Achieving full dispenser compatibility is the only way to prevent supply chain bottlenecks from turning into a total facility shutdown. When a maintenance team realizes their bulk JRT inventory won’t fit the existing hardware, the business faces immediate risks of hygiene lapses and wasted procurement spend. Most facility managers feel trapped by proprietary systems that force them into high-priced contracts, but the real danger lies in the operational downtime that occurs when essential supplies can’t be sourced during a shortage.

This guide serves as a technical standard for auditing your current hardware and identifying the specific dimensions required for a perfect fit. We provide the exact measurements for core diameters and roll widths that define the difference between a universal and a closed system. By following these steps, you can establish a reliable refill protocol that allows you to switch suppliers and maintain consistent stock levels without the need for expensive hardware replacements.

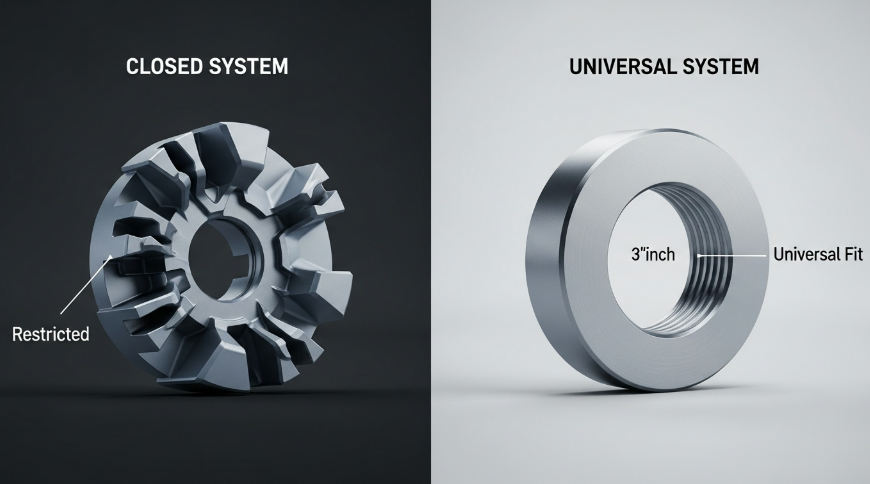

Why Do Proprietary Dispensers Limit Your Sourcing Options?

Proprietary dispenser systems use mechanical lock-outs to secure high-margin refill contracts, often increasing long-term consumable expenses by 20% to 80% compared to universal alternatives.

Physical Barriers in Proprietary Design

Manufacturers engineer physical lock-ins by utilizing non-standard core diameters and notched end-caps. These specific mechanical features prevent standard jumbo rolls from rotating or even fitting into the housing. This hardware-level restriction effectively removes a facility’s ability to capitalize on market price drops or superior material availability from secondary suppliers.

- Unique core diameters and notched end-caps stop standard jumbo rolls from spinning in the dispenser.

- Custom-shaped soap or towel cartridges ensure only the original manufacturer’s refills fit the hardware.

- These physical constraints force facilities to buy from a single source regardless of market price fluctuations.

Financial Impact of System Lock-in

Restricting sourcing to a single vendor eliminates competitive bidding and often results in significantly higher long-term operating expenses. While “free” dispenser programs seem attractive during initial procurement, they hide the true total cost of ownership behind multi-year contracts and fixed pricing. Procurement teams in the 2026 fiscal year face limited leverage when restricted to a single vendor, as the high capital cost of replacing hardware prevents them from switching to more cost-effective suppliers.

- Consumable costs for proprietary refills typically run 20% to 80% higher than universal alternatives.

- Multi-year purchasing contracts often accompany ‘free’ dispenser programs, hiding the true cost of the paper products.

- Limited vendor options prevent procurement teams from negotiating better rates in the 2026 fiscal year.

Barriers to Sustainability and Sourcing Flexibility

Facility managers face difficulties meeting environmental goals when proprietary vendors do not offer eco-friendly or FSC-certified options. Closed systems prevent the integration of specialized green products or high-efficiency rolls from manufacturers like Top Source Hygiene. Transitioning to open, non-proprietary systems allows for bulk refills from multiple vendors, preserving facility autonomy and design flexibility.

- Closed systems prevent the integration of locally sourced or specialized green products from manufacturers like Top Source Hygiene.

- Rigid refill requirements increase waste and labor costs because staff cannot swap brands for more efficient high-capacity rolls.

- Non-proprietary, open systems allow for bulk refills from multiple vendors, preserving facility autonomy and design flexibility.

How to Identify if Your Dispenser Is “Universal” or “Closed”?

Differentiating between open and proprietary dispensing systems is the most effective way to eliminate vendor lock-in and reduce long-term consumable costs by up to 80%.

Examining Locking Mechanisms and Spindle Designs

Physical hardware cues reveal whether a dispenser requires a specific manufacturer’s product or accepts a wide range of refills. Look for proprietary locks or specialized keys that only work with one brand’s specific refill containers. Many closed systems utilize these physical barriers to prevent facility managers from sourcing cheaper, high-quality alternatives. You should also inspect the spindle for unique notches, “fins,” or irregular shapes designed specifically to block standard paper cores.

Closed systems typically feature sealed housings that prevent the use of third-party rolls to maintain a brand-specific hygiene loop. If the dispenser requires a “cartridge” rather than a raw roll of paper, it is almost certainly a closed system. Universal dispensers, by contrast, often use a simple push-button or a standard universal key, allowing for easier access and maintenance by facility teams.

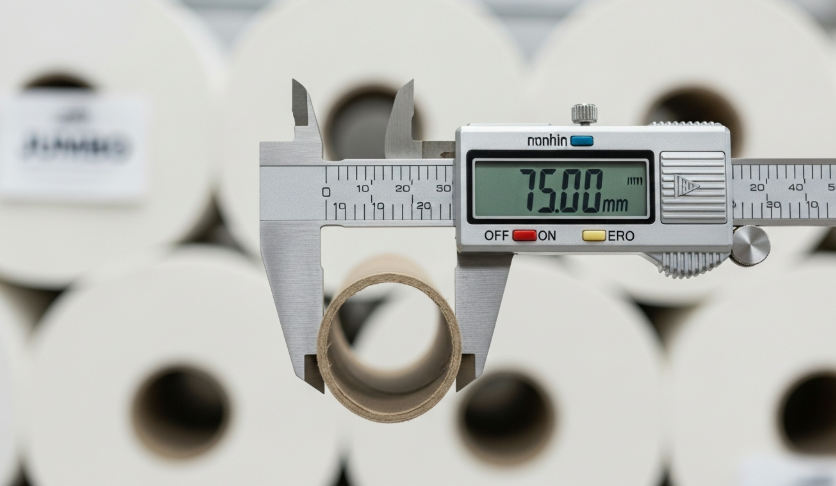

Verifying Compatibility with Standard Paper Cores

Universal dispensers prioritize versatility, allowing facility managers to source paper from various global manufacturers like Top Source Hygiene. To verify compatibility, measure the spindle or the core of the roll currently in use. Most universal commercial JRT (Jumbo Roll Tissue) dispensers utilize a standard 3.3-inch (75mm) or 2.25-inch core. If your current dispenser only fits a roll with a very small or unusually shaped plastic insert, you are likely tied to a proprietary supplier.

| Feature | Proprietary (Closed) System | Universal (Open) System |

|---|---|---|

| Spindle Design | Notched, finned, or irregular shapes | Smooth, circular 2.25″ or 3.25″ diameter |

| Key/Lock Mechanism | Unique brand-specific plastic keys | Standard metal keys or push-buttons |

| Sourcing Flexibility | Limited to one manufacturer (e.g., Tork, GP) | Compatible with any OEM or generic roll |

| RFID/Electronics | May feature ‘handshake’ sensors | Mechanical or sensor-only (no tag check) |

Universal models accommodate diverse ply options and paper weights without requiring hardware adjustments. Check for the absence of electronic sensors or RFID tags. In 2026, some premium closed systems use these tags to “handshake” with specific branded refills; if the dispenser works without a battery or electronic components, it is almost certainly a mechanical universal unit.

Evaluating Touchless Systems and 2026 Hygiene Standards

Modern commercial environments adopt automated dispensers that balance contamination control with sourcing flexibility. When inspecting touchless units, determine if they allow for adjustable paper lengths. This is a common feature in universal automatic dispensers that allows you to control consumption regardless of the paper brand you choose.

- Review whether touchless units allow for adjustable paper lengths, a key sign of an open-market compatible unit.

- Analyze the dispenser housing to see if it can fit any roll meeting standard physical dimensions (e.g., 9-inch to 12-inch diameters).

- Prioritize systems that reduce cross-contamination while maintaining low maintenance costs through bulk sourcing from direct factories.

Facility managers in 2026 focus on systems that provide high-capacity dispensing without the “system lock-in” of previous decades. Choosing an open-market compatible housing ensures that your facility remains autonomous and can switch to cost-effective 100% virgin wood pulp rolls without replacing expensive hardware.

Custom OEM Jumbo Tissue at Wholesale Prices

What Measurements Are Critical for a Guaranteed Roll Fit?

Achieving a seamless fit in commercial dispensers requires precise alignment between the spindle diameter, roll outer clearance, and winding tension to eliminate mechanical jams and unnecessary paper waste.

Core Inner Diameter and Spindle Compatibility

The inner diameter of the paper core must align perfectly with the dispenser spindle to ensure smooth rotation. Standard commercial jumbo rolls typically utilize a 75mm (3-inch) core, though specialized or handheld units often require 25mm to 50mm variants. If the core is too large, the roll wobbles, leading to uneven dispensing; if it is too small, it will not mount on the hardware at all.

| Critical Metric | Standard Specification | Top Source Hygiene Capability |

|---|---|---|

| Core Inner Diameter | 75mm (approx. 3″) | Custom sizing (25mm to 75mm+) |

| Max Outer Diameter (OD) | 230mm – 300mm | Calibrated logs up to 300mm |

| Standard Roll Width | 90mm – 100mm | Precision cut 102mm to 132mm |

Top Source Hygiene provides custom core sizing in 2026 to match specific OEM hardware. We use high-density cardboard cores that maintain structural integrity even as the weight of the roll decreases, preventing the common “slipping” issue found in lower-quality alternatives.

Maximum Outer Diameter for Cabinet Clearance

The total width from the center of the roll to its outer edge determines physical compatibility with the dispenser housing. Most high-capacity commercial dispensers accommodate a maximum outer diameter (OD) between 230mm and 300mm. Exceeding these limits creates friction against the dispenser walls, causing the paper to tear or the roll to jam during the first few uses.

- We calibrate our production logs to ensure rolls fit within 1mm of specified housing limits.

- Precision OD management allows facilities to maximize sheet count per roll without hardware upgrades.

- Proper clearance reduces maintenance labor by preventing internal paper dust buildup caused by friction.

Roll Width and Lateral Alignment

The height or width of the paper roll must fit the internal tracks of the dispenser to prevent lateral shifting. Standard jumbo roll widths usually range between 90mm and 100mm to fit universal brackets. If a roll is too narrow, it will slide side-to-side, potentially dismounting from the spindle; if it is too wide, the dispenser cover will not close.

Our manufacturing process involves CNC-precision cutting for every 40’HQ container order. This ensures that every roll meets the exact width specifications for your target market, whether you are supplying 102mm luxury rolls to the Middle East or 100mm industrial JRT to the North American market.

Unwind Direction and Tension Calibration

The orientation of the paper wind affects how the product feeds through the dispensing throat. Facilities must identify if their hardware requires “wire-side out” or “felt-side out” winding. Mismatched winding can cause the paper to peel incorrectly or tear before it reaches the user.

We use advanced 2026 winding technology to maintain uniform density throughout the roll. This prevents “telescoping”—where the center of the roll pushes out—during transit. Uniform density ensures the paper pulls cleanly from the first sheet to the core, maximizing the value of the 100% virgin wood pulp material.

Can Our JRT Refills Fit a Tork or Georgia Pacific Dispenser?

Technical compatibility with Tork and Georgia Pacific systems depends on matching the specific system designation—such as T1 or T2—through millimeter-precise core engineering and outer diameter calibration.

Compatibility with Proprietary Spindles and Hubs

Major brands like Tork and Georgia Pacific often use unique core shapes or stepped spindle diameters to enforce “system lock-in,” forcing buyers into high-cost contracts. We manufacture custom cores that bypass these mechanical locks by matching the internal roll diameter to the dispenser’s specific hub design. Our 2026 production lines utilize CNC-controlled core winding to ensure a friction-free fit on major industry hardware, allowing facilities to maintain their existing hardware while sourcing more cost-effective refills.

- We produce precision-engineered cores designed to fit seamlessly onto proprietary T1 and T2 system spindles.

- Advanced internal diameter testing ensures the roll rotates freely without catching on the hub.

- Our TSH-JRT08 series supports diverse core sizes to accommodate the most common closed-system dispensers in the global market.

Customizing Roll Diameter for Specific Housing Dimensions

Enclosed jumbo roll cabinets have rigid physical limits that cause rotation failure if the roll is even slightly oversized. Top Source Hygiene regulates the total roll length and winding tension to ensure our refills maintain the necessary clearance within compact Elevation or GP cabinets. We provide millimeter-accurate customization of the outer diameter (OD) for every 40’HQ order, preventing friction against dispenser walls that leads to paper jams and user frustration.

- Roll length and tightness are calibrated to fit within the strict 9-inch to 12-inch diameter limits of brand-name housings.

- Mechanical compression technology during the bagging process preserves paper fluffiness while maintaining the required roll dimensions.

- Clients receive physical samples to verify rotation clearance before full-scale container production begins.

Matching Ply and GSM for Reliable Performance

A compatible refill must match the tensile strength and basis weight of the original manufacturer’s product to prevent tearing at the dispenser mouth. We calibrate our GSM (grams per square meter) and ply count to match the performance benchmarks of premium commercial refills. Using 100% Virgin Wood Pulp ensures our paper handles the high-tension demands of automatic and manual dispensers without snapping inside the housing.

- We match the specific GSM and ply density (13–22g/m²) to ensure the paper pulls smoothly through narrow dispenser openings.

- Precision perforation technology guarantees a clean break, reducing waste caused by “shredded edges” or paper jams.

- Our high-wet-strength durability prevents the paper from disintegrating prematurely during use in high-traffic environments.

How to Switch Suppliers Without Changing Your Hardware?

Breaking proprietary “system lock-in” allows facilities to reduce long-term consumable costs by 20% to 80% by utilizing universal roll standards and modular hardware adapters.

Use Standardized Adapters and Universal Roll Specs

Facility managers can bypass manufacturer-specific restrictions by adopting refills that meet international size standards. Many legacy dispensers rely on specialized core designs to prevent the use of third-party rolls. By utilizing polypropylene or specialized adapters, you can bridge the gap between varied core sizes and existing dispenser spindles. This strategy preserves your capital investment in hardware while opening the door to competitive bidding.

- Utilize specialized adapters to accommodate varied core sizes or container necks in existing housings.

- Prioritize suppliers like Top Source Hygiene that manufacture products according to universal 2026 industry dimensions for global compatibility.

Align Material Properties with Dispenser Mechanics

A successful transition requires matching the paper’s tensile strength and ply thickness with the dispenser’s internal cutting or pulling mechanism. Automated sensors and manual tear-bars are calibrated for specific paper weights. If the new material is too thin, it may shred; if it is too thick, the motor or blade may jam. Testing the GSM (grams per square meter) ensures the paper feeds through the hardware without leaving excessive dust or residue that could damage internal gears.

| Feature | Proprietary Systems | Top Source Universal |

|---|---|---|

| Core Diameter | Exclusive/Notched | Standard 75mm or Coreless |

| Material Quality | Standard Recycled | 100% Virgin Wood Pulp |

| Supply Flex | Single Brand Only | Multi-Hardware Compatible |

Implement Modular Internal Components

Modern dispensing systems often allow you to replace internal cartridges or spindles rather than the entire housing unit. This modularity reduces capital expenditure significantly. Instead of tearing out branded shells, you can swap the internal components to fit different core diameters. This approach is particularly effective for high-traffic environments where maintaining a consistent aesthetic is necessary but supplier flexibility is the priority.

- Swap internal spindles to fit different core diameters while retaining the external branded or generic shells.

- Use modular design features to facilitate faster supplier transitions during the fiscal year without disrupting facility operations.

Verify Dimensional Compatibility Before Bulk Orders

Precise measurements of the roll’s outer diameter (OD) and core width guarantee a seamless fit within legacy hardware. Even a 5mm discrepancy in roll width can cause friction against the dispenser walls, leading to paper breakage. We recommend requesting free samples to test roll rotation and pull-through efficiency before finalizing high-volume procurement contracts. Confirming that the jumbo roll’s maximum diameter allows the dispenser door to close and lock securely ensures you maintain hygiene standards without waste.

- Test roll rotation and pull-through efficiency by requesting physical samples before signing contracts.

- Confirm that the roll diameter allows the dispenser door to lock securely to maintain safety and hygiene.

Conclusion

Matching the right jumbo roll specifications to your existing hardware eliminates the risk of sourcing proprietary refills that lock you into high-cost contracts. Measuring core diameters and dispenser clearance ensures that 100% virgin wood pulp refills fit perfectly, maintaining both restroom hygiene and operational efficiency. Moving to universal sizing allows you to optimize your supply chain without the expense of replacing functional dispensers.

To determine which high-capacity JRT models are compatible with your current facility setup, you can review our technical specifications or request a sample for a direct fitment test. Contact our team to discuss container-load optimization and private label options for your regional market.

Frequently Asked Questions

Can I use generic rolls in a Tork dispenser?

Yes, provided the core diameter and outer diameter match the specific Tork system requirements (such as T1 or T2). Top Source Hygiene manufactures custom-sized cores designed to bypass proprietary spindle locks, allowing you to use high-quality generic refills without changing your hardware.

What is the most common core size for jumbo rolls?

The industry standard for universal commercial jumbo roll tissue (JRT) is a 3-inch (75mm) core. However, many proprietary systems use a smaller 2.25-inch core or unique “notched” inserts to prevent the use of universal refills.

How do I measure my dispenser’s maximum roll capacity?

Measure the distance from the center of the spindle to the nearest wall of the dispenser housing and multiply by two. This gives you the maximum Outer Diameter (OD). We recommend leaving a 5mm-10mm safety margin to ensure the roll spins freely when full.

Does roll width matter for touchless dispensers?

Yes, roll width is critical. If a roll is too wide, it will cause friction against the housing, leading to motor strain and paper jams. If it is too narrow, the sensors may not accurately detect the paper edge for consistent feeding.

Can I switch from a closed to an open system easily?

The easiest way to switch is by installing a universal spindle adapter or replacing the internal housing components. This allows you to retain the existing exterior shell while opening your procurement options to competitive factory-direct pricing.

Why are proprietary refills so much more expensive?

Proprietary systems are often sold under a “razor and blade” business model. Manufacturers provide the dispensers at a low cost or for free to lock the customer into high-margin, exclusive refill contracts that typically cost 20% to 80% more than universal equivalents.