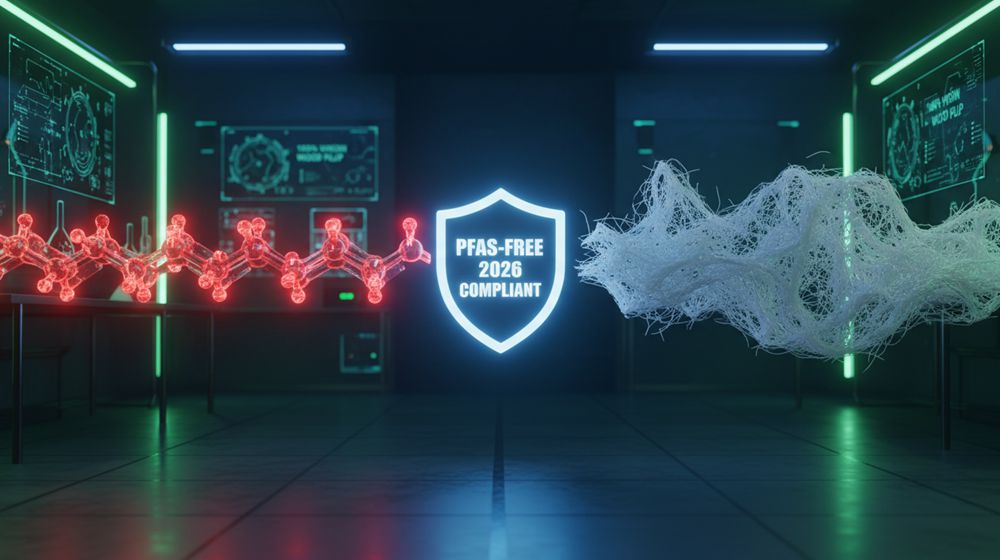

Chemical Safety & PFAS compliance is now a survival requirement for retailers as 2026 bans on forever chemicals approach. Sourcing failures in this category trigger immediate customs seizures and institutional liability, threatening the market access of non-compliant hygiene brands.

This analysis benchmarks material purity against the 100% Virgin Wood Pulp and OBA-Free standards required for medical-grade tenders. We evaluate how 13–22g/m² ply density and total acid digestion testing prevent heavy metal migration, ensuring 40HQ orders meet strict FDA and REACH benchmarks.

Why is There a Global Panic Over PFAS in Consumer Goods?

PFAS trigger global panic because they never break down. With major 2026 bans approaching, manufacturers must switch to certified chemical-free materials to maintain market access and protect consumers.

Health Risks and Environmental Persistence of Forever Chemicals

PFAS earn the nickname “forever chemicals” because their carbon-fluorine bonds are among the strongest in organic chemistry. These synthetic compounds do not degrade naturally. Instead, they migrate from consumer products into water systems and bioaccumulate in human tissue over decades. Research suggests that without immediate intervention, 4.4 million tonnes of these substances could enter the environment within the next thirty years.

Regulators are moving away from testing individual chemicals and are instead targeting the entire class of PFAS. This shift creates a massive compliance hurdle for supply chains that haven’t mapped their chemical inputs. The primary drivers for the current market shift include:

- Regulatory Deadlines: The European Union and major US states like California have set 2026 as a hard deadline for banning PFAS in food-contact materials and various consumer goods.

- Chemical Diversity: Authorities now track over 10,000 PFAS variants, making it impossible for manufacturers to rely on “low-risk” sub-variants.

- Global Market Access: Japan and the EU are updating safety laws to prohibit PFAS in packaging by mid-2025 and 2026, respectively, effectively de-platforming non-compliant suppliers.

Ensuring Safety Through OBA-Free Virgin Pulp Standards

For B2B buyers, the most effective way to bypass PFAS and heavy metal contamination is through strict raw material control. Top Source Hygiene utilizes 100% Virgin Wood Pulp to eliminate the “legacy contamination” common in recycled paper streams. Recycled materials often carry traces of PFAS from old food packaging or industrial coatings that were introduced during previous manufacturing cycles.

We maintain safety at the source by focusing on high-purity long-fiber pulp that requires no synthetic “enhancers” for performance. This strategy ensures our household and jumbo rolls meet the stringent requirements of medical and high-end hospitality tenders. Our material standards include:

- 100% OBA-Free Guarantee: We eliminate Optical Brightening Agents and fluorescent whiteners, preventing skin irritation and ensuring the paper is safe for sensitive intimate care.

- Virgin Fiber Integrity: By avoiding mixed recycled waste, we remove the risk of accidental chemical introduction from non-vetted supply sources.

- Standard Compliance: Our production processes align with FDA and EU hygiene standards, providing the necessary documentation for international customs and safety audits.

- Natural Brightness: We achieve an 85-92% brightness level through mechanical fiber selection rather than aggressive chemical bleaching.

How to Audit Your Supply Chain for “Forever Chemicals”?

Auditing for 2026 PFAS compliance requires mapping supply chains, securing Full Material Disclosures (FMDs), and validating material purity through independent LC-MS laboratory testing and virgin pulp verification.

Implementing Systematic Material Mapping and Risk Assessments

Supply chain visibility identifies where toxic chemicals might enter the production cycle. Most contamination occurs at unmonitored touchpoints during chemical processing or secondary packaging. Businesses must move beyond surface-level certificates and analyze the substance-level data of every component.

- Full Supply Chain Mapping: Trace every stage from raw pulp harvesting through chemical processing and final packaging to identify potential PFAS contact points.

- Supplier Risk Matrix: Categorize partners based on their geographic location and their use of sensitive materials known for chemical additives.

- Full Material Disclosures (FMDs): Request comprehensive substance lists and CAS numbers to verify compliance against 2026 EPA and REACH thresholds.

- Diligence Documentation: Maintain detailed records of all communication and verification efforts to demonstrate regulatory compliance and protect against penalties.

Risk assessments prioritize resources by focusing on suppliers who lack transparency or operate in regions with lax chemical oversight. This systematic approach ensures that high-volume orders meet safety standards before they reach the port.

Validating Purity with OBA-Free and 100% Virgin Wood Pulp Standards

Material integrity serves as the strongest defense against “forever chemicals.” Recycled paper often carries legacy PFAS from previous industrial uses, making 100% Virgin Wood Pulp the professional standard for safety. We enforce strict manufacturing protocols to ensure that no whitening agents or moisture barriers introduce toxins during production.

- 100% Virgin Wood Pulp: Use primary fiber sources to eliminate the risk of legacy PFAS and chemical residues commonly found in recycled waste.

- OBA-Free Protocols: Ban Optical Brightening Agents to ensure paper products remain free from fluorescent whiteners and hidden irritants.

- Third-Party Lab Testing: Submit 13–22g/m² ply samples for LC-MS analysis to confirm the absence of intentionally added or unintentional PFAS contaminants.

- Pre-Shipment Verification: Use batch color consistency checks and visual inspections to ensure long-fiber purity remains uniform across 40HQ container orders.

Physical testing confirms that the paper meets the technical specifications required for global markets. Relying on 100% Virgin Wood Pulp ensures the product achieves natural brightness without the need for high-risk chemical bleaching agents.

Premium OEM Toilet Paper Manufacturing Solutions

What are the Strict Limits for Heavy Metals (Lead/Cadmium)?

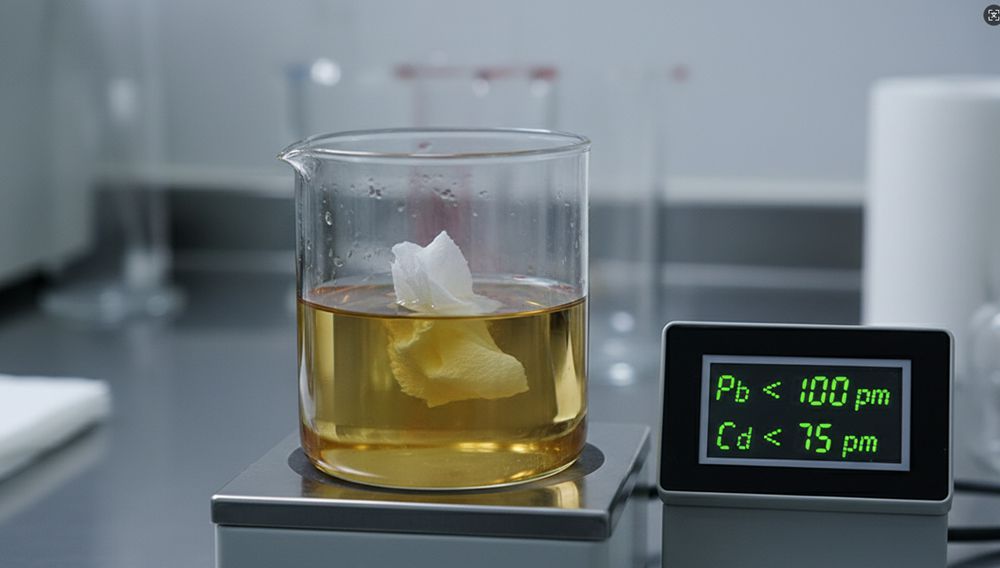

2026 standards mandate lead below 100 ppm and cadmium under 75 ppm. Compliance requires total acid digestion testing to prevent toxic migration in skin-contact hygiene products.

Global safety standards for 2026 emphasize strict concentration caps on heavy metals to protect consumer health. Regional protocols, particularly California’s Proposition 65 and updated US state laws, now require manufacturers to verify these levels through total acid digestion testing. This method ensures that no toxic migration occurs during skin contact with hygiene products.

Global Regulatory Thresholds for Lead and Cadmium

International and regional safety bodies have established specific concentration limits that dictate B2B procurement requirements. These standards represent the legal floor for entering major markets like North America and Europe.

- CPSIA Federal Limit: The Consumer Product Safety Improvement Act maintains a federal limit of 100 ppm for total lead in all accessible product components.

- Minnesota Safety Revisions: Updated 2025 standards enforce a maximum of 90 ppm for lead and 75 ppm for cadmium across major consumer product categories.

- California Proposition 65: Mandates daily exposure limits (MADL) of 0.5 mcg/day for lead to prevent reproductive toxicity.

- Total Acid Digestion Testing: Regulatory compliance now relies on complete acid digestion rather than simple leaching tests to measure the total metal mass within a sample.

Ensuring Purity Through 100% Virgin Wood Pulp Strategy

Material selection serves as the primary defense against heavy metal contamination. Recycled waste streams often carry legacy toxins, making high-purity virgin fibers the industry standard for medical and premium hygiene tenders.

- 100% Virgin Wood Pulp: Top Source Hygiene utilizes 100% virgin wood pulp to eliminate the heavy metal risks typically associated with contaminated recycled paper streams.

- 100% OBA-Free Production: We guarantee an OBA-free process with no optical brightening agents or fluorescent whiteners, preventing the introduction of metal trace elements.

- Natural Brightness Standards: Our products achieve an 85-92% brightness level through fiber selection and mechanical processing rather than chemical bleaching.

- Batch Consistency: Manufacturing protocols follow ISO 9001 and FDA hygiene standards to ensure that fiber performance and tensile strength meet North American and European benchmarks.

Routine laboratory screening confirms that high-purity wood pulp maintains these safety levels across every container load. This strategy protects distributors from regulatory fines and ensures the product remains safe for long-term skin contact.

Are Volatile Organic Compounds (VOCs) Present in Scented Tissue?

Scented tissues emit VOCs like terpenes and aldehydes from synthetic fragrances. Distributors now prioritize fragrance-free, 100% virgin pulp to eliminate respiratory risks and ensure user safety.

Sources of Volatile Emissions in Fragranced Paper

Fragranced personal care products act as direct pathways for VOC exposure. When manufacturers add synthetic scents to tissue products, they introduce volatile organic compounds that evaporate easily at room temperature, impacting indoor air quality and user health.

- Chemical Composition: Synthetic additives often contain terpenes, alcohols, and aromatic hydrocarbons that increase emission concentrations.

- Emission Comparison: Scented tissue variants emit significantly higher levels of volatile compounds than unscented equivalents.

- Health Correlation: Chronic exposure to these volatile elements is linked to systemic inflammation and irritation of the mucous membranes.

- Primary Pathways: Fragrance ingredients serve as the main source of VOCs in consumer paper goods, often masking lower-quality base materials.

Ensuring Purity with OBA-Free Virgin Wood Pulp

Sourcing high-purity raw materials eliminates the need for chemical additives or masking fragrances. Top Source Hygiene utilizes 100% Virgin Wood Pulp to ensure that softness and strength come from natural fiber quality rather than synthetic coatings.

- Virgin Wood Pulp: Premium long-fiber pulp provides natural softness and tensile strength without requiring chemical softeners.

- OBA-Free Manufacturing: We guarantee the absence of Optical Brightening Agents and fluorescent whiteners, making products safe for sensitive skin.

- Natural Brightness: Fiber selection achieves 85-92% brightness levels, removing the need for heavy chemical processing or masking scents.

- Industry Standards: High-purity wood pulp ensures a lint-free experience that meets strict medical and luxury hospitality standards.

- Safety Compliance: Our manufacturing processes align with ISO 9001, FDA, and EU hygiene standards to protect B2B supply chains.

How to Achieve Full FDA and REACH Compliance?

Compliance requires registering substances via REACH-IT for Europe and utilizing OBA-free virgin pulp to meet North American safety and plumbing standards.

| Regulatory Body | Primary Requirement | Material Benchmark |

|---|---|---|

| EU REACH | Substance Registration (REACH-IT) | SVHC < 0.1% by weight |

| US FDA | Material Safety / Non-Toxicity | 100% OBA-Free Virgin Pulp |

Documenting Chemical Safety through REACH-IT Registration

Entering the European market requires manufacturers and importers to register chemical substances with the European Chemicals Agency (ECHA). This process centralizes data on the properties and hazards of substances used in paper production. We manage these requirements through the REACH-IT portal to maintain supply chain transparency.

- Chemical Safety Report (CSR): We submit a CSR for imports exceeding 10 metric tonnes annually to identify and manage toxicological risks.

- SVHC Monitoring: The lab screens for Substances of Very High Concern to ensure concentrations remain below the 0.1% weight threshold.

- Safety Data Sheets (SDS): We maintain current SDS for all multi-ply products, documenting substance properties and handling precautions for downstream users.

Utilizing 100% OBA-Free Virgin Wood Pulp for FDA Standards

North American distributors prioritize material purity and plumbing compatibility. FDA compliance for tissue products centers on eliminating harmful whitening agents and ensuring the fibers are safe for sensitive skin. We use high-purity virgin wood pulp to hit these hygiene benchmarks without relying on chemical additives.

- OBA-Free Integrity: We guarantee 100% OBA-Free materials, removing fluorescent whiteners and skin irritants from the production cycle.

- Septic-Safe Engineering: TSH-2559 and similar models use rapid-disintegration fibers to meet North American plumbing and septic standards.

- Manufacturing Quality: ISO 9001 certified processes maintain an 85-92% natural brightness level through fiber selection rather than chemical bleaching.

Why is Chemical-Free Certification Vital for Medical Tenders?

Chemical-free certification eliminates carcinogens and neurotoxins from medical supplies, meeting 2026 procurement targets to reduce institutional liability and ensure total patient safety.

Patient Safety and Risk Mitigation in Healthcare Procurement

Healthcare organizations are shifting toward rigorous toxicant screening to protect patients from long-term chemical exposure. This transition moves beyond basic regulatory minimums, focusing on proactive risk reduction through transparent sourcing.

- Toxicant Screening: Elimination of neurotoxins and reproductive toxins by auditing materials against authoritative toxicant databases.

- 2026 Healthcare Targets: Strategy alignment to remove harmful substances in 75% of hospital products to meet emerging global safety benchmarks.

- Liability Reduction: Requirement for full ingredient disclosure and supply chain audits to shield institutions from legal risks associated with contaminated supplies.

OBA-Free Virgin Wood Pulp for Clinical Environments

Medical-grade hygiene paper must maintain high purity levels to prevent skin irritation and maintain sterile conditions. Top Source Hygiene utilizes specific manufacturing standards to meet these technical requirements for 2026 tenders.

- 100% OBA-Free: Guaranteed absence of Optical Brightening Agents and fluorescent whiteners to protect sensitive patient skin from chemical contact.

- 100% Virgin Wood Pulp: High-purity fiber selection ensures a lint-free experience, which is essential for maintaining hygiene in sterile clinical settings.

- Regulatory Compliance: Strict adherence to FDA and EU hygiene standards to fulfill the technical compliance criteria of international medical tenders.

Frequently Asked Questions

Does standard B2B toilet paper contain PFAS from the manufacturing process?

Research confirms PFAS chemicals like 6:2 diPAP exist in many toilet paper products. These enter the supply chain through intentional additives used to improve pulping, recycled materials contaminated by food packaging, or treated industrial water. Studies show toilet paper contributes significantly to PFAS levels in municipal wastewater systems. Top Source Hygiene mitigates these risks by utilizing 100% virgin wood pulp, avoiding the chemical baggage often found in recycled alternatives.

Which laboratory methods effectively test for heavy metal residues in wood pulp?

Inductively Coupled Plasma Mass Spectrometry (ICP-MS) serves as the primary method for quantitative heavy metal analysis. Manufacturers also use X-Ray Fluorescence (XRF) for non-destructive elemental testing and Atomic Absorption Spectroscopy (AAS) to detect specific metal concentrations. These protocols align with ISO and TAPPI standards to ensure raw material purity before production begins.

Are fragrances and dyes in tissue products safe for users with chronic skin sensitivities?

Fragrances and synthetic dyes often trigger allergic contact dermatitis and respiratory irritation. Since tissue products do not always require full ingredient disclosure, “hypoallergenic” labels can be misleading. Dermatologists recommend that users with eczema or sensitive skin switch to unbleached, fragrance-free products. Top Source Hygiene addresses this by providing 100% OBA-Free (No Optical Brightening Agents) virgin pulp options that eliminate fluorescent whiteners.

What standards apply to medical-grade hygiene paper?

Medical-grade products must comply with specific ISO standards for sanitary materials and FDA or regional hygiene regulations. These standards govern chemical purity, antimicrobial treatments, and the absence of optical brightening agents (OBAs). This ensures the paper is safe for clinical environments and sensitive skin. Top Source Hygiene processes meet ISO 9001 and FDA requirements to support these professional standards.

How can a buyer verify the authenticity of a manufacturer’s REACH compliance report?

Buyers should cross-reference registration numbers directly with the European Chemicals Agency (ECHA) database. Valid documentation must include Tonnage Coverage Certificates and current Safety Data Sheets (SDS). Regular supplier audits and checking the latest SVHC Candidate List help maintain compliance and prevent the use of fraudulent certificates.

Is unbleached toilet paper safer for intimate care than ECF bleached options?

Unbleached paper eliminates chlorine byproducts like dioxins, making it gentler for many users. While Elemental Chlorine-Free (ECF) bleaching is an improvement over traditional methods, it does not guarantee the absence of PFAS. The safest choice for intimate care is 100% virgin wood pulp that is both unbleached and certified PFAS-free. Top Source Hygiene prioritizes high-purity long-fiber wood pulp to ensure skin-friendly softness without relying on harsh chemical treatments.

SEO

Title: PFAS-Free and Zero Contaminants: The Chemistry of Non-Toxic Sourcing

Description: PFAS free toilet paper factory. 100% Virgin Wood Pulp, OBA-free, FDA/REACH compliant. Secure 40HQ wholesale orders for 2026.

URL: pfas-free-toilet-paper

Keywords: PFAS Free Toilet Paper