Choosing between virgin vs recycled (quality) paper is no longer just a procurement preference; it is a decision that dictates your facility hygiene standards and long-term plumbing maintenance costs. In high-traffic commercial environments, the wrong fiber type leads to increased dispenser downtime, higher consumption rates, and a measurable rise in cross-contamination risks. Facilities that ignore these technical specifications often see an immediate spike in janitorial labor costs and tenant complaints regarding skin irritation and lint buildup.

This technical comparison breaks down the structural differences between virgin wood pulp and recycled fibers, focusing on wet-strength performance, dust emission levels, and chemical purity. We evaluate the impact of fiber length on tensile strength and provide a specific framework for identifying low-grade recycled shipments before they reach your restrooms. By understanding the manufacturing standards for whiteness, brightness, and microbial safety, you can establish a procurement SOP that balances environmental goals with the rigorous performance requirements of sensitive professional spaces.

Why is 100% Virgin Wood Pulp the Gold Standard for Hygiene?

Virgin wood pulp provides the highest microbial safety and structural integrity in the hygiene industry, ensuring a lint-free, high-absorbency performance that recycled fibers cannot replicate.

Superior Fiber Integrity and Softness

Virgin wood pulp relies on long, intact cellulose fibers harvested directly from timber. These natural fibers maintain their structural geometry, creating a smooth surface texture that minimizes skin abrasion. In high-traffic hospitality and healthcare settings, this physical property reduces irritation for sensitive users while maintaining high tensile strength. Unlike recycled alternatives that often shred under tension, virgin pulp ensures the paper remains intact during use, even when fully saturated.

The inherent capillary action of long-fiber pulp maximizes liquid retention. Users find that fewer sheets achieve the necessary absorption, which effectively lowers the total volume of waste generated in commercial facilities. Top Source Hygiene utilizes this 100% virgin material to reach a ply density of 13–22g/m², balancing a cloud-like feel with the durability required for heavy-duty institutional applications.

| Performance Metric | 100% Virgin Wood Pulp | Recycled Paper Fiber |

|---|---|---|

| Bacterial Count | Extremely Low / Sterile Base | 100x to 1000x Higher |

| Fiber Length | Long & Unbroken | Short & Brittle |

| Chemical Purity | OBA-Free / FDA Compliant | May contain Inks & BPA |

Unmatched Purity and Microbial Safety

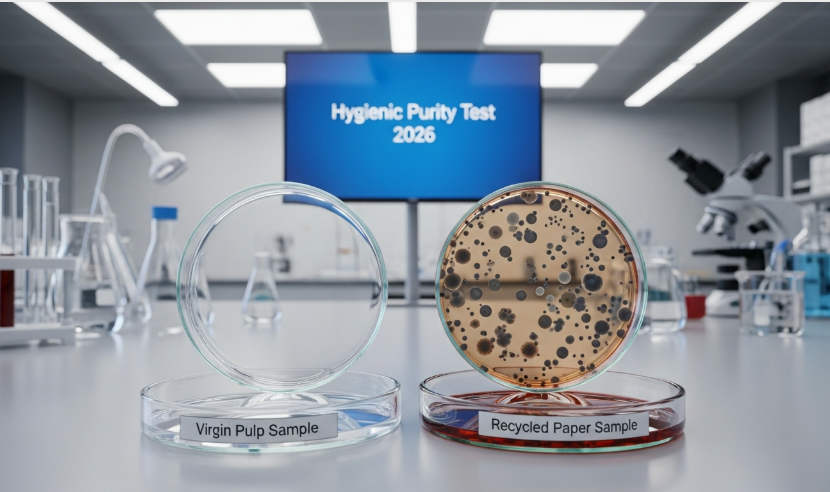

Contamination risks represent a primary concern in the B2B hygiene sector. Recycled paper streams often carry residues from inks, adhesives, and heavy metals that survive the de-inking process. Virgin wood pulp eliminates these variables entirely because the fibers have never been exposed to post-consumer waste. This purity is essential for medical-grade products and facial tissues where chemical safety is non-negotiable.

Research indicates that virgin pulp production avoids the accumulation of bacteria-harboring starches found in recycled mills. Top Source Hygiene guarantees that all products remain 100% OBA-Free, meaning we use no fluorescent whiteners. This commitment ensures our paper meets ISO 9001 and FDA standards, providing a safe solution for users with respiratory sensitivities or dermatological concerns.

Consistent Quality for Global Branding

OEM and ODM clients require batch-to-batch uniformity to protect their brand reputation. Virgin pulp offers a natural, stable whiteness (85-92%) that allows for precise custom embossing and logo printing. Because the fiber morphology is consistent, we maintain standardized GSM across our 2,860-ton monthly capacity. This reliability prevents the “lottery” effect often seen with recycled shipments, where texture and color vary wildly based on the waste source.

- Uniform Whiteness: Achieved through fiber selection rather than heavy chemical bleaching.

- Precise Embossing: Point-to-point CNC technology increases absorbency by 30% on virgin surfaces.

- Global Compliance: Naturally meets North American and European septic-safe and disintegration standards.

Would you like me to provide a detailed comparison of freight costs for 40HQ containers across our virgin pulp product line?

How Does Recycled Paper Compare in Terms of Softness and Dust?

Recycled fibers undergo structural degradation during repeated pulping cycles, leading to a significant increase in bacterial concentration and airborne dust compared to 100% virgin wood pulp.

Texture and Fiber Structural Differences

The tactile quality of tissue products depends on the physical integrity of cellulose fibers. Virgin paper utilizes long, intact fibers harvested directly from timber, which creates a naturally smooth and pliable surface. In contrast, the recycling process involves mechanical refining that shortens and weakens these fibers with every cycle. Once a fiber has been processed multiple times, it loses its ability to flex, resulting in a coarse, sandpaper-like texture that fails to meet the comfort standards required for premium hygiene products.

| Performance Metric | 100% Virgin Wood Pulp | Recycled Fiber Pulp |

|---|---|---|

| Fiber Integrity | Long, unbroken cellulose chains | Shortened, brittle fibers (5-7 cycles max) |

| Bacterial Load | Ultra-low; naturally sterile processing | 100x to 1,000x higher concentrations |

| Dust Generation | Lint-free; high tensile resilience | High; brittle fibers break during use |

| Standard Brightness | Natural 85-92% (OBA-Free) | Dull grey or off-white appearance |

Top Source Hygiene prioritizes fiber length consistency to maintain high softness ratings in 2026. By avoiding the mixed waste streams common in recycled production, we ensure that every roll maintains the “cloud-like” feel that B2B buyers in the hospitality sector demand. This focus on material purity eliminates the variability that often plagues recycled shipments.

Bacterial Concentration and Manufacturing Hygiene

Hygiene standards diverge sharply when examining the microbial environments of these two materials. Research from Laval University indicates that recycled paper often harbors bacterial concentrations significantly higher than those found in virgin wood pulp. These microorganisms thrive within the de-inking and cleaning stages required to treat post-consumer waste. Furthermore, recycled processes often involve starches that act as nutrients for bacteria, leaving behind slime residues that compromise the final product’s sanitary profile.

Virgin paper production avoids these contamination risks entirely. Because the pulp has never been exposed to external contaminants or repeated processing cycles, it maintains a level of chemical and biological purity essential for healthcare and food-contact environments. Commercial facilities with high foot traffic select virgin fiber specifically to minimize the risk of spreading pathogens in sensitive areas.

Industrial Performance and Application Standards

Performance metrics such as linting and durability dictate the suitability of paper for B2B applications. Recycled paper is prone to “dusting”—the release of fine cellulose particles—because its brittle, short fibers break easily during mechanical dispensing or use. This creates maintenance issues in high-end office spaces and luxury hotels where dust accumulation on surfaces is unacceptable. Virgin wood pulp, with its superior tensile strength and wet-condition resilience, provides a lint-free experience and better absorbency.

- Hospitality buyers utilize virgin pulp to ensure “hotel-grade” aesthetics and 90%+ brightness without using harmful fluorescent whiteners.

- Healthcare sectors rely on the structural integrity of virgin fibers to prevent shredding in wet environments.

- Bulk wholesale distributors prefer virgin wood pulp for its consistent quality, which reduces returns and buyer dissatisfaction.

While recycled options exist for low-tier value projects, the 2026 market has shifted toward virgin pulp as the primary solution for performance-driven B2B procurement. The balance of skin-friendly softness and high-wet-strength durability remains unmatched by recycled alternatives.

Scale Your Brand With Premium OEM Toilet Paper

Is Virgin Pulp More Sustainability Than You Might Think?

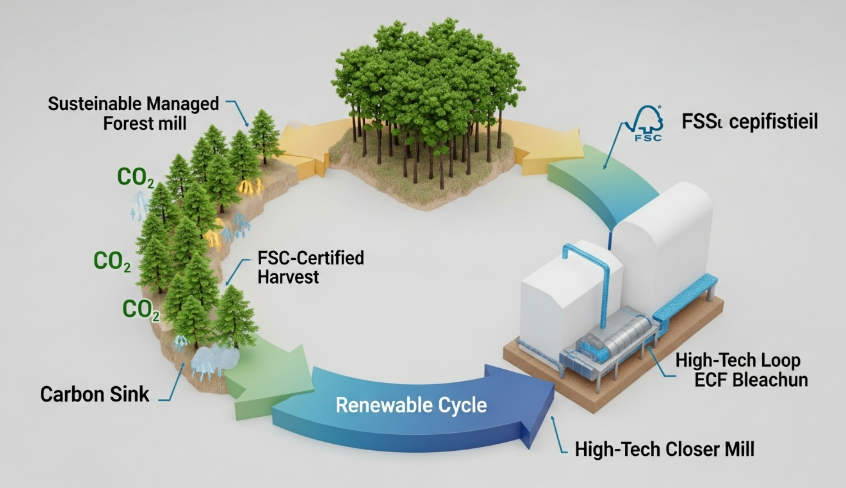

Modern virgin fiber production utilizes managed forest cycles and closed-loop manufacturing to offer a scalable, low-contamination alternative to the chemically intensive recycling of degraded fibers.

Certified Forest Management and Renewable Cycles

Sourcing virgin wood pulp in 2026 relies on a sophisticated ecosystem of managed forests that serve as active carbon sinks. Top Source Hygiene utilizes FSC-certified materials, ensuring that every harvest follows strict international protocols for biodiversity and soil health. Because young, rapidly growing trees sequester CO2 at a higher rate than stagnant, unmanaged timberland, these professional cycles play a vital role in climate mitigation.

For every tree harvested for pulp, we ensure multiple saplings are planted, creating a perpetual resource loop. This regenerative approach prevents the depletion of natural habitats while maintaining the long-term health of the global wood supply. Professional forest management shifts the conversation from extraction to cultivation, turning the hygiene supply chain into a renewable engine.

Energy Efficiency and Chemical Safety in Production

Manufacturing virgin pulp often demands lower chemical intensity than the aggressive de-inking required for post-consumer waste. Our facilities in the Hebei paper industrial hub employ elemental chlorine-free (ECF) bleaching, which prevents harmful runoff and preserves the integrity of the local water table. In contrast, recycled paper must undergo multiple cycles of chemical stripping to remove adhesives, dyes, and synthetic inks.

| Sustainability Metric | 100% Virgin Wood Pulp | Recycled Paper Fiber |

|---|---|---|

| Chemical Usage | Low (ECF/TCF Bleaching) | High (De-inking/Solvents) |

| Bacterial Levels | Near-Zero (Purity Guarantee) | 100x to 1,000x Higher |

| Water Systems | Closed-Loop Recovery | Variable Efficiency |

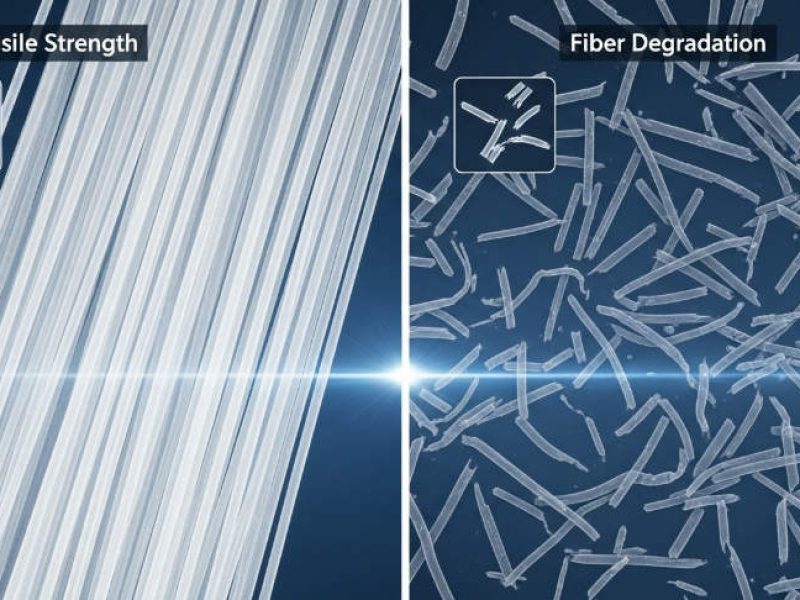

The Infinite Loop Myth and Fiber Degradation

A common misconception suggests that paper can be recycled indefinitely. In reality, cellulose fibers shorten and weaken each time they pass through a pulping plant, typically losing structural viability after five to seven cycles. Virgin wood pulp provides the essential injection of long, strong fibers needed to keep the global paper cycle functioning. Without this fresh supply, the entire industry would face a collapse in product quality and durability.

- Virgin fibers provide the tensile strength required for high-performance 5-ply toilet paper.

- Managed forest intake prevents the fiber pool from becoming exhausted and brittle.

- High-purity virgin pulp eliminates the risk of heavy metal or ink residue contamination.

By integrating virgin fiber into the supply chain, we create durable hygiene solutions that satisfy the strict plumbing and safety standards of North America and Europe. This ensures that even the most demanding B2B clients receive consistent, high-wet-strength products that perform reliably under high-traffic conditions.

Would you like me to analyze the specific container loading efficiencies of our virgin wood pulp bundles for your next 40HQ shipment?

Why Do Sensitive Environments Require Virgin Fiber Purity?

Virgin wood pulp eliminates the risk of cross-contamination from legacy inks and pathogens, ensuring compliance in medical and food-service facilities where recycled alternatives fail safety benchmarks.

High-stakes environments like hospitals, commercial kitchens, and food processing plants operate under zero-tolerance policies for chemical leaching and bacterial growth. While recycled paper serves general office needs, it carries a legacy of previous uses. Virgin fibers have never undergone industrial processing before their current application, meaning they lack the chemical residues—such as heavy metals, phthalates, and mineral oil hydrocarbons—frequently found in de-inked recycled stocks.

Chemical Purity and Food Safety Compliance

Standard recycled paper can contain up to 138 distinct chemical compounds, including bisphenols (BPA/BPS) and solvents from original printing inks. In contrast, Top Source Hygiene utilizes 100% virgin wood pulp to bypass these risks entirely. This raw material purity allows products to meet FDA and EU 10/2011 standards naturally, without the need for intensive chemical detoxification or OBA (Optical Brightening Agent) additives.

The absence of these contaminants also prevents sensory transfer. For food-contact paper, ensuring that the material does not impart off-flavors or odors to the product is a critical performance metric. Virgin fibers provide a neutral profile that protects the integrity of the end-user’s experience in the hospitality sector.

Structural Integrity and Performance Reliability

The physical strength of a hygiene product depends on the length and bonding capacity of its cellulose fibers. Every time paper is recycled, the fibers shorten and weaken, eventually losing their ability to hold together under stress. Virgin wood pulp retains its full-length long fibers, which translates directly to higher tensile strength and better wet-state performance.

In high-traffic commercial zones, this durability reduces waste. A single sheet of high-density virgin fiber paper often performs the work of multiple recycled sheets because it resists shredding and maintains high absorbency. For items like jumbo rolls and heavy-duty kitchen towels, virgin fiber ensures the product does not fail when exposed to moisture or grease.

Traceability and Regulatory Assurance

Sensitive sectors rely on documented safety. Virgin fiber sourcing provides a transparent chain of custody from the forest to the final roll. Top Source Hygiene utilizes FSC-certified sources, offering B2B clients full traceability that simplifies audits and regulatory filings for healthcare and hospitality groups.

By opting for virgin fibers, procurement teams reduce the need for constant, expensive batch testing for contaminants like lead or cadmium, which are mandatory for recycled lots in certain jurisdictions. This consistency streamlines the supply chain and guarantees that every shipment meets the “Pure Quality” standard required for professional care.

Would you like me to develop the technical specifications for our 100% OBA-Free hospitality rolls for your next procurement guide?

How to Identify Low-Quality Recycled Paper in a Shipment?

Distinguishing high-tier recycled stock from degraded waste requires a rigorous shift from tactile guesswork to standardized fiber analysis and contaminant screening.

Visual Homogeneity and Surface Contaminants

Surface inspection serves as the first line of defense against poor processing. We look for “stickies”—residual adhesives or microscopic metal fragments—that signify a failure in the repulping and cleaning stages. A uniform surface without clumps suggests proper fiber distribution, whereas visible ink residues or dark spots indicate inadequate de-inking. These contaminants do not just affect aesthetics; they compromise the hygiene profile and bacterial safety of the final product.

Fiber Integrity and Reject Mass Analysis

Technical analysis focuses on fiber yield to separate high-quality recycled streams from those burdened by excessive “reject mass.” Repeated recycling cycles shorten cellulose fibers, leading to a brittle texture and significantly higher dust levels during converting. We evaluate whether the stock requires heavy supplementation with virgin wood pulp just to achieve baseline tensile strength. If the paper sheds easily or lacks wet-strength resilience, the fiber integrity has likely passed its 5-7 cycle limit.

Standardized Testing and Compliance Documentation

Professional procurement relies on industry-recognized protocols like CEPI, PTS-RH, or Aticelca. These frameworks move beyond subjective assessment to provide a quantifiable grade of recyclability and purity. We utilize optical spectroscopy data to confirm the chemical composition of the waste stream, ensuring it remains free from hazardous residues like bisphenol A or heavy metals found in poorly managed collections. Aligning with 2026 sustainability benchmarks ensures the shipment meets both economic and regulatory requirements for global export.

What Are the Whiteness and Brightness Standards for B2B Paper?

Standardized measurement of blue light reflectance and full-spectrum color balance allows B2B buyers to verify paper quality and chemical safety across global supply chains.

Industry experts utilize ISO Brightness to quantify how paper reflects blue light at a 457 nm wavelength. This metric serves as a primary indicator of brilliance in commercial office-grade and high-end hygiene products. Standardized measurements ensure that paper consistency remains uniform regardless of the production batch or manufacturing location.

- Global consistency relies on standards established by ISO and TAPPI (Technical Association of the Pulp and Paper Industry).

- High-performance papers typically fall within the 80 to 100 range for brightness.

- The value dictates how vivid the paper looks under specific laboratory and retail lighting conditions.

CIE Whiteness and Color Balance

CIE Whiteness evaluates the paper’s appearance across the entire visible spectrum to ensure a neutral color profile. This standard helps prevent products from appearing aged or dull by managing the delicate balance between blue and yellow tints. For B2B applications where professional presentation is a requirement, maintaining a “true white” is essential for brand integrity.

- The International Commission on Illumination governs these measurements to define a perfect white.

- Accurate whiteness prevents the paper from appearing yellow or grey under natural light.

- Color-critical branding depends on high CIE values to ensure a clean, premium aesthetic.

The Role of Optical Brightening Agents (OBAs)

Manufacturers like Top Source Hygiene control the use of Optical Brightening Agents (OBAs) to meet specific market demands for whiteness. These chemicals enhance visual appeal by converting ultraviolet light into visible blue light. While OBAs boost brightness, many modern buyers now prioritize chemical purity and skin-safe standards over artificial whiteness.

- Top Source Hygiene provides OBA-free options for clients who require maximum chemical purity and eco-friendly standards.

- North American and European markets often enforce different regulatory standards for chemical additives in 2026.

- Strategic management of additives allows for high visual standards without sacrificing the inherent strength of the virgin wood fibers.

How Does Fiber Length Impact the Performance of Your Toilet Paper?

Fiber morphology serves as the structural DNA of hygiene tissue, where the ratio of long-chain softwood fibers to short hardwood fibers dictates the ultimate balance between industrial-grade tensile strength and premium tactile softness.

Fiber length directly determines how well a sheet holds together under stress. Longer fibers, typically sourced from softwood trees, create an intricate web of overlapping bonding points. This network provides the necessary structural framework to prevent the paper from tearing easily, which is a critical performance metric for B2B buyers in the hospitality and commercial sectors. When paper encounters moisture, these long-fiber chains maintain their integrity, reducing the likelihood of sheet degradation or “shredding” during use.

| Performance Metric | Long-Fiber (Virgin Pulp) | Short-Fiber (Recycled) |

|---|---|---|

| Tensile Strength | High; resists tearing when wet | Low; prone to disintegration |

| Surface Linting | Minimal; fibers remain anchored | Significant “dusting” effect |

| Tactile Texture | Luxurious, smooth finish | Rough, scratchy feel |

The Role of Long Fibers in Tensile Strength

Top Source Hygiene utilizes 100% virgin wood pulp to ensure high fiber integrity, meeting 2026 global hospitality standards. This reliance on virgin fiber ensures that every roll possesses high wet-strength durability. Because these fibers have not undergone the punishing de-inking and mechanical pulping cycles associated with recycled materials, they retain their full natural length and bonding capacity. This results in a product that can withstand high-pressure manufacturing processes and rigorous daily use without failing.

Short Fibers and the Softness Trade-off

While long fibers provide the “skeleton” of the paper, shorter fibers—typically from hardwood—act as the “filler” that creates a smooth, velvet-like surface. Expert manufacturing balances these two types to optimize the user experience. However, a major disadvantage of recycled paper is the unintentional shortening of fibers. Each time paper is recycled, the fibers break, eventually becoming too short to bond effectively. This leads to a rougher texture and high dust levels, as the tiny fiber fragments easily detach from the sheet.

Impact on Absorbency and Durability

Proper fiber alignment and morphology dictate how well the paper holds liquid while maintaining its shape. We engineer our tissue to handle up to 2,860 tons of monthly production pressure while preserving the delicate balance of softness and absorbency. For eco-conscious markets, emerging materials like bamboo offer naturally longer fibers compared to many traditional recycled blends, providing a robust and lint-free alternative. Strategic fiber selection prevents the common “linting” effect found in low-quality products, ensuring a clean and professional experience in commercial environments.

Would you like me to analyze the specific fiber blend ratios of our TSH-4010 luxury series for your next procurement report?

Conclusion

Choosing between virgin wood pulp and recycled fiber determines the balance of softness, strength, and hygiene safety for your end users. High-quality virgin pulp ensures a lint-free, OBA-free experience that meets strict international standards for sensitive environments. Prioritizing these technical specifications helps prevent plumbing issues and maintains consistent product quality across large-scale B2B shipments.

Review your current inventory requirements to see if our 100% virgin wood pulp models align with your market needs. We can provide technical datasheets or production samples to assist with your next procurement cycle.

Frequently Asked Questions

Is virgin pulp better than recycled?

Virgin pulp is generally considered superior for premium hygiene products because it consists of longer, stronger fibers that provide better softness and absorbency. While recycled paper is an eco-friendly alternative for certain applications, virgin wood pulp remains the industry standard for high-end comfort and structural integrity.

Does recycled paper have chemicals?

Recycled paper often requires chemicals during the de-inking and processing stages to remove residues like inks, dyes, and adhesives. In contrast, modern virgin pulp production utilizes advanced elemental chlorine-free (ECF) and totally chlorine-free (TCF) bleaching technologies to ensure a clean, high-purity final product.

Which is softer: virgin or bamboo?

Virgin wood pulp is typically softer than bamboo. While bamboo is a sustainable alternative, wood-based virgin fibers can be engineered for maximum plushness and skin comfort, making them the preferred choice for premium “ultra-soft” tissue categories.

Is virgin pulp sustainable?

Yes, virgin pulp is highly sustainable when sourced through responsibly managed forests. The industry validates environmental credentials through FSC and PEFC certifications, ensuring forest regeneration and low-impact production processes such as closed-loop water recycling systems.

Why is some paper so dusty?

Paper dust is usually the result of shorter, weaker fibers breaking off during use, which is common in low-quality or recycled products. Premium virgin pulp uses longer, more durable fibers that bond together more effectively, significantly reducing the amount of lint and dust produced.

What is the whitest toilet paper?

The whitest toilet paper is made from 100% virgin wood pulp treated with TCF (Totally Chlorine Free) or ECF (Elemental Chlorine Free) bleaching. These processes achieve high brightness and purity without the gray or off-white undertones often found in recycled paper products.