and quality standards. By utilizing accredited protocols like ISO 17020, these firms conduct physical inspections and laboratory tests. This process gives buyers an objective assessment of order accuracy, defect rates, and packaging integrity before final payment and transport.

Legal Accreditation and Quality Compliance Standards

Legitimate inspection firms operate under strict ISO 17020 and CNAS17020 accreditations. These standards guarantee that the agency maintains technical competence and absolute impartiality during the evaluation process. In China, third-party entities must hold a minimum registered capital of 2.3 million RMB to operate legally. Major firms like V-Trust, SGS, and Intertek also secure APSCA, IFIA, and Sedex AAC certifications to monitor social and quality compliance across global supply chains. These organizations often utilize in-house CNAS and ILAC-certified laboratories to conduct over 100,000 product safety tests every year.

Systematic Inspection Phases and Advanced Metrology

Agencies manage quality through specific physical inspection stages. Pre-Shipment Inspection (PSI) acts as the final validation for product specifications, quantities, and packaging before container loading. During Production Inspection (DPI) allows inspectors to identify manufacturing defects while the production line remains active, preventing large-scale errors. For complex machinery and components, technical teams use advanced metrology tools like the FARO Quantum M CMM and laser trackers to reach precise dimensional accuracy. Some firms also implement 3D blue light scanning and drones for remote or highly detailed inspections of large-scale projects.

AQL Standards (Acceptable Quality Level) for Tissue Products

Inspectors use ISO 2859-1 standards to evaluate tissue batches, typically applying a 0% threshold for critical safety risks, 2.5% for major functional issues like tearing strength, and 4.0% for minor visual flaws. This sampling method ensures quality without testing every individual unit in a 2026 production run.

| Defect Category | AQL Threshold | Tissue Quality Examples |

|---|---|---|

| Critical Defects | 0% | Sharp objects, needles, or hazardous chemical odors |

| Major Defects | 2.5% | Poor absorbency, low tearing strength, or shade variation |

| Minor Defects | 4.0% | Loose threads, creases, or packaging misalignments |

ISO 2859-1 Sampling Framework for Bulk Paper Shipments

Inspectors use ANSI/ASQC Z1.4-2003 (ISO 2859-1) tables to set statistically valid sample sizes for large orders. General Level II serves as the default inspection intensity for standard 2026 quality audits, providing a balance between testing time and data reliability. The lot size determines exactly how many rolls or boxes the team must pull for randomized testing. These sampling plans identify the specific number of allowed defects before a batch faces rejection, ensuring that quality control remains objective throughout the manufacturing process.

Classification Levels for Critical, Major, and Minor Defects

Quality teams reject any batch containing critical defects, such as sharp objects, needles, or hazardous chemical odors, maintaining a strict 0% AQL. Major defects, capped at a 2.5% AQL, cover functional failures including poor absorbency, low tearing strength, or significant shade variation that impacts product performance. Staff also monitor minor defects at a 4.0% AQL to manage visual imperfections like loose threads, creases, or slight packaging misalignments. ISO 9001 compliance protocols ensure these thresholds remain consistent across various 2026 production lines, allowing manufacturers to maintain high standards across global supply chains.

The “Burn Test” and “Absorbency Test” on the Factory Floor

Inspectors perform burn tests to verify fiber purity and flame safety, while absorbency tests quantify liquid retention capabilities, ensuring paper products meet international hygiene and safety standards before shipment in 2026.

Flame Spread Analysis and Material Purity Verification

Burn testing at the factory floor provides immediate evidence of a material’s chemical and organic composition. Inspectors follow ASTM E84 guidelines to evaluate flame spread and smoke density, which determines how the paper reacts under extreme thermal stress. By analyzing combustion behavior, we can verify the use of 100% virgin wood pulp. Pure fibers typically leave behind fine grey ash and produce white smoke. In contrast, paper containing heavy chemical fillers or fluorescent whiteners often generates darker smoke and charred, brittle residue during the test.

Maintaining a Class A fire safety rating is a requirement for many commercial paper supplies. This rating requires a flame spread index between 0 and 25, measured against a red oak baseline. During pre-shipment inspections, these tests distinguish between materials that melt or drip and those that maintain structural integrity. Verifying these indices ensures that the final product adheres to strict safety codes required for high-occupancy commercial environments and industrial settings.

Fluid Retention Metrics and Performance Testing Standards

Absorbency testing quantifies the functional performance of tissues and towels through specific liquid intake benchmarks. We use ASTM C413 protocols to measure retention capacity, ensuring the products meet the high standards of the North American and European hygiene markets. Quality control teams verify grams per square meter (GSM) consistency throughout the production run. This data confirms that the thickness of 2-ply to 5-ply products provides the necessary liquid barrier and absorption speed for consumer use.

Beyond initial absorption, we test mechanical strength under wet conditions to assess how jumbo rolls perform in real-world applications. A high-capacity roll must retain its tensile strength when saturated to prevent tearing or failure during dispensing. Comparing these results against updated 2026 industry standards allows manufacturers to confirm that their goods provide the durability and efficiency required for medical and industrial use. These technical metrics provide a reliable quality assessment before the shipment leaves the factory.

Build Your Unique Toilet Paper Brand with Global OEM Experts

Verifying Roll Counts and Packaging Integrity Before Loading

By 2026, quality protocols require active physical count reconciliation and standardized leak testing before container loading. Inspectors use ASTM and ISO methods to detect microscopic seal defects and verify that roll counts meet contract specifications, ensuring every shipment aligns with NIST net content standards and GMP packaging controls.

Mandatory Reconciliation for Roll Counts and Content

Quality teams perform physical counts of roll labels at receipt or issue to comply with GMP packaging controls. Logistics managers only rely on supplier data if the vendor is formally qualified and provides a certified exact count per roll or uses consecutive numbering. This verification process prevents inventory discrepancies and ensures that the physical stock matches the digital record before shipping begins.

Lot acceptance follows Maximum Allowable Variation (MAV) rules defined in NIST Handbook 133 for count-based packaged goods. Inspectors check count declarations against physical samples to ensure the shipment meets legal metrology requirements. Teams reconcile any missing or extra units against specific work orders, maintaining strict inventory control before the truck leaves the loading dock.

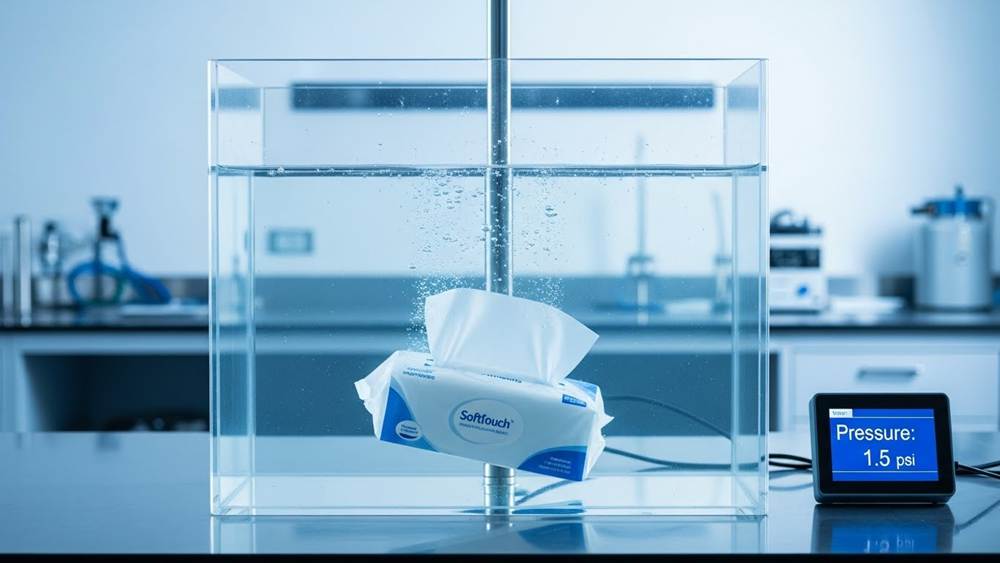

Technical Validation for Seal Integrity and Shipping Durability

ASTM F1886 visual inspection methods detect seal channel defects as narrow as 75 µm in flexible packaging. These standards define the limits of visual detection on the dock. To identify gross leaks, bubble emission tests under ASTM F2096 involve inflating packages to 0.5–2 psi while submerged in water. This quantitative method provides a reliable verification of package integrity for sterile or high-risk products.

Quantitative seal strength tests following ASTM F88 or EN 868-5 Annex D validate the mechanical thresholds of pouch seams. These measurements confirm that seals can withstand the stresses of sterilization and handling. Distribution simulations, including ISTA 3A and ASTM D4169, verify that packaging maintains its sterile barrier throughout the logistics cycle. ISO 11607 frameworks guide the demonstration of stability after the product undergoes handling, distribution, and storage.

The Container Loading Supervision (CLS) Process

Container Loading Supervision serves as the final security gate, occurring once 100% of the goods are packed. Inspectors verify container condition, supervise the stacking of cartons to prevent damage, and apply security seals, providing a report with 20+ photos within 48 hours to ensure shipment accuracy.

Verification of Container Integrity and Quantity Matching

Inspectors examine the container for structural damage, holes, leaks, pests, and odors. This step ensures paper products remain dry and uncontaminated during transit. The team cross-references SKU codes, lot numbers, and production batch IDs against the purchase order and packing list to confirm the correct inventory. We verify that 100% of the paper products are manufactured and packed before the loading process begins at the factory or warehouse. Initial records include the container number, truck plate details, and current weather conditions to establish a clear chain of custody.

Supervised Loading Protocols and Security Sealing

Inspectors manage the stacking pattern and weight distribution to prevent carton crushing and shifting during sea transport. The workflow includes witnessing the application of high-security seals and recording the seal ID numbers in the final report to prevent tampering. Quality teams capture more than 20 high-resolution photos documenting the empty container, the loading progress, and the sealed doors. A structured report reaches the buyer within 24 to 48 hours, providing forensic-grade data for logistics planning and liability protection.

Approving the Bill of Lading (B/L) and Final Documents

Shippers must review the carrier-generated draft Bill of Lading to verify cargo descriptions, weights, and entity details before final issuance. This process ensures compliance with DCSA standards and federal regulations like 49 CFR Part 1035, preventing amendment fees and logistical delays in the 2026 shipping cycle.

Draft Review and Amendment Protocols

Carriers generate a draft B/L based on the equipment loading report from the terminal for shipper verification. Shippers review cargo descriptions and container numbers to match the actual loaded goods before the vessel departs. Requesting amendments at this stage, before final issuance, avoids the requirement to surrender original paper documents and prevents extra carrier charges. Modern digital systems utilize UN/CEFACT semantic definitions to streamline electronic Bill of Lading (eBL) approvals, which facilitates faster cargo release at the destination.

Mandatory Data Fields and Regulatory Compliance

Final documents must include the Standard Carrier Alpha Code (SCAC) and Transportation Control Number (TCN) to ensure accurate line-haul tracking. Federal regulations under 49 CFR Part 1035 mandate signatures from the carrier, shipper, and receiver to establish a legally binding contract. To maintain global synchronization across logistics platforms in 2026, all dated entries follow the YYMMDD format. Verification checklists also incorporate the Standard Transportation Commodity Code (STCC) and National Motor Freight Classification (NMFC) to determine precise freight classes and prevent rating errors.

Handling Major vs. Minor Defects in the PSI Report

Inspectors classify findings as critical, major, or minor based on their impact on safety and performance. The Pre-Shipment Inspection report compares these counts against AQL limits defined in ISO 2859-1 standards. This objective data helps buyers decide whether to accept or reject a 2026 paper product batch based on specific defect thresholds.

| Defect Severity | Impact on Product | Acceptance Quality Limit (AQL) |

|---|---|---|

| Critical | Safety hazards (broken needles, insects, sharp points). | Zero tolerance (usually 0%). |

| Major | Functional failure or poor salability (tears, wrong size). | Typically 2.5%. |

| Minor | Cosmetic issues (loose threads, slight shade variation). | Typically 4.0%. |

Defining Defect Severity Levels in Paper Products

Critical defects present immediate safety risks or violate regulations. These include the presence of insects, sharp edges, or broken needles left in the product. Finding even one critical defect in a sample set triggers an immediate rejection of the entire shipment. These hazards endanger the end-user and expose the brand to significant legal liability.

Major defects hinder the product’s performance or marketability. For household paper goods or related textiles, these include open seams, fabric tears, or incorrect dimensions. A buyer likely receives complaints or refund requests if these items reach the store shelves. Inspectors count these carefully to ensure they do not exceed the agreed-upon tolerance levels in the quality agreement.

Minor defects represent aesthetic issues that do not impact the product’s function. Loose threads, light shade variations, or small glue marks fall into this category. Most customers ignore these imperfections during regular use. Quality standards allow for a higher number of minor defects because they pose a low risk to the brand’s reputation and do not affect the utility of the item.

Evaluating AQL Counts and Shipment Decisions

Quality professionals use ISO 2859-1 sampling plans to determine the number of units to check. For an order of 10,000 pieces, a standard Level II inspection requires checking 315 units. This sampling size provides a statistically significant overview of the entire batch without requiring the inspector to examine every individual item. The resulting defect counts serve as the primary evidence for the final pass or fail result.

The PSI report benchmarks these findings against specific thresholds, often set at 2.5% for major defects and 4.0% for minor defects. If the count stays within these limits, the batch passes. If the counts exceed the limits, management must decide between shipping at a discount, demanding a 100% factory re-inspection, or requiring the supplier to perform rework on the affected lot. Detailed reports include photographs of each defect type to verify the findings against current quality benchmarks.

Final Thoughts

A thorough inspection process protects your investment and ensures customers receive safe, functional paper products. Checking goods against AQL standards and supervising container loading reduces the risk of logistics delays and financial losses. These protocols turn technical data into a reliable foundation for final payment and global distribution.

Accurate documentation and secure loading procedures finalize the supply chain cycle. Shippers who verify Bill of Lading details and maintain strict count reconciliation avoid unnecessary fees and regulatory hurdles. Consistently applying these quality gates helps you build a resilient supply chain that meets the demands of modern international trade.

Frequently Asked Questions

What is a Pre-Shipment Inspection (PSI) and why is it necessary for tissue products?

A PSI verifies quality once production reaches 80-100% completion. We use random sampling to check visual details, safety, and functionality before the goods leave the factory. This process minimizes the risk of receiving substandard items and ensures the shipment complies with international standards like ISO 9001.

How do we interpret an AQL report during a paper product inspection?

We use ANSI/ASQ Z1.4 tables to set sample sizes based on the total lot. For a batch of 3,201 to 10,000 rolls, we typically inspect a 200-unit sample. We accept the lot only if defects stay below the limits for critical (0%), major (2.5%), and minor (4.0%) categories.

Can we perform a remote inspection via video call in 2026?

Yes, remote video inspections (RVI) are effective if the factory provides a stable 4G signal and uses a high-resolution platform. Inspectors view quality checks in real-time. If the video quality or connectivity fails to meet protocol, we require an on-site visit to ensure accuracy.

What common defects appear during toilet paper quality checks?

Inspectors identify issues such as holes, edge cracks, stains, and loose cores. We follow ISO 12625 standards to test for weight, softness, and absorbency. We also verify packaging integrity, looking for poor seals or incorrect roll counts that could affect retail sales.

Who pays for the re-inspection if the factory fails the first time?

While no universal rule exists, most buyers negotiate contracts that require the supplier to cover re-inspection fees if they fail. These costs usually range from USD 300 to USD 800 per day. Setting these terms in the purchase agreement ensures the factory maintains strict quality control.

How do we verify that the container is loaded properly (CLS)?

We follow a 6-step Container Loading Supervision process. This includes inspecting the container for holes or odors, checking shipping marks against the packing list, and supervising the stacking to prevent damage. We finish by securing the container and recording the seal number for security.