Microscopic Analysis of tissue surface topography is the primary defense against batch inconsistencies that trigger bulk order rejections. Failing to quantify fiber density at the nanoscale leads to high-linting products and weakened ply-bonding, directly compromising the contract margins of international hygiene distributors.

This technical evaluation benchmarks production against the 13–22g/m² GSM standard using 100% virgin wood pulp. We analyze fiber morphology and OBA-free purity to ensure that every 40HQ container maintains the mechanical durability and softness required for high-volume hospitality and retail partnerships.

How Does SEM Technology Revolutionize Tissue Engineering?

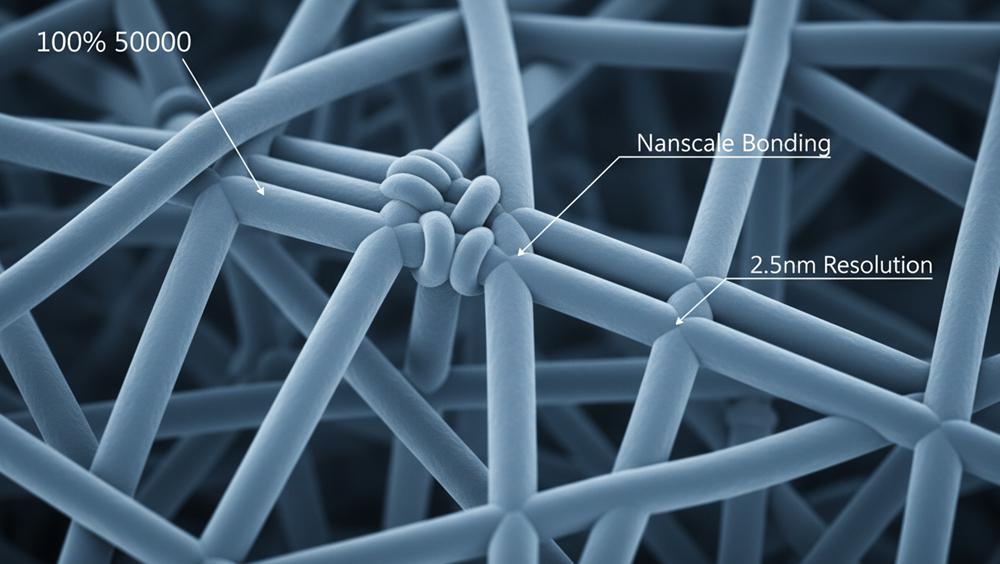

SEM provides 100,000x magnification to quantify fiber density and bonding at the nanoscale, ensuring engineered constructs meet precise durability and absorbency requirements for professional B2B distribution.

Scanning Electron Microscopy (SEM) moves beyond surface-level inspection by providing high-resolution 3D imaging of complex microarchitectures. In 2026, researchers and manufacturers use this technology to quantify surface topography and structural integrity. This ensures that engineered constructs meet specific density and strength requirements by visualizing cell morphology and fiber bonding at the nanoscale.

Nanoscale Visualization of Three-Dimensional Microstructures

Engineers utilize SEM to define the structural boundaries of biomaterials. By capturing data at the highest spatial resolutions, we can observe how cells interact with various substrates over time. This level of detail allows for the optimization of scaffold surface properties before moving into mass production.

- Magnification Range: Visualization at levels exceeding 100,000× to analyze surface topography.

- Resolution Limits: Imaging precision between 2.5 nm and 10 nm for clear fiber identification.

- 3D Evaluation: Focused ion beam (FIB)-SEM tomography provides high-resolution 3D nanoscale reconstructions.

- Morphology Tracking: Quantification of cell kinetics on hydrogel structures to simulate native extracellular matrices.

Validating Ply-Bonding and Fiber Performance Specifications

At Top Source Hygiene, we apply SEM topography analysis to verify the mechanical integrity of our high-pressure ply-bonding technology. This microscopic validation ensures that multi-ply layers remain bonded under stress while maintaining a lint-free experience. The data collected from these scans informs our adjustments to fiber density and embossing depth.

- Bonding Verification: Testing high-pressure lamination in multi-ply layers to prevent separation during use.

- Absorbency Optimization: Microscopic validation of point-to-point embossing patterns that increase liquid retention by 30%.

- Fiber Integrity: Analysis of 100% virgin wood pulp long-fibers to guarantee high-wet-strength and zero lint.

- Density Mapping: Controlling fiber density within the 13–22g/m² GSM range to balance cloud-like softness with structural strength.

This rigorous inspection protocol allows us to maintain batch consistency across large-scale 40HQ container orders. By evaluating the physical state of the fibers and their arrangement, we mitigate defects before products leave our Hebei facility, protecting the margins of our B2B partners.

Can We Visualize Hydrogen Bonding Between Fibers?

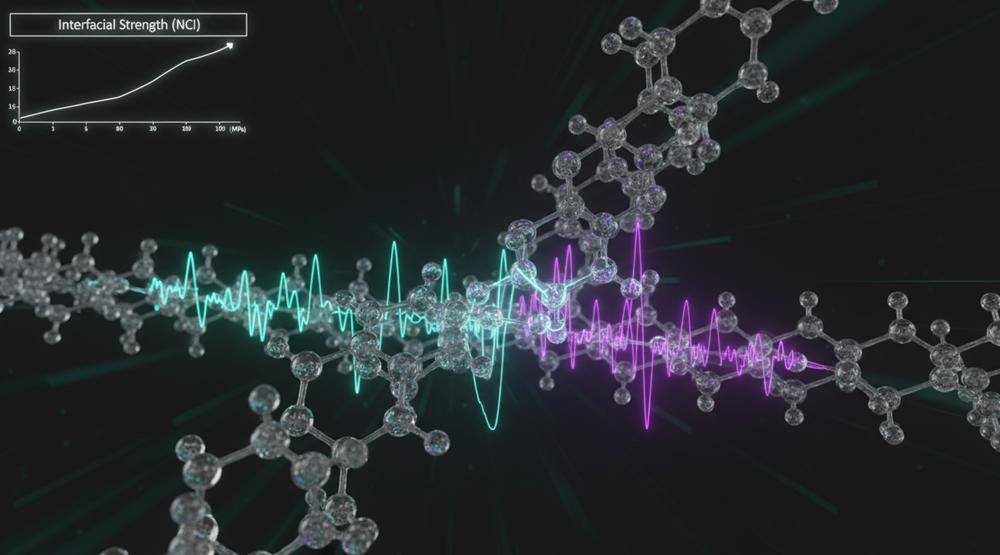

Researchers use atomistic simulations and NCI indices to map invisible hydrogen bonds, while Top Source Hygiene applies high-pressure ply-bonding to maximize these molecular interactions.

Molecular Mapping and Electron Density Simulations

Hydrogen bonds serve as the invisible glue in high-performance tissue paper. While traditional microscopes cannot see these molecular forces, atomistic molecular dynamics models track the distribution of interprotein hydrogen bonds as fibers deform. This computational approach provides a clear look at how the network responds to stress.

- Electron Density Maps: Quantum calculations generate spatial data to identify precise bond locations and strengths within complex fiber structures.

- NCI Index: The Non-Covalent Interaction index allows researchers to visualize the geometry of fiber interfaces, showing exactly where strength is concentrated.

- Molecular Dynamics: These models track how bonds form and increase during paper processing, directly influencing the final tensile strength.

Structural Integrity and Ply-Bonding Performance

Visualization techniques prove the mechanical superiority of 100% virgin wood pulp. By combining debonding tests with optical imaging, researchers observe “fiber bridging”—the moment where interfacial interactions keep the layers together. This data confirms that long-fiber pulp provides more hydroxyl groups for bonding than short, fragmented recycled fibers.

- 100% Virgin Wood Pulp: Premium long fibers maximize the surface area available for hydrogen bonding, creating a naturally stronger paper web.

- High-Pressure Ply-Bonding: Top Source Hygiene uses mechanical lamination to stabilize the fiber network, ensuring multi-ply products like the TSH-2269 maintain integrity without chemical adhesives.

- Interfacial Interaction Mapping: Optical imaging during fiber pull-out tests measures deflections up to 899 μm, providing quantitative proof of bond strength.

This microscopic precision is why Top Source Hygiene maintains a strict 13–22g/m² ply density. By understanding the molecular layout, we engineer toilet rolls that balance cloud-like softness with the structural durability required for global distribution in 40HQ containers.

Build Your Brand With Premium OEM Toilet Paper

How Does Creping Frequency Impact Tactile Softness?

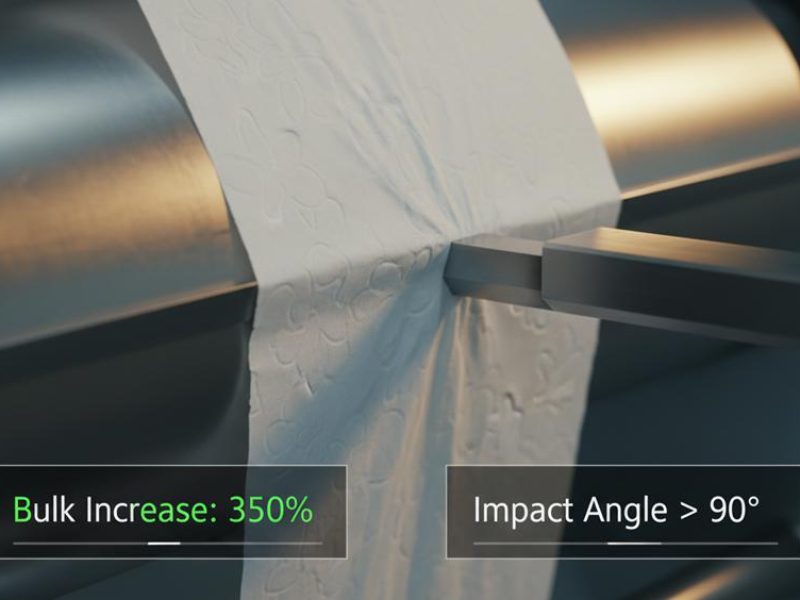

Higher creping frequencies create micro-structures that increase tissue bulk by up to 350% while improving surface smoothness for a premium, lint-free handfeel.

| Parameter | Tactile Impact | TSH Manufacturing Standard |

|---|---|---|

| Creping Frequency | Finer micro-crepes per inch | High-frequency precision |

| Blade Impact Angle | Controls spacing and bulk | Optimized > 90 degrees |

| Ply Density | Deep pocket formation | 13–22g/m² per ply |

Mechanical Formation of Micro-Crepe Structures

The creping process fundamentally changes the paper’s physical structure at the microscopic level. By impacting the sheet against a creping blade, we break internal fiber bonds to create a flexible, compressed texture that defines the final handfeel of the product.

- Micro-Crepe Density: Higher frequencies generate more micro-crepes per inch, creating a finer and more uniform surface texture for luxury-grade rolls.

- Blade Impact Angle: Adjusting the blade angle to over 90 degrees produces the closely spaced crepes required for high-end hospitality tissue.

- Bulk Increase: Precision creping increases paper bulk by 200-350%, providing the “squishy” compressive softness that distributors expect in premium categories.

- Friction Reduction: Fine crepe structures reduce surface friction, making the paper feel significantly smoother against sensitive skin.

Optimizing 13–22 GSM Virgin Wood Pulp for Creping

Material selection dictates how well the paper survives the mechanical stress of creping. At Top Source Hygiene, we focus on fiber integrity to ensure consistent quality across high-volume 40HQ container shipments.

- Long-Fiber Strength: 100% Virgin Wood Pulp provides the structural resilience needed to withstand high-frequency creping without shedding or linting.

- GSM Control: Maintaining a ply density between 13–22g/m² ensures the sheet has enough mass to form deep, soft pockets during the creping stage.

- Adhesion Uniformity: Consistent adhesion to the Yankee cylinder prevents coarse creping, ensuring every roll in a batch maintains the same tactile standard.

- Chemical Purity: OBA-free fibers maintain natural structural flexibility, preventing the stiffness often caused by chemical whiteners under mechanical pressure.

Why is Microscopic Inspection Essential for Identifying Contaminants?

Microscopy reveals the physical origin of contaminants that bulk tests miss, allowing manufacturers to trace foreign matter and ensure 100% virgin wood pulp remains lint-free and chemically pure.

Detailed Morphological Analysis for Source Tracking

Stereo-microscopy provides the first line of defense by capturing physical evidence that chemical bulk analysis often overlooks. Analysts use this data to pinpoint exactly where and when foreign particles entered the production cycle.

- Visual Evidence: Captures critical data on particle size, shape, and color consistency.

- Timing Accuracy: Physical characteristics determine the exact stage of contaminant introduction during manufacturing.

- Analytical Roadmap: Morphological data guides advanced testing like SEM-EDS or Raman microspectroscopy.

- Particle Isolation: Manual separation enables sensitive chemical identification of trace materials that are too small for standard bulk methods.

Maintaining Fiber Integrity and Virgin Pulp Purity

We use microscopic verification to uphold the standards of 100% virgin wood pulp. This process prevents the inclusion of recycled waste or fragmented fibers that degrade the user experience and cause linting.

- Purity Validation: Verifies 100% virgin wood pulp fibers to exclude recycled waste and structural fragments.

- Chemical Safety: OBA-free testing confirms the absence of optical brightening agents and fluorescent whiteners.

- Natural Brightness: Monitors fiber selection to achieve 85–92% brightness without the need for aggressive chemical bleaching.

- Standard Compliance: Quality control aligns with ISO 9001 to guarantee a consistently lint-free tissue product.

How Does Wood Pulp Topography Compare to Bamboo?

Wood pulp offers uniform, separated fibers for lint-free softness, whereas bamboo uses a composite structure of vascular bundles and parenchyma, resulting in higher structural rigidity but less smoothness.

Cellular Organization of Vascular Bundles and Parenchyma

Bamboo culms function as a complex composite system rather than a collection of uniform fibers. Microscopic analysis shows that the stem consists of a heterogeneous mix, typically containing 10% vascular bundles and 50% parenchyma cells. This composition creates a dense, integrated anatomical landscape that differs significantly from the singular fiber profile of refined wood pulp.

- Vascular Gradient: Bundle concentration decreases across the radial cross-section, moving from the outer layers to the inner regions.

- Parenchyma Density: These cells average 60% at the base of the stem, declining to 40% toward the apex.

- Fiber Walls: Bamboo features thick, poly-laminated cell walls with alternating fibril orientations that increase overall rigidity.

The highest concentration of fiber bundles appears in the upper outer parts of the stem, reaching approximately 3 bundles per mm². This structural distribution provides the plant with its famous resistance, but it also creates a surface topography characterized by structural irregularities when processed for tissue.

Surface Smoothness of 100% Virgin Long-Fiber Wood Pulp

We utilize 100% virgin wood pulp to produce a high-purity surface. Unlike the raw composite structure of bamboo, wood pulp consists primarily of separated cellulosic fibers. Our chemical processing removes lignin and isolates these fibers, creating a topography that balances high tensile strength with the cloud-like softness required for premium hygiene products.

- Fiber Purity: 100% virgin long-fiber wood pulp ensures a surface free from the “splinter-like” irregularities of bamboo composites.

- Controlled Density: We maintain a strictly controlled 13–22g/m² per ply to optimize the tactile profile.

- Lint-Free Finish: The removal of non-fibrous cells during processing prevents the shedding common in less refined materials.

- Chemical Safety: All pulp remains 100% OBA-Free, ensuring the smooth surface is safe for sensitive skin without fluorescent whiteners.

The refined fibers in our multi-ply sheets provide a smoother contact point than bamboo’s lignified cell walls. This uniformity allows for precision embossing and perforation, ensuring that wholesalers receive a consistent, high-performance product that dissolves quickly in water while remaining durable during use.

Frequently Asked Questions

How does Scanning Electron Microscopy (SEM) help analyze toilet paper quality?

SEM enables direct examination of fiber fineness, density, and surface patterns at a microscopic scale. Analysts use these visuals to assess fiber diameter and porosity, which determine absorbency and tactile feel. Finer fibers, like the premium long-fiber wood pulp used in our Hebei facility, correlate with superior softness, while specific pore structures influence how effectively the sheet absorbs liquid.

How do microscopic fiber bonds influence final product softness?

Softness depends on the balance of hydrogen bonding between fibers. Reducing bond density through chemical debonders increases the distance between fibers, creating a more compliant and softer sheet. Top Source Hygiene utilizes 100% virgin wood pulp with long-fiber integrity to maintain high tensile strength while achieving a cloud-like quilted texture through precision ply-bonding.

Can microscopic analysis distinguish between virgin wood pulp and recycled fibers?

Magnification reveals clear physical differences. Virgin fibers maintain structural integrity with a higher proportion of long, coarse particles. Recycled fibers show substantial fragmentation, deteriorated microstructures, and weakened cell walls due to mechanical stress. We use genuine virgin pulp to ensure a lint-free experience and superior fiber strength for all wholesale orders.

Why is surface topography data used to evaluate skin irritation?

Topography parameters like roughness and scaliness reflect the three-dimensional organization of paper relief. Quantitative measurements help researchers track how different paper textures interact with the epidermis. Our 100% OBA-free production process and smooth virgin fibers minimize mechanical friction, making the paper safe for sensitive skin and compliant with EU hygiene standards.

What does the creping structure of tissue look like at 5000x magnification?

At 5000x magnification, creping appears as a complex network of wrinkled, compressed patterns and undulating waves. These microscopic folds provide the paper with its characteristic bulk, stretch, and softness. Precise control over these structures during manufacturing ensures high-density rolls, such as our TSH-3396 model, maintain fluffiness even after mechanical compression for 40HQ container loading.

How is SEM technology used to troubleshoot defects in high-speed production?

Automated SEM inspection systems detect microscopic defects as small as 10 nanometers by comparing production images against reference standards. This real-time analysis identifies contaminants or structural anomalies that could cause web breaks or quality inconsistencies. This rigorous monitoring at our Hebei industrial hub ensures batch color consistency and structural integrity for all wholesale container orders.

Final Thoughts

Choosing SEM-validated 100% virgin wood pulp eliminates the structural risks and linting issues common in lower-grade recycled or bamboo alternatives. Our rigorous control of ply-bonding and 13–22g/m² density ensures that every roll survives high-speed distribution while maintaining premium tactile softness. Securing inventory with verified microscopic integrity protects your dealer margins by preventing batch inconsistencies and consumer complaints.

Verify our fiber bonding and handfeel firsthand by requesting a comprehensive sample kit for your quality control team. We recommend starting with a trial 40HQ order of our best-selling TSH-2559 or high-efficiency TSH-3396 models to test market response. Contact our Hebei manufacturing specialists today to discuss private label specifications and secure your next shipment’s logistics timeline.

SEO

Title: Scanning Electron Microscopy (SEM): Mapping Tissue Surface Topography

Description: Tissue Surface Topography analysis for 100% virgin pulp. Hebei factory OEM: 13–22 GSM, OBA-free. Wholesale 40HQ containers only.

URL: tissue-surface-topography

Keywords: tissue-surface-topography