Optimizing Absorbency Rate vs. Capacity in tissue procurement directly dictates whether a facility reduces annual consumption or wastes budget on low-performance fibers. Choosing materials with poor capillary speed increases sheet waste and risks expensive plumbing clogs in high-traffic environments.

Technical benchmarks use ISO 12625-8 standards to verify 100% Virgin Wood Pulp and CNC point-to-point embossing that increases retention by 30%. These metrics prioritize sinking time and 13-22g/m2 density to ensure every 40HQ shipment meets strict clinical and hospitality requirements.

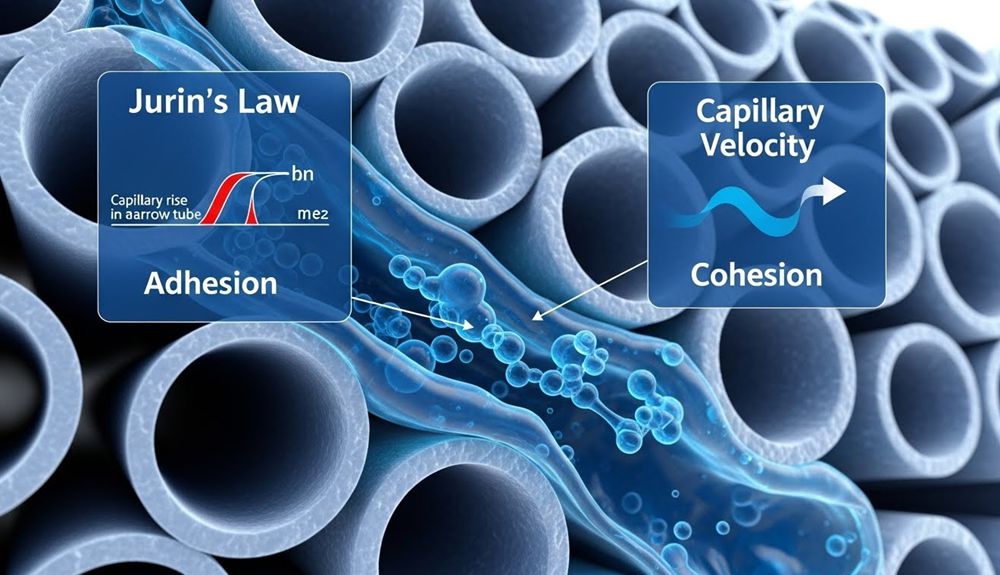

How Does Capillary Action Function in Tissue Fibers?

Capillary action pulls liquid through microscopic fiber gaps using adhesive and cohesive forces, optimized by 100% virgin wood pulp and CNC-precision embossing patterns.

The Interplay of Adhesion and Pore Geometry

Capillary action relies on the relationship between water molecules and the physical structure of cellulose. Liquid travels through tissue because water molecules are attracted to the organic cellulose walls. This adhesive force draws the moisture into the tiny spaces between fibers, while cohesive forces keep the water molecules bonded to each other, maintaining a consistent flow.

The speed and height of moisture transport depend heavily on the diameter of the fiber pores. Physics dictates an inverse relationship here: the narrower the space, the higher the liquid climbs. Engineering a tissue with precise, microscopic gaps ensures that moisture moves quickly and stays contained within the fiber network rather than sitting on the surface.

- Adhesion: Attraction between water and organic cellulose walls.

- Cohesion: Internal bonding that maintains the liquid column.

- Jurin’s Law: Scientific principle where smaller pore diameters increase liquid climbing height.

Fiber Purity and Point-to-Point Embossing Efficiency

Material choice determines the efficiency of the capillary network. We utilize 100% Virgin Wood Pulp because its long-fiber structure creates a more robust and predictable wicking path. These high-purity fibers prevent the network from collapsing when wet, allowing the capillary pathways to remain open and functional during heavy use.

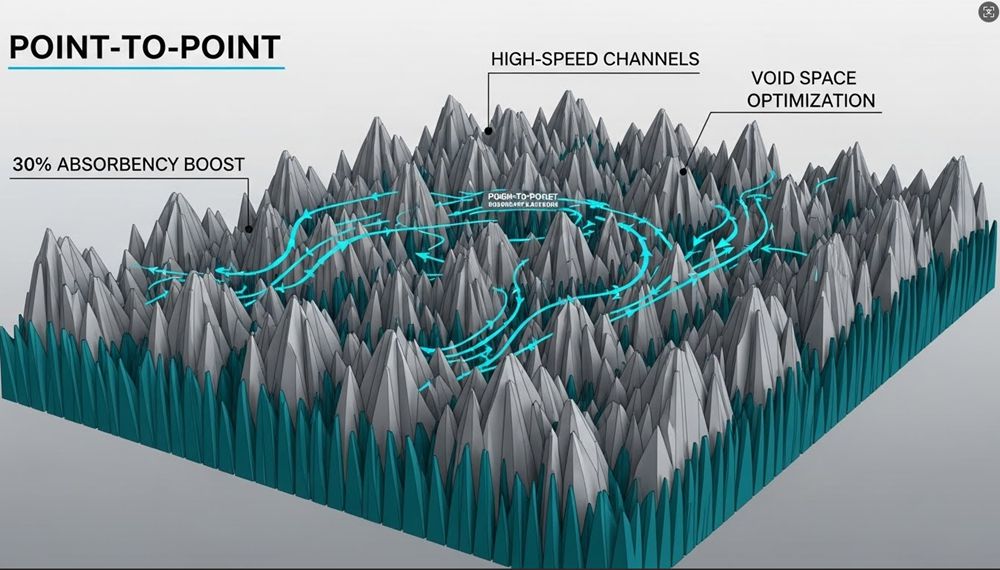

Advanced manufacturing techniques further optimize these natural forces. Point-to-Point Embossing creates intentional microscopic valleys that increase the total surface area. This specific pattern, combined with CNC-precision channels, organizes the fiber pathways to distribute fluid evenly across the sheet, preventing localized saturation and maximizing the total capacity of the roll.

- 100% Virgin Wood Pulp: Premium long-fiber base for faster wicking.

- Point-to-Point Embossing: Increases absorbency by 30% through surface expansion.

- CNC-Precision: Uniform distribution channels for consistent fluid management.

Why is “Sinking Time” the Critical Test for Absorption Rate?

Sinking time tracks the seconds between surface contact and full immersion. It measures capillary speed—how fast fibers pull liquid in—rather than total storage capacity.

Measuring Liquid Penetration Speed through Immersion

The test tracks the exact seconds a specimen takes to submerge under its own weight. We use this to benchmark how fibers behave the moment they touch moisture. Rapid sinking shows high fiber porosity and clear capillary pathways for fluid transport. Lab results provide a standardized metric for comparing the saturation velocity of different ply counts and material densities.

- Standard Metric: Seconds required for a sample to achieve 100% immersion.

- Porosity Indicator: Faster sinking correlates with efficient capillary action within the fiber matrix.

- Commercial Application: Shorter immersion times are necessary for high-traffic environments where immediate moisture removal is a priority.

How CNC Point-to-Point Embossing Accelerates Saturation

Top Source Hygiene uses CNC-precision embossing to create specialized patterns that increase the surface area available for fluid contact. We apply high-pressure bonding to ensure the multi-ply sheets maintain structural integrity during the sinking process. This prevents the layers from delaminating when they hit the water.

- 30% Absorbency Boost: Point-to-point lamination technology creates microscopic air pockets between layers that trap liquid faster.

- 100% Virgin Wood Pulp: Long-fiber pulp provides a superior wicking network compared to the short, broken fibers found in recycled paper.

- Capillary Efficiency: The CNC patterns create intentional peaks and valleys that act as high-speed channels for water movement.

- Ply Density: Strictly controlled 13–22g/m² per ply ensures the paper remains porous enough for rapid wicking without losing strength.

For B2B distributors, sinking time is a key quality gate. If a tissue sits on top of the water for too long, it indicates a dense or low-porosity fiber structure that will fail in medical or hospitality settings where speed is everything. We rely on the 100% OBA-free virgin pulp to maintain the natural capillary strength of the cellulose, ensuring the paper reacts the second it touches liquid.

Build Your Unique Toilet Paper Brand

How to Measure Total Capacity (Grams of Liquid vs. Grams of Paper)?

Labs measure capacity using the gravimetric method, calculating the difference between dry and saturated weights to identify how many grams of liquid one gram of virgin pulp holds.

Gravimetric Analysis and ASTM D570 Standards

Gravimetric analysis provides the most accurate data for quantifying how paper products behave in high-moisture environments. Testing begins by establishing a precise dry weight baseline. This initial measurement ensures that the final absorption ratio reflects the liquid held within the fiber network rather than the weight of the material itself.

- Saturation Protocol: Technicians immerse samples in distilled water at a controlled 23°C to satisfy ISO 62 and ASTM D570 requirements.

- Capacity Formula: Calculation involves subtracting the Dry Weight (g) from the Saturated Weight (g) to determine total intake.

- Retention Metrics: Testing differentiates between free-swell capacity and the liquid retained after the sample undergoes centrifugal force.

Point-to-Point Embossing and Retention Capacity

The physical structure of the sheet determines its ultimate retention limits. At Top Source Hygiene, we apply specific manufacturing tolerances to 100% virgin wood pulp to maximize these results. This focus on fiber architecture ensures that distributors receive product that maintains integrity even at peak saturation levels.

- CNC Embossing: Point-to-point patterns increase fluid retention by 30% by creating additional microscopic pockets for water storage.

- GSM Range: We maintain a density of 13–22g/m² to optimize the balance between sheet softness and total liquid volume.

- Ply-Bonding: High-pressure lamination prevents the separation of layers during saturation, which is critical for multi-ply commercial rolls.

- Fiber Purity: 100% virgin wood pulp eliminates lint residue, allowing for cleaner absorption compared to recycled alternatives.

Does Embossing Pattern Impact Fluid Retention Speeds?

Embossing changes tissue geometry to control liquid penetration. Specific patterns and CNC-precision point-to-point textures increase absorbency by 30% by expanding void space and directing fluid flow.

Embossing is not merely an aesthetic choice for luxury tissue; it is a mechanical modification that fundamentally alters how a sheet interacts with liquids. By pressing the 100% Virgin Wood Pulp fibers between engraved rollers, we create a three-dimensional architecture that dictates both the speed of initial wetting and the total volume the material can hold before reaching saturation.

Structural Mechanics of Pattern-Induced Retention

The physical relationship between pattern types and fluid behavior relies on capillary action. When the embossing process creates microscopic peaks and valleys, it increases the total surface area available for liquid contact, allowing adhesion forces to pull moisture into the fiber network more efficiently.

- Micro-embossing: These patterns increase material thickness and bulk, providing essential void space for liquid storage within the sheet.

- Groove Spacing: Tightly-spaced patterns can trigger active drainage, directing fluid through the material layers rather than trapping it on the surface.

- Calibration Pressure: Maintaining a standard 2.8 bar pressure during production balances the trade-off between high bulk and surface softness.

- Spreading Dynamics: Geometric patterns influence how quickly a droplet expands across the sheet, preventing localized pooling.

Performance Gains from Point-to-Point Embossing

For B2B wholesalers and distributors, the technical execution of the pattern determines product tiering. We use specific manufacturing protocols to ensure that high-ply products do not just feel thicker, but actually perform at a higher metric during industrial “sinking time” tests.

- CNC-Precision: Our point-to-point embossing increases total absorbency by 30% compared to non-embossed alternatives.

- High-Pressure Lamination: This ply-bonding technology creates a quilted texture that traps fluid securely between the plys.

- Strategic Alignment: Floral and dot patterns prevent layer separation when the tissue is exposed to heavy fluid volume.

- Batch Consistency: Uniform pattern depth across large-scale 2026 production runs ensures consistent sinking times and retention rates for global shipments.

The choice of pattern serves as the primary tool for balancing absorption speed and total capacity. While micro-patterns focus on volume, specific geometric grooves ensure the liquid moves away from the point of contact rapidly, maintaining the structural integrity of the tissue fibers even when saturated.

Why Do Labs and Hospitals Prioritize “Instant” Absorption?

Medical facilities require instant absorption for immediate diagnostic results. Rapid fluid intake improves clinical decisions, prevents cross-contamination, and ensures patient safety in high-stakes sterile environments.

| Clinical Requirement | Technical Specification | Operational Impact |

|---|---|---|

| Rapid Diagnostics | 100% Virgin Wood Pulp | Immediate wicking for POCT accuracy |

| Patient Safety | 100% OBA-Free | Zero skin irritation or microbiome disruption |

| Fluid Management | Point-to-Point Embossing | 30% increase in total fluid retention |

| Facility Maintenance | Rapid Disintegration Tech | Prevents plumbing clogs in high-traffic wards |

Clinical Decision-Making and Diagnostic Speed

Speed in medical environments isn’t just about convenience; it directly influences patient outcomes. When clinicians use Point-of-Care Testing (POCT), the material’s ability to pull liquid instantly determines how fast a diagnosis is reached. Slow absorption creates delays that disrupt the entire consultation flow.

- Real-Time Results: Immediate diagnostics allow doctors to make treatment decisions during the first visit, removing the need for follow-up calls.

- POCT Efficiency: Fast-wicking materials eliminate the lag time in cardiovascular or respiratory screenings.

- Therapeutic Delivery: In intravenous settings, rapid fluid management supports concentrated nutrient delivery by bypassing the digestive system.

- Data Reliability: Modern diagnostic microchips require consistent fiber absorption rates to produce accurate, repeatable data.

Point-to-Point Embossing and OBA-Free Safety Standards

Hygiene standards in hospitals require materials that perform under pressure without introducing chemical risks. We utilize specific manufacturing techniques to meet these sterile requirements, focusing on physical structure and chemical purity to protect both the facility and the patient.

- CNC Point-to-Point Embossing: This precision texture increases fluid retention by 30% compared to standard paper, ensuring spills or samples are contained instantly.

- 100% OBA-Free: By excluding Optical Brightening Agents, we ensure the material is safe for sensitive skin and does not disrupt the patient’s microbiome.

- Septic-Safe Disintegration: Our paper meets 2026 standards for rapid breakdown, which is vital for preventing clogs in high-volume hospital plumbing systems.

- 100% Virgin Wood Pulp: The use of long-fiber virgin pulp ensures a lint-free performance, preventing fiber shed from contaminating sensitive laboratory equipment.

Frequently Asked Questions

What are the standard international methods for testing tissue paper absorbency?

ISO 12625-8:2010 provides the primary framework using a basket-immersion test. This protocol measures water-absorption time and water-absorption capacity, expressed in grams of water per gram of paper. Testing involves five replicate pieces submerged for 30 seconds and drained at a 30-degree angle. This ensures data accuracy for high-volume procurement, like our 40HQ container shipments from the Hebei industrial hub.

Is 3-ply tissue significantly more absorbent than 1-ply options?

Multi-ply tissues, such as 3-ply or 5-ply ultra-soft rolls like the TSH-4010, offer superior absorbency compared to single-ply versions. The additional layers and high-pressure lamination allow for higher fluid retention. In commercial environments, using higher-ply counts reduces total sheet consumption per use. Our CNC-precision point-to-point embossing increases this absorbency by 30% compared to non-embossed alternatives.

Why is Net Absorption a critical metric for facility managers?

Net absorption reflects true market demand by accounting for space vacated during a specific period. For commercial procurement, high net absorption indicates a tightening market where facility managers should secure supply chains early to protect their inventory. Unlike gross figures, net metrics help forecast inventory turnover accurately, allowing buyers to optimize the payload in a 40HQ container and lower landed costs.

Does embossing actually improve the liquid absorption rate?

Embossing patterns like honeycomb or quilted designs enhance capillary action by increasing the total surface area. By creating microscopic peaks and valleys, embossing facilitates faster liquid movement through the fiber network. This structural modification also maintains the integrity of 100% virgin wood pulp when wet, preventing fibers from collapsing. We utilize point-to-point embossing to ensure high-wet-strength durability in models like TSH-2559.

How does the absorbency of bamboo tissue compare to 100% virgin wood pulp?

Bamboo and virgin wood pulp offer comparable moisture-wicking. Bamboo fibers are typically shorter (1.2mm) than softwood fibers (2.7mm), which influences specific retention rates and texture. While bamboo serves eco-targeted projects, 100% virgin wood pulp remains our industry standard for maximum tensile strength and cloud-like softness. Both materials provide OBA-free solutions safe for sensitive skin.

What standards govern the absorbency and barrier properties of medical-grade paper?

Medical paper products must comply with ISO 11607-1 and ASTM F1608 standards. These protocols evaluate microbial barrier performance and air permeance. For clinical environments, we focus on high wet strength, specific pH levels, and residue-free performance. These specifications ensure safety during sterilization cycles and aseptic presentation, maintaining product integrity under moisture exposure.