Mastering 1. The Fiber Science is the primary defense for brand owners against the high cost of retail returns. Choosing the wrong pulp geometry leads to surface linting and structural failure, which drains the margins of high-volume distributors.

We evaluate wood and bamboo against the 13–22 GSM density standard and OBA-Free requirements. This structural comparison helps wholesalers identify the specific material properties needed for durable, septic-safe 40HQ container shipments.

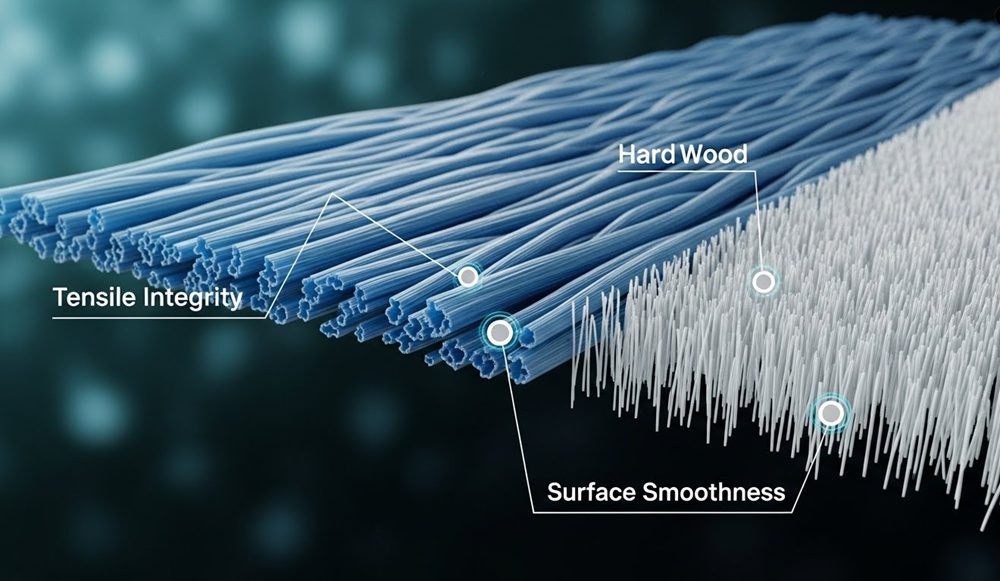

Hardwood/Softwood Blends: The Secret to Wood Pulp’s Versatility

Blending long-fiber softwood for structural strength with short-fiber hardwood for surface smoothness creates high-tensile, skin-friendly tissue optimized for premium multi-ply retail and commercial configurations.

| Fiber Category | Wood Sources | Fiber Length | Primary Benefit |

|---|---|---|---|

| Softwood | Pine, Spruce, Fir | 2.0 – 4.0 mm | Tensile strength and flexibility |

| Hardwood | Eucalyptus, Birch, Aspen | 1.0 – 1.5 mm | Surface smoothness and bulk |

Structural Synergy Between Long and Short Wood Fibers

Softwood fibers provide the internal “skeleton” of a tissue sheet. Because these fibers reach up to 4 mm, they interlock to create a reinforced framework. This structure allows the paper to withstand pulling and wet-use without disintegrating.

Hardwood fibers fill the gaps within that softwood framework. They collapse into flat, ribbon-like shapes during manufacturing. This creates a compact, lint-free surface that eliminates the scratchy feel often found in low-grade paper.

- Standard Fiber Ratio: Premium retail tissue typically uses a 35% softwood and 65% hardwood mix.

- Formation Quality: Shorter hardwood fibers improve sheet formation, ensuring the surface remains even and predictable.

- Absorbency Balance: The blend maintains high vertical wicking capacity without sacrificing the physical integrity of the 2-ply or 3-ply structure.

Engineering High-Tensile Strength in 100% Virgin Pulp Products

Top Source Hygiene utilizes 100% virgin wood pulp to ensure maximum fiber length. Recycled alternatives contain shortened, brittle fibers that compromise strength. By focusing on pure North China virgin pulp, we achieve the durability required for ultra-soft 4-ply and 5-ply rolls.

We control technical parameters to balance softness with performance. This allows high-traffic hospitality groups and retail distributors to offer a product that feels soft but performs under heavy-duty use.

- GSM Control: Each ply is strictly maintained between 13–22g/m² to ensure the ideal balance of thickness and softness.

- Ply-Bonding Technology: We use high-pressure lamination to bond layers together without chemical adhesives, preserving a quilted texture.

- 100% OBA-Free: The fiber blend stays safe for sensitive skin by excluding optical brightening agents and fluorescent whiteners.

- Septic Safety: Despite high tensile strength, our engineering ensures the fiber network dissolves rapidly in water to prevent plumbing clogs.

Bamboo’s Long Fiber Structure: Is It Too Stiff for Facial Use?

Modern processing adapts naturally rigid bamboo fibers into soft, facial-grade tissue by controlling ply density between 13–22 GSM and utilizing precision mechanical softening techniques.

Mechanical Rigidity of Aligned Cellulose Microfibrils

Bamboo fibers are biologically built for structural support, not immediate comfort. The semicrystalline lignocellulosic microfibrils align tightly along the fiber axis. This specific orientation maximizes longitudinal stiffness and explains why raw bamboo feels significantly harder than hardwood or softwood alternatives.

Data from raw material testing shows untreated fiber bundles exhibit a tensile strength of approximately 858 MPa. This rigidity varies based on the maturity and location of the plant:

- Fiber Maturity: Five-year-old bamboo shows significantly higher bending properties and rigidity than younger culms.

- Vertical Position: Fibers taken from the top portions of the plant have different geometry and elasticity compared to those from the base.

- Tensile Strength: The 858 MPa rating ensures durability but requires aggressive mechanical intervention to become skin-friendly.

Softness Engineering through 13–22 GSM Ply Density

To meet 2026 facial tissue standards, we convert raw bamboo pulp into ultra-fine material using specific manufacturing parameters. The primary tool for managing stiffness is ply density control. By maintaining a strict 13–22g/m² density per ply, we balance the fiber’s inherent strength with tactile softness.

Our factory processes rely on several mechanical adjustments to ensure the final product is safe for sensitive skin and comfortable for daily use:

- Multi-ply Lamination: High-pressure bonding keeps 2-ply to 5-ply layers together without adding chemical adhesives that increase stiffness.

- 100% OBA-Free Processing: We avoid optical brightening agents, relying on fiber selection to achieve an 85-92% natural brightness level.

- Point-to-Point Embossing: CNC-precision patterns break up fiber rigidity, increasing surface flexibility and absorbency by 30%.

- Mechanical Fine Processing: This converts raw pulp into 100% OBA-free material, removing the “woody” feel while retaining the high tensile strength bamboo is known for.

These engineering steps ensure that while the fibers remain strong enough to prevent tearing, the surface texture remains gentle enough for facial applications in the premium retail and hospitality sectors.

Build Your Unique Toilet Paper Brand

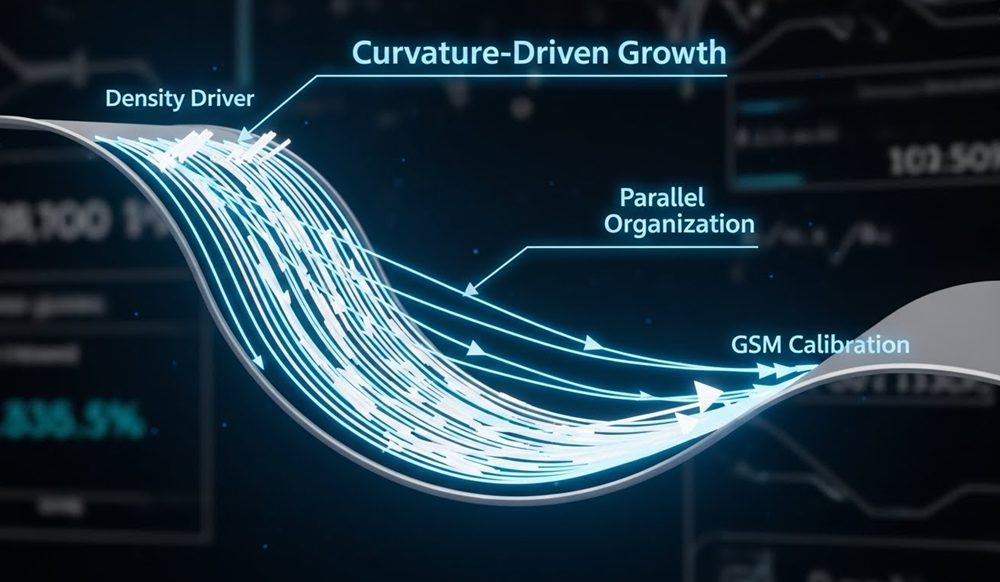

How Fiber Geometry Affects the Final Tissue Density

Fiber curvature and channel perimeters drive material deposition rates. We use virgin wood pulp and precise GSM calibration to ensure consistent tissue density across every roll.

The physical shape of a fiber determines how it settles during the manufacturing process. Density isn’t just a result of weight; it is a mechanical outcome of how local geometric parameters, like curvature and perimeter length, interact during tissue formation.

Local Curvature and Perimeter as Density Drivers

Mechanical principles show that tissue thickness isn’t uniform. Instead, the rate of material growth follows specific mathematical laws governed by the space where the fibers land.

- Curvature-Driven Growth: Regions with higher local curvature naturally achieve greater tissue thickness during deposition.

- Perimeter Control: The perimeter length of a channel governs the rate of material deposition, functioning independently of the overall channel shape.

- Parallel Organization: Fiber alignment at the tissue-fluid interface creates a parallel structure, which significantly increases the final material density.

- Percolation Thresholds: Network structures that facilitate higher fiber intersection tendencies result in lower percolation thresholds, altering the tissue’s mechanical properties.

High-Density Virgin Wood Pulp and GSM Calibration

Top Source Hygiene applies these geometric principles to manufacture tissue that maintains structural integrity without sacrificing softness. By controlling the fiber geometry at the source, we ensure that bulk orders remain consistent from the first roll to the last.

- Material Selection: We utilize 100% Virgin Wood Pulp to provide the long-fiber geometry required for high tensile strength.

- Density Calibration: We maintain a strict ply density between 13–22 GSM, balancing material volume with skin-friendly softness.

- CNC Embossing: Our point-to-point embossing modifies the geometric surface to increase absorbency by 30% without increasing bulk.

- Structural Perforation: Precision perforation ensures clean separation while protecting the integrity of the underlying fiber network.

This focus on fiber-level geometry allows us to produce high-density rolls that perform reliably in both residential and commercial environments. By managing the way fibers intersect and bond, we deliver a product that dissolves quickly in water but resists tearing during use.

Why Wood Pulp Offers a More Consistent Surface Smoothness?

Wood pulp uses standardized fiber dimensions and hemicellulose bonding to create a predictable, lint-free texture that stays uniform across high-volume production batches.

Fiber Uniformity and Hemicellulose Structural Bonding

Wood pulp provides a level of tactile uniformity that recycled or alternative fibers struggle to match. This consistency starts at the microscopic level, where softwood species offer standardized fiber lengths (2–4 mm) and diameters. These precise dimensions allow for predictable fiber packing during the sheet formation process, which minimizes surface irregularities and prevents the “gritty” feel often associated with uneven materials.

The bonding mechanism also plays a critical role. Hemicellulose compounds within the pulp facilitate uniform fiber-to-fiber bonding. This creates a cohesive and stable paper structure that doesn’t shred or lint during use. To further refine the finish, the manufacturing process employs specific mechanical treatments:

- Refining Forces: Shear and compressive forces increase fiber flexibility and surface area.

- Hydration Control: Proper moisture during refining ensures fibers remain pliable for even densification.

- Hydrogen Bonding: Increased fiber flexibility promotes stronger bonds, resulting in a smoother surface finish.

Batch Color Consistency and Precision Embossing Specs

As a direct factory source, we prioritize material purity to ensure every container load meets the same smoothness profile. 100% Virgin Wood Pulp naturally achieves a brightness level of 85-92% without the need for heavy chemical whiteners or the inclusion of recycled debris. This purity ensures that the paper surface remains clean and free of the microscopic wood particles or ink residues that compromise the texture of lower-grade tissues.

Beyond the raw material, we utilize CNC-precision technology to maintain surface integrity across high-volume orders. This allows for specific technical standards that wholesalers and hospitality groups rely on for quality assurance:

- Ply Density: Strictly controlled 13–22g/m² per ply to balance softness with high-wet-strength durability.

- Point-to-Point Embossing: High-pressure lamination bonds multi-ply sheets while increasing absorbency by 30% through quilted textures.

- Chemical Safety: 100% OBA-Free (No Optical Brightening Agents), ensuring the product is safe for sensitive skin and meets 2026 international hygiene standards.

- Compliance Standards: Production follows ISO 9001, FDA, and EU hygiene requirements for global distribution.

By removing lignin and impurities through chemical pulping, the final product yields a higher cellulose content. This results in a brighter, more uniform paper surface that remains consistent from the first roll to the last in a 40HQ container.

Comparing the Tensile Strength of Virgin Wood vs. Bamboo

Bamboo reaches 28,000 psi, but Top Source Hygiene utilizes long-fiber wood pulp and high-pressure lamination to provide commercial-grade tear resistance for global export.

Structural Physics of Bamboo Fiber Resilience

Bamboo functions differently than traditional hardwoods because it is biologically a grass. Its mechanical rigidity comes from aligned semicrystalline lignocellulosic microfibrils. These fibers arrange themselves in parallel bundles along the stalk, allowing the material to absorb energy and bend under stress instead of cracking like oak or maple.

- Tensile Rating: Reaches 28,000 psi, exceeding the 23,000 psi threshold of standard steel.

- Natural Binder: High lignin content acts as a polymer binder, enhancing impact resistance compared to birch or pine.

- Pressure Tolerance: Cellulose microfibrils maintain structural integrity under 10 times the pressure capacity of oak.

- Energy Absorption: Parallel fiber arrangements enable the material to flex before reaching a breaking point.

Optimizing Wood Pulp Strength Through Ply-Bonding Technology

We specialize in 100% virgin wood pulp, focusing on fiber length to meet international quality standards. While bamboo offers high raw tensile strength, long-fiber wood pulp provides the necessary balance between durability and the surface smoothness required for premium tissue products. We use mechanical reinforcement to ensure these rolls perform in high-traffic commercial environments.

- Fiber Selection: We use premium long-fiber wood pulp to ensure high-wet-strength durability for 2026 global export standards.

- Ply-Bonding: High-pressure lamination technology prevents layer separation in 3-ply and 4-ply roll configurations.

- Density Metrics: Precision-controlled GSM ranges (13g/m² to 22g/m²) protect against accidental tearing during use.

- CNC Embossing: Point-to-point patterns increase functional thickness and absorbency by 30% without adding material weight.

Frequently Asked Questions

Wood and bamboo fibers offer distinct structural benefits for B2B hygiene sourcing, balancing tensile strength with skin-friendly softness across different pulp grades.

What are the primary differences between wood and bamboo fibers?

Bamboo is a grass that matures in 3–5 years, while wood takes 20–50 years to harvest. Structurally, bamboo fibers provide a mix of strength and absorbency similar to softwood pulps, making them a sustainable alternative for high-volume tissue manufacturing.

How does bamboo fiber length compare to softwood and hardwood?

Bamboo fiber length is intermediate. It is shorter than softwood tracheids but longer than most hardwood fibers. This allows bamboo to deliver the structural strength associated with softwoods while maintaining the bulk and softness found in hardwood-based products.

Why is virgin wood pulp considered the best material for facial tissue?

Virgin wood pulp creates fibers that are longer and more flexible than recycled stock. This results in a smoother surface that prevents skin irritation. Top Source Hygiene uses 100% virgin wood pulp to ensure products stay OBA-free and safe for sensitive skin.

Is bamboo toilet paper rougher than traditional wood pulp paper?

No. Modern manufacturing softens the fibers to create a smooth, hypoallergenic texture. High-quality bamboo tissue is engineered to be as soft as traditional wood pulp paper and often feels smoother than lower-grade recycled options.

Does fiber length significantly impact the strength of the tissue?

Yes. Longer fibers enhance tensile strength by creating a more interconnected structure. This added length prevents tearing during use, so we balance fiber length with density to ensure a uniform surface and consistent performance.

Which natural fiber offers the highest water absorption capacity?

Lyocell (TENCEL™) is the most absorbent, holding about 50% more water than cotton. Among standard natural fibers, bamboo exceeds the absorption capacity of cotton and is preferred for hygiene products due to its natural antibacterial properties.