Whiteness & OBA Customization is the primary technical safeguard against the perception of low hygiene that leads to rejected shipments and damaged brand reputation. Inconsistent color management between ISO Brightness and CIE Whiteness often results in costly visual discrepancies across 40HQ container loads, impacting retail sell-through and hospitality guest satisfaction scores.

We solve these stability risks by utilizing 100% Virgin Wood Pulp to achieve a natural 85-92% brightness without unstable chemical agents. This focus on fiber purity and OBA-free engineering ensures batch color consistency and compliance with strict FDA and EU hygiene standards.

How Does the Perception of Whiteness Influence Consumer Buying Behavior?

Buyers associate bright white paper with hygiene and purity. While visual appeal drives initial choice, the 2026 market demands this aesthetic be achieved without toxic chemical additives.

Psychological Drivers and Cultural Associations of Paper Color

Visual signals dictate the first impression of hygiene. Consumers across different demographics show a consistent automatic preference for white products over darker alternatives. This isn’t just a surface-level choice; data suggests that these color associations significantly predict actual purchasing behavior in the retail and hospitality sectors.

Context matters when managing global distribution. How a buyer views a white roll depends heavily on their regional background:

- Western Markets: Whiteness is inextricably linked to purity and cleanliness, reinforcing the demand for the brightest possible household paper.

- Asian Markets: Traditional associations link white with mourning, but modern commercial settings are shifting toward the global standard of whiteness as a marker of hygiene.

- Hospitality Standards: 5-star hotels use bright white paper as a non-verbal cue for “sterile” and “premium,” influencing guest satisfaction scores.

Balancing Visual Appeal with OBA-Free Material Standards

The 2026 market presents a challenge: consumers want the visual “pop” of white paper but are increasingly wary of the chemicals used to get there. We bridge this gap by focusing on fiber purity rather than chemical masks. Achieving high brightness naturally ensures the product remains safe for sensitive skin and maintains microbiome health.

Top Source Hygiene meets these premium aesthetic expectations through strict material engineering:

- Fiber Selection: We utilize 100% Virgin Wood Pulp to provide a naturally high-purity finish.

- Natural Brightness: Our rolls achieve an 85-92% brightness level through mechanical fiber selection rather than chemical whitening.

- 100% OBA-Free: We guarantee zero Optical Brightening Agents, addressing the growing demand for fluorescent-free hygiene products.

- Compliance Standards: All materials meet ISO 9001, FDA, and EU hygiene requirements to ensure safety for high-frequency skin contact.

By focusing on the inherent quality of long-fiber wood pulp, we provide the “Super White” look that drives sales while protecting the end-user’s health. This strategy allows distributors to market a premium product that solves both the visual preference for whiteness and the technical requirement for chemical safety.

ISO Brightness vs. CIE Whiteness: Which Metric Truly Defines Your Brand?

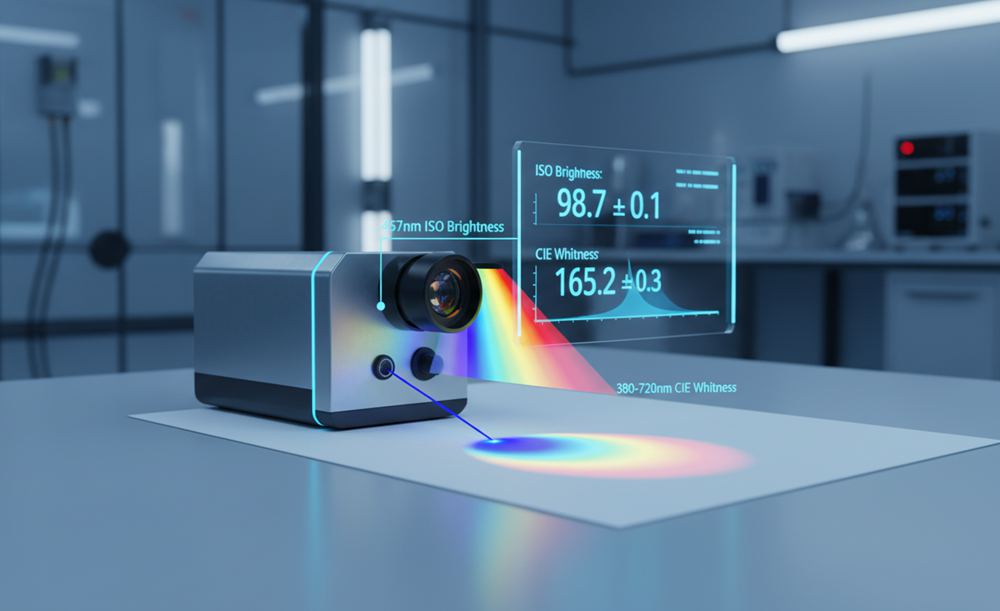

ISO Brightness measures blue light intensity, while CIE Whiteness reflects human-perceived “true white.” Managing both ensures color consistency across massive private-label container orders.

| Metric | Wavelength Focus | Human Perception | Primary Purpose |

|---|---|---|---|

| ISO Brightness | 457nm (Blue Light Only) | Reflective Intensity | Technical Material Spec |

| CIE Whiteness | 380–720nm (Full Spectrum) | True Shade (Tint/Tone) | Visual Brand Consistency |

The Technical Distinction Between Blue-Light Reflectance and Full-Spectrum Whiteness

Standardized measurements prevent visual discrepancies when shipping high-volume tissue orders. Human eyes see color balance, but narrow technical specs often miss the details. ISO Brightness (ISO 2470/2469) measures only the reflectance of blue light at a specific 457-nanometer wavelength. This tells us how “bright” the paper is but ignores the longer red and green wavelengths that define the actual shade.

CIE Whiteness uses D65 illumination to simulate natural outdoor daylight. It assesses the entire visible spectrum to determine if the paper looks neutral, bluish, or cream-toned. Two paper batches can share identical ISO Brightness values yet look completely different to a distributor if their CIE Whiteness values do not align.

- ISO 2470 Standard: Measures blue light reflectance on a scale of 0 to 100.

- CIE D65 Illumination: Evaluates full-spectrum color balance across 380–720nm.

- Shade Classification: Accounts for bluish vs. cream tones that affect consumer quality perception.

- Spectral Accuracy: Prevents batch-to-batch visual variance in large 40HQ shipments.

Achieving Natural 85-92% Brightness Through OBA-Free Fiber Selection

Top Source Hygiene prioritizes material integrity over chemical enhancements. We achieve a natural brightness range of 85-92% by selecting premium long-fiber 100% Virgin Wood Pulp from our Hebei manufacturing hub. This approach ensures the paper remains soft and strong without the brittleness caused by excessive chemical bleaching.

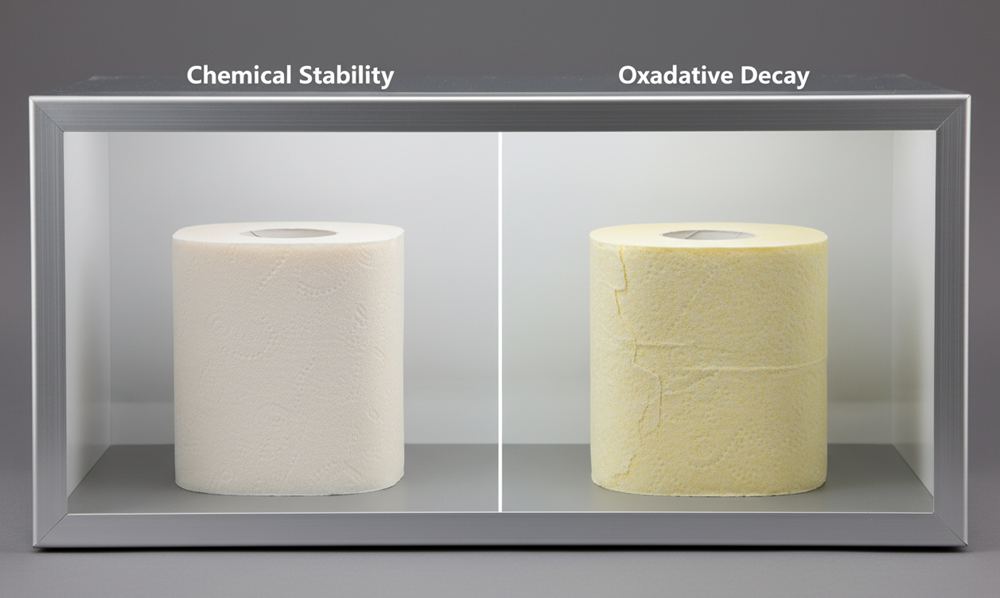

Our OBA-Free guarantee means we do not use Optical Brightening Agents to artificially inflate whiteness. While OBAs can push CIE Whiteness levels above 100%, they often cause skin irritation and lead to rapid yellowing during storage. By focusing on high-purity pulp, we maintain color stability and hygiene compliance for sensitive skin markets.

- Material Base: 100% Virgin Wood Pulp ensures a naturally bright, lint-free finish.

- Safety Standard: OBA-Free production meets EU hygiene and ISO 9001 compliance.

- Color Consistency: Strict batch protocols protect distributor reputations by ensuring uniform roll appearance.

- Storage Stability: Purer fibers resist the “vintage yellowing” effect common in low-grade recycled alternatives.

Scale Your Brand With Expert OEM Manufacturing

What Is the Strategic Role of Optical Brightening Agents (OBAs) in Perception?

OBAs mask pulp yellowing with blue-violet fluorescence. Modern B2B standards favor OBA-free, 85-92% natural brightness through premium long-fiber wood pulp to ensure total skin safety.

Color Compensation and the Fluorescence Mechanism

OBAs utilize molecular conjugated systems to absorb short-wave ultraviolet light, re-emitting it as visible blue-violet light. This physical shift fundamentally changes how the human eye processes the material surface by altering light reflection patterns.

- Light Superimposition: Emitted blue light counteracts natural gray or yellow tints inherent in wood fibers, making the surface look whiter than the base material.

- Hygiene Signaling: Visual enhancement directly influences purchasing decisions in the paper sector by signaling superior hygiene through perceived brightness.

- Market Consistency: Major players like BASF and Archroma focus on performance consistency to meet these visual consumer expectations across batches.

Natural Brightness and 100% OBA-Free Safety Standards

Top Source Hygiene replaces chemical fluorescence with high-grade raw material selection. We rely on the inherent quality of virgin fibers to meet aesthetic requirements while maintaining a strict safety profile for professional environments.

- Natural Brightness: We achieve an 85-92% brightness level through premium long-fiber wood pulp selection rather than chemical bleaching agents.

- 100% OBA-Free Guarantee: This standard ensures no fluorescent whiteners contact sensitive skin or the microbiome, preventing irritation in hospitality and healthcare settings.

- Tensile Strength: Virgin wood pulp maintains higher structural integrity and a lint-free texture compared to recycled fibers that require heavy OBA loading.

- Certification Alignment: Our process follows ISO 9001 and FDA hygiene standards, requiring strict control over chemical additives to ensure user safety.

How to Custom-Engineer Whiteness for Hospital vs. Eco-Luxury Markets?

Clinical markets prioritize high-opacity TiO2 and FDA-grade purity for sterility, while eco-luxury demands 100% OBA-free virgin pulp achieving natural brightness through fiber selection rather than chemicals.

Engineering High-Opacity and Regulatory Purity for Clinical Environments

Hospital and clinical environments view whiteness as a functional signal of sterility. In these settings, the technical focus shifts away from aesthetic “warmth” toward maximum light-blocking capabilities and hygiene compliance. Engineering for this sector requires a heavy reliance on mineral pigments and high-durability resins that can withstand medical-grade processing.

- TiO2 Loading: We use high-opacity TiO2 loading between 35-75% to create uniform, bright surfaces that satisfy sterile environment protocols.

- Regulatory Purity: Formulations must maintain 100% FDA and EU hygiene compliance for medical device packaging and direct clinical contact.

- Thermal Stability: We prioritize base material stability to prevent yellowing or degradation during intense autoclaving and chemical disinfection cycles.

- Contamination Control: High-integrity fibers ensure a lint-free experience, preventing particle contamination in sensitive hospital zones.

Customizing OBA-Free Natural Brightness for the Eco-Luxury Segment

The eco-luxury market rejects synthetic appearance in favor of “clean” sustainability. Achieving premium whiteness without chemicals is a matter of fiber quality and mechanical finishing. For these high-end brand owners, the goal is a soft, natural white that communicates safety and environmental responsibility.

- Fiber Selection: We utilize premium long-fiber 100% Virgin Wood Pulp to reach natural brightness levels of 85-92% without chemical bleaching.

- OBA-Free Guarantee: We maintain 100% OBA-Free production lines to meet the demand for skin-safe, non-fluorescent hygiene products.

- Optical Texture: Our CNC-precision point-to-point embossing enhances light reflection, using texture to increase perceived whiteness naturally.

- Sustainable Purity: High-purity fiber selection replaces synthetic brighteners, allowing products to meet strict environmental and ISO certifications.

Can You Successfully Manage Whiteness Stability During Long-Term Storage?

Yes. Maintain storage at 25°C and 30% humidity. Using 100% OBA-free virgin pulp prevents the chemical yellowing common in low-tier products during extended global shipping cycles.

Standard wood pulp fibers degrade during storage, but the rate of decay depends entirely on the environment. High-brightness paper relies on specific fiber structures that react poorly to heat and moisture. When temperature and humidity fluctuate, the chemical composition of the paper shifts, leading to brittleness and a visible loss of aesthetic appeal.

Impact of Temperature and Humidity on Fiber Degradation

Heat acts as a catalyst for acid hydrolysis, a chemical breakdown process that destroys whitening compounds. In 2026 global shipping routes, freight environments often reach extreme levels that jeopardize material integrity before the product even reaches the warehouse.

- Temperature Ceiling: Maintaining storage at 25°C (77°F) prevents acidity spikes of over 120% in pulp-based products.

- Thermal Resistance: Extreme freight temperatures reaching 165°F cause a significant loss of brightness and tensile strength.

- Humidity Control: Relative humidity of 30% stops water absorption that leads to fiber swelling and texture changes.

- Climate Barriers: Controlled warehousing serves as a critical defense against heat-induced potency loss in finished rolls.

Achieving Batch Color Consistency with OBA-Free Virgin Pulp

Top Source Hygiene avoids the use of Optical Brightening Agents (OBAs) to ensure long-term stability. While OBAs create a temporary blue-white glow, they are chemically unstable and yellow rapidly when exposed to UV light or heat. We rely on high-purity raw materials to maintain a natural, stable brightness.

- Purity Standards: 100% Virgin Wood Pulp offers higher stability than recycled alternatives containing residual contaminants.

- OBA-Free Stability: Removing brighteners eliminates the risk of chemical breakdown and yellowing under environmental stress.

- Natural Brightness: We achieve 85-92% brightness levels through fiber selection rather than adding unstable chemical additives.

- Uniformity Protocols: Rigid quality control ensures batch color consistency across 40HQ container loads, even through extended logistics cycles.

Wholesalers and distributors must prioritize these technical specs to protect their inventory value. Products engineered in the Hebei Paper Industrial Hub utilize long-fiber wood pulp to balance this visual stability with the tensile strength required for premium household and commercial rolls.

Is the Rise of “Unbleached” Natural Pulp a Threat or an Opportunity for Your Brand?

Unbleached pulp presents a $28.4 billion opportunity for brands to meet OBA-free demand and regulatory standards through sustainable fiber diversification like bamboo.

Consumer and Regulatory Shifts Toward Unbleached Fibers

The unbleached kraft pulp market provides a clear path for growth, moving toward a projected $28.4 billion valuation by 2026. This isn’t a temporary trend; it’s a shift in procurement strategy driven by both legislative pressure and buyer psychology.

- Market Growth: Global demand for unbleached softwood kraft pulp maintains a 4.6% CAGR.

- Regulatory Pressure: North American and European bans on single-use plastics accelerate the move to fiber-based hygiene and packaging.

- Aesthetic Shift: Professional buyers recognize that consumers now associate unbleached, cream-toned fibers with “purity” and chemical-free safety.

Customizing Eco-Friendly Lines with Bamboo and OBA-Free Pulp

Top Source Hygiene helps brands build these sustainable lines using specific fiber blends. We move away from high-brightness bleaching to focus on natural fiber integrity and skin safety.

- Fiber Diversity: We offer bamboo and recycled pulp options for eco-targeted private label orders.

- 100% OBA-Free: Every roll is guaranteed free of fluorescent agents, meeting strict microbiome and sensitive skin safety standards.

- Infrastructure Compliance: Our unbleached alternatives maintain rapid disintegration properties to stay septic-safe in North American and European markets.

- Natural Brightness: Our fiber selection process achieves an 85-92% brightness level without chemical assistance.

Frequently Asked Questions

What are the standard whiteness levels for premium toilet paper in 2026?

Premium toilet paper usually targets 88-92 ISO brightness. While marketing often highlights softness or ply count, technical quality is verified by ISO 2469 and 2470 standards. Top Source Hygiene reaches a natural brightness of 85-92% by selecting high-purity long-fiber wood pulp rather than relying on heavy chemical bleaching.

How do ISO Brightness and CIE Whiteness measurements differ?

ISO Brightness measures the reflectance of blue light at a specific 457nm wavelength. CIE Whiteness is a broader metric that evaluates the entire visible spectrum (380–720 nm) under D65 illumination. ISO tells you the intensity of the light, but CIE describes the actual shade and neutrality of the white paper.

Is 100% OBA-Free toilet paper better for sensitive skin?

Optical Brightening Agents (OBAs) stay on the fibers and can cause contact dermatitis or rashes in sensitive users. Using 100% OBA-Free products, like those from Top Source Hygiene, removes the risk of fluorescent whitener exposure. This makes the paper safer for individuals with eczema or skin allergies.

Why does high-brightness paper yellow over time in storage?

Yellowing is caused by acid hydrolysis and the breakdown of wood pulp fibers. UV light exposure and stressors like high humidity or fluctuating temperatures in bathrooms speed up this chemical degradation. These factors cause whitening compounds to lose effectiveness and the paper to discolor.

Can distributors request custom whiteness levels for private label orders?

B2B manufacturers allow for specific whiteness engineering. Brands can choose 100% Virgin Wood Pulp for a premium white finish or natural, unbleached bamboo pulp for eco-conscious market segments. These customization options are available for 40HQ container orders at Top Source Hygiene.

How does wood pulp compare to bamboo pulp in natural color?

Virgin wood pulp naturally reaches high brightness levels after chemical processing. Bamboo pulp maintains a characteristic yellowish or beige tone because it is processed without fluorescent agents. This natural color is an inherent trait of the bamboo fiber rather than a quality deficiency.

Final Thoughts

Relying on chemical brighteners risks inventory yellowing and skin safety complaints that erode distributor reputations. Our 100% Virgin Wood Pulp achieves a natural 85-92% brightness, ensuring your stock remains stable and premium throughout long global shipping cycles. Investing in material purity protects your margins from the high cost of quality disputes and returned shipments.

Review our “Big 10” inventory to see how our OBA-free standards align with your regional market requirements. We recommend requesting a sample pack to verify the texture and full-spectrum whiteness under your local lighting conditions. Contact our Hebei manufacturing team today to secure a production slot for your next private label 40HQ container.